Dive into the intricate world of induction motor components, the silent powerhouses behind countless machines and devices in various industries. From exploring the fundamental components that ensure their smooth operation to dissecting manufacturing materials and processes, this article will navigate through the dynamic landscape of induction motor components. Address the common concerns of users and anticipate the future of motor technologies, offering invaluable insights for both the seasoned professional and the curious learner.

Introduction to Induction Motor Components

Induction motors form the backbone of modern industry, seamlessly converting electrical energy into mechanical movement. Hidden within the casing of these motors lies a marvel of engineering that allows for a direct connection to an electric supply, eschewing the need for brushes or commutators found in their DC counterparts. This design simplicity not only enhances reliability but also reduces maintenance needs, making induction motors a favored choice across a breadth of applications.

The essence of an induction motor’s operation lies in its ability to induce an electromotive force (EMF) in the rotor without any physical connection, thus the name “induction.” This elegantly simple principle belies the intricate dance of its internal components, each playing a pivotal role in converting electrical input into the kinetic output that powers everything from conveyor belts in manufacturing plants to the cooling fans in household appliances.

The omnipresence of induction motors across various industries cannot be overstated. Their efficiency and durability make them indispensable in sectors that demand reliability and cost-effectiveness. Whether it’s in the vast agricultural fields powering irrigation systems, the complex assembly lines of the automotive industry, or the energy sector relying on them for both generation and consumption, induction motors are pivotal. Their scalability means they are just as useful in large-scale industrial operations as they are in small, specialized machinery.

Moreover, the global shift towards sustainability and energy conservation further underscores the importance of induction motors. Their ability to operate at variable speeds with proper control systems allows for significant energy savings, aligning with the modern ethos of “doing more with less.” This adaptability not only ensures they meet the stringent regulatory standards for energy efficiency but also reduces the operational costs for businesses, making them a cornerstone in the journey towards eco-friendly industrial practices.

Thus, as we delve deeper into understanding the components of an induction motor, we’re not just uncovering the technicalities of its operation. We’re exploring a key component of modern technological advancement, a testament to human ingenuity, and a crucial player in the narrative of sustainable development. The continuous improvement and innovation in the design and materials of these components not only promise enhanced performance and reliability but also pave the way for a future where the full potential of electrically powered machinery can be realized across all walks of life.

Basics of Induction Motor Components

Like a perfectly choreographed performance, the induction motor depends on the harmonious interaction of its various components to convert electrical energy into mechanical motion. Although it may seem complex, the basic operating principle of an induction motor can be explained in a manner that illuminates the functionality of each component.

At the core of any induction motor’s operation lies the transfer of energy through electromagnetic induction. This process begins with the stator—the static part of the motor composed of coils wound around a steel core. When alternating current (AC) is passed through these coils, a rotating magnetic field is generated within the motor.

Submerged in this rotating magnetic field is the rotor—the motor’s moving component. As the magnetic field sweeps across the rotor, it induces an electric current into its conductive bars, which, in turn, generates its magnetic field. The interaction between these magnetic fields causes the rotor to spin, providing the necessary mechanical power.

Each component of the induction motor, from the windings of the stator that generates the magnetic field to the rotor that reacts to this field, plays an intrinsic role in its operation. Without the stator, there would be no rotating magnetic field, and without the rotor, there would be no interaction to produce mechanical motion.

Beyond these main components, other elements contribute to the seamless operation of an induction motor. The bearings, for instance, support the rotating shaft, minimizing friction and facilitating smooth operation. The frame not only acts as a protective casing but also aids in heat dissipation—a critical factor in enhancing the longevity of the motor and maintaining its performance.

The inherent beauty of an induction motor resides in the co-dependency and interaction of these components. Each serves a specific function, and their collective functionality enables the conversion of electrical energy into kinetic power. Understanding their roles, cooperation, and design nuances not only enhances your knowledge of these powerhouses but also empowers you to ensure their optimal performance and maintenance. In the grand narrative of electrical motors, each component holds its importance, with its absence disrupting the rhythm of this complex, yet intriguing, dance of electromagnetic energy conversion.

