Low-leakage slip rings are pivotal for several applications that require optimized electrical performance, including medical equipment and precision instrumentation. This article delves into the vital role of low-leakage slip rings, addresses user concerns, and anticipates the technology trends shaping their future.

Introduction to Low-Leakage Slip Rings

Slip rings, also known as rotary electrical interfaces, rotating electrical connectors, or electrical rotary joints, perform a simple but vital function: they transmit electrical signal and power from a stationary structure—such as a base or a shaft—to a component that rotates. From wind turbines harnessing renewable energy to giant Ferris wheels offering panoramic views, slip rings facilitate rotation without the hindrance of managing dangling wires.

Every application has specific needs regarding the transfer of power or data. Some require simple transmission, while others demand complex signal handling. Across these varying needs and manifold applications, the principle of friction-induced electrical continuity remains a defining factor that makes slip rings indispensable.

The concept of “low-leakage” slip rings extends from the foundational principles of regular slip rings but focuses on a key performance metric—minimizing electrical leakage. Electrical leakage is a phenomenon where electricity escapes the intended path, leading to inefficiency and potentially hazardous situations. This escape of electricity can be due to various reasons such as insulation degradation, humidity, dust, or even the design of the electrical circuitry itself.

In advanced applications like medical devices or precision industrial equipment, even minute electrical leakage can lead to operational inefficiency, data inaccuracies, or equipment malfunctions—consequences that could have deep implications for patient health or industrial throughput.

Enter the low-leakage slip rings. Designed with superior materials, precision-engineered layouts, improved insulation, and attention to minimizing electrical resistance, low-leakage slip rings provide a secure pathway for electricity even in environments posing challenges like dust, moisture, or constant wear and tear.

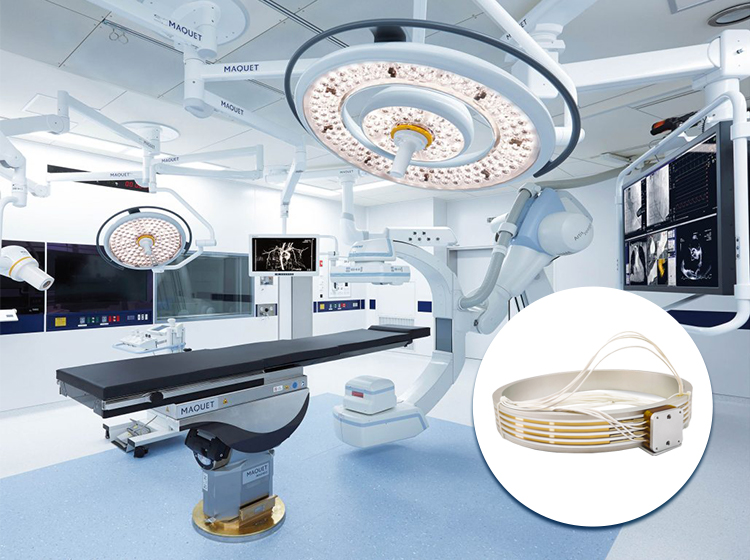

These specialized slip rings are therefore beneficial, even crucial, in applications where minimizing leakage is paramount. Whether it’s an MRI machine scanning the human body with millimeter precision or a robotic arm assembling intricate parts, low-leakage slip rings ensure reliable performance, making them a core component in the grand scheme of operations.

The Importance of Low-Leakage Slip Rings

In the realm of electromechanical systems, the fight against electrical leakage is akin to a delicate balancing act: overlooked, it might not immediately undermine the system, but over time, it can escalate into a significant problem, both functionally and financially. Minimizing electrical leakage in slip rings is not just a matter of enhancing efficiency; it’s about safeguarding the integrity of the entire system they serve. Electrical leakage, in its essence, represents wasted energy—energy that, instead of performing useful work, dissipates into the surroundings, potentially causing interference, signal corruption, and even hazardous conditions due to overheating.

Moreover, in high-precision applications, even the smallest amounts of leakage can introduce noise that corrupts the data integrity, leading to inaccuracies. This is particularly critical when these systems form the backbone of operations where precision is not just desired but required. In these contexts, the role of low-leakage slip rings transcends basic operational necessity, embodying a fundamental component that ensures safety, reliability, and performance.

