This article aims to serve as a comprehensive guide, offering detailed insights into the world of 6kV slip ring motors. From their basic understanding, applications, and design principles to prospects, we’ve covered it all.

Introduction to the 6kV Slip Ring Motor

Definition and Basic Functionality

A 6kV slip ring motor, as suggested by its name, is a type of electric motor that operates at a voltage rating of 6 kilovolts. This motor is part of the broader category of Induction Motors, which operate based on the principle of electromagnetic induction – the process of generating an electromotive force based on Faraday’s Law of Induction.

The basic functionality of a 6kV slip ring motor lies in its ability to convert electrical energy into mechanical energy. This powerful motor is designed to operate under high-voltage conditions, making it possible to drive machinery and equipment that demands a higher power supply.

Tapping into its high starting torque and excellent speed control attributes, 6kV slip ring motors serve an array of industries, including metal processing, marine, cement production, utilities, and oil and gas, among others.

Fundamentals of Operation and Design Concept

In terms of operation, a 6kV slip ring motor is an AC (Alternate Current) motor. When an alternating voltage supply is applied to the stator (the stationary part of the motor), it generates a rotating magnetic field. This field induces a current in the rotor (the rotating part of the motor), thereby generating a magnetic field around the rotor.

The interaction between these magnetic fields (of stator and rotor) creates a torque that causes the rotor to turn. The speed of the motor can be controlled by varying the resistance in the rotor circuit, achieved by adjusting the slip rings. This is a crucial aspect in applications that have varying load or speed requirements.

In terms of design, a distinctive feature of the 6kV slip ring motor is the rotor segment, which consists of insulated windings connected via copper bars to three slip rings mounted on the motor shaft. This design allows external resistors to be inserted into the rotor circuit through brushes sliding on the slip rings. The resistors help manage the starting current and adjust the speed as required.

Overall, 6kV slip ring motors offer a combination of robust design, power, and versatility in operation, making them indispensable in a variety of heavy-duty applications. While their design may seem complex, understanding the fundamental concepts helps users appreciate their functionality and the engineering prowess behind them.

6kV Slip Ring Motor Theoretical Background

Principle of Operation for Slip Ring Motor

A Slip Ring Motor, including the 6kV variant, operates on the principles of electromagnetism and induction, underpinning the broader category of “induction motors”. The principle of operation can be explained in two key stages – starting and normal running.

During the starting phase, variable resistors (which are connected via the slip rings and brushes) are included in the rotor circuit. This inclusion results in a high starting torque but restricts the rotor current, protecting the motor from an extreme current surge.

As the motor gains speed, these resistors are gradually short-circuited. When the motor reaches close to its normal speed, all the resistors are effectively cut off from the circuit, turning the rotor into a short-circuited winding, just like a squirrel cage rotor.

During normal running, the high voltage applied to the stator winding produces a rotating magnetic field. This field ‘cuts’ the rotor conductors, inducing a current due to electromagnetic induction (Faraday’s Law). Because the rotor circuit is shorted (through the slip rings and brushes), this induced current generates its magnetic field. Interaction between the rotating stator field and the rotor field produces torque, causing the rotor to turn and delivering the mechanical energy output.

Relevance of the 6kV Voltage Rating

The voltage rating of an electric motor is a key parameter that determines many traits of the motor’s behavior, including its power output capacity, efficiency, size, and thermal management. In the case of the 6kV slip ring motor, the “6kV” essentially denotes that the motor is designed to operate efficiently under a voltage supply of 6000 volts.

This high-voltage rating is necessary for applications that require greater power or those that involve driving heavy machinery and equipment. A higher voltage rating also enables the motor to deliver high torque, even at a low speed, thereby offering improved control over motor speed.

Moreover, the utilization of high voltage reduces the current required for a given amount of power, which is an advantage in terms of thermal management. Machines operating at high voltages typically have lower losses and are more efficient than their lower-voltage counterparts, given that power losses are proportional to the square of the current.

In the context of distribution and installation, using a higher voltage rating also reduces cable size and weight, delivering economic benefits.

