Computed Tomography (CT) has become an essential imaging tool in modern medicine, offering detailed cross-sectional images of the body’s internal structures. Slip ring technology plays a pivotal role in the functionality and performance of CT scanners. This guide provides a comprehensive understanding of slip ring technology in CT scanners, its advantages and disadvantages, and its influence on the growth of CT scanners.

Table of Contents

- What is Slip Ring Technology?

- How Does Slip Ring Technology Work in CT Scanners?

- Advantages of Slip Ring Technology in CT Scanners

- Disadvantages of Slip Ring Technology in CT Scanners

- How has Slip Ring Technology Driven the Development of CT Scanners?

- The Development of CT Scanner Technology Before and After Slip Ring Participation

- Application of Slip Ring Technology in CT Scans

- Types of Slip Rings Suitable for CT Scanners

- Conclusion

- FAQs about Slip Ring CT

What is Slip Ring Technology?

Slip ring technology refers to the use of an electromechanical device called a “slip ring” to establish a continuous electrical connection between stationary and rotating components in a system.

A slip ring, also known as a rotary electrical joint, rotating electrical connector, or collector, is a device that allows power and electronic signals to be transmitted from a stationary structure to a rotating one. It comes in a variety of designs but fundamentally consists of two main parts:

- The Ring: This central component is a conductive material that rotates with the device’s moving part. The rotating ring might be singular or multiple depending on the design and the purpose it serves.

- The Brush: This component is typically constructed of metal. It touches the ring and creates an electrical connection that can transmit both power and data.

As the ring rotates, the brush, which remains stationary, stays in constant touch with the ring. This interaction allows for the continuous transmission of electrical signals or power from the stationary part of the device to the rotating part.

This technology has been instrumental in various fields, including wind turbines, radar systems, video systems, and more notably in medical imaging technologies, such as Computed Tomography (CT) scanners. In CT scanners, slip rings are an integral part of the rotating slip ring gantry—the part of the scanner that circles around the patient to capture images from various perspectives.

Slip ring technology has undergone many improvements over the years to reduce mechanical wear and extend lifespan, increase transfer rates for signals and power, reduce electrical noise, and adapt to various environmental conditions. These improvements have led to the vast adoption and reliance of different industries on slip ring technology, solidifying it as a fundamental element in numerous applications.

How Does Slip Ring Technology Work in CT Scanners?

Slip ring technology in CT scanners is an integral part of CT scans and is used to rotate the X-ray source and detectors around the patient. The slip ring technology is a device that allows for the transmission of electrical power and signals through rotating shafts. It consists of an inner and outer ring, with a series of metal brushes that make contact with the rings. The rings are connected to the rotating parts of the CT scan, such as the X-ray tube and the detector panel, and the brushes are connected to the power and signal sources.

When the slip ring in ct scan is activated, the rings and brushes rotate with the X-ray source and detectors. The brushes allow for the transmission of the electrical power and signals necessary to operate the scan. This ensures that the X-ray source and detectors receive the necessary power and commands to take the necessary images. The brushes also provide a secure connection that prevents electrical interference and signal loss.

A slip ring CT scan is a reliable and efficient way of transmitting electrical signals and power to rotating parts of a CT scan. A CT scanner slip ring ensures that the X-ray source and detectors receive the necessary power and commands to carry out the scan, while also preventing electrical interference and signal loss.

Slip ring technology is an important part of CT devices, as it allows them to rotate freely while providing power and data. It has several advantages, such as allowing for the accurate acquisition of CT images and having a long lifetime. However, it does have some drawbacks, such as the potential for data errors, electrical noise, and high costs. Understanding how slip ring technology works in a CT scan is essential for ensuring the accuracy of the images produced by the device.

Advantages of Slip Ring Technology in CT Scanners

Slip ring technology is a critical component of CT devices, enabling them to rotate and collect data from a variety of angles. Slip rings are electrical rotary connectors that enable the transfer of electrical power and signals from a stationary to a rotating structure. This technology is used in a variety of medical imaging applications, including CT (Computed Tomography) scanning.

The main advantages of slip ring technology in CT devices are as follows:

- Enhanced Accuracy: Slip rings enable the CT device to collect data from multiple angles with greater accuracy. This ensures that the images obtained from the CT device are of the highest quality, providing physicians with a more accurate diagnosis.