Critical Applications of Low-Leakage Slip Rings

Medical Equipment: In the medical field, equipment like MRI machines and CT scanners epitomize the zenith of diagnostic precision and operational complexity. These devices rely heavily on low-leakage slip rings to transmit power and data between stationary and rotating parts without compromising the quality of the images produced. Any significant electrical leakage in these systems could mean the difference between an accurate diagnosis and a potential oversight. The stakes are incredibly high, as patient health and safety are directly impacted by the reliability and precision of these devices.

Precision Instrumentation: Industries that employ precision instrumentation—for instance, aerospace, satellite communications, and advanced manufacturing—also depend on the reliability of low-leakage slip rings. In satellite communications, signal integrity is paramount; any leakage or noise introduced into the system can compromise communication, leading to data loss or corruption. Similarly, in aerospace applications, where slip rings are used in equipment from turret systems in military vehicles to rotary sensors in aircraft, maintaining low electrical leakage is crucial to ensure the operational readiness and safety of the systems involved.

Thus, the importance of low-leakage slip rings transcends mere technical preference, becoming a cornerstone of modern technological infrastructure across various high-stakes fields. By minimizing electrical leakage, these specialized slip rings safeguard the integrity of sensitive data transmissions and ensure that the systems they support operate with the highest levels of efficiency and reliability. In doing so, they play an indispensable role in enabling technological advancements and ensuring the safety and effectiveness of critical applications worldwide.

Technical Specifications of Low-Leakage Slip Rings

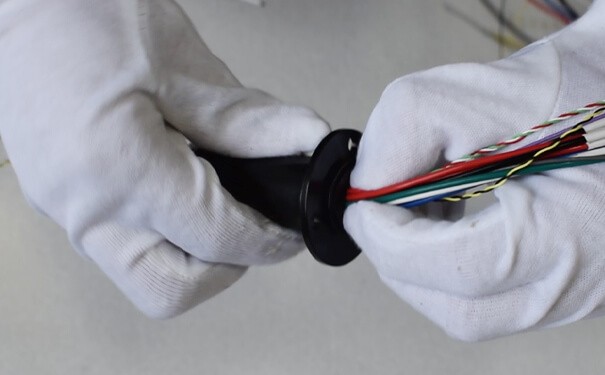

Understanding the technical aspects that culminate in a low-leakage slip ring involves several factors—factors that intertwine to curate a solution capable of delivering under demanding circumstances. The performance and reliability of low-leakage slip rings rest largely on careful material selection, thoughtful design considerations, and meticulous assembly.

Material Choice

The materials chosen to construct a low-leakage slip ring play a vital role in its performance. High-quality, low-resistance materials are typically employed to ensure optimum electrical conductivity and thus minimize leakage. For instance, the conductive rings and brush materials (which form the pivotal point of electricity transmission) are often made of precious metals or their alloys due to their low contact resistance and superior durability. Simultaneously, the choice of insulation materials is equally crucial as they prevent accidental bridging of conductive paths, a primary source of electrical leakage.

Design Considerations

The design of a low-leakage slip ring also significantly influences its performance. Ensuring minimal electrical contact resistance and maximized insulation efficiency requires specialized design strategies. For instance, manufacturers may use protective sealants to secure the slip ring from dust, humidity, and other environmental factors that could compromise insulation. Further, adopting an axial brush design can reduce contact resistance and ensure stable transmission, thereby minimizing electrical leakage.

Impact on Performance and Reliability

The careful combination of material choice and design consideration directly impacts the slip ring’s effectiveness and longevity. High-quality materials and an efficient design safeguard against premature wear and tear, maintain consistent performance at varying operating conditions and thus contribute to longer operational life.

However, the improved performance and reliability that low-leakage slip rings offer come with their own considerations. The use of high-quality, low-resistance materials, and intricate design often dictates their cost—making them more expensive than standard variants. Likewise, they might require more rigorous maintenance routines to ensure continued low-leakage performance.

The balance between improved performance, higher costs, and increased maintenance needs must be carefully considered when assessing low-leakage slip rings. However, when reliability and efficiency matter most—as they undoubtedly do in critical applications—low-leakage slip rings justify their need, contributing an unparalleled level of certainty and operational integrity.

