This article delves into the critical role slip rings play in the functionality and safety of amusement rides. By exploring their importance, types, user concerns, and future trends, we illuminate how this technology enhances ride experiences.

Introduction to Slip Ring Application in Amusement Rides

In the enchanting world of amusement parks, where thrill and innovation intertwine, an often-overlooked component plays a pivotal role in delivering the joy and excitement that visitors seek: the slip ring. At its core, a slip ring is an electromechanical device designed to transmit electrical power and signals from a stationary structure to a rotating one. This fundamental function is critical in applications where rotation is inherent and continuous, uninterrupted power flow is essential. Essentially, slip rings create a bridge that allows electrical circuits to rotate freely, facilitating the transmission of current and data crucial for operation and control systems without limiting movement.

Within the amusement industry, the application of slip rings extends beyond mere functionality. They embody the nexus between operational efficiency and safety, two paramount concerns for any amusement ride designer or operator. On rides that captivate the imagination through motion—be it the vertical spins of a Ferris wheel or the complex rotations of a modern thrill ride—slip rings ensure that power and signals are consistently delivered to the moving parts of the ride. This uninterrupted power supply is vital not only for the ride’s performance but also for the sophisticated control systems that monitor speed, balance, and safety mechanisms.

The role of slip rings in rides is akin to the role of nerves in the human body: just as nerves relay signals that enable movement and perception, slip rings convey the electrical signals that control and power rides, making them move and respond as designed. Through their function, slip rings contribute significantly to the smooth operation of rides, reducing the risk of downtime and ensuring that safety systems are always active and responsive. In essence, they are the unsung heroes of the amusement park, ensuring that the thrill of motion and the joy of an uninterrupted experience are always within reach for every visitor.

As the amusement industry continues to evolve, pushing the boundaries of speed, rotation, and design, the demand for reliable, high-performing slip rings has never been greater. Their contribution to the operational efficiency and safety of amusement rides makes them indispensable components of the modern amusement park experience, empowering designers to realize their most ambitious visions and ensuring that thrill-seekers can safely enjoy the fruits of this creativity. In this light, the importance of slip rings extends beyond their technical function, becoming central to the very essence of what makes amusement rides thrilling, safe, and memorable.

Importance of Slip Rings in Amusement Rides

When fear and anticipation rise as amusement rides soar, spin, and flip, one critical aspect remains constant—the safety of riders. In this intricate plane where fun meets technology, slip rings play an essential role in protecting riders against unforeseen mishaps. By ensuring a reliable flow of power and signal transmission from a stationary structure to rotating parts, slip rings provide the lifeblood to rides’ control systems. These systems control every aspect of ride operation, from speed control to the activation of safety mechanisms. The safety nets, barriers, locking mechanisms, and other intricacies of amusement ride safety rely heavily on power and signal stability that is assured by efficient slip rings. An interruption or inconsistency in this flow potentially compromises these systems, posing risks to riders. Thus, slip rings indirectly but significantly contribute to maintaining the uncompromised safety of amusement rides.

When talking about reliability, slip rings stand as silent yet crucial pillars in the bustling dynamic of amusement parks. Amusement rides need to operate smoothly and consistently, sometimes running for several hours a day without compromising performance. This endurance demands a constant and reliable supply of power and data to rotating components. Slip rings achieve just that, facilitating efficient electrical contact between static and rotating parts while mitigating possible wear and tear caused by friction. They sustain ride functionality, reduce the risk of downtime, and ensure ride longevity, contributing to a seamless and fun-filled experience for park visitors.

Amusement park rides are theatres of technological marvel and innovation, pushing the boundaries of engineering and design. These creations, ever-evolving in complexity and thrill, owe much to the unnoticed contribution of slip rings. Complex rides, with spinning cabins, rotating arms, and oscillating platforms, critically depend on unrestricted rotational movement aided by power and signal flow. By providing this unrestricted transfer of electricity from stationary to rotating parts, slip rings empower designers to experiment with dynamic designs. They allow platforms to rotate uninhibitedly while receiving the necessary power and data, opening up a world of possibilities for ride design. In essence, the discreet presence of slip rings is empowering the next wave of innovative ride experiences, supporting designers in pushing the envelope of amusement technology.

