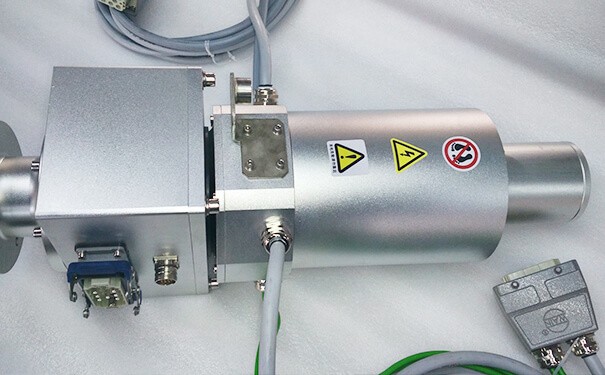

A standard slip ring is designed to withstand extreme environmental conditions in wind turbines effectively. It makes use of rotating rings and solid brushes to provide an excellent contact surface. The components of the slip ring should also be arranged in such a way that it can save space. It is important that you choose slip rings that are capable of operating efficiently, even under harsh or severe weather conditions.

Power transmissions and data signals are required in the case of wind turbines. Data signals are transmitted to the control system from the nacelle, which is needed for the proper functioning of the rotary blades. The operation of a slip ring is required for this purpose. As you may already know, the primary function of a slip ring is to help in the transfer of electric charges or current from a stationary part to a rotating component.

Though slip rings may be smaller in size in comparison to generators or gearbox bearings, however, they play a significant role in wind turbines and other applications. The performance or efficiency of a wind turbine can be adversely affected when there is a defect in a slip ring, hence the need to choose a slip ring carefully. Communication data will either be lost or interrupted due to a failure in the slip ring. Signal transmission through controls and pitch mechanisms in the top and hub boxes may be affected due to a faulty slip ring.

Furthermore, there will be a downtime or an overall shutdown of the wind turbine if this happens. Before selecting a wind turbine slip ring, you must pay close attention to some important details, which shall be discussed herein. Engineers are putting more effort into manufacturing high-quality wind turbine slip rings that will last longer and perform optimally with less maintenance cost.

Factors to Consider when Choosing Slip Rings that Last for Wind Turbines

- Efficiency

The efficiency of wind turbine slip rings is a critical factor that can affect the overall performance of slip rings. How then can you choose a slip ring with the right efficiency? There is a wide array of circuitry which can be selected based on the requirements for power. There are also different voltage and amperage combinations that can give you the right efficiency for your wind turbine slip ring.

According to advancements in slip ring design, they are built to operate with very low power loss and high wattage value. A good amperage and voltage combination for wind turbine slip rings may be 690 VAC and 100 amps, which is suitable for a 55kw pitch motor control.

You may choose to get a wind turbine slip ring that is custom-made to suit your power demand. Power losses and wattage transfer capacity may be adversely affected by several other factors hence the need for a carefully selected or a tailor-made slip ring to maximize efficiency.

- Material type consideration

The operation and maintenance cost of wind turbines is significantly reduced when you purchase a wind turbine slip ring of good quality. When a wind turbine is placed in a remote and hostile environment, which is usually the case, choosing a high-grade and right-quality slip ring may come in handy. It is, therefore, important to select wind turbine slip rings, which can help reduce or limit surface degradation. Some gold-plated slip rings with a wire brush may wear down, which could result in conductivity losses and a reduction in transfer capacity.

- Visual inspection

Visual inspection is another means of choosing wind turbine slip rings. In the wind industry, analytic platforms that aim to extract and monitor data can help make decisions for slip ring selections. Some of these analytic platforms can effectively provide information about the performance of turbines with respect to the type of slip ring being used.

Apart from providing a proper maintenance plan, visual inspection, when carried out on wind turbine slip rings before a purchase, may give you an insight as to the quality of the slip rings. You can carefully examine all the components of the slip ring to see if they are well-fitted together and if the metal brush makes complete contact with the rotating surface. By so doing, you may have prevented unnecessary spending on repair or corrective maintenance.

- Good slip ring design and brush compatibility

In selecting a wind turbine slip ring, it is important for you to select one that has a proper surface finish. You have to ensure that there is stability in the surface finish to prevent the brush from diminishing. Since the repair of wind turbine slip rings is expensive and time-consuming, it is necessary to select one with a good-quality brush. Doing this can also help to prevent abrupt shutdown of the turbine, which may also lead to downtime of equipment.

The mechanical properties of a brush used in a wind turbine slip ring should be compatible with the application for which it is needed. The brush should be designed to meet its electrical specifications.

Conclusion

Wind turbine slip rings should be carefully selected to ensure that their performance and efficiency are maintained. We have seen that when choosing a slip ring for your wind turbines, the type of slip ring material has to be considered. The slip ring brush may be plated with gold to be able to withstand extreme temperatures. It should also be less susceptible to corrosion and should make complete contact with the rotating surface. You may also make use of visual design as a means of identifying a good wind turbine slip ring.

Ensure that you observe all the components to make sure that they are well-fitted to avoid loose parts, which may hamper the slip ring performance. Also, pay attention to some technical details like the efficiency and power of the slip ring. Is it capable of accommodating the load that it is to be used for?

What is the amperage and voltage value, and how would it affect the output when operational? Does the wind turbine slip ring operate at higher conditions than its original design conditions? Getting answers to these questions will help you make an informed decision when choosing a high-performance and durable wind turbine slip ring.