Robots are becoming increasingly prominent in manufacturing and production, due to their ability to automate repetitive processes and improve accuracy and productivity. A key component in robotic systems is the robot slip ring, which allows data, power, and control signals to be transferred between stationary and rotating elements.

- What is a Robot Slip Ring?

- Benefits of Using a Robot Slip Ring

- How to Choose the Right Robot Slip Ring?

- Conclusion

What is a Robot Slip Ring?

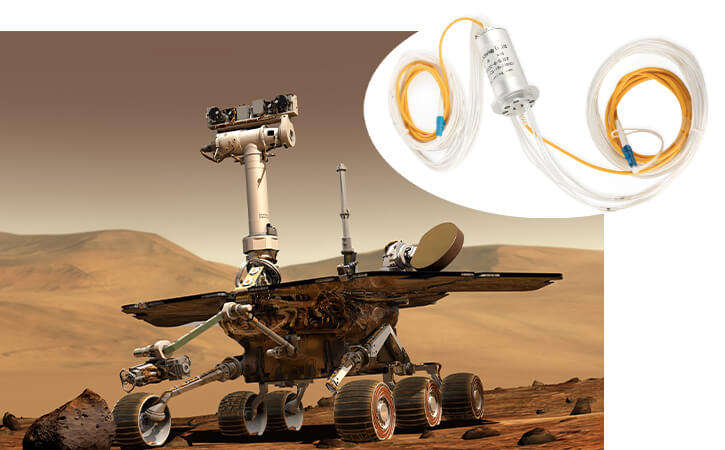

A Robot Slip Ring is an electrical device used to enable the transmission of power and data signals between a rotating and a stationary component. It is typically used in robotic applications to enable a robotic arm to rotate and maintain a continuous connection to its control system. The slip ring is also known as a rotary electrical connector, rotary electrical joint, rotary electrical interface, or rotary electrical transfer.

The slip ring consists of two parts: a stationary component mounted to the robot base, and a rotating component, which is mounted to the robot arm. The two components are connected to each other by a series of wires, which run through a gap between the stationary and rotating parts. As the robot arm rotates, the wires wind around a rotating hub, enabling the transmission of power and data signals between the stationary and rotating components.

The slip ring is typically made from a combination of metal and insulating materials. It is designed to minimize the contact resistance between the two components while allowing for high-speed data transfer and robust electrical connections. Slip rings are available in a variety of sizes and configurations, and can be customized to meet specific application requirements.

Robot slip rings enable robots to maintain a continuous electrical connection while rotating, enabling them to move with greater precision and control. They are typically used in robotic arms, medical robots, automated machinery, and other robotic applications.

Benefits of Using a Robot Slip Ring

Robot slip rings are an important part of any robotic system. They are used to transfer power and data between the robot and an external device, such as a control system or a computer. By allowing the robot to move freely while still being connected, robot slip rings provide several key benefits.

1. Improved Reliability: Robot slip rings are designed for reliable and long-term operation. They are typically made from metal and are tested for durability, which ensures that they will last for a long time. This improved reliability helps to reduce downtime and maintenance costs.

2. Improved Flexibility: Robot slip rings allow for a wide range of movement and flexibility. This means that the robot can move in a variety of directions, making them suitable for a variety of tasks.

3. Reduced Wear and Tear: Robot slip rings reduce wear and tear on the robot and its components. The slip ring helps to reduce friction and wear on the robot’s motors and other parts, which can help to extend its life.

4. Improved Safety: Robot slip rings also help to improve safety. By providing a reliable connection between the robot and an external device, they help to reduce the risk of electric shock or other hazards.

5. Reduced Cost: Robot slip rings are designed to be cost-effective and long-lasting. This means that they can help to reduce maintenance costs, as well as the cost of replacement parts.

Overall, robot slip rings provide a variety of benefits, which make them an important part of any robotic system. They provide improved reliability, flexibility, safety, and cost savings, making them an invaluable tool for any robot system.

How to Choose the Right Robot Slip Ring?

Robot slip rings are an essential component of robotic systems. They allow for electrical current and data to pass through a rotating joint, enabling the robot to perform its tasks efficiently and reliably. When choosing the right slip ring for a robotic system, there are several factors to consider.

1. Size and Weight: The size and weight of the slip ring need to be taken into account, especially when designing a robotic system. A slip ring that is too small or too large may not be able to provide the necessary power or data transfer, resulting in poor performance. Additionally, the weight of the slip ring should be compatible with the weight of the robot and its components.

2. Current and Voltage Ratings: The voltage and current ratings of the slip ring need to be taken into consideration as well. The current and voltage ratings of the slip ring should match the requirements of the robot and its components. It is important to choose a slip ring that can handle the current and voltage of the system.

3. Environmental Conditions: The environment in which the robot is operating can also influence the selection of the slip ring. Certain slip rings may be better suited for extreme temperatures or high-vibration environments.

4. Data and Signal Transfer: The type of data and signal that needs to be transferred should also be taken into account. Slip rings come in different configurations, depending on the type of data and signal that needs to be transmitted.

5. Cost: The cost of the slip ring should also be taken into consideration. Slip rings can range from a few dollars to several hundred dollars, depending on the size, features, and quality.

By taking all of these factors into consideration, you can ensure that you choose the right slip ring for your robotic system.

Conclusion

Robot slip rings are an essential component in robotic systems, as they enable the continuous transmission of data, power, and control signals between stationary and rotating elements. The rings offer several advantages such as improved accuracy and productivity, higher power and data transmission rates, and increased durability and reliability. When selecting a robot slip ring, it is important to consider the application requirements and the environment in which the robot will be used.

See What We Can Do