Altogether, the safety, reliability, and innovation offered by slip rings illustrate the intrinsic connection between amusement ride enjoyment and the technical functionalities of these devices. Through their often-overlooked role, slip rings ensure that amusement parks continue to provide thrilling, safe, and unforgettable experiences to their visitors.

Types of Slip Rings Used in Amusement Rides

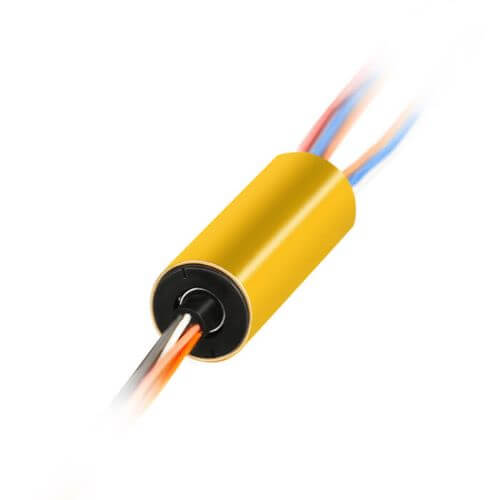

Capsule Slip Rings

Compact and efficient, capsule slip rings are the perfect fit for amusement rides where space is at a premium but the need for reliable power and signal transmission remains high. Encapsulated in a small, cylindrical form, these slip rings offer versatility without compromising performance. Due to their compact nature, they are typically used in smaller amusement rides or parts of rides with limited installation space, such as control panels, light fixtures, and miniature rotating displays. Their design allows for a smooth integration without altering the ride’s aesthetics or functionality, making them an indispensable part of the amusement ride machinery that demands subtlety and efficiency in equal measures.

Through-bore Slip Rings

The engineering marvel of through-bore slip rings lies in their hollow-shaft design, which allows them to be integrated around pre-existing mechanical structures—a feature especially beneficial for larger amusement rides. This unique structure enables them to carry a variety of signals and power loads while accommodating other components, such as hydraulics or pneumatics, through their central void. You’ll find through-bore slip rings at the heart of towering Ferris wheels, sophisticated rotational rides, and complex mechanical structures where their ability to manage high-power transmission and facilitate intricate rotations is paramount. They are the backbone of large-scale rides, ensuring that even the most daunting mechanical giants operate smoothly and reliably.

Pancake Slip Rings

When the challenge is not just the availability of space but the specific requirement of a low profile, pancake slip rings come into play. Characterized by their flat, disc-like design, these slip rings offer a solution where axial length (the length along the rotation axis) is limited, but there is sufficient radial space (space along the radius). Their design makes them suitable for applications in amusement rides where equipment needs to be fitted in areas with restricted height, such as turntables and stage equipment used in performances or rotating platforms that demand a sleek integration without impacting the ride’s design integrity. Despite their slim profile, pancake slip rings do not compromise on power and signal transmission capabilities, making them an elegant solution for specific engineering challenges in amusement park rides.

Mercury Slip Rings

Mercury slip rings represent a specialized category used in scenarios where exceptionally low electrical resistance and high performance are required. Containing liquid mercury as a conductive medium, they can transfer current and signals with minimal loss, making them highly efficient. However, due to mercury being a hazardous substance, its use comes with stringent safety measures and is usually limited to very specific applications within amusement rides where no other slip ring can meet the required performance levels. The use of mercury slip rings is accompanied by comprehensive containment, monitoring, and emergency procedures to mitigate the risks associated with mercury exposure. Despite these challenges, in applications where their performance benefits outweigh the safety concerns—such as in highly sophisticated simulation rides or high-speed rotating platforms—mercury slip rings play a crucial role, ensuring unparalleled efficiency and reliability.

