In today’s fast-paced and interconnected world, the demand for uninterrupted power and data transmission has become paramount. From advanced industrial machinery to complex medical equipment, the ability to establish seamless connections across rotating interfaces is vital. Enter the realm of electrical slip ring assemblies, a marvel of engineering poised to revolutionize the way we transmit electrical currents and signals. Embark on a journey through the intricate world of electrical slip ring assemblies and discover the technology that is reshaping industries.

Electrical slip ring assemblies represent the pinnacle of innovation in rotary electrical connectors. These remarkable devices are meticulously crafted to enable the transfer of electrical power and signals between stationary and rotating components, all while maintaining a continuous rotation. The complexity and precision involved in designing and manufacturing electrical slip ring assemblies are awe-inspiring, offering a glimpse into the future of seamless connectivity.

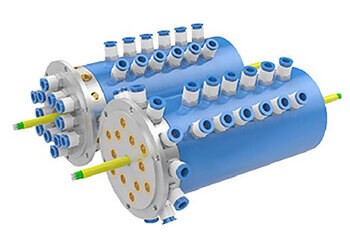

At the heart of every electrical slip ring assembly lies a sophisticated arrangement of components. The assembly consists of multiple conductive rings, brushes, and a housing that facilitates smooth rotation. These components work in unison to ensure reliable contact, minimizing signal loss and maximizing efficiency. Through careful engineering and advanced materials, electrical slip ring assemblies can handle high voltages, complex signals, and even fluid transmission, depending on the specific application.

The applications of electrical slip ring assemblies are diverse and far-reaching. In the realm of industrial automation, these connectors are indispensable for transmitting power and control signals in rotating machinery. From conveyor systems to robotic arms, electrical slip ring assemblies enable seamless and uninterrupted operation, enhancing productivity and efficiency.

The aerospace and defense sectors also heavily rely on electrical slip ring assemblies to power critical systems. In applications such as radars, satellite communication, and aircraft turrets, these assemblies ensure the continuous transmission of power and data across rotating interfaces. The seamless connectivity provided by electrical slip ring assemblies plays a pivotal role in enhancing the safety, performance, and capabilities of aerospace and defense technologies.

The medical field is another arena where electrical slip ring assemblies are making a significant impact. In medical imaging equipment, such as MRI machines and CT scanners, these connectors enable the rotation of vital components while ensuring uninterrupted power and data transmission. This technology enhances diagnostic accuracy and patient care, revolutionizing the healthcare industry.

As technology continues to advance, electrical slip ring assemblies are being pushed to new frontiers. The need for higher speeds, greater data transmission capacity, and improved reliability has led to ongoing research and development. Engineers are exploring advanced materials, such as fiber optics and high-temperature alloys, to meet the demands of cutting-edge applications. These advancements pave the way for even more efficient and robust electrical slip ring assemblies in the future.

Despite their remarkable capabilities, electrical slip ring assemblies face challenges that require continuous innovation. One primary concern is the wear and tear of the brushes and rings due to constant rotation. Friction and contact degradation over time can impact the reliability and lifespan of the assembly. To address this, engineers are developing innovative solutions such as self-lubricating materials and contact monitoring systems to detect and mitigate potential issues before they affect performance.

Moreover, customization plays a vital role in the world of electrical slip ring assemblies. Each application has unique requirements, and assembly manufacturers work closely with customers to design and manufacture bespoke solutions. This collaborative approach ensures that electrical slip ring assemblies are tailored to specific needs, providing seamless integration and optimal performance.

In conclusion, electrical slip ring assemblies represent a pinnacle of engineering achievement, enabling seamless power and data transmission across rotating interfaces. Their applications span a wide range of industries, from industrial automation to aerospace and healthcare. As ongoing advancements push the boundaries of connectivity, electrical slip ring assemblies continue to evolve, promising enhanced efficiency, reliability, and customization. Brace yourself for a future where seamless connections drive innovation and transform industries as we know them.

See What We Can Do