- Safety: Slip rings are designed to be safe in operation and prevent the risk of electric shock or fire. This is particularly important in medical settings, where safety is of the utmost importance.

- Reliability: Slip rings are designed to provide reliable performance over time and are able to withstand the rigorous demands of a slip ring CT scanner. This ensures that the CT device will be able to perform reliably over time.

- Cost-effective: Slip rings are an economical solution for CT device applications, as they are less expensive compared to other electrical connectors. This makes them an attractive option for medical facilities that are looking to reduce their costs.

- Durability: Slip rings are designed to be highly durable, as they are able to withstand the rigorous demands of CT scanning. This ensures that the CT device will be able to perform reliably over time. In addition, the high-voltage slip ring on the market supports the passage of large currents, which is a factor that can be considered when selecting slip rings for electrical equipment.

These advantages make CT slip rings an attractive option for medical facilities that are looking for a reliable and cost-effective solution for their CT device applications.

Disadvantages of Slip Ring Technology in CT Scanners

CT slip ring technology has been used in current transformer installations for many years and has several advantages. However, it also has some disadvantages, which should be considered when deciding whether to use this technology.

- Low Efficiency: Slip rings are made of copper which has high electrical resistance. This means that the energy lost through the ring is relatively high, resulting in lower efficiency than other transformer technologies.

- Requires regular maintenance: Over time, the copper rings corrode, causing increased electrical resistance, which reduces efficiency. Regular maintenance is required to inspect and replace worn brush contacts and bearings to ensure optimum function and performance. Additionally, the brushes in the slip ring assembly can wear out and need to be replaced periodically.

- Friction: The constant contact between the brushes and the rings causes friction, which leads to wear and ultimately shortens the life of the slip ring.

- Noise: The rotation of the slip ring will generate noise, which may affect the image quality, especially in high-speed scanning mode.

Finally, slip ring technology is relatively expensive compared to other transformer technologies. This is because additional components are required and regular maintenance is required.

How has Slip Ring Technology Driven the Development of CT Scanners?

Slip Ring Technology has been instrumental in revolutionizing Computed Tomography (CT). It has served as a catalyst in significantly enhancing the functionality and efficiency of CT Scanners, enabling an unprecedented progression in radiograph imaging.

Before the adoption of Slip Ring Technology, the common scanning methodology was the “stop-and-shoot” or step-and-shoot approach. These refer to the process of taking images in separate angles followed by periods of inactivity as the gantry (the circular component housing the X-ray tube and detectors) resets to its original position. As you can imagine, this approach was laboriously slow and often led to motion artifacts due to patient movement in between scans. Also, it produced lower-quality images as the intervals between each rotation caused an inconsistent data set.

The introduction of Slip Ring Technology addressed these issues by allowing the gantry to rotate continuously for an extended period. Slip Rings provided an effective means to simultaneously supply power to the X-ray tube and transmit signals from the detectors to the stationary image reconstruction computer. This eliminated the necessity of stop intervals and allowed for faster, consistent, and superior image acquisition.

The implementation of Slip Ring Technology enabled a significant shift from conventional or sequential CT scanning to spiral or helical CT scanning. In helical CT, the patient moves through the bore of the scanner while the X-ray tube continuously revolves around the patient. This approach allowed for fewer motion artifacts, quicker scan times, improved image resolution, and superior multi-planer reformatting ability.

Moreover, Slip Ring Technology has paved the way for other advanced and more refined techniques such as multi-slice CT scanning, which enables acquiring numerous slices in a single rotation, as well as volume scanning. It also allows for complex post-processing capabilities like 3D Reconstruction, CT Angiography, and Cardiac-Gated Imaging.

In summary, Slip Ring Technology has been a transformative force in CT scanner development. By enabling continuous rotation of the gantry and constant data transmission, it brought about significant improvements in scanning speed, image quality, and the overall efficiency of CT systems. These advancements collectively have contributed to the wide-ranging clinical applications of Computed Tomography we see today.

The Development of CT Scanner Technology Before and After Slip Ring Participation

Before Slip Ring Technology

The initial development of Computed Tomography (CT) in the 1970s was a milestone in medical diagnostics. Early CT scanners, often referred to as “first-generation” scanners, used a “pencil beam” of X-rays that translated and rotated around the patient to capture a single slice of anatomy.

The first generation of CT scanners was characterized by a slow scan speed. The total scan time could take several minutes to hours, and image reconstruction could take several days. This was largely due to the basic “Translate-Rotate” technique these scanners used, along with their extremely few detector channels (usually one or two).