In summary, the selection of slip rings in amusement rides is dictated by a variety of factors including size constraints, power and data transmission requirements, and specific operational needs. From the compact capsule slip rings to the versatile through-bore models, and the low-profile pancake variations to the highly efficient but cautiously used mercury slip rings, each type plays a vital role in ensuring rides operate seamlessly, safely, and delightfully thrilling.

Key Concerns of Users Regarding Slip Rings in Amusement Rides

Safety is paramount for users when it comes to equipment within amusement rides, and rightly so, given the potential risks involved. Slip rings, being critical to the operation of rides, are subject to rigorous testing standards and regular maintenance schedules to prevent failures that could lead to accidents. Users are often concerned about the reliability of these components under dynamic ride conditions. To address these concerns, slip rings undergo a series of tests that simulate extreme operating conditions, including rotational speed, electrical load, and environmental factors. Furthermore, the health of slip rings is monitored continually with diagnostic tools that can detect early signs of wear or electrical anomalies. Regular maintenance, including cleaning and inspection, ensures that the slip rings meet safety standards and certifications, instilling confidence in their continued safe operation.

Durability and Maintenance

For operators and maintenance teams, the durability of slip rings is a focal point since replacement and repair can be costly and time-consuming, leading to ride downtime. Users require slip rings that not only last but are also easy to service. The wear and tear of slip rings, being a natural consequence of their function, present concerns regarding longevity. Therefore, they are designed with robust materials and coatings that can withstand wear from repeated use. To further allay these concerns, manufacturers often provide explicit maintenance guidelines and training for operators. This ensures that the slip rings are kept in optimal condition throughout their service life, maintaining their functionality and reducing the frequency of necessary replacements.

Weather Resistance

Amusement rides, often exposed to the elements, necessitate slip rings that can stand up to a variety of weather conditions, including rain, snow, and extreme temperatures. Users are concerned with how these elements can affect the performance and lifespan of slip rings. As a result, weather-resistant slip rings, built with materials and seals capable of preventing moisture penetration and resisting temperature extremes, are crucial. Such slip rings are also treated to resist corrosion and UV damage, securing their reliability for outdoor rides. Users prioritize these weatherproof slip rings to minimize the likelihood of weather-related failures and to ensure the continuous operation of rides in varying climatic conditions.

Technological Advances

In response to common concerns related to wear and tear, and the broader need for improved safety and efficiency, technological advancements in slip ring design are continually being made. For instance, the development of contact materials with better wear properties, the integration of fiber brush technology for signal transmission, and the implementation of modular designs for easy replacement of worn components are all innovations aimed at enhancing slip ring performance. Users look for these advancements as they often translate to lower maintenance needs, longer intervals between servicing, and ultimately, a more reliable and safer amusement ride experience. On top of that, the advent of contactless slip rings, which use magnetic fields or inductive coupling to transmit power and data without physical contact, addresses many traditional concerns head-on by decreasing mechanical wear altogether.

In the context of amusement rides, where user experience is directly impacted by behind-the-scenes technology, user concerns over slip rings encompass safety, durability, weather resistance, and technological progression. Addressing these concerns is fundamental for ride manufacturers and operators to sustain trust and ensure the uninterrupted delight of riders.

Slip Ring Application in Amusement Rides: Case Studies/Examples

Effective Utilization of Slip Rings in Amusement Rides

One of the most intriguing applications of slip rings is seen in the renowned Ferris wheels found around the globe, such as the London Eye in the United Kingdom. The London Eye, a massive, slowly rotating observation wheel, provides an uninterrupted power supply to each of its passenger capsules through the use of slip rings. These slip rings ensure that lighting, air conditioning, and the audio-visual systems within the capsules continue to operate smoothly throughout the rotation. The key benefit here is the seamless power and signal transmission that enhances passenger comfort and experience, making the ride a memorable one.

