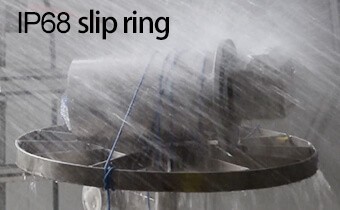

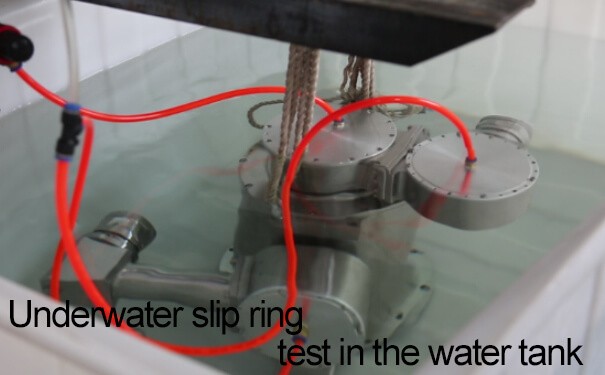

Underwater slip ring is one type of IP68 waterproof slip ring, that can work stably underwater for a long time. The electrical slip ring provides power supply and data transmission, at the same time, it solves the problem that the rigid connection of wire and rolling bearing reduces the flexibility of underwater equipment. When the underwater equipment moves and turns, the electrical slip ring can make the connecting wire and rolling bearing stationary, while the movable part can rotate freely around the fixed bearing.

Structure of Electrical Slip Ring

In order to prevent water from entering the slip ring, there are rubber seals, oil seals,s and other methods. In order to ensure the stability of the rotating equipment, the overall height of the slip ring is concentric, and the internal structure has good sealing. In order to prevent oil pollution, corrosion, or aging, stainless steel material is selected, and processed by a high-precision lathe, and the surface is treated with special protection to meet military grade.

Design of Connecting Wire

On the upper side of the sliding bearing, the wire is fixedly connected to the sliding bearing. In the sliding bearing, the wire and the contact are directly connected and fixed.

Design of Slip Ring Shaft

Due to the requirements of sealing and pressure bearing, the center shaft of the underwater slip ring needs to keep the same height when it rotates. The integrated stainless steel center shaft is adopted, and the supporting design of the ring is adopted. The shaft body is provided with a clamping groove, concave-convex, and other structures for assembly.

Hangzhou Grand Technology has a patent for an underwater rotating electrical slip ring, which solves the problem of poor sealing performance of underwater slip rings. The sliding ring shaft and the flange of the shell are sealed by the rotating gley ring, and the sliding ring shaft and the flange end cover are sealed by the pan plug. The slip ring has a double continuous seal, so the safety and reliability are greatly improved.