South Korea, a nation forging ahead in renewable energy with ambitious offshore wind targets, faces a unique engineering challenge: maximizing turbine lifespan and reliability in harsh marine environments. At the heart of this challenge lies a critical, yet often overlooked component: the slip ring. Achieving the coveted benchmark of 20 million reliable rotations – equivalent to 20+ years of continuous operation – is a major focus for South Korean research labs, pushing the boundaries of materials science and electrical engineering.

What is a Slip Ring & Why is it Crucial?

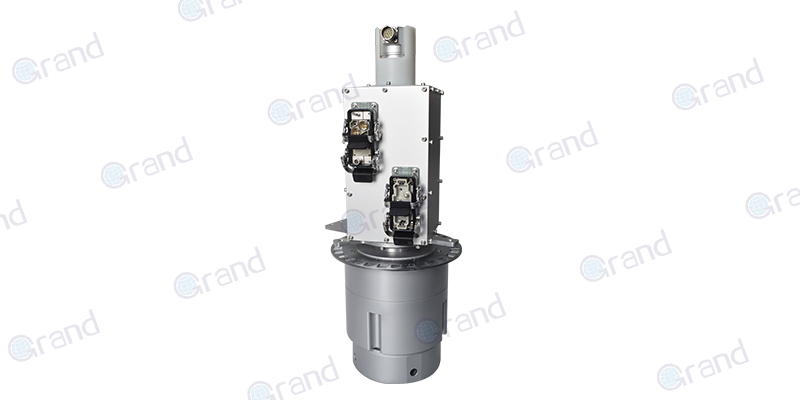

Imagine a wind turbine‘s nacelle (the housing atop the tower) rotating constantly to face the wind, while cables carrying vital power and data need to connect it to the stationary grid and control systems below. A slip ring is the electromechanical device that makes this possible. It consists of:

Stationary Brushes (Contacts): Made from precious metals or advanced composites.

Rotating Conductive Rings: Precisely machined metal rings mounted on the rotor shaft.

As the shaft turns, the brushes maintain continuous sliding contact with the rings, enabling the transfer of:

High Power: Generated electricity flowing down to the grid.

Critical Data: Signals from pitch control systems, sensors (vibration, temperature, wind speed), yaw control, condition monitoring, and communication systems.

Control Signals: Commands sent up to control blade pitch and nacelle yaw.

The “20 Million Rotation” Challenge: Why Korea Cares

South Korea’s focus on massive offshore wind farms (like the 8.2 GW project off Sinan) means turbines are exposed to:

Corrosive Saltwater: Accelerating wear on metal components.

High Humidity & Temperature Swings: Affecting material properties and lubrication.

Constant Vibration: From wind, waves, and machinery.

Limited Accessibility: Making repairs extremely costly and time-consuming.

A slip ring failure isn’t just an inconvenience; it can mean:

Complete loss of power generation.

Loss of critical control (e.g., inability to pitch blades in a storm).

Loss of vital monitoring data.

Costly, complex repairs requiring specialized vessels and downtime.

Achieving 20 million rotations (approx. 20-25 years of operation) without significant degradation or failure is paramount for the economic viability and safety of these multi-billion-dollar offshore investments. It represents the gold standard for ultra-longevity.

South Korean Research Labs: Pioneering Solutions

Korea’s advanced R&D infrastructure is tackling this challenge head-on:

Advanced Materials Development (KRICT, KIMS, University Labs):

Next-Gen Contact Materials: Researching ultra-wear-resistant, low-friction composites and precious metal alloys resistant to corrosion and fretting wear. Nano-coatings (like DLC – Diamond-Like Carbon) are a key area.

Corrosion-Resistant Substrates: Developing rings and housings using specialized stainless steels, superalloys, or advanced polymers.

High-Performance Lubricants: Formulating greases that withstand extreme temperatures, humidity, salt, and maintain stable contact resistance for decades without drying out or washing away.

