Welcome to our comprehensive guide on slip ring’s influence in the domain of industrial automation. From their definition and benefits to contemporary applications, this article will delve into the nuances of slip ring usage within automated systems, addressing vital questions for industrialists, engineers, and automation enthusiasts.

Introduction to Slip Ring Application in Industrial Automation

At the intersection of motion and electrical connectivity lies the humble yet indispensable device known as the slip ring. Industrial automation, with its relentless pursuit of efficiency, relies on various mechanical and electrical components to translate raw power and data into canny productivity. Among these components, the slip ring stands out for its simple yet profound function.

What Is a Slip Ring?

A slip ring is an electromechanical device that enables the transmission of power and electrical signals across a rotating interface. Picture a merry-go-round with ornate carriages of electrical functions, interconnected yet in constant motion – this is where the slip ring shines. Comprising stationary brushes and a rotating ring, it ensures a seamless and continuous connection, even as machinery parts spin and twirl in their industrial ballet.

Introducing Industrial Automation

Industrial automation is the synergistic orchestration of machinery and technology to execute tasks with minimal human intervention. In this era of smart manufacturing and production, automation not only speeds up processes but also scales precision and productivity to new heights. Within this framework, machinery forms an intricate network of choreographed movements and tasks, all aimed at a more efficient and less error-prone production line.

The Role of Slip Rings in Automation

Within the complex systems of industrial automation, slip rings serve a pivotal function. They are the vital linkages that reconcile the demand for constant electrical flow with the inexorable need for movement; they make it possible for a robotic arm to weld car frames while receiving uninterrupted power. In tasks where a rotary motion is essential—like bottle filling in a rotary machine, or the pan-and-tilt operations of a security camera—slip rings provide a dynamic solution for power and data transfer.

The coherence of an automated system is contingent on the reliable function of all its parts. Slip rings facilitate the coexistence of two contrasting states: the static and the dynamic, enabling machines to operate with an eloquence that borders on the poetic. It is within this nexus of ceaseless energy and data transfer that slip rings play their silent, essential role in the grand performance of industrial automation.

Importance of Slip Ring Application in Industrial Automation

In the microcosm of industrial automation, two qualities reign supreme – consistency and reliability. Here, machines must interact in a meticulously calculated dance, where every move is critical, and any pause can ripple into costly downtime. As the invisible maestros enabling this ballet of machines, slip rings deserve special recognition.

Significance of Continuous Power and Data Transmission

In an automated industrial system, continuous power and data transmission form the heartbeat of the operation. As machines relentlessly perform their tasks around the clock, they necessitate an uninterrupted supply of both power and data. Power allows the mechanical components to execute their movements, while data acts as the essential blueprint instructing each part of the system in what they must do and when they must do it.

Every stoppage, every loss of connection, signifies an interruption to the task, leading to inefficiencies, product wastage, or, worse, safety risks. Therefore, the significance of seamless and uninterrupted transmission for both power and data is paramount in maintaining the flow, lessening the scope for errors, and ensuring consistent productivity at par with industry standards.

Advantages of Using Slip Rings in Uninterrupted Rotary Motion

This is where the brilliance of a slip ring comes to the fore, harmonizing the demands of continuous transmission and rotary motion. In areas where a rotary interface is in play, be it a rotating table, carousel, wind turbine, or a pivotal robotic arm, slip rings perform their magic.

By ensuring an uninterrupted connection, slip rings handily overcome the limitations imposed by traditional cables which can tangle, fray, or wear out. They provide a compromise-free solution that allows rotating parts to move freely while maintaining a steady flow of power and data signals. This functionality enhances the system’s overall longevity and performance, contributing to the precision, speed, and efficiency that are the hallmarks of industrial automation.

In the grand scheme of industrial automation, the slip ring, therefore, emerges as more than a component; it is the lynchpin that marries motion with connectivity, holding the system together, and propelling it forward.

Types of Slip Rings Used in Industrial Automation

Navigating through the modular world of industrial machinery, one will encounter various embodiments of slip rings. Each type bears specific characteristics designed to fulfill the inherent needs of different automation tasks. Knowing the unique properties and applications of these slip rings equips designers and engineers with the power to tailor solutions that align precisely with the demands of their projects.