In conclusion, the 6kV rating for a Slip Ring Motor reiterates its suitability for applications that require high power, torque, and efficiency, further highlighting its adaptability in industrial settings.

Applications of the 6kV Slip Ring Motor

Industries and Applications Where These Motors Are Typically Used

Given their features that offer high-voltage capability, robust torque efficiency, and superior speed modulation, 6kV slip ring motors find their usage across several industries. They are widely favored owing to their adaptability and strength for driving heavy-duty machinery.

- Utilities Industry: These motors are usually seen in power generation units where high-energy outputs are necessary. They are utilized in driving pumps, compressors, or fans that require significant power.

- Oil and Gas Industry: Here, the motors are required in oil extraction processes, powering drills, and heavy-duty pumps. In gas plants, they fulfill tasks of compressing gas or pumping it over great distances.

- Marine Industry: The maritime sector employs these motors for ship propulsion systems, winches, bow thrusters, and pumps. Their robust durability is useful in marine environments.

- Cement Production: Slip ring motors are crucial in operating large grinding mills and rotary kilns.

- Metal Processing Industry: These motors are employed in driving heavy machinery, including rolling mills, crushers, or large fans.

Specific Use-Cases in The Context of Each Industry

Below are a few examples of specific applications in which a 6kV slip ring motor can play a key role:

- Power Utilities: Within thermal or nuclear power plants, these motors are used in turning the massive blades of cooling tower fans critical to prevent overheating cases.

- Oil and Gas: High-torque and high-voltage characteristics are used well in maintaining high-pressure pumping systems or running large drilling machines.

- Marine Applications: In the ship propulsion systems, these motors enable the cruising of large commercial or military vessels.

- Cement Production: The high rotational power of the 6kV slip ring motor is utilized in turning large kilns used to produce cement clinker.

- Metal Processing: In rolling mills, these motors can drive heavy cylindrical rollers that shape and deform the metal.

In summary, the 6kV slip ring motor, with its substantial voltage rating and stellar performance, finds its place in several industrial applications where high power, exceptional torque, and a reliable duty cycle are pertinent. Be it utilities, maritime, oil, and gas, or metal processing, this motor fits seamlessly into the operations, thereby showcasing its practical and economic viability.

6kV Slip Ring Motor Design & Construction

Breakdown of the Different Parts and Components

The design of a 6kV slip ring motor is composed of several key components, each playing a pivotal role in the motor’s operation and performance. Here’s a simplified breakdown of its key parts:

- Outer Frame/Housing: The outer frame, or housing, protects the internal components against environmental conditions. It also acts as a heat sink, absorbing and radiating the heat generated within the motor.

- Stator: The stator is an essential stationary component, consisting of a series of insulated windings or coils placed inside the outer frame. When an AC voltage is applied, it generates a rotating magnetic field.

- Rotor: Complementing the stator is the rotor, the rotating component. The rotor is a wound type with insulated windings that are connected to the slip rings.

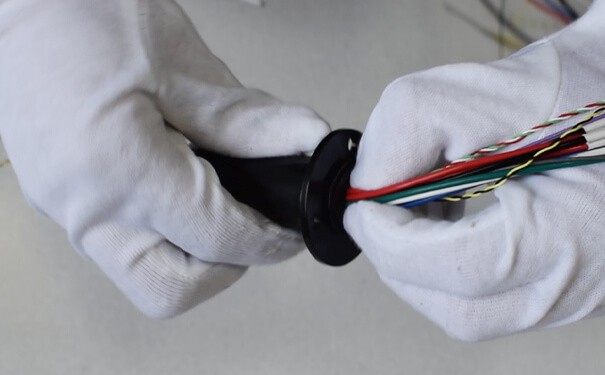

- Slip Rings and Brushes: The slip rings are mounted on the rotor shaft and rotate with it, while the brushes are stationary and maintain contact with the slip rings. They enable the connection of external resistors during starting and variable speed operation.

- Bearings and Shaft: The rotor is mounted on a shaft, which is supported by bearings at both ends. These enable smooth movement and effective transmission of mechanical power.