User Concerns Regarding Low-Leakage Slip Rings

The shift towards incorporating low-leakage slip rings into essential applications comes with its set of user concerns. These concerns range from reliability and maintenance to cost and the necessity for customization. Each of these facets plays a crucial role in the decision-making process, significantly impacting the operational dynamics of industries relying on such advanced components.

Reliability

In the arena of sensitive applications, such as medical diagnostics, aerospace, and precision manufacturing, the margin for error is minimal to non-existent. Reliability in these sectors is not just a preference; it’s a stringent requirement. Low-leakage slip rings are pivotal in ensuring that crucial equipment functions without faltering, as even minor discrepancies or malfunctions can lead to dire consequences. The importance of reliability in these contexts cannot be overstated, making it a prime concern for users who depend on the unwavering performance of their equipment. The expectation is that low-leakage slip rings will not only perform consistently under varying operational conditions but also sustain this performance over an extended period.

Maintenance

While low-leakage slip rings are engineered for optimal performance, like all electromechanical components, they require regular maintenance to ensure their integrity and functionality. For users, the concern often revolves around the extent of maintenance required to maintain low leakage rates and the associated downtime and costs. Regular maintenance checks, involving inspections for wear and tear, cleaning, and possible component replacements, become essential to avoid sudden failures. This necessity for upkeep can pose resource allocation and scheduling challenges for operations, especially those running around the clock or in remote locations.

Cost

The perception that low-leakage slip rings are considerably more expensive than their standard counterparts often gives users pause. The advanced materials, intricate design considerations, and manufacturing processes that contribute to the low leakage performance naturally come at a higher price point. For organizations, especially those requiring a significant quantity of slip rings or operating under tight budget constraints, the initial investment can be a significant concern. Balancing the cost against the expected performance improvement and operational reliability is a critical consideration that impacts the adoption rate of low-leakage slip rings.

Customization

Finally, the need for customization introduces another layer of complexity. Given the diversity of applications relying on slip rings, a one-size-fits-all solution is rarely feasible. Specific applications demand customizations in dimensions, material selections, electrical specifications, and even operating conditions like temperature or humidity ranges. This need for tailor-made solutions raises concerns regarding lead times, additional costs, and the potential need for ongoing adjustments to ensure the slip rings precisely meet application requirements.

Together, these concerns encapsulate the challenges users face when integrating low-leakage slip rings into their operations. Addressing these concerns requires a comprehensive understanding of the applications, ongoing communication between users and manufacturers, and a clear-eyed assessment of the cost-benefit ratio that these advanced components bring to the table.

Comparing Low-Leakage Slip Rings with Standard Slip Rings

The selection between low-leakage and standard slip rings is a critical decision that hinges on the application’s specific requirements and desired outcomes. Understanding the key differences between these two types of slip rings and the contexts in which each is most appropriately used can guide users in making informed choices that align with their operational objectives.

Key Differences

Performance and Precision: The primary distinction lies in their performance capabilities, notably in terms of electrical leakage and signal integrity. Low-leakage slip rings are engineered to minimize electrical noise and interference, making them ideal for applications where signal clarity and precision are paramount. Standard slip rings, while effective in managing power and signal transfer in general applications, may not offer the same level of precision, especially in environments susceptible to electromagnetic interference.

Material and Design: This heightened performance in low-leakage slip rings is a result of superior material choices and advanced design considerations. They often employ high-grade, low-resistance materials and incorporate design features that optimize signal fidelity. Standard slip rings, in contrast, might use materials and designs that are adequate for general purposes but do not specifically address the issue of leakage reduction.

Cost Implications: Given their advanced materials and intricate designs, low-leakage slip rings typically come at a higher cost compared to standard options. This cost differential is justified by the performance and reliability they bring to critical applications, a factor that may not be as pressing in less sensitive environments.

Application Scenarios

When Standard Slip Rings Suffice: For general industrial applications where the primary requirement is the transmission of power or signals without the need for high precision, standard slip rings may suffice. Examples include basic rotating displays or conveyor belts where the consequences of signal interference are minimal. In these scenarios, the cost-efficiency and straightforward functionality of standard slip rings make them a practical choice.