Common Types of Slip Rings

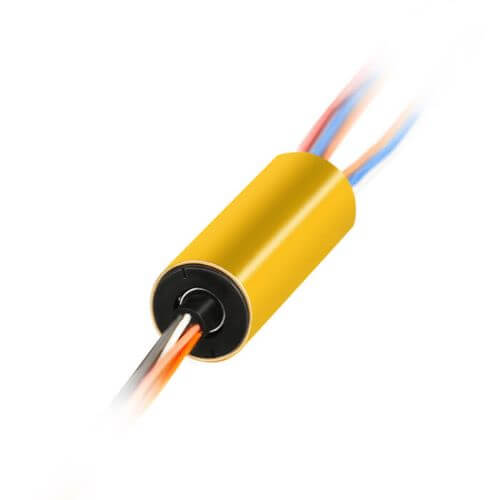

- Capsule Slip Rings: As compact powerhouses, these are crafted to fit into the most space-conservative applications. Resembling a capsule in shape, they are ideal for small-scale, precise tasks such as CCTV systems or rotary tables, where size constraints are significant, but functionality cannot be compromised.

- Through-Bore Slip Rings: Characterized by a hollow shaft, through-bore slip rings are designed for tasks requiring a central pass-through for shafts or other components. This design is especially useful in machinery like wind turbines and medical equipment, where there needs to be room for not just wires and cables, but also other physical elements to pass through the center unimpeded.

- Pancake Slip Rings: The flat, disc-like structure of pancake slip rings makes them suitable for situations where the length of the slip ring is critical but the height can be traded off. Their form factor serves applications like packaging machinery or cable reels where space along the rotational axis is limited.

- Wireless Slip Rings: This represents a leap into the realm of contactless data transfer, with wireless slip rings utilizing advanced methods such as inductive coupling to transmit power and signals. Such devices are employed in settings where physical contact is untenable due to environmental conditions like extreme temperatures or cleanliness requirements, as in semiconductor manufacturing or certain scientific research apparatuses.

Comparative Analysis in Automation Applications

When examining these slip rings head-to-head, several facets crystallize, defining their suitability for various automation realms. The compact capsule slip rings are the darlings of confined spaces, offering core functionality without spatial imposition. In contrast, the through-bore is the centerpiece of scenarios where the integrity of a central passage is non-negotiable, making it a beacon for integrations that run through the axis of rotation.

With their unique geometry, pancake slip rings sacrifice axial compactness but shine brightly in low-height realms where space along the rotational axis is a rare commodity. And finally, the wireless slip rings—these are the harbingers of a new era where contact is no longer a constraint, serving environments that demand immaculate conditions or where wear and maintenance are significant concerns.

Each type of slip ring holds its ground decisively in the industrial automation landscape, marked for very particular terrains of applications. They are selected not only based on space but also considering the demands for data integrity, power continuity, environmental resilience, and maintenance constraints.

In sum, when engineers craft the nervous system of an automated module, these slip rings are the chosen conduits, each bringing to the fore its distinct flavor, melding into a solution that’s as efficient as it is elegant. It’s the precise understanding and application of these varieties that ensure the automated systems operate with a symphony-like coherence, expected of modern industrial marvels.

Slip Ring Application in Industrial Automation: Key Concerns and Considerations for Users

The conscientious engineer, faced with the challenge of devising a robust and efficient automated system, will spare no effort in contemplating the very best fit for each component. With slip rings playing a pivotal role in these systems, the right choice becomes a matter of vital concern. The users must weigh a multitude of factors, such as reliability, precision, ease of integration, and maintenance, to arrive at a decision that benefits their project.

Reliability and Durability in Harsh Industrial Environments

The industrial landscape is often an unforgiving one, as machines are subjected to harsh environments, including excessive heat, moisture, dust, and vibration. Here, slip rings should be built to withstand these challenges and continue functioning seamlessly, maintaining a constant connection to ensure the flow of power and data.

To that end, users will need to scrutinize a slip ring’s environmental tolerance – its ability to brave extremes in temperature, humidity, and particulate matter without jeopardizing performance. The choice of materials and the quality of construction become essential factors in determining both the durability and resilience of the slip ring, consequently affecting the overall uptime and effectiveness of the automated system.

Precision and Data Integrity

As the backbone of power and signal transmission, a slip ring’s capacity to maintain data integrity and deliver the intended power levels to its destination in the automated process is critical. Any lapses in signal quality or power consistency can lead to errors, delays, and possible safety hazards.