Second-generation CT scanners improved scanning speed by increasing the number of detectors, typically ranging from 30 to 300. Even though they were faster, the scan time was still long (several minutes per slice), mainly because these scanners continued to use the Translate-Rotate technique.

The third-generation system, introduced by EMI in 1975-76, marked a significant advancement. Instead of a narrow “pencil beam,” these scanners used a wide “fan beam” of X-rays in a “Rotate Only” technique, reducing scan time considerably.

After Slip Ring Technology

Introduced in the early 1980s, the fourth-generation CT scanners featured a notable step forward with the application of slip ring technology. With the implementation of slip rings, the “stop-and-shoot” requirement ceased, leading to the development of ‘continuous rotation.’ Also known as ‘spiral’ or ‘helical’ scanning, this allowed for faster, uninterrupted image acquisition.

Slip ring technology facilitated non-stop data collection and transmission, significantly reducing scanning times. As a result, faster-rotating X-ray tubes and a higher number of detector rows became feasible, leading to further improved temporal and spatial resolution.

The usage of slip rings also paved the way for multi-slice CT scanning. This advent allowed capturing multiple slices simultaneously, reducing patient scanning time, and enhancing both longitudinal resolution and volumetric coverage.

Today’s CT scan configurations often use multi-detector arrays with more than 64 rows of detectors, thanks to the advanced slip ring technology. They have minimized scan times to the scale of a few seconds, leading to potential applications even in emergencies.

Moreover, advanced post-processing techniques like 3D reconstruction, virtual endoscopy, and perfusion studies are all enabled by the continuous scanning facilitated by slip ring technology.

In summary, the incorporation of slip ring technology marked a before-and-after point in CT scanning. Enhancing scan speed, improving image quality, and enabling advanced scanning techniques, slip rings have dramatically revolutionized the landscape of CT scanning.

Application of Slip Ring Technology in CT Scans

Slip rings are applied for several components and techniques in CT scans such as the facilitation of continuous gantry rotation, as well as multiple acquisition types including:

- Helical CT (or Spiral CT)

A technique that involves a continuous and simultaneous scanning motion and table feed, thereby acquiring data in a spiral or helical trajectory. This enables volume scanning with improved speed and z-axis resolution.

- Cine CT

Also known as dynamic or time-dependent CT, this involves repeated sequential scans obtained at the same location dictated by the continuous rotation of the X-ray tube and detector assembly, enabled by slip rings.

- Cardiac CT

A technique specifically designed to visualize the heart and surrounding structures. For acquiring precise and blur-free images of the constantly moving heart, ultra-fast image acquisition is crucial, enabled by the continuous rotation achieved by slip ring technology.

- CT Perfusion

This is a type of imaging used to determine the blood flow to tissues, enabled by the ability of slip ring technology to allow continuous imaging over a designated volume, thus aiding in capturing the passage of contrast material.

- Gated Lung Imaging (4D CT)

This type of imaging also referred to as time-resolved or phase-correlated CT, is primarily applied to assess respiratory motion, especially relevant in radiation therapy planning. Slip rings are fundamental in enabling continuous image acquisition during the various stages of the respiratory cycle.

- CT Fluoroscopy

Slip rings enable real-time guidance in interventional procedures by providing near-real-time imaging feedback.

Let’s also mention specific examples of CT scanner models that employ slip ring technology:

- GE LightSpeed Series – This series of scanners by General Electric uses slip ring technology for high-speed, high-resolution imaging.

- Siemens SOMATOM Series – Siemens’ SOMATOM scanners also use slip ring technology for continuous, high-speed image acquisition.

- Philips Brilliance Series – Philips Brilliance CT scanners employ slip ring technology to permit fast, high-resolution scanning.

These are just a few examples of how slip ring technology contributes to the constant evolution and refinement of CT scanning capabilities, enhancing precision, improving image resolution, and broadening clinical applications.

Types of Slip Rings Suitable for CT Scanners

Canvassing the market to find the right slip ring solution to be integrated into CT scanner technology isn’t a simple task. It requires a comprehensive understanding of the unique requirements of CT systems and intricate manufacturing processes. Not all slip rings are created equal – selecting the right type is crucial to maximize the scanner’s performance.