Another notable example is the extensive use of slip rings in modern roller coasters, which incorporate complex lighting and onboard audio systems. The TRON Lightcycle Power Run at Shanghai Disneyland is a prime example where slip rings are utilized to power dynamic lighting effects on the train itself, contributing to the futuristic theming and enhancing the overall immersive experience of the ride. Here, slip rings play a crucial role in maintaining the visual and auditory effects that are synchronized with the ride’s movements, showcasing their capability to support the integration of advanced technological features in high-speed amusement rides.

Incidents Involving Slip Ring Failures and Resolutions

While incidents directly attributable to slip ring failures in amusement rides are not commonly reported in the public domain, there have been occurrences where electrical failures in rides have led to operational issues, indirectly highlighting the importance of slip ring integrity. For instance, in certain cases, rides have been temporarily shut down due to unexpected power losses or malfunctions in the rotation mechanisms, scenarios where slip ring failures could be a potential cause.

In addressing these incidents, comprehensive diagnostics are performed to identify the failure points, which include examining the slip rings for wear and tear, electrical continuity issues, or debris accumulation that might hinder their function. Upon identifying the issue, corrective measures often involve the replacement of worn parts, thorough cleaning of the slip ring assemblies, and upgrading to more robust slip ring models designed to withstand the specific stresses of the application more effectively.

Post-incident, ride operators typically implement more stringent maintenance routines, including regular inspections and preemptive replacement strategies to minimize the risk of future failures. Additionally, there’s been a move towards adopting slip ring technologies with advanced monitoring capabilities, allowing for real-time health assessment of the slip rings. This proactive approach ensures that potential issues can be addressed before they lead to operational disruptions, enhancing both the safety and reliability of amusement rides.

These real-world applications and incident responses underscore the critical role that slip rings play in the operation of amusement rides. They not only enable the incorporation of advanced technological features that elevate the user experience but also require careful attention to ensure their reliability and safety. Through continuous innovation and adherence to stringent maintenance protocols, slip rings continue to support the magical experiences found in amusement parks worldwide.

Future Trends in Slip Ring Technology for Amusement Rides

Smart Slip Rings

The evolution of slip ring technology is increasingly intertwined with the advancements in the Internet of Things (IoT) and sensor technology, heralding the era of “Smart Slip Rings”. These next-generation slip rings are equipped with embedded sensors capable of gathering and transmitting real-time data regarding their operational status and environmental conditions. This innovation is particularly transformative for amusement rides, where operational reliability and safety are paramount.

The practical application of smart slip rings in amusement rides involves the use of predictive maintenance strategies. By continuously monitoring parameters such as temperature, vibration, and wear, operators can anticipate potential failures before they occur, scheduling maintenance activities during off-peak hours to prevent unscheduled downtimes and enhance ride safety. For example, a smart slip ring equipped with vibration sensors can detect unusual patterns indicative of wear or misalignment, prompting preemptive interventions.

This proactive approach not only extends the lifespan of the slip rings but also contributes significantly to the overall reliability of amusement rides. As rides become more complex and the demands for high uptime increase, the adoption of smart slip rings could become a standard, ensuring that every spin, twist, and turn is delivered with consistent performance and safety.

Material Advances

In the relentless pursuit of excellence, the development of slip rings is also benefiting from significant material advances. Engineers are exploring the utilization of new materials and coatings to improve the performance and longevity of slip rings, especially in the harsh environments often found in amusement parks, where dust, moisture, and wide temperature variations are common.

One area of focus is the use of composite materials and advanced alloys that offer superior wear resistance and reduced friction. These materials are designed to withstand the electrical and mechanical stresses encountered by slip rings in high-speed rides, thereby reducing maintenance needs and enhancing durability. Additionally, surface treatments and coatings that can repel water and resist corrosion are being developed, making slip rings more resilient in outdoor or maritime environments.

The exploration of graphene-based materials presents another promising frontier. Graphene, known for its excellent conductivity, mechanical strength, and thermal properties, could revolutionize slip ring technology by offering unparalleled performance in terms of efficiency and durability. Amusement rides equipped with slip rings utilizing these advanced materials would benefit from reduced power loss, lower operating temperatures, and extended service intervals, contributing to a more sustainable, cost-effective operation.