Thus, engineers must consider the rated voltage, current, and signal compatibility to create an optimized system where the slip ring ensures the precision and integrity essential for the automated process. More advanced slip rings with superior material, contact, and design technologies may offer improved performance in demanding data or power transmission applications.

Ease of Integration and Maintenance

The companies driving industrial automation must also consider the ease with which a slip ring can be integrated into their existing systems, weighing factors such as size, configuration, and compatibility. An amenable design that simplifies the task of implementation is much valued, as it saves time and resources.

Maintenance, too, features prominently in user concerns. The more straightforward and less frequent the maintenance process, the more attractive the slip ring is to users. As slip rings contain components such as brushes and rings that may necessitate periodic replacement, engineers should consider wear resistance, self-lubricating properties, and low-contact resistance materials as ways to minimize downtime and extend intervals between maintenance events.

In the end, it is the delicate balance of these factors that guides the user in selecting the appropriate slip ring for their industrial automation project. The right mix of durability, precision, ease of integration, and maintenance preserves the stability of a world where machines operate in symphony, maintaining the harmony that forms the core of efficient industrial automation.

Slip Ring Application in Industrial Automation: Material and Design Innovations

In an age where the minutiae of industrial automation are scrutinized for any sign of inefficiency, materials and design innovations are burgeoning within the realm of slip ring technology. These advancements not only refine performance but also revolutionize how slip rings contribute to the longevity and efficiency of automation systems.

Materials Enhancing Slip Ring Performance

Material science has leaped bounds in recent years, and slip rings have been direct beneficiaries. For instance, the incorporation of advanced composites and precious metals has led to contacts that exhibit lower electrical resistance and higher conductivity, leading to more efficient power transmission with reduced losses.

The development of novel metal alloys and surface treatments has also markedly improved the wear characteristics of slip rings, meaning they can operate for longer periods before maintenance or replacement is necessary. Here, gold-gold contacts have risen in prominence, being celebrated for their exceptional low-resistance and anti-corrosion properties, thus reducing maintenance cycles and ensuring consistent performance.

New plastic compounds have also made their mark, contributing to the insulation and structural components, ensuring that slip rings are not only lighter but are also capable of withstanding high temperatures and chemical exposure without degradation. In tandem, the integration of fiber-reinforced polymers offers exceptional strength-to-weight ratios, vital for dynamic applications where every gram counts.

Engineering Designs Elevating Automation Efficiency

Design innovation is just as crucial as material innovation in the evolution of slip rings. One revolutionary design is the modular slip ring, which allows for easy customization and adaptability to different configurations. This flexibility means slip rings can now be tailored to meet specific industrial automation requirements, reducing turnaround time from design to deployment.

The advancements in computer-aided design (CAD) and finite element analysis (FEA) have enabled engineers to simulate and model slip ring performance under various conditions, leading to optimized designs for improved reliability and efficiency. These tools have facilitated the creation of slip rings with reduced contact wear rates, lower electrical noise, and better signal integrity.

Another novel design approach is the introduction of contactless slip rings, utilizing inductive or capacitive coupling. These designs eliminate the need for physical contact, reducing maintenance and wearing whilst allowing for data and power transmission across rotational interfaces. This is particularly transformative for environments where contaminants can compromise traditional slip ring systems.

Furthermore, the application of hybrid designs that combine power and data transmission within a single unit enhances system integration by reducing the footprint and complexity of the assembly, thereby streamlining automation processes and allowing for higher throughput.

Impact on Longevity and Efficiency

The ramifications of these material and design innovations are profound. With components that last longer and perform more efficiently, the overall cost of ownership of automation systems plummets. Increased durability from these innovations translates to less downtime for maintenance and repairs, emphasizing continuity in critical manufacturing processes.

Efficiency sees a direct boost not just in the energy-saving aspects but also in the enhanced data transmission rates and reliability. These factors are pivotal in robotic systems and other precision-dependent applications where every microsecond of delay or data corruption can lead to tangible financial losses or quality control issues.

In summary, the relentless pursuit of material and design innovations in the slip ring industry is reforging the landscape of industrial automation. By investing in cutting-edge technologies and continually pushing the boundaries of possibility, the creators and users of these systems are solidifying the bedrock upon which the future of industrial automation steadily builds.