When Low-Leakage Models are Essential: Conversely, in environments where precision and reliability are non-negotiable—such as in medical imaging equipment, aerospace systems, or high-end data communication networks—low-leakage slip rings become indispensable. The potential cost of signal degradation or interference in these applications could be catastrophic, ranging from compromised patient safety to mission failure in aerospace operations. The advanced technology of low-leakage slip rings ensures that they perform reliably under such critical conditions, justifying their higher investment and operational costs.

In essence, the decision between opting for a low-leakage or standard slip ring is dictated by the balance between the required level of performance and the associated cost implications. Understanding the distinctions and application scenarios for each type of slip ring enables users to navigate these choices effectively, ensuring that their operational needs are met while optimal functionality and reliability are maintained.

Selecting the Right Low-Leakage Slip Ring

Choosing the correct low-leakage slip ring for your application involves a nuanced understanding of various factors, from the specific demands of your application to the operational environment of the slip ring. Given the investment and the critical role these components play in ensuring the precision and reliability of equipment, a careful selection process is imperative. Below are key considerations and questions to guide you in selecting a slip ring that aligns with your requirements.

Factors to Consider

Application Requirements: The nature and specifics of your application are paramount. Consider the level of electrical noise tolerable, the signal types being transmitted (digital, analog, high-frequency, data), and the criticality of signal integrity. For applications in medical imaging or satellite communication, for example, the demands on signal quality and consistency are significantly higher than in less sensitive applications.

Operating Environment: Environmental factors such as temperature, humidity, exposure to corrosive substances, and potential mechanical stresses (vibration, shock) need careful consideration. A slip ring designed for a controlled indoor environment may not perform well in an outdoor setting subject to weather variations and pollutants.

Operational Parameters: Evaluate the required operational speed, rotational freedom (continuous vs. limited rotation), and lifecycle of the slip ring. The electrical current and voltage ratings of the slip ring should align with those of your system to avoid overloading and potential failure.

Size and Integration: The physical space available for the slip ring within your equipment and its compatibility with existing components will influence your choice. A compact, modular design may be advantageous in space-constrained applications.

Questions for Suppliers or Manufacturers

To ensure that the selected slip ring meets your application demands, consider asking suppliers or manufacturers the following questions:

- Customization Capabilities: Can the slip ring be customized to meet specific application requirements? If so, what is the process, and how does it impact lead times and costs?

- Material and Design Justification: What materials are used in the construction of the slip ring, and what design features facilitate its low-leakage performance? How do these choices affect the slip ring’s durability and longevity?

- Performance Validation: What testing protocols do you use to verify the slip ring’s performance, particularly regarding signal integrity and leakage rates? Are there any independent certifications or test results available?

- Environmental Resistance: How does the slip ring perform under various environmental stresses? Can you provide data or case studies on its operation in conditions similar to those it will encounter in its intended application?

- Maintenance and Support: What is the expected maintenance schedule for the slip ring? In the event of a failure, what support services do you offer, and what is the typical turnaround time for repairs or replacements?

- Cost-Benefit Analysis: Lastly, ask for a detailed cost-benefit analysis comparing the selected slip ring with other options. This analysis should include not only the purchase price but also the costs associated with maintenance, potential downtime, and the expected operational lifespan.

By meticulously considering these factors and posing informed questions to your slip ring supplier or manufacturer, you can be more confident in selecting a low-leakage slip ring that meets the specific demands of your application, ensuring optimal performance and reliability.

Maintenance and Care for Low-Leakage Slip Rings

Proper maintenance and care of low-leakage slip rings are vital for ensuring their longevity and reliability, especially given their application in critical and precision-demanding environments. A well-maintained slip ring can significantly reduce downtime and maintenance costs over its operational life. Here are guidelines, common maintenance practices, and troubleshooting tips to keep these sophisticated components performing at their best.

Guidelines for Maintenance

Regular Inspection Schedule: Establish a routine inspection schedule to check for signs of wear, corrosion, or damage to the slip rings and brushes. Frequency should be determined based on the operational intensity and the environment in which the slip ring is used.

Cleanliness: Keep slip rings clean from dust, debris, and other contaminants that can interfere with operation. Use a soft, dry cloth for cleaning; certain manufacturers may recommend specific cleaning agents.

Electrical Testing: Periodically perform electrical tests to monitor the insulation resistance and continuity. Such testing can help identify potential issues before they lead to failure.