Contact Technology & Design Optimization (KAERI, KIMM, KERI):

Precision Engineering: Ensuring flawless ring concentricity and brush alignment to minimize vibration and uneven wear.

Brush Geometry & Pressure: Optimizing brush shape, contact area, and spring pressure to balance low wear, stable electrical contact, and minimal heat generation.

Multi-Path & Redundant Contacts: Designing systems where multiple brush contacts share the load per ring, providing redundancy and extending overall life.

Signal Integrity & Noise Mitigation (ETRI, University EE Depts.):

Shielding & Filtering: Advanced electromagnetic shielding within the slip ring assembly to prevent data corruption from power line noise or external interference, crucial for reliable sensor and control signals over 20+ years.

Fiber Optic Rotary Joints: Researching hybrid systems where fiber optics (immune to EMI) handle high-bandwidth data, reducing the electrical load on traditional rings.

Condition Monitoring & Predictive Maintenance (KIST, KRISO):

Embedded Sensors: Developing slip rings with integrated sensors to monitor brush wear, temperature, vibration, and contact resistance in real-time.

AI-Driven Analytics: Using data from these sensors and turbine SCADA systems to predict remaining useful life and schedule maintenance before failure occurs, maximizing uptime.

The Core Challenge: 20 Million Rotations Under Siege

The Math: 20 million rotations equate to:

~25 years: Assuming an average operational rotational speed of ~10 RPM (highly variable, but a common design basis).

~3.8 Billion Degrees of rotation.

Sliding Distance: For a brush contacting a ring with a diameter of, say, 0.5 meters, the sliding distance per brush could exceed 60,000 km (over 37,000 miles) – more than circling the Earth 1.5 times. Per brush. Under constant pressure.

The Environment: Korean offshore sites (Yellow Sea, Korea Strait) deliver a brutal cocktail:

Salt Aerosols: Penetrating seals, causing electrochemical corrosion (galvanic, pitting, crevice) on metals.

High Humidity (>80% RH): Promotes condensation inside housings, leading to short circuits and accelerated corrosion.

Temperature Extremes: From freezing winters to hot, humid summers, causing material expansion/contraction, lubricant degradation, and thermal stress.

Constant Vibration: From wind gusts, wave action, and gearbox/machine dynamics. This induces fretting wear (micro-motion wear at the contact point), disrupts the crucial lubricant film, and risks contact bounce causing arcing/data loss.

Limited Maintenance Windows: Repair vessels cost >$100,000/day, require calm seas, and take turbines offline for weeks. Preventative maintenance is preferred; predictive maintenance is the holy grail.

South Korean R&D: Dissecting the Solutions

Research labs are attacking every failure mode systematically:

Materials Science Frontline (KRICT, KIMS, POSTECH, KAIST):

Ring Materials: Moving beyond standard copper alloys. Investigating:

Corrosion-Resistant Copper Alloys (e.g., CuNiSn, CuCrZr): Enhanced strength and seawater resistance.

Stainless Steel Clad Copper: Stainless outer layer for corrosion, copper core for conductivity (machining/bonding challenges).

Superalloys (Inconel variants): Extreme corrosion/heat resistance (cost/conductivity trade-offs).

Advanced Polymer Composites: Reinforced with conductive fibers (CNTs, graphene) for specific signal rings (lower current).

Brush Materials: The sacrificial element. Focus on:

Precious Metal Alloys: Gold-Palladium, Platinum-Iridium-Ruthenium. Superior corrosion resistance, stable contact resistance, low friction. Cost is major hurdle; research targets thinner, optimized plating or composite structures.

Advanced Metal-Graphite/Carbon Composites: Engineered with nano-additives (MoS2, WS2, hBN) for self-lubrication, corrosion inhibitors (e.g., cerium compounds), and tailored fiber reinforcement for wear resistance and current carrying.

Nano-Coatings: Diamond-Like Carbon (DLC) coatings applied to rings and brushes offer extreme hardness, low friction, and chemical inertness. Research focuses on adhesion under thermal cycling and preventing delamination.

