Welcome to this enlightening piece on clean slip rings, which aims to demystify this pivotal component found in many industrial machines. In this article, we journey into the vast world of slip rings, specifically focusing on the importance of cleanliness to improve the device’s functionality and impact on operations significantly. Each section has been meticulously designed to cover the subject comprehensively, providing you, the reader, with a wholesome understanding of this often overlooked yet crucial mechanical element.

Diving into the depth of why maintaining cleanliness in slip rings holds prime importance, we shall shatter the complex technical jargon into easy-to-understand concepts, providing an enjoyable ride as we learn together. This article aims to unravel the intricate relationship between clean slip rings and every machinery’s overall performance as they operate, clarifying how the thorough upkeep of this inconspicuous part can spread significant ripples throughout an industrial operation.

The array of benefits this article provides the reader extends beyond merely imparting theoretical knowledge. As we leaf through each topic, you can expect to gain empirical wisdom and practical insights. Understanding the best practices in cleaning and maintaining slip rings enables you to not only enhance the efficiency of your machinery but also significantly increase longevity.

With a clear, user-friendly tone, we’ll present insights for both novices and veterans alike, making this information beneficial for anyone interested in machinery upkeep. By the end of the journey, readers will be armed with the necessary knowledge, empowering them to devise their strategies for maintaining clean slip rings. This, in turn, promises a smoother operation, a reduction in downtime attributed to slip ring-related failures, and an overall increase in the lifespan of the machinery.

Stay with us as we explore the cog that keeps your machinery’s wheel spinning, ensuring your gears are always well-oiled and running smoothly. Get ready to become immersed in the world of clean slip rings. By understanding its significance, you will inevitably pave the way for a more efficient and productive industrial operation. Let the journey begin.

The Concept and Importance of Clean Slip Ring

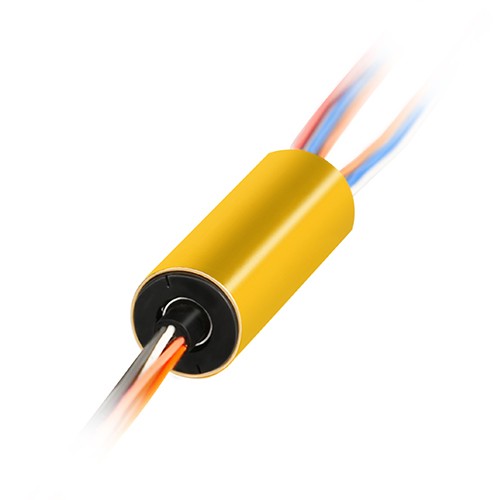

Beginning with the core of this article, let’s delve into what a slip ring is – defined at the most basic level, it is an electromechanical device that enables electrified parts’ rotation while maintaining a constant connection. In other words, it ensures an unceasing flow of power or data from a stationary component to a rotating component, thereby maintaining their seamless operation. Its applications are far and wide, found in various equipment, from wind turbines and satellite antennas to CT scanners and video cameras.

As central as a slip ring is to the functioning machinery, it can often be forgotten when it comes to maintenance, particularly around the aspect of cleanliness. The importance of a clean slip ring cannot be overstated. When overlooked, it can accumulate dust, grime, and wear particles due to its operation, leading to increased friction, poor electrical contact, and eventual breakdown of communication. This not only affects the component’s performance but can also lead to costly repairs, unscheduled downtime, and, at worst, the replacement of whole machines. However, when adequately maintained, clean slip rings enhance equipment performance, decrease energy consumption, prevent abrupt operational failure, and extend the overall lifespan of the equipment. It’s a small component that holds the key to significant cost savings and improved efficiency.

As we seek to provide a complete understanding of this crucial topic, we draw from personal and professional experiences in the field of designing and manufacturing slip rings. Over the years, we’ve seen firsthand the equipment failures caused by neglected slip rings, failures that could have been easily prevented with regular cleaning and maintenance. Drawing on these experiences enables us to provide real-world, hard-won insights into the best practices for keeping your slip rings clean, significantly reducing breakdowns, and ensuring the smooth running of your industrial operations.

These experiences, insights, and the scars earned over years of working in this field, serve as powerful testaments to the mantra – a clean slip ring is a happy slip ring. And a happy slip ring means a smooth-running, efficient machine, that optimally delivers on its purpose. Stay with us as we continue on this journey through the world of clean slip rings, sharing insights from the trenches, to keep your machinery in prime health for years to come.

Cleaning of Different Types of Slip Rings

Continuing our journey, let’s explore the diverse types of slip rings that cater to varied equipment and applications, each with its unique functionalities and structures. This broad categorization of slip rings will not only emphasize their versatility and specificity in machine designs but will also contextualize the importance of maintaining cleanliness regardless of their type.