Lubrication: If the manufacturer recommends lubrication, ensure that an appropriate non-conductive lubricant is used. Over-lubrication should be avoided as it can attract dust and lead to the accumulation of debris.

Environment Control: In harsh environments, consider additional protective measures, such as enclosures, to shield the slip ring from corrosive substances, extreme temperatures, or excessive humidity.

Common Maintenance Practices

Brush Inspection and Replacement: The brushes that maintain contact with the slip ring’s surface are critical to its operation. Check for even wear and replace brushes according to the manufacturer’s guidelines or if any irregularities are detected.

Surface Care: The condition of the slip ring’s contact surface is crucial. Look for signs of uneven wear, pitting, or scorch marks. Lightly polishing the contact surface can sometimes restore performance but consult the manufacturer before performing any surface modifications.

Connection Checks: Verify that all connection points and wiring are secure and intact. Loose connections can cause intermittent electrical performance and signal loss.

Troubleshooting Tips for Common Issues

Intermittent Signals: If experiencing intermittent signal or power transmission, check for loose connections, worn brushes, or contaminants on the slip ring surface. These are common culprits that can disrupt the continuity.

Noise in Signal Transmission: Electrical noise can often be traced back to dirty or damaged slip ring surfaces, or worn brushes. Cleaning the slip rings and replacing the brushes can mitigate this issue.

Rapid Wear: If components seem to be wearing out faster than expected, ensure that the system is operating within the specified parameters. Overloading the slip ring with excessive speed or electrical load can lead to premature wear. Additionally, verify that the correct type of brush is being used, as mismatched materials can increase wear rates.

Overheating: Overheating can result from overloading, excessive speed, or insufficient cooling. Ensure the operational parameters do not exceed the slip ring’s specifications and check for adequate ventilation around the component.

Maintaining low-leakage slip rings requires a proactive approach, centered on regular inspections, adherence to cleaning and care protocols, and prompt attention to any signs of trouble. By following these guidelines and practices, you can enhance the performance and extend the operational life of your slip rings, ensuring they continue to meet the demanding requirements of your applications.

Future Trends in Low-Leakage Slip Ring Technology

Advancements in low-leakage slip ring technology are poised to open up new possibilities in various sectors, pushing the envelope in terms of performance, durability, and applications. As manufacturers and researchers delve deeper into materials science and electronic design, the goal is to reduce leakage current to even lower levels, enhance signal integrity, and create slip rings that are more resistant to environmental challenges.

Ongoing Developments Aimed at Reducing Leakage

Nanomaterials and Advanced Composites: One promising area of development involves incorporating nanomaterials and advanced composite materials, which offer superior electrical characteristics. These materials can provide better wear resistance and lower electrical noise, leading to more reliable performance over extended periods.

Surface Engineering: Surface treatments and coatings are being investigated to reduce contact resistance and minimize noise during operation. These techniques can also improve the lifespan and reliability of slip rings in harsh environments.

Miniaturization: There is a significant push towards the miniaturization of slip ring components, which can not only save space but also reduce leakage by bringing the electrical contacts closer together and reducing the pathway for leakage currents.

Integrated Sensors: Integrating sensors directly into the slip ring can provide real-time monitoring of performance metrics such as contact resistance, temperature, and rotational speed. This data can be used to predict maintenance needs and prevent failures before they occur.

Wireless Power Transfer: Advancements in wireless power and data transfer technologies may lead to hybrid systems that combine traditional slip ring mechanisms with wireless modules to reduce points of contact and, thus, potential leakage pathways.

Emerging Applications for Low-Leakage Slip Rings

Quantum Computing: Quantum computers, which require incredibly precise and noise-free electrical connections, could benefit from low-leakage slip ring technology. These devices may play a crucial role in providing stable and reliable connections within cryogenic environments where quantum processors operate.

Telemedicine Robotics: As telemedicine advances, particularly with robotics performing remote surgeries, low-leakage slip rings could ensure the highly precise control signals required for these procedures are transmitted without interference, crucial for patient safety and procedural accuracy.

Space Exploration Systems: With an increasing focus on long-duration space missions, low-leakage slip rings can be an asset for satellite systems, rovers, and habitat modules where signal fidelity can quite literally make or break a mission.