Addressing Signal Interference and Data Transmission Challenges

In the intricate dance of automated manufacturing lines, ensuring stable, reliable data transmission between equipment becomes critical. However, factors such as signal interference can introduce chaos into this symphony, clouding the communication channels and causing missteps. Identifying these problems and implementing robust solutions are indispensable in maintaining harmony and retaining the integrity of data transmission.

Common Signal Interference Issues

Signal interference can be a wrench in the works of an otherwise flawlessly functioning automated manufacturing line. Common sources of this disruption come in two forms: external and internal interference.

External interference originates from sources outside the automation system. This often includes electromagnetic interference (EMI) emanating from nearby equipment, cable networks, or high-voltage electrical lines. Radiofrequency interference (RFI), another familiar source, may stem from wireless devices, radio transmitters, and similar technology present in the surroundings.

Internal interference, conversely, arises within the system. One common cause is cross-talk, which occurs when one channel’s signal bleeds into an adjacent channel, distorting the information conveyed. Another potential source is thermal noise, produced by the fluctuating voltage across components due to the inherent thermal movement of charged particles.

The implications of these disruptions can be severe, often detracting from system reliability. They may result in data corruption and slowdowns that harm productivity, or in the worst cases, cause catastrophic system failure.

Ensuring Robust Signal Integrity

To conquer these obstacles, several strategies have come to the fore, each designed to bolster signal integrity and provide relief from the perils of interference.

Comprehensive shielding and grounding is a key preventive measure against EMI and RFI. By encasing delicate signal wires within metallic shields and grounding these shields, we can reflect or safely divert the intruding electromagnetic waves. Similarly, automated machinery can be located judiciously to minimize exposure to external interference sources.

To cope with internal interference, differential signaling can be used to cancel out common-mode noise, including cross-talk and thermal noise. In this scheme, information is transmitted over two complementary channels. Any common disturbance is likely to affect both channels equally, allowing the receiver end to nullify the interference by comparing the two signals.

Yet, another approach is the dedicated use of slip rings designed to counter signal interference. This involves deploying slip rings equipped with noise suppression circuits or those designed from materials with superior EM-resistant properties.

In complex systems where numerous components are interconnected, the use of optical or contactless slip rings becomes particularly valuable. These designs eliminate physical contact, thereby reducing crosstalk, improving signal integrity, and enabling the undisturbed transmission of high-speed data and sensitive signals.

In conclusion, maintaining robust signal integrity in automated manufacturing lines demands a proactive, multi-tiered approach. By identifying potential sources of signal interference and implementing the appropriate preventative and mitigative measures, engineers can ensure that the flow of information, the lifeblood of automation, remains unhindered and precise.

Maintenance and Operational Life of Slip Rings

Within the intricate production lines of industrial automation, the necessity of minimizing downtime and maximizing component lifespan is crucial. As significant links in the communication chain, slip rings demand particular attention for their maintenance and operational life. The processes for maintenance and strategies for life extension can vastly vary depending on their types and designs.

Maintenance Requirements of Different Types of Slip Rings

Slip rings come in many shapes and sizes, each carrying its own set of maintenance needs. At a high level, these requirements can be traced back to the fundamental design principles intrinsic to these models, with each design choice imparting a unique set of maintenance considerations.

Traditional contact-based slip rings, armored with brushes and rotating discs, are known for requiring regular maintenance. This primarily includes routine inspection of contacts for any signs of wear and tear, contamination, or degradation. Additionally, it entails the regular application of specialized lubricants to minimize friction and reduce wear.

On the other hand, contactless slip rings, such as capacitive or inductive types, require significantly less routine maintenance owing to the absence of physical wear and tear. However, these systems necessitate frequent checks for alignment and calibration, ensuring optimal electrical transfers across the air gap.

Fiber optic slip rings, owing to their reliance on advanced optical communication techniques, must be kept clean and free from physical obstructions or damage that could affect light transmission. Additionally, devices like optical transceivers may require periodic calibration to maintain top performance.

Hybrid slip rings, which incorporate different types of interfaces in one housing, lump the maintenance requirements of their segments and therefore require a comprehensive upkeep protocol.

Strategies for Extending the Operational Life of Slip Rings

The extension of slip rings’ operational life hinges on several strategic approaches, aimed at both preventive care and optimal utilization.