- Cooling Fan and Air Ducts: Depending on the design, the motor could have an external fan or internal cooling ducts to manage heat through forced convection.

The Materials Used in the Motor Components and Their Importance

Different materials are used in constructing the various components of a 6kV slip ring motor, chosen based on their properties to ensure optimal functioning of the motor:

- Outer Frame: Often made from cast iron or steel, providing strength and durability, as well as good heat conduction properties.

- Stator and Rotor Cores: Made from laminated silicon steel, which optimizes magnetic properties while minimizing eddy current losses.

- Windings: Copper is commonly used for windings due to its excellent electrical conductivity.

- Slip Rings: Usually crafted from copper or brass for good conductivity with minimum wear and heating.

- Brushes: Typically composed of graphite, due to its ability to maintain a stable contact without causing excessive wear on slip rings.

- Bearings: Often made from high-strength steel with suitable lubrication, to withstand high speeds and loads.

In all, the design and construction of a 6kV slip ring motor are a harmonious blend of various components and materials, carefully picked to ensure optimal, reliable performance, and long service life. The materials are chosen for their specific properties to not only withstand the conditions they would be subjected to but also to deliver the roles they are intended to satisfactorily.

6kV Slip Ring Motor Installation Process

Step-by-Step Guide on How to Install a 6kV Slip Ring Motor

Here is a generalized step-by-step guide to installing a 6kV slip ring motor. Keep in mind that the specific process may vary depending on the manufacturer’s instructions and site requirements.

- Transport and Unpacking: Carefully transport and unpack the motor while following the manufacturer’s guidelines for unpacking and handling.

- Inspect Components: Inspect the motor and components for any damage that might have occurred during transit.

- Choose the Installation Location: Select the appropriate location for the motor, accounting for factors such as ambient temperature, accessibility, and the presence of dust, moisture, or corrosive substances.

- Foundation and Mounting: Ensure a solid and leveled foundation to avoid excessive vibrations. Use appropriate leveling tools and securely mount the motor using proper anchoring bolts.

- Align the Motor with Driven Equipment: Precisely align the motor shaft with the driven equipment (pump, fan, etc.) to reduce wear on the bearings and maintain efficient power transfer.

- Electrical Installation: Connect the power cables to the motor’s terminal box following the manufacturer’s wiring diagram. Ensure proper grounding of the motor and install the external resistors as specified.

- Brush and Slip Ring Assembly: Mount the brush assembly onto the slip rings, ensuring a secure fit and proper contact pressure.

- Thermal Monitoring: Install any additional thermal monitoring components (such as temperature sensors) as per the manufacturer’s instructions.

- Cooling System: Assemble the cooling system (air ducts or external fan) and verify proper placement and functionality.

- Test Run: Conduct a test run without load to evaluate the motor operation and identify any potential installation issues.

Important Safety Precautions and Factors to Consider During Installation

- Adhere to all applicable safety regulations and standards.

- Consult the manufacturer’s installation guidelines and verify the compatibility of the motor with the driven equipment.

- Appropriately manage lifting, handling, and installation procedures since 6kV slip ring motors can be heavy and demand careful handling.

- Properly isolate the motor from any power supply during installation to avoid potential electrical hazards.

- Use appropriate personal protective equipment (PPE) during the installation process.

- Train personnel involved in the installation, operation, and maintenance of the motor to ensure safe and proper handling.

In conclusion, the installation process of a 6kV slip ring motor demands careful attention to the manufacturer’s guidelines, adherence to safety precautions, and precise alignment of the motor and driven equipment. Ensuring proper installation through the outlined steps is essential for reliable and efficient motor operation, as well as the safety of the personnel involved.

6kV Slip Ring Motor Operating Parameters

The Right Conditions for Operating a 6kV Slip Ring Motor

Operating conditions matter considerably when it comes to the efficiency and longevity of 6kV slip ring motors. The following are the preferred operating conditions:

- Voltage and Frequency: The motor is designed to perform optimally under the rated voltage of 6kV and a standard frequency, typically 50Hz or 60Hz as per regional power systems.