As material science progresses, the future of slip ring technology in amusement rides looks promising. The exploration of new materials and the incorporation of smart technologies are set to vastly improve the efficiency, safety, and reliability of these critical components. These advancements not only promise to enhance the experience of amusement ride enthusiasts but also underscore the commitment of the industry to innovate and adopt technologies that support sustainable and safe entertainment options.

Conclusion

Slip rings play a pivotal role in the safe and efficient operation of amusement rides. By addressing user concerns and embracing technological advancements, the future of slip ring technology promises even greater reliability and innovation in ride design, contributing to memorable and thrilling amusement experiences.

FAQs about Slip Ring Application in Amusement Rides

Q: How often do slip rings need maintenance on amusement rides?

A: The maintenance schedule can vary based on the ride’s design and operational frequency, but regular inspections are crucial for optimal performance.

Q: Are there any slip ring alternatives for amusement rides?

A: While alternatives exist, slip rings are preferred for their reliability and ability to transmit power and data efficiently across rotating interfaces.

Q: Can slip rings affect the speed of an amusement ride?

A: Slip rings do not directly affect the speed but ensure the smooth operation of the ride’s control systems, indirectly influencing the ride experience.

Q: What is a slip ring and why is it crucial for amusement rides?

A: A slip ring is an electromechanical device that allows for the transmission of power and electrical signals from a stationary part to a rotating part. In the context of amusement rides, slip rings are crucial because they enable consistent power supply and data transfer for elements that rotate or move, such as Ferris wheels or carousel rides. This ensures that lighting, audio systems, and safety mechanisms on the ride can operate smoothly without interruption caused by movement.

Q: How do slip rings enhance the safety of amusement rides?

A: Slip rings contribute to the safety of amusement rides in several ways. By providing a reliable electrical connection, they ensure that safety systems, such as emergency lighting and communication devices, remain operational regardless of the ride’s motion. Furthermore, the integration of smart slip rings, equipped with sensors, allows for real-time monitoring and predictive maintenance, identifying potential issues before they lead to failures. This proactive approach significantly reduces the risk of accidents and enhances the overall safety and reliability of amusement rides.

Q: What maintenance do slip rings in amusement rides require?

A: Maintenance for slip rings in amusement rides involves regular cleaning, inspection for wear and tear, and testing for electrical continuity. Depending on the type of slip ring and the environmental conditions, lubrication may also be necessary to ensure smooth operation. Advanced slip rings with built-in sensors can simplify maintenance routines by providing alerts on the condition and performance, thereby enabling targeted maintenance actions. Strict adherence to the recommended maintenance schedule by the manufacturer is crucial to prolong the life of slip rings and ensure the uninterrupted operation of the ride.

Q: Are there any weather-related concerns for slip rings used in outdoor amusement rides?

A: Yes, slip rings used in outdoor amusement rides must be designed to withstand various weather conditions, including rain, humidity, extreme temperatures, and UV exposure. This is achieved through the use of weather-resistant materials and protective coatings that shield the slip ring from moisture and corrosion. Additionally, the design may include sealing mechanisms to prevent the ingress of water and dust. These measures ensure the reliable function of slip rings in outdoor environments, maintaining the safety and enjoyment of the ride.

Q: How is slip ring technology evolving to meet the demands of modern amusement rides?

A: Slip ring technology is rapidly evolving to meet the sophisticated demands of modern amusement rides. Innovations include the development of smart slip rings with IoT capabilities for predictive maintenance, the use of advanced materials for improved durability and performance, and the design of modular slip rings for easy serviceability. Additionally, there is a trend toward developing slip rings with higher power capacity and more compact sizes to accommodate rides with complex electronics and limited space. These advancements aim to enhance the safety, efficiency, and entertainment value of amusement rides, ensuring they continue to captivate and thrill visitors.

See What We Can Do