Slip rings and slip ring connectors, since their introduction has been the primal components in the heavy industries consisting of aerospace, steel production, shipbuilding, crane building, and so on.

Slip rings, given their micro size and efficient nature, are electromechanical devices that act as a pathway for smooth power and electrical signal transmission occurring between stationary and rotating components. Some other names used for slip rings are collector ring, rotary electrical contact, and electrical slip ring, owing to their wide array of industrial and commercial applications.

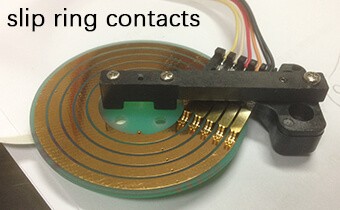

Now, coming on to the slip ring contacts, this device provides and creates much-needed electrical connections or pathways between slip rings and other system components. They are intended to function in combination with slip rings.

Slip rings and slip ring contacts, due to their ubiquitous use, are utilized in many different industrial applications, such as wind turbines, robots, medical equipment, and packing machines.

How Do Slip Rings Work

Sliding rings use sliding electrical contacts to transmit electrical signals and power over a revolving interface.

Design

A spinning ring and a stationary brush, or wiper, that glides along the ring surface during rotation are common design components of a slip ring.

These materials and design techniques have been improved to minimize wear and increase electrical performance.

Slip Ring Construction

A slip ring is an electrical connection used to transfer current or signals between a fixed wire and a revolving object.

A stationary graphite or metal contact (brush) scrapes against the outer diameter of a spinning metal ring.

If more than one electrical circuit is required, more ring/brush assemblies are stacked along the revolving axis.

Functionality

The electrical current or signal is carried via the stationary brush to the metal ring while the metal ring spins, completing the connection.

For decades, this basic design has been utilized as a crude means of delivering electricity into a revolving gadget.

How Does the Slip Ring Connector Work

A slip ring connection is also known as the slip ring contact. Like, any other slip ring, it also aids in allowing the electrical power and signals to be transferred between a stationary and a revolving component.

Design of Slip Ring Contacts

A slip ring contact consists of three parts: a rotor, a stator, and a set of brushes.

Typically, the rotor is attached to the spinning component, while the stator is attached to the stationary component. To transport electrical power and signals, the brushes, which are constructed of conductive materials like graphite, silver, or gold, make contact with the rotor.

Slip Ring Assembly

A slip-ring connector assembly is made up of conductive rings and brushes. Metal rings are commonly used and are installed on the rotor.

While the rotor revolves, the brushes are kept in position by a brush block and make contact with the rings.

The brush block is positioned on the stator and is intended to keep the brushes in place relative to the rings.

Functionality

The brushes maintain contact with the rings while the rotor rotates, allowing electrical power and signals to be exchanged between the fixed and spinning components.

The rings are usually linked to wires or cables that provide power and signals to the brushes.

The power and signals are subsequently transferred to the stator by the brushes, where they can be further processed or dispersed.

Frequently Asked Questions

What Are the Advantages of Slip Ring Contacts

Slip ring contacts hold various advantages, especially when compared to other types of electrical connectors. They facilitate perpetual rotation which eliminates the need for slip ring adjustment. Moreover, owing to their low electrical resistance, low noise, and great signal quality, they can be customized for different industrial applications as well.

What Are the Applications of Slip Ring Contacts

Slip ring connections are widely utilized in a variety of applications, including wind turbines, robots, medical equipment, and packing machines. Slip ring contacts are used in wind turbines to transport electrical power and information from the revolving blades to the fixed nacelle. They are further used in robotics to carry power and communications between the stationary base and the revolving arm. Furthermore, slip ring contacts are crucial parts of medical equipment as they transfer power and signals between fixed and revolving components such as MRI machines.

How Does a Slip Ring Work

A slip ring transmits electrical messages and power over a revolving interface using sliding electrical contacts. A spinning ring and a stationary brush, or wiper, that glides along the ring surface during rotation are common contacts.

Is There a Rotational Speed Limitation on Slip Rings

A definite yes. When it comes to rotational speed limitation slip rings have to comply with it. Conventionally, the factory-permitted operational limit of slip rings ranges from 250 to 1000 rpm, depending on the size, material, and environment. However, various special designs for slip rings have shown their operational limit of up to 20,000 rpm which is way beyond to conventional limit.

What is the Difference Between a Slip Ring and a Commutator

While both slip rings and commutators are used to transmit electrical data and power over a revolving interface, they are intended for distinct purposes. Slip rings are utilised in wind turbines, robotics, and medical equipment, whereas commutators are designed for usage on DC motors and generators.

What Materials Are Used for Electrical Slip Rings Contacts

Since its inception, a variety of materials have been used in slip ring contact designs, each with its own set of advantages. To reduce surface impurities and keep contact resistance low, the contacting surfaces are virtually always noble metal (often gold or silver) alloys.

Conclusion

Thus, slip rings and slip ring contacts are essential components in a variety of industrial, automotive, and aerospace applications.

They are crucial in the transfer of power and electrical information between rotating and stationary components.

However, slip ring contacts as the technology progresses are anticipated to continue to play a key part in a wide range of applications due to their adaptability and customization opportunities.