The simple categorization could range from capsule slip rings, designed compactly to fit in small spaces while providing smooth electrical transmission, to large and robust through-bore slip rings, permitting the passage of shafts or other equipment through their center. Another type is the pancake slip ring, named due to its disc-like formation, best used in applications where length usage is limited, typically favoring spaces with an abundance of height. Then, there are also hybrid slip rings combining power lines and signal lines to form a complex structure that meets multifaceted needs.

Each of these types serves different functionalities, and fittingly, their design and construction vary, although their core function remains the same – to transmit electrical power or data signals from fixed to rotating parts. But one common thread that binds them all is the necessity of cleanliness for their optimum performance.

It’s this maintenance facet that often goes overlooked in the regular care protocols. The cleanliness of slip rings directly influences their performance and, by extension, the machines they’re an essential part of. For instance, capsule slip rings, given their compact nature, can quickly accumulate debris, affecting their conductivity and thereby, efficiency. Large through-bore slip rings, while robust, can still fall prey to dust accumulation and grime build-up, potentially clogging the central passage and leading to uneven rotation of the machine elements.

Our experiences working with these different slip ring types have acquainted us with the common issues they face when cleanliness is not prioritized. Time and again, the evidence proves that the longer a slip ring is allowed to operate without sufficient cleaning, the more it is likely to develop problems. Hence, although the types of slip rings are diverse, encompassing a wide range of applications, one theme remains constant – the absolute importance of maintaining cleanliness for optimized performance.

By appreciating the breadth of slip ring types and understanding their unique characteristics, you’re better equipped to keep them clean, optimize their function, and enhance the longevity and efficiency of your machinery. So, let’s continue our exploration, next, into the specifics of maintaining slip ring cleanliness.

The Process of Cleaning Slip Rings

Now that we have acquired an understanding of slip ring types and their importance, let’s navigate through the crucial process of cleaning slip rings effectively and safely. Often touted as a simple task, cleaning slip rings actually requires a systematic approach and a keen eye for detail to avoid mishaps that could have adverse effects.

The cleaning process usually follows a step-by-step progression:

- Safety First: Always disconnect the power source to the machine before proceeding. Wearing appropriate safety gear, such as gloves and protective eyewear, is critical.

- Prep the Surface: Initially, lightly clean the surface of the slip rings with a dry cloth to remove loose particles and dust.

- Choose the Right Cleaning Agent: Find a cleaning agent that is suitable for the specific materials your slip ring is made from – incorrect cleaning agents can cause corrosion or further damage.

- Clean Thoroughly But Gently: Apply the cleaning agent gently, scrubbing the slip rings without exerting too much pressure, which could cause scratches or other damages.

- Dry the Slip Rings: After cleaning, ensure to dry the slip rings thoroughly before reapplying power as any residual cleaning agent or moisture could cause issues.

Despite the basic outline above, it’s essential to remember that variations might exist based on the specific slip ring type and the machine it is part of. Regular cleaning and maintenance should always be a part of the machine’s upkeep schedule to ensure its long-term operation.

Alongside these steps, we must shine a light on common mistakes that occur during the cleaning process. One significant error is the use of incompatible cleaning agents, which can lead to corrosion or other damage to the slip ring surface, deteriorating its functionality. Another common mistake is the use of excessive force during the cleaning process. It’s necessary to clean slip rings gently to avoid leaving scratches or other damage on the surface that could hinder their effectiveness. Ignoring safety precautions can also prove devastating, hence always prioritize safety before initiating the cleaning process.

Learning the correct way to clean your machine’s slip rings can make a significant difference to the efficiency and lifespan of the unit itself. Furthermore, by being aware of common mistakes, you can ensure your cleaning practices are on the right path towards effective maintenance, ultimately ensuring the smooth operation of your industrial activities. Let’s persevere the journey in our mission to glean the importance of maintaining clean slip rings.

Periodic Maintenance of Slip Rings

Delving deeper into the mechanics of slip ring maintenance, we must broach the topic of the frequency of cleaning and the importance of periodic checks for optimal performance. The ‘one-size-fits-all’ principle doesn’t apply to the maintenance frequency as it largely hinges on several factors, such as the machine’s operational environment, the usage frequency, and the slip ring type.

Generally, slip rings in high dust environments or those associated with heavy-duty equipment might require more frequent cleaning intervals. Similarly, slip rings installed in machines with less strenuous applications or in cleaner environments might not need as frequent cleaning. However, it’s advisable to conduct a thorough inspection every few months to nip potential issues in the bud.

Routine checks are an integral part of keeping your slip rings in optimal condition. You should keep an eye out for signs of excessive wear or dust accumulation between maintenance intervals. Regular visual checks can help identify potential issues before they escalate. Additionally, using tools to measure the resistance or temperature of the slip ring can further help in outlining their health, enabling prompt action to be taken if needed.

