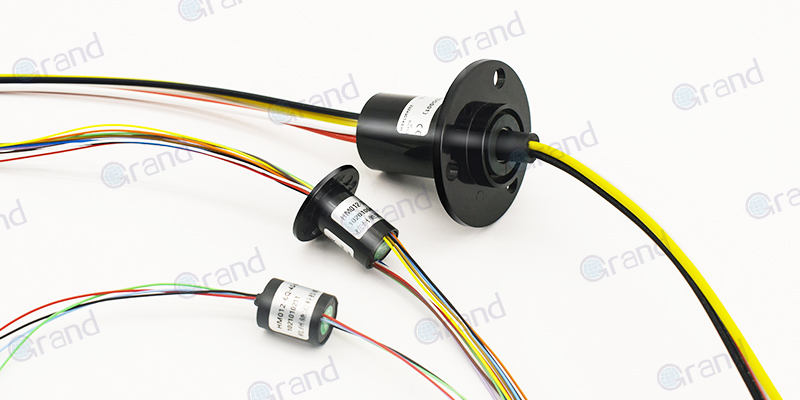

The relentless pursuit of satellite performance, miniaturization, and reliability demands increasingly rigorous ground testing. One critical, yet often overlooked, component enabling these tests is the humble slip ring. When testing involves high-speed rotational dynamics – particularly simulating the intense spin stabilization or separation forces satellites experience – conventional slip rings falter. Achieving reliable electrical and data transmission at speeds like 6000 RPM represents a significant engineering frontier in aerospace testing, pushing slip ring technology to its absolute limits.

The Imperative for High-RPM Testing

Satellites face extreme rotational environments:

Spin Stabilization: Many satellites, especially cylindrical designs or upper stages, achieve stability through rapid axial spin (often hundreds, sometimes exceeding 1000 RPM).

Separation Dynamics: During deployment from launch vehicles or dispensers, satellites can experience high transient spin rates.

Centrifuge Testing: Simulating high-G launch or re-entry loads often involves spinning the entire satellite or critical components at very high speeds.

Attitude Control System (ACS) Testing: Validating reaction wheels or control moment gyroscopes under extreme operational scenarios requires high rotational speeds.

Testing these scenarios on the ground is non-negotiable for mission success. Failure to accurately replicate flight conditions risks undetected design flaws, leading to catastrophic in-orbit failures. This necessitates powering sensors, actuators, heaters, and telemetry systems while the unit under test (UUT) spins at representative speeds – precisely the role of the slip ring.

The 6000 RPM Challenge: Why It’s Difficult

Transmitting power and high-fidelity data across a rotating interface at 100 revolutions per second (6000 RPM) presents formidable obstacles:

Tribological Nightmares (Friction & Wear)

Extreme Centrifugal Forces: At 6000 RPM, centrifugal forces acting on contact brushes, wires, and even lubricants become colossal. Standard brushes can deform, lift off the track, or wear catastrophically fast.

Frictional Heating: High rotational speed combined with contact pressure generates intense localized heat. This can degrade lubricants, accelerate wear, oxidize contacts, and even melt components if not meticulously managed.

Material Selection: Contact materials must possess exceptional hardness, wear resistance, low friction coefficients, high electrical conductivity, and stability at elevated temperatures – often conflicting properties.

Signal Integrity Under Siege

Electrical Noise (EMI): Sliding contacts are inherent noise generators. At 6000 RPM, the mechanical “chatter” increases dramatically, creating significant electrical noise that can swamp sensitive analog sensor signals (thermocouples, strain gauges) or corrupt high-speed digital data (Ethernet, video).

Impedance Variations: High-speed rotation can cause minute, rapid variations in contact resistance and inductance, impacting signal quality, especially for high-frequency data.

Crosstalk: Packing numerous circuits into a compact slip ring operating at high-speed slip rings increases the risk of electromagnetic crosstalk between channels.

Mechanical Integrity & Dynamics

Vibration & Balance: Any imbalance in the rotating assembly is magnified at high RPM, leading to severe vibration. The slip ring itself must be perfectly balanced and robust enough to withstand these forces without degradation or inducing excessive vibration into the test article.

Bearing Performance: High-precision, low-friction bearings capable of handling axial/radial loads at 6000 RPM with minimal heat generation and long life are critical. Bearing failure is a primary point of slip ring failure at these speeds.

Sealing & Contamination: Preventing lubricant migration into sensitive satellite components and keeping external contaminants out of the slip ring’s critical contacts requires advanced, reliable sealing solutions that function under high centrifugal loads.

Thermal Management: Dissipating the significant frictional and electrical resistive heat generated within the confined space of a slip ring is a major challenge of High-Temperature Slip Ring. Inadequate cooling leads to thermal runaway and rapid failure.

