As a pillar industry of clean energy, the reliability and economy of wind power generation technology is important. The wind turbine slip ring is a key component that connects the rotating hub with the fixed engine compartment, also it is a pain point in operation and maintenance. The wind power pitch slip ring based on fiber optic transmission technology is an effective solution for signal transmission.

Traditional wind turbine slip ring facing constraints such as mechanical wear, electromagnetic interference, unstable signals and bandwidth bottlenecks. The innovative optoelectronic slip rings use fiber optic transmission technology to reconstruct the signal transmission path of the pitch control system, fundamentally avoiding a series of problems caused by electric friction sliding contact.

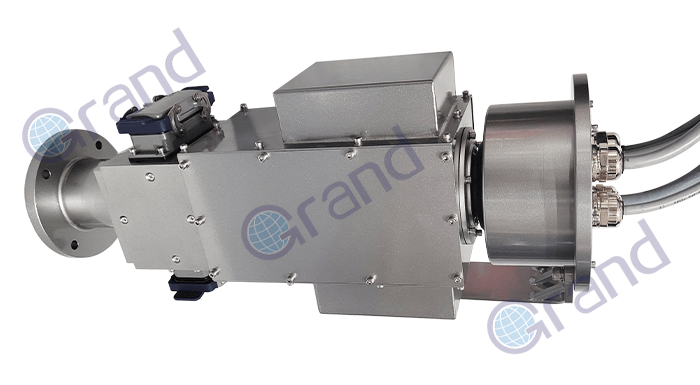

The wind turbine pitch photoelectric slip ring converts all control commands, sensor data, status information, etc. into optical signals. Optical signals are transmitted through total reflection in optical fibers, achieving data communication between the rotating end and the fixed end. Without physical contact, electromagnetic interference, low loss and high bandwidth. The power transmission still adopts the electric ring. As it only transmits electricity and does not involve signals, the requirements for its materials and structure can be appropriately relaxed, also the reliability can be improved.

The wind power slip ring using fiber optic transmission technology has ultimate reliability, reducing costs and increasing efficiency. Eliminating the core worn components on the signal transmission path significantly extends the mean time between failures (MTBF) of the pitch system. This means fewer unplanned shutdowns, lower maintenance costs, and higher human efficiency, directly improving the economic benefits of wind farms. In addition, the natural immune electromagnetic interference characteristics of optical fibers ensure the absolute purity of control signals and the ultimate fidelity of sensor data. At the same time, the huge fiber optic bandwidth provides the possibility to deploy more and more advanced monitoring equipment on the wheel hub side, such as built-in cameras for internal inspection of blades and high-frequency vibration sensors for early fault diagnosis of bearings, laying a solid foundation for building “transparent fans” and achieving predictive maintenance.

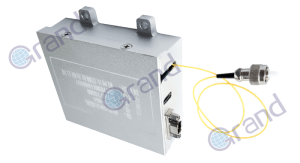

Hangzhou Grand Technology Wind Turbine Slip Ring (Supporting Optical Terminal Machine)