Main Components of an Induction Motor

Induction motors, in their role as the prime movers for countless devices, owe their utility to the design and function of their main components. These are the stator, rotor, bearings, and frame. Each plays an integral part in the motor’s reliability and efficiency.

Stator

The stator is the immovable outer part of an induction motor, its stationary stance belying the dynamism of its function. Structurally, it comprises a series of laminated steel rings with slots for housing the motor’s windings or coils. When an alternating current flows through these windings, it generates an electromagnetic field that incessantly rotates within the motor’s housing. This rotating field is the heart of an induction motor, the invisible force that interacts with the rotor. The design and construction of the stator are meticulously calculated to create an effective and efficient magnetic field, dictating the motor’s performance capabilities.

Rotor

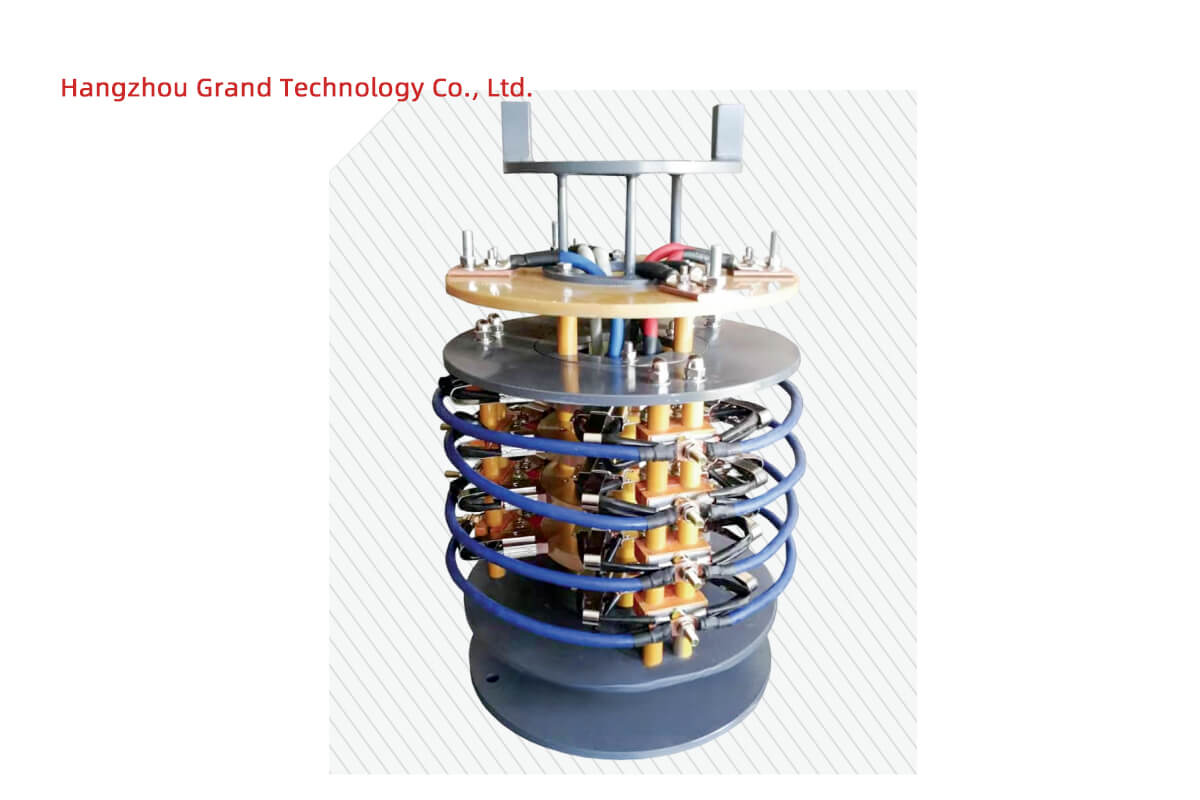

Central to an induction motor’s operation is the rotor, which is positioned inside the stator. The rotor comes in two major variants: the squirrel cage and the wound rotor.

- Squirrel Cage Rotor: The most common type due to its simple and robust design. It consists of bars of aluminum or copper, short-circuited by end rings, and resembling a cage—a design which gives it its name. When the rotor is subjected to the stator’s rotating magnetic field, currents are induced in these bars, creating a force that rotates the rotor.