- Operating Temperature: The motor should function within specified temperature ranges. Standard slip ring motors are generally designed for an ambient temperature of -20°C to +40°C.

- Humidity and Environment: The motor should not be exposed to unusual humidity or corrosive substances. It should preferably be operated in clean, dry settings with good ventilation.

- Load Conditions: The motor is intended to operate under a certain range of load conditions. Overloading should be strictly avoided as it may lead to overheating and motor failure.

- Starting Conditions: The chosen starting technique, such as star-delta starting or auto-transformer starting, should comply with the motor’s specifications.

The Impact of Load, Speed, Torque, and Environment on the Motor’s Performance

- Load: Overloading the motor can significantly reduce its lifespan, causing overheating and potential motor failure. Conversely, under-loading can lead to poor efficiency and power factor.

- Speed: Operating speed affects the motor’s performance considerably. While these motors can operate over a range of speeds, it is crucial to maintain the speed within the designed range to ensure optimal performance.

- Torque: The torque delivery of 6kV slip ring motors can vary based on load and speed. Excessive torque demands, especially during startup, can strain the shaft and other motor components.

- Environment: Environmental factors, such as temperature, humidity, dust, and corrosive substances can significantly impact the motor’s performance. Unfavorable conditions may lead to rusting, insulation breakdown, overheating, and increased wear and tear.

In summary, while 6kV slip ring motors are robust and designed for challenging operating conditions, it is essential to monitor and maintain their operating parameters within prescribed limits. Awareness of the impact of load, speed, torque, and the environment on motor performance can go a long way in optimizing motor longevity and efficiency.

6kV Slip Ring Motor Maintenance and Troubleshooting

Routine Maintenance Needed to Keep the Motor Running Smoothly

The performance and longevity of a 6kV slip ring motor can be significantly enhanced with proper maintenance. The following routine maintenance practices are recommended:

- Cleaning: Regularly clean the motor and its surroundings. Accumulated dirt or dust can interfere with ventilation and could lead to overheating.

- Inspection: Regularly inspect the motor for wear and tear, especially at the bearings, brush assembly, and slip rings. Ensure the brushes are not excessively worn and the slip rings are not grooved or pitted.

- Lubrication: Bearings should be lubricated as per the manufacturer’s guidelines. Proper lubrication reduces friction and prevents overheating and wear on the bearings.

- Temperature Monitoring: Regularly monitor the motor’s temperature during operation to identify potential issues such as ventilation blockage, overloading, or bearing problems.

- Electrical Checks: Regularly check the motor’s electrical conditions. Measure and log parameters such as voltage, current, and insulation resistance.

- Maintenance Records: Maintain a record of all maintenance activities and any unusual occurrences or issues. This can aid in identifying trends or recurring problems.

Common Issues and Troubleshooting Guide

Here are some common issues that could be experienced with a 6kV slip ring motor and some troubleshooting guidance:

- Excessive Noise or Vibration: This could be due to misalignment, bearing wear, or imbalance. Realign the motor with the driven equipment, replace worn-out bearings, and inspect for balance.

- Motor Overheating: Overheating could be due to overloading, insufficient ventilation, or bearing problems. Reduce the load, clean the ventilation passage, and inspect the bearings.

- Motor Not Starting: This could be due to an issue with the power supply, damaged windings, or issues with starting equipment. Verify the power supply, inspect the windings for damage, and check the condition of the starting equipment.

- Low Efficiency: This could be due to excessive motor load, poor power quality, or under-utilized capacity. Correct the load conditions, check the power supply quality, and ensure that the motor is appropriately sized for the application.

The recommended maintenance practices and troubleshooting guide are not exhaustive but provide a solid basis for maintaining the 6kV slip ring motor. It’s always crucial to refer to the manufacturer’s guidelines or consult with a professional in case of persistent or major problems.

6kV Slip Ring Motor Advancements and Future Trends

Technological Advancements in 6kV Slip Ring Motor Design

Technological advancements in the design and manufacturing of 6kV slip ring motors have led to improved performance and greater reliability. Below are some notable advancements:

- Improved Insulation Materials: The use of advanced electrical insulation materials has enhanced motor durability, and thermal resistance, and increased the insulation lifespan.