Electric Vehicle (EV) Infrastructure: The rise of EVs and the associated charging infrastructure may benefit from advancements in low-leakage slip ring technology, particularly in rotating connectors for charging stations or power transfer in electric drivetrains.

Renewable Energy Systems: In wind turbines and other renewable energy generators, where maintaining efficiency is key to optimizing energy production, low-leakage slip rings can provide reliable transmission of power and data from the moving parts of the generator.

The horizon for low-leakage slip ring technology is vibrant and expansive. Innovations aimed at reducing leakage further are critical in this era of miniaturization and precision, where even the slightest electrical noise can be detrimental. The emerging applications for these components span from the micro in medical robotics to the macro in space technology, marking low-leakage slip rings as foundational elements in shaping the future landscape of high-tech applications.

Conclusion

Understanding low-leakage slip rings is crucial when dealing with sensitive applications. Knowledgeable selection, maintenance, and a watchful eye on future technology trends enable users to reap the most out of these devices, securing dependable performance and significant operational benefits.

FAQs about Low-Leakage Slip Rings

Q: How often should I perform maintenance on a low-leakage slip ring?

A: While it varies per model, typically, an inspection is recommended approximately once a year.

Q: Is the higher cost of low-leakage slip rings justified?

A: Yes, especially for applications that require superior performance and reliability. The cost is justified as a protective measure against system failures.

Q: Can low-leakage slip rings be custom-designed for my specific application?

A: Yes, many manufacturers offer customized solutions to meet the specific requirements of various applications.

Q: Will low-leakage slip rings remain relevant with future tech changes?

A: Yes. In fact, with the rise of EVs, medical robots, and other technologies, the applicability of low-leakage slip rings is expected to increase.

Q: What exactly does ‘low-leakage’ mean in the context of slip rings?

A: In slip rings, ‘low-leakage’ refers to minimizing unwanted electrical current that can pass from one circuit within the slip ring to another, which is not part of the intended electrical path. This leakage can cause signal interference and degrade performance, particularly in sensitive applications.

Q: Aren’t all slip rings low-leakage by design?

A: While all slip rings aim to minimize leakage, “low-leakage” slip rings are specifically designed to have extremely low levels of electrical noise and are used in applications where even minute leakage currents can have significant consequences, such as in medical imaging or precision robotics.

Q: Can you retrofit a standard slip ring to make it ‘low-leakage’?

A: Retrofitting a standard slip ring to achieve low-leakage performance can be challenging. It typically requires changes to the design, materials, and construction that are not feasible after manufacture. It’s usually more cost-effective to purchase a slip ring designed for low leakage from the outset.

Q: How can I test for leakage in a slip ring?

A: To test for leakage, you’ll need a multimeter capable of measuring the intended voltage range of the slip ring. Disconnect all power sources and measure the resistance between circuits within the slip ring. A low-resistance reading indicates potential leakage paths. For accurate results and safety, refer to the specifications provided by the slip ring manufacturer.

Q: What maintenance steps can I take to prevent increased leakage over time?

A: Regular maintenance should include cleaning the slip ring contacts and brushes, ensuring they are free from debris and contaminants, and checking for wear and proper alignment. Follow the manufacturer’s guidelines for any additional maintenance specific to your low-leakage slip ring model.

Q: How often should I replace the brushes or contacts to maintain low-leakage performance?

A: There’s no one-size-fits-all answer to this question since it depends on the slip ring’s material composition, the operational environment, and usage frequency. Monitor the performance and inspect these components regularly. Replace them according to the manufacturer’s suggested timeframe, or earlier if any irregularities are observed during inspection.

Q: Is there a need for specialty lubrication for low-leakage slip rings?

A: Yes, some manufacturers recommend using specialty lubricants that are non-conductive and specifically formulated to avoid increasing the contact resistance or attracting contaminants. Always use the type and amount of lubricant recommended by the slip ring manufacturer to maintain optimal performance.

Q: Does the size of a slip ring affect its leakage rate?

A: The size itself isn’t directly related to leakage, but smaller slip rings often require more precision in their manufacturing to ensure that any leakage is minimized. The tolerance for error is less in a smaller package, so high-quality engineering and materials are essential.

See What We Can Do