- Wound Rotor: This contains a set of windings that are connected through slip rings to external resistances. Adjusting these resistances can control the motor’s performance and speed—providing greater control and starting torque compared to squirrel cage designs.

The interplay between the rotor and the stator’s magnetic field is vital. The induced electrical current and associated magnetic field of the rotor strive to catch up with the stator’s rotating field, resulting in the rotor’s turning motion.

Bearings

The bearings in an induction motor hold a discrete yet crucial role. They cradle the rotor, facilitating its rotation within the motor’s frame. Typically made of high-grade steel or advanced composites, bearings must be chosen carefully for their ability to endure the load and reduce friction. Their reliability ensures the smooth operation of the rotor and, by extension, the motor itself. Without effective bearings, a motor can suffer from vibration issues, noise, and even premature failure, all of which can significantly impair efficiency and performance.

Frame

Providing the skeleton structure to the induction motor, the frame is not merely a container but an integral component of the motor’s build. Its robust construction supports the weight of the internal components and secures them in place, while its design is pivotal for heat dissipation. As the motor operates, heat is generated, and an effective frame, often made with fins or other heat-dissipating features, acts as a heat sink, keeping temperatures within operational limits. The frame’s durability and design directly influence the protection, cooling, and overall lifespan of the motor.

In the complex interplay of these main components, we see the genius of induction motor design—a synergy that results in a reliable and efficient conversion of electrical energy into mechanical work. Understanding and maintaining these elements is key to ensuring the induction motor continues its quiet work as a foundational link in modern technology’s ever-moving chain.

Manufacture and Materials of Induction Motor Components

Often overlooked compared to the operational aspects of an induction motor are the manufacturing processes and materials that lead to its creation. These elements are pivotal in determining the performance, reliability, and longevity of the motor.

Manufacturing Processes of Major Components

In the creation of each component, specific processes are applied to ensure its functionality and reliability.

- Stator: The manufacturing process for the stator starts with the creation of laminated steel cores, formed by stacking thin sheets of silicon steel—a material with excellent magnetic properties. These cores have slots where the windings, made from copper or aluminum, are installed. The use of multiple thin laminations reduces the loss due to eddy currents, enhancing the motor’s efficiency.

- Rotor: For squirrel cage rotors, aluminum or copper bars are set into the slots of the laminated rotor core and shorted at both ends by end rings. In wound rotors, the rotor core is wound with insulated copper wire and the ends are connected to slip rings.

- Bearings: Typically produced using high-precision machining processes to ensure a smooth surface that minimizes friction. Materials like high-grade steel or advanced composites are used due to their robustness and wear resistance.

- Frame: Generally cast from sturdy materials like iron to provide rigid support. Special attention is given to creating a design that can effectively aid in cooling, leading to additional machining or casting processes to form cooling fins or ducts.

Material Selection for Each Component

Choosing the right material for each component is crucial for its function and the motor’s overall durability and performance.

- Stator: The core’s material, silicon steel, is chosen for its good magnetic properties, while the windings are typically copper for its excellent electrical conductivity, although aluminum may be used for less demanding applications due to its lower cost.

- Rotor: In squirrel cage rotors, aluminum is often chosen for its balance of cost-effectiveness and good electrical conductivity. In some high-power motors, copper may be used for better efficiency. Wound rotors typically use copper windings due to their superior electrical conductivity.

- Bearings: High-strength steel is commonly used for its durability and wear resistance. In some high-end motors, advanced materials like ceramic composites may be employed for their superior heat resistance and smoothness.

- Frame: Cast iron is a common choice due to its high strength and rigidity and its thermal properties that assist in cooling the motor. Higher-cost motors might use aluminum frames, which are lighter and offer better heat dissipation.

In essence, the manufacture and material selection of each component in an induction motor play a significant role in its performance and durability. By optimizing manufacturing processes and materials, motor manufacturers seek to maximize efficiency and lifespan, thus providing increased value to the user and a lower total cost of ownership for the motor.