- Computational Analysis: The use of computational software programs for vibration analysis, heat management, and structural analysis has led to optimized motor design, reduced vibration, effective heat management, and enhanced structural integrity.

- Enhanced Cooling Systems: New cooling technologies, including advanced fan designs and materials, have improved the cooling efficiency, leading to a reduction in overheating risks.

- Precision Engineering: Improved precision manufacturing has resulted in greater mechanical accuracies, leading to increased efficiency, reduced noise and vibration, and extended lifespan of the motor.

- Intelligent Monitoring Systems: The integration of advanced sensors and IoT (Internet of Things) technology allows for real-time monitoring and predictive maintenance, thus increasing motor availability and reducing downtime.

Likely Future Trends and Their Potential Impact on Motor Functionality

Looking ahead, several trends are likely to shape the future of 6kV slip ring motors:

- Smart Motor Solutions: With Industry 4.0, fully integrated intelligent motors capable of self-diagnosis and autonomous adjustments to their operating conditions are anticipated. This should further reduce downtime, provide predictive maintenance, and enhance the motor’s efficiency.

- Energy Efficiency: As energy conservation continues to be a priority, the push towards the development of even more energy-efficient slip ring motors can be expected. This may involve improvements in motor design, materials, and control technologies.

- Sustainability: There will likely be a greater focus on sustainability. This could manifest as increased use of recyclable materials in motor construction, energy-saving designs, and longer motor lifecycles.

- Customizable Options: Customizable motors built to specific user requirements may become more common, offering manufacturers and consumers a chance to optimize their motors according to specific operational conditions.

The future trends in the 6kV slip ring motor industry point towards greater efficiency, reliability, connectedness, and sustainability. It is a testament to the ongoing innovation in the field to keep up with modern industrial demands and environmental considerations.

6kV Slip Ring Motor Price Range and Buying Guide

Price Range of the 6kV Slip Ring Motor in the Current Market

The price range of 6kV slip ring motors can vary greatly depending on their size, design, capabilities, features, and the manufacturer’s brand. Based on the current market, the price could range from a few thousand dollars for a basic model, to tens of thousands of dollars for a larger, more heavy-duty model with advanced features.

Key Factors to Consider When Purchasing Such a Motor

Before investing in a 6kV slip ring motor, several factors need to be considered:

- Size and Rating: Choose a motor that is the correct size and power rating for your specific application. An over- or under-sized motor can lead to inefficiency and motor failure.

- Efficiency: Energy-efficient motors can offer significant cost savings in the long run, despite a higher initial cost.

- Durability: Consider the motor’s specifications concerning temperature, humidity, and dust resistance, especially if it’s going to be used in a harsh environment.

- Maintenance and Support: Ease of maintenance, availability of replacement parts, and the manufacturer’s after-sales service are important considerations.

- Advanced Features: Features such as integrated sensors for performance monitoring and fault detection can improve the overall efficiency and reliability of your operation.

Reliable Brands and Buying Sources

Several well-known and reliable brands manufacture 6kV slip ring motors including ABB, Siemens, CG Global, GE, and Schneider among others. However, the suitability of a brand also depends on the individual’s specific requirements, availability in their region, and budget.

As for purchasing, you can buy directly from the manufacturer, from an authorized distributor, or a trusted industrial supply or electrical equipment store. Another option is online marketplaces like Alibaba, Indiamart, or Amazon Business, where you can compare prices from different sellers.

When purchasing, especially online, it is crucial to verify the seller’s credibility, read product reviews, and ensure that the product comes with a warranty. Consulting with a motor specialist or an experienced industry professional can also be beneficial in making an informed buying decision.

Conclusion

Understanding 6kV slip ring motors helps optimize their functionality and extend their lifespan, ensuring you make the most of your investment. For more detailed queries or assistance, don’t hesitate to connect with the professionals or refer to the manufacturer’s resources.

See What We Can Do