What is a slip ring for motor? This question often perplexes individuals seeking to comprehend the intricate mechanisms of electrical systems. The functionality and importance of slip rings for motors can be challenging to grasp. However, fear not! In this article, we embark on a journey to unravel the mysteries of slip rings, shedding light on their purpose, significance, and role in enhancing electrical connectivity within motors.

Answering the Questions

Understanding Slip Rings for Motors

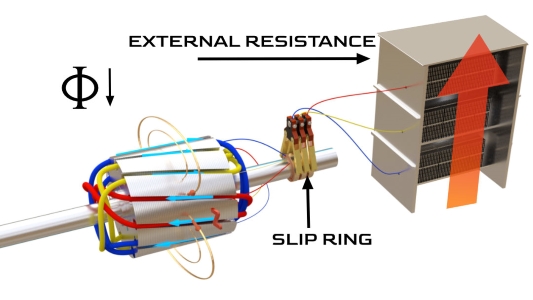

Slip rings for motors, also known as rotary electrical connectors or commutators, serve as vital components in various motorized systems. These ingenious devices enable the transmission of electrical signals, power, and data between stationary and rotating parts of motors.

Key Components and Functions

Within a slip ring for a motor, several crucial components work in harmony to ensure seamless electrical connectivity. These include brushes, rings, conductive paths, and brush holders. Brushes, typically made of carbon or graphite, maintain constant contact with the rotating rings, facilitating the flow of electrical signals and power.

Applications and Industries

Slip rings for motors find applications in a wide range of industries, including manufacturing, automotive, robotics, wind turbines, and industrial machinery. They play an essential role in transmitting signals and power for motor control, data acquisition, and various other electrical functions in rotating machinery.

Exploring the Mechanisms

To gain a deeper understanding of the intricate mechanisms of slip rings for motors, we can refer to insightful videos available on platforms like YouTube. Video A showcases the working principles of slip rings in electric vehicle motors, while Video B provides an in-depth exploration of their applications in industrial machinery. These visual aids enhance comprehension of slip rings for motors and their practical implementations.

Benefits and Advancements

Advancements in slip ring technology have led to the development of specialized slip rings for motors, such as Ethernet slip rings and high-speed data transmission slip rings. These innovations enable enhanced data transmission rates, improved signal integrity, and compatibility with modern communication protocols. Slip rings for motors offer benefits like low electrical noise, high reliability, and long service life, making them indispensable in various industries.

Conclusion

In conclusion, slip rings for motors play a vital role in ensuring efficient electrical connectivity between stationary and rotating parts. Through this article, we have explored the purpose, mechanisms, applications, and advancements of slip rings for motors.

Understanding their inner workings provides valuable insights into the complexity behind these essential components. If you have any questions or seek further clarification, we encourage you to comment below. Slip rings for motors serve as critical connectors, facilitating seamless electrical communication within motors and driving the efficiency of motorized systems.

Frequently Asked Questions

How Do Slip Rings for Motors Facilitate Electrical Connectivity?

Slip rings for motors enable electrical connectivity between stationary and rotating parts by providing a continuous path for the transmission of electrical signals and power. The brushes and rings maintain constant contact, allowing for the seamless transfer of electrical currents.

What Are the Main Components of a Slip Ring for a Motor?

The main components of a slip ring for a motor include brushes, rings, conductive paths, and brush holders. Brushes, typically made of carbon or graphite, make contact with the rotating rings, ensuring electrical continuity and enabling the transfer of signals and power.

Which Industries Rely on Slip Rings for Motors for Their Operations?

Slip rings for motors find applications in various industries, including manufacturing, automotive, robotics, wind turbines, and industrial machinery. These industries rely on slip rings for motors to facilitate motor control, data acquisition, and other electrical functions in rotating machinery.

Are there any specific maintenance requirements for slip rings for motors?

Slip rings for motors may require periodic maintenance to ensure optimal performance. This maintenance often involves cleaning the brushes and rings to remove debris or carbon buildup, inspecting for wear or damage, and lubricating the components as needed. The specific maintenance requirements may vary based on the manufacturer’s recommendations and the operating conditions of the motor.

Can Slip Rings for Motors Handle High-Speed Data Transmission?

Yes, slip rings for motors can handle high-speed data transmission. Advancements in slip ring technology have led to the development of specialized slip rings designed to support high-speed data transmission, such as Ethernet slip rings. These advanced slip rings ensure reliable and efficient data transfer in applications that require high data rates.

By addressing these frequently asked questions, we hope to provide further clarity on slip rings for motors and address common inquiries regarding their role in facilitating electrical connectivity, their components, maintenance requirements, and capabilities.

Understanding the function and significance of slip rings for motors is crucial for engineers, technicians, and individuals working with motorized systems. These components play a vital role in enabling the efficient operation of rotating machinery. If you have any additional questions or seek further information, please feel free to comment below or reach out for assistance.