Engineering Solutions for 6000 RPM Reliability

Achieving robust 6000 RPM performance demands a holistic, multi-faceted engineering approach:

Advanced Contact Technologies:

Precision Monofilament Brushes: Engineered from specialized precious metal alloys (e.g., gold, palladium alloys) or composite materials, formed into single, precisely shaped wires. These offer controlled pressure, reduced friction, and superior wear life compared to traditional multi-strand brushes.

Liquid Metal Contacts (Mercury or Galinstan): Utilizing a rotating pool of conductive liquid metal (like mercury or safer gallium alloys – Galinstan) eliminates solid-solid friction. Offers extremely low noise, low contact resistance, and virtually unlimited rotational life. Requires meticulous sealing and handling due to toxicity (mercury) or reactivity (gallium alloys).

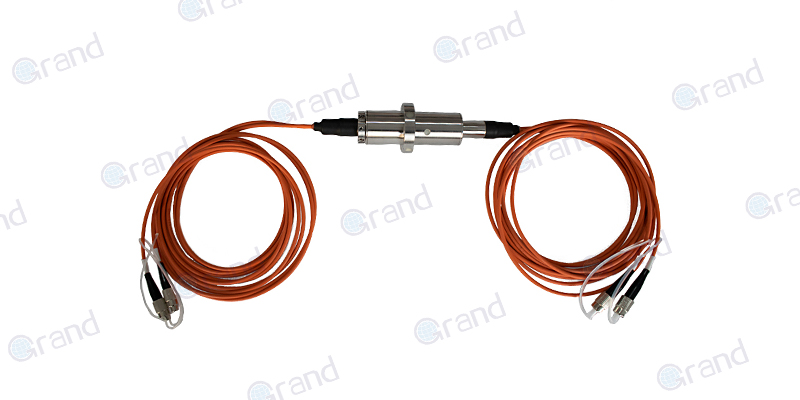

Hybrid Fiber-Optic/Electric: For critical high-speed data, Fiber Optic Rotary Joints (FORJs) transmit data optically (immune to EMI) alongside a traditional electrical slip ring for power and lower-speed signals. This offloads the most demanding data transmission requirements.

Optimized Mechanical Design:

Ultra-Precision Balancing: Dynamic balancing performed at or near operational speeds (e.g., 6000 RPM+) is essential to minimize vibration.

High-Speed Bearings: Utilizing ceramic hybrid bearings (ceramic balls, steel races) or specialized, lubricated-for-life precision steel bearings designed explicitly for ultra-high-speed operation.

Robust Housing & Shafts: Materials and construction designed for stiffness and dimensional stability under thermal and centrifugal loads.

Advanced Sealing: Labyrinth seals, magnetic seals, or specialized low-friction contact seals tailored for high-RPM environments.

Thermal Management Systems:

Integrated Cooling Channels: Circulating coolants (air or liquid) directly through the slip ring housing or stator.

Heat Sinking: Strategic use of high-conductivity materials and external fins to dissipate heat.

Thermal Modeling: Sophisticated simulation during design to predict hot spots and optimize cooling strategies.

Signal Conditioning & Noise Mitigation:

Shielding & Grounding: Multi-layer shielding and meticulous grounding schemes within the slip ring and cabling.

Filtering: Integration of passive (LC filters) or active filtering on sensitive lines.

Differential Signaling: Using LVDS or similar differential protocols for digital data to enhance noise immunity.

Careful Circuit Layout: Isolating high-power and sensitive signal paths within the slip ring assembly.

The Payoff: Enabling Next-Generation Satellite Validation

Successfully deploying 6000 RPM slip rings transforms satellite testing capabilities:

Higher Fidelity Simulation: Test articles can be spun at speeds truly representative of flight conditions, uncovering potential issues invisible at lower test speeds (e.g., micro-vibrations affecting sensitive instruments, wiring harness fatigue, lube migration).

Comprehensive System Testing: Allows for integrated testing of power systems, sensors, communication links, and ACS components under operational dynamics, providing unprecedented confidence in system integration.

Reduced Risk: Early identification and mitigation of rotational dynamics issues drastically lower the risk of costly in-orbit failures.

Supporting Innovation: Enables the testing of novel satellite concepts relying on aggressive spin stabilization or experiencing extreme separation dynamics.

The demand for 6000 RPM slip rings in aerospace satellite testing is not merely a technical curiosity; it’s a critical enabler for validating the safety and reliability of increasingly sophisticated spacecraft operating in harsh environments. Conquering the tribological, electrical, mechanical, and thermal challenges at this extreme speed requires cutting-edge materials science, precision engineering, and innovative design. These high-velocity conduits of power and data, operating silently at the heart of spin test rigs and centrifuges, are fundamental to ensuring that satellites survive the violent journey to orbit and perform flawlessly in the unforgiving realm of space. As satellite technology continues its relentless advance, the race to push slip ring performance even higher – towards 10,000 RPM and beyond – remains a vital frontier in aerospace ground testing.

See What We Can Do