In the journey of slip ring maintenance, always bear in mind that prevention is better than cure. Observing good cleaning practices and carrying out routine checks can alleviate the costly repercussions of major machinery failure. The exact timing and specific routine measures may vary, but the underlying principle of regular maintenance remains unaltered, which is akin to industrial health insurance.

Indeed, the process requires a discerning eye, a vigilant approach, and the understanding that every machinery component matters – even the humble slip ring. The expert eye to identify the signs of wear, grime, or breakdown, and the quick reflexes to respond to these signs with timely intervention – this is the recipe for machine longevity, efficiency, and uninterrupted operations. Remember, it’s not just about running the machines but keeping them running smoothly, and the cleanliness of your slip rings can play a big role in that. As we continue on this journey of learning, let’s explore the broader benefits that clean slip rings bestow on your industrial operations.

Impact of Using Clean Slip Rings

Having traversed the landscape of slip ring types, their cleaning, and periodic maintenance, let’s reflect on the cumulative benefits that clean slip rings bring to the table, from boosting the overall efficiency of machinery to paving the way for potential cost savings and enhanced productivity.

At the most fundamental level, clean slip rings ensure the smooth transmission of power or data signals from stationary components to their rotating counterparts. Their cleanliness reduces friction, prevents electrical noise, and minimizes the chances of communication breakdown. This overall improved operation, in turn, directly contributes to the machinery’s efficiency, resulting in less energy consumption and increased effectiveness of the machine.

To paint a more precise picture, let’s consider real-world examples. Suppose you are operating a wind turbine equipped with a slip ring for power transmission. If the slip ring is kept clean and friction-free, the turbine’s rotational capability is enhanced, leading to optimal energy generation. On the other hand, if the slip ring is neglected, accumulated dirt can increase friction, hinder power transmission, and cause the turbine to operate inefficiently, leading to significant energy loss.

Another scenario could be a production line in a factory that uses a rotary table equipped with a through-bore slip ring. Maintaining the cleanliness of this slip ring will ensure a smooth, uninterrupted functioning of the rotary table and, in turn, the production line. However, if the slip ring gets dirt accumulated and is not cleaned promptly, it could cause an abrupt operational failure of the production line, resulting in unscheduled downtime, delayed output, and increased costs.

These examples underscore the potential for significant cost savings, enhanced productivity, and the overarching theme of proactive maintenance when clean slip rings are in play. Beyond just the monetary savings, the reliability of operations, the extended lifespan of machinery, and, by extension, the peace of mind of knowing your equipment is running at its optimal capacity, are invaluable advantages.

As we conclude our exploration, the take-away message is clear – paying attention to the small details can yield big benefits. In this case, the regular cleaning of slip rings can directly contribute to improved machinery efficiency, cost savings, and enhanced productivity. Always remember, that a clean slip ring is a gateway to a successful, smooth-running machinery operation.

Insights from an Industry Professional

In our journey so far, we have derived insights from the technical and practical perspectives. To further enrich our understanding, it would be instrumental to glean insights from an industry professional, one who has hands-on experience in designing, producing, and maintaining slip rings.

Drawing from their years of practical experience, industry professionals could vouch for the fact that successful operation of machinery isn’t limited to its design or production but extends to its maintenance as well. They understand the real-world challenges and nuances that come with using and maintaining slip rings because they’ve seen and experienced them firsthand.

One practical advice they consistently underscore is the importance of educating oneself about the slip ring – get to know its design, understand the materials it is made from, and comprehend its operation in the context of the overall machinery. By doing this, you’ll be better equipped to identify issues before they escalate, and better able to apply the correct cleaning techniques and materials.

Additionally, they emphasize the criticality of adopting a proactive approach rather than a reactive one. It’s always easier to prevent a problem than to solve it after it has occurred. Implementing a routine maintenance schedule and sticking to it can prevent a lot of issues from arising in the first place.

This professional experience often bundles an assortment of tips and tricks for users to keep their slip rings clean and efficient. For instance, they advise using a visual aid, such as a magnifier, which can help spot minor issues or potential damage that might not be visible to the naked eye. Another wise tip they often share is to document all observations, cleaning cycles, and any issues encountered. This record can be incredibly useful in identifying recurring problems, tracking the efficiency of preventative measures, or determining the cleaning frequency.

In the end, these insights derived from industry professionals’ experience can greatly add value to your slip ring maintenance regimen, making it both effective and efficient. It’s about combining the acquired technical knowledge with these practical insights to come up with a comprehensive approach towards maintaining your slip rings’ cleanliness and, thereby, contributing positively to your machinery’s performance. As we close this chapter, remember that, in maintenance as in life, consistency is key.

Conclusion

This article aims to provide an in-depth understanding of clean slip rings for its readers. The utility of clean slip rings extends beyond machinery operation, it has far-reaching positive effects resulting in cost savings and heightened industrial productivity.

See What We Can Do