User Concerns Regarding Induction Motor Components

Understanding user concerns related to induction motor components is essential for ensuring the reliability, performance, and cost-effectiveness of these motors in various applications. The key areas of concern often revolve around maintenance and replacement, efficiency, cost implications, and compatibility of components during maintenance or replacement.

Maintenance and Replacement

Users frequently express concerns about the lifespan of key induction motor components and the complexities involved in their maintenance or replacement. Each component requires specific attention:

- Stator: Stator winding failures due to insulation breakdown are a common issue. Regular inspection and maintenance are crucial for identifying wear and tear early, but replacement can be costly and time-consuming, often requiring specialized skills.

- Rotor: Rotor issues can range from broken bars in squirrel cage designs to wear and tear on the slip rings of wound rotors. While scheduled inspections can mitigate sudden failures, repairs or replacements can significantly impact the motor’s uptime.

- Bearings: Bearing failures are among the most common motor issues. Users can extend bearing life through lubrication and alignment checks, but eventual replacement is inevitable. Fortunately, bearings are generally easier and less costly to replace than other components.

- Frame: While frames are less prone to failure, their condition is crucial for protection and heat dissipation. Impact damage or corrosion can compromise the frame’s integrity and affect the motor’s performance.

Efficiency

The efficiency of an induction motor is a collective measure of its components’ performance:

- Stator and Rotor: These components play a direct role in the conversion of electrical energy to mechanical energy. Losses due to resistance in winding, eddy currents, and hysteresis directly affect overall motor efficiency.

- Bearings: While bearings might not seem related to efficiency, friction losses in bearings can contribute to increased energy consumption and reduced operational efficiency.

- Frame: An adequately designed frame aids in heat dissipation, preventing overheating and ensuring that the motor operates within optimal temperature ranges for efficient performance.

Costs

Cost implications are a significant concern for users and include upfront costs, replacement costs, and operational costs:

- Upfront Costs: Initial costs are influenced by the choice of materials and the design sophistication of each component, with more efficient or durable options often commanding higher prices.

- Replacement Costs: Maintenance and the potential need for replacement parts like bearings, windings, or even a new rotor can contribute to the total cost of ownership.

- Operational Costs: Partly determined by the motor’s efficiency, operational costs encompass the energy consumption and potential downtime during maintenance or replacements.

Compatibility

During maintenance or the replacement of components, ensuring compatibility is crucial for preserving or enhancing motor performance:

- Component Compatibility: Users must source replacement parts that not only fit physically but also match performance specifications. Non-compatible parts can lead to reduced efficiency, increased wear, or even component failure.

- System Compatibility: Especially in complex machinery, the induction motor must be compatible with the overall system in terms of power requirements, speed, and control mechanism. Any changes or replacements involving the motor components must consider these broader system requirements to avoid mismatches that could undermine performance.

In conclusion, awareness and proactive management of these concerns are paramount for users relying on induction motors. Knowledgeable maintenance, combined with informed component selection and a keen understanding of cost implications, ensures that induction motors continue to provide reliable and efficient service in their various applications.

Innovations and Future Trends in Induction Motor Components

The landscape of induction motor technology is continually evolving, shaped by advancements in materials science, controls, and diagnostics. These developments promise enhanced performance, energy efficiency, and smarter operation.

Advanced Materials

In the quest for efficiency and durability, the adoption of new materials stands out:

- Stator and Rotor: Manufacturers are experimenting with superconducting materials and amorphous metals to reduce losses in stator windings and rotor constructions. These materials can sharply decrease electrical resistance and hysteresis losses, leading to motors that are both smaller and more efficient.

- Bearings: The integration of ceramics and other advanced composites in bearings is gaining traction. These materials reduce wear, handle higher temperatures, and improve longevity, diminishing the need for frequent maintenance.

- Frame: The trend towards lightweight and high-strength materials, such as carbon fiber composites and advanced aluminum alloys, is progressing. These materials offer better heat dissipation and reduce overall weight, enhancing the motor’s efficiency and ease of installation.

Smart Monitoring Systems

Smart sensors and monitoring systems are revolutionizing how induction motors are managed:

- Predictive Maintenance: Instead of scheduled maintenance intervals, smart sensors can monitor the condition of motor components in real-time, predicting failures before they occur. By analyzing data on vibration, temperature, and other critical indicators, these systems can optimize maintenance schedules and prevent unscheduled downtime.