Lubrication Revolution: Standard greases fail. Labs are developing:

Synthetic Base Oils: With ultra-high viscosity indices (stable across temperature) and oxidation stability.

Thickeners: Resistant to seawater washout and mechanical shear.

Additive Packages: Extreme Pressure (EP)/Anti-Wear (AW) additives that don’t corrode metals, corrosion inhibitors, conductive additives to stabilize contact resistance, and moisture-displacing agents.

Ionic Liquids: Emerging as potential “non-volatile” lubricants with inherent conductivity and thermal stability.

Precision Engineering & Contact Physics (KAERI, KIMM, Hanyang Univ.):

Micro-Geometry: Not just round rings and flat brushes. Researching optimized brush profiles (crown, radius) and ring micro-grooving to:

Enhance lubricant retention.

Manage debris evacuation.

Stabilize the contact point.

Minimize contact bounce.

Contact Force Optimization: Too high = accelerated wear & heat. Too low = unstable contact, arcing, signal noise. Using Finite Element Analysis (FEA) and multi-body dynamics simulations to model spring systems under vibration and thermal distortion, ensuring consistent optimal force for 20M+ cycles.

Vibration Damping: Integrating advanced elastomeric dampers within the slip ring assembly itself to isolate the critical brush/ring interface from nacelle vibrations.

Thermal Management: Modeling heat generation (I²R losses, friction) and designing heat dissipation paths (conductive housings, heat sinks, even micro-fluidic channels in extreme concepts) to prevent localized overheating and lubricant breakdown.

Sealing Perfection: Multi-stage labyrinth seals combined with hydrophobic/oleophobic membranes that allow pressure equalization while blocking salt aerosols and liquid water ingress. Testing under accelerated salt fog (ASTM B117) and pressure cycling.

Signal Integrity & Hybridization (ETRI, SNU, KERI):

EMC/EMI Fortress: Shielding isn’t just a box. It involves:

Conductive Gaskets: Maintaining shield continuity across rotating/stator interfaces.

Compartmentalization: Separating high-power rings from sensitive signal rings within the assembly using internal shielded partitions.

Filter Integration: Embedding low-pass filters directly at the signal ring contacts to suppress high-frequency noise induced by power switching (converters) or arcing.

Differential Signaling: Using twisted pairs with differential drivers/receivers on critical data lines for inherent noise rejection.

Fiber Optic Rotary Joints (FORJs): Crucial for high-bandwidth data (condition monitoring cameras, lidar, high-speed comms). Korean labs are advancing:

Low-Loss, Multi-Channel FORJs: Using expanded beam lens technology for robustness against dust/misalignment.

Hybrid Slip Ring -FORJ Modules: Integrating power, lower-speed data (CAN bus, analog sensors), and fiber channels into a single, sealed, optimized unit. This drastically reduces the number of electrical circuits needing ultra-long-life contacts.

The Impact: Powering Korea’s Green Future

Solving the 20-million-rotation challenge for slip rings delivers tangible benefits:

Reduced LCOE (Levelized Cost of Energy): Lower maintenance costs and maximized uptime directly improve project economics.

Enhanced Grid Stability: Reliable power transmission from offshore farms.

Improved Safety: Uninterrupted control system operation is critical in severe weather.

Validating Korean Technology: Positions domestic manufacturers as global leaders in ultra-reliable offshore wind components.

Accelerating Offshore Deployment: Proven reliability reduces investor risk, enabling faster rollout of Korea’s ambitious wind plans.

While the towering blades capture the imagination, it’s the relentless, silent work of components like the slip ring that truly enables the wind energy revolution. South Korea’s research labs, driven by the demanding 20-million-rotation goal, are at the forefront of transforming this humble component into a paragon of endurance. Their success in developing slip rings capable of surviving decades in the brutal offshore environment is not just an engineering triumph; it’s a fundamental enabler for powering the nation’s sustainable future with reliable, clean energy from the sea. The race for 20 million flawless turns is on, and Korea is a leading contender.