Here are some types of slip rings suitable for CT scanners:

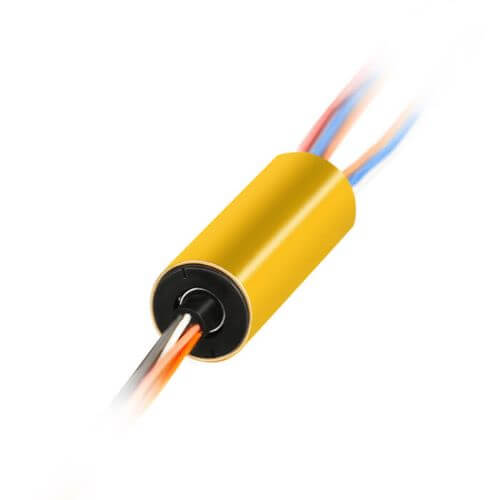

1. Capsule Slip Rings

These are compact and robust slip rings that come with a ‘plug-and-play’ feature. They can seamlessly fit into a confined space of traversing cables where other larger types of slip rings might be unsuitable. However, due to their size, they typically support a limited number of circuits.

2. Pancake Slip Rings

Shaped like a disk or ‘pancake,’ they can be a space-efficient option for CT scanners. However, these slip rings are typically used for slow-speed or static applications due to the constraints presented by their design.

3. High-Speed Slip Rings

CT scanners typically require slip rings that can accomplish high rotational speeds. High-speed slip rings have been designed specifically to cater to applications like CT that require rapid rotation without compromising data transmission or equipment’s lifespan.

4. Fiber Optic Rotary Joints (FORJ)

These are slip rings for fiber optics systems. They transmit optical signals over 360 degrees of rotation. They could benefit from CT scanners leveraging fiber optics for networking and communication.

5. Through Bore or Hollow Shaft Slip Rings

CT scanner manufacturers often make use of hollow shafts or through bore slip rings. The hollow shaft design efficiently manages wire routing, which makes it easier to install and perform maintenance.

Need expert advice on slip rings? Fill out the form and our specialists will assist you.

6. Mercury Wetted Slip Rings

These enhance performance concerning data quality for signal communications as they are constructed from channels that are immersed in liquid metal. However, they require regular maintenance and careful handling due to the use of mercury.

7. Customized Slip Rings

To meet the unique specifications of CT scanners, several slip ring manufacturers offer bespoke products. Custom-made, these slip rings are developed in line with the precise demands of the given CT scanner application. This can include specific size, the number of circuits, rotational speed, connectivity, materials, etc.

In conclusion, the selection of a suitable slip ring for CT scanners is determined by the unique requirements of the systems such as space constraints, speed needs, number of circuits, and durability. Understanding the various types available can help pinpoint the most beneficial fit for both the scanner’s performance and longevity.

Please note that the essential requirement is for the slip ring to operate effectively within the scanner continuously, with little to no maintenance, and no performance depreciation.

Conclusion

Slip ring technology has played a critical role in the advancement of CT scanners, enabling faster, more accurate imaging with less mechanical wear. Understanding the principles, advantages, and disadvantages, and different applications of slip ring CT is essential in gaining a comprehensive understanding of modern computed tomography.

FAQs about Slip Ring CT

Q: How do slip rings contribute to faster scanning times in CT scanners?

A: Slip rings allow for continuous rotation and data acquisition by maintaining an uninterrupted electrical connection between the rotating gantry and stationary components. This enables faster scanning times compared to the stop-and-shoot method.

Q: What maintenance is required for slip ring technology in CT scanners?

A: Regular maintenance involves checking and replacing worn brush contacts and bearings to ensure optimal functionality and prevent potential failures.

Q: What are the different types of slip rings used in CT scanners?

A: Electric slip rings, fiber optic slip rings (FORJ), and hybrid slip rings are used in CT scanners to transmit electrical power, optical data signals, or a combination of both.

Q: Will the introduction of newer, advanced CT scanning technologies replace the need for slip rings?

A: While advancements in CT scanning technology may change certain aspects of slip ring usage, the core functions of slip rings in providing continuous power and data transmission during gantry rotation are critical and will likely continue to be an essential component in CT scanners.

Q: Is noise generated by slip rings in CT scanners an issue for image quality?

A: Although slip ring-induced noise can be a concern in high-speed scanning modes, manufacturers have developed advanced noise reduction techniques and improved slip ring designs to minimize this issue and maintain high-quality imaging.

See What We Can Do