- Energy Efficiency: Smart monitoring can also keep track of a motor’s energy consumption, enabling more precise control over its operation. This can lead to adjustments in real-time, improving the motor’s efficiency and reducing energy wastage.

- Adaptive Performance: Advanced control systems and sensors may adjust motor performance on the fly to match the load requirements, thereby reducing wear on components and conserving energy.

- Connectivity and Integration: With the Internet of Things (IoT), motors can be integrated into wider networked systems, providing a wealth of data for operational planning and coordination. This connectivity allows for seamless integration with Building Management Systems (BMS) or Manufacturing Execution Systems (MES), optimizing not just the motor but the entire operation it powers.

In conclusion, innovations in materials and the adoption of smart monitoring systems are setting the stage for the next generation of induction motors. These advancements are not only increasing efficiency and durability but are also integrating motors into a broader ecosystem of smart industrial machinery and systems. Users can expect to see induction motors that are not only more energy-efficient and reliable but also more cognizant and interactive within their operating environments.

Conclusion

A comprehensive understanding of induction motor components and their interplay is essential for anyone involved with their operation, maintenance, or design. With a foresight into upcoming technological trends and a solid understanding of the core components, professionals can ensure these motors continue to operate at peak efficiency.

FAQs about Induction Motor Components

Q: How often should induction motor bearings be lubricated?

A: Lubrication frequencies can vary based on the motor’s application and environment. Manufacturer guidelines typically outline the optimum lubrication schedule.

Q: Do more expensive induction motors equate to better quality components?

A: Not necessarily. Higher costs may reflect more durable materials or advanced features, but assessing the overall value comes down to performance, longevity, and maintenance requirements.

Q: Can the efficiency of an existing induction motor be improved by upgrading components?

A: Some improvements can be made, such as retrofitting with more effective cooling systems or better-quality bearings. However, the fundamental design of the motor will limit the extent of the efficiency upgrade.

Q: What materials are used in the construction of the stator and rotor?

A: The stator core is typically made from laminated silicon steel to minimize eddy current losses, while the stator windings are usually copper due to their excellent electrical conductivity, although aluminum can be used for its cost-effectiveness. The rotor, depending on its type (squirrel cage or wound), is constructed using aluminum or copper for the conducting bars or windings, with a laminated iron core to facilitate magnetic flux.

Q: How can the lifespan of bearings be extended in an induction motor?

A: Extending the lifespan of bearings involves regular lubrication, maintaining proper alignment and balancing of the motor, and ensuring that the motor is not overloaded beyond its capacity. Additionally, using high-quality bearings and implementing predictive maintenance through vibration analysis can also significantly contribute to their longevity.

Q: Are there any innovations in materials that are making induction motors more efficient?

A: Yes, advancements such as the use of superconducting materials and amorphous metals in stator windings and rotor designs are reducing energy losses, thus enhancing the motor’s efficiency. Additionally, the introduction of new composite materials for bearings and lightweight, high-strength materials for motor frames is improving motor performance and durability.

Q: How do smart monitoring systems improve the maintenance of induction motors?

A: Smart monitoring systems equipped with IoT technology allow for real-time tracking of critical motor parameters, such as temperature, vibration, and current consumption. This enables predictive maintenance, where potential issues can be addressed before they lead to motor failure, ultimately reducing downtime and extending the motor’s lifespan.

Q: What are the cost implications of using advanced materials or integrating smart systems in induction motors?

A: Initially, the use of advanced materials and the integration of smart monitoring systems can increase the upfront cost of an induction motor. However, these investments often lead to reductions in operational costs through improved energy efficiency, fewer maintenance requirements, and extended component lifespans, resulting in a lower total cost of ownership over time.

Q: How important is component compatibility during maintenance or replacement?

A: Component compatibility is crucial during maintenance or replacement to ensure the motor operates efficiently and reliably. Using incompatible parts can result in reduced performance, increased wear-and-tear, and even premature failure of the motor. Always ensure replacement components match the original specifications or consult with the manufacturer for compatible alternatives.

See What We Can Do