Routine inspections and timely maintenance form the cornerstone of these strategies. Regular assessments help to identify any emerging issues and address them proactively, preventing minor issues from escalating into full-blown malfunctions.

The effective use of high-quality lubricants at regular intervals for contact-based slip rings can minimize wear, extend the life of brushes and rings, and reduce electrical noise. Moreover, judicious selection of the electrical contact material, like using precious metals, can offer better resistance to wear and corrosion, reducing the need for constant maintenance.

The adoption of contactless slip rings could be instrumental in extending the overall operational lifespan due to their non-wearing operational characteristics. Despite a commonly higher upfront cost, these rings minimize maintenance and downtime, offering significant long-term benefits.

Implementing proper operational techniques, such as controlling speeds within advised limits, maintaining appropriate ambient temperature, and avoiding overloading, can go a long way in preserving the integrity of the rings.

Furthermore, operators should consistently abide by manufacturer guidelines regarding proper installation, operation, and maintenance procedures, as these instructions are tailored specifically to extend the life of the product.

In conclusion, the maintenance requirements and strategic considerations for extending the operational life of slip rings are inherently tied to their specific designs and use cases. Yet, no matter the style of the slip ring deployed, diligent upkeep and conscientious adherence to operational guidelines will always help boost efficiency and longevity in any automation setting.

Slip Ring Application in Industrial Automation: Cost Considerations in Selecting Slip Rings

In the tableau of industrial automation, slip rings play a pivotal role in ensuring seamless connectivity between stationary and rotating parts of a system. Given their importance, making cost-effective selections for slip ring technologies that align with operational needs is a critical process. This process demands detailed analysis, balancing the short-term and long-term financial implications associated with different slip ring technologies.

Cost Implications of Various Slip Ring Technologies

When it comes to selecting slip rings, the field is rich and diverse. The cost of these systems can vary significantly based on their design, construction, and material characteristics.

Traditional contact-based slip rings, typically constructed with metal or graphite brushes and metallic rings, tend to be relatively low-cost upfront owing to their straightforward design and widespread availability. However, they have a greater maintenance cost over time due to wear and tear caused by physical contact, resulting in relatively short lifecycles and possible downtime for repairs.

In contrast, contactless slip rings, such as capacitive or inductive types, usually have a higher initial cost. The sophistication of their design and implementation, along with the specialized components necessary to facilitate non-contact operation, account for this cost. However, with no physical wear and tear, these rings offer substantial savings in maintenance costs over their operational life.

Fiber optic slip rings, designed for high-speed data transfer, may carry a hefty price tag due to the advanced optical components employed. However, their ability to transmit vast amounts of data across rotating interfaces without interference or degradation can often justify the cost.

The cost of hybrid slip rings typically lies on the higher end of the spectrum, considering their multifaceted functionality. Combining power, signal, and at times, high-speed data transmission into a single unit, their high initial cost should be assessed against their multi-functional value and potential cost savings at the system integration level.

Balancing Upfront Costs and Long-term Benefits

The true cost of a slip ring isn’t ultimately determined by its initial price tag alone. Instead, financial considerations should factor in long-term operational costs, performance reliability, and potential downtime implications, creating a more comprehensive total cost of ownership (TCO) over the slip ring’s lifespan.

A low-cost option with high maintenance requirements or frequent replacements due to limited lifespan may end up costing more in the long run. Conversely, a pricier, high-quality slip ring that offers long life, low maintenance, and superior performance can deliver substantial cost savings over time.

The balance between upfront costs and long-term benefits starts with identifying the specific needs of the industrial automation setting. This includes evaluating the extent of rotation, data or power transmission requirements, environmental conditions, and system integration demands.

Understanding these factors can guide the selection towards a slip ring technology that best matches operational necessities and cost-effectiveness over its lifespan. This strategy helps avoid over-spending on unnecessary features or under-spending on a solution that might fail to satisfy the system’s performance requirements.

In conclusion, selecting slip ring technologies in industrial automation represents a pivotal financial decision. This process calls for a comprehensive understanding of not just the initial expenses but also the long-term cost implications. The ultimate goal is to strike a balance that considers both upfront investment and operational costs to maximize return on investment across the ring’s operational life.

The Future of Slip Rings in Automation: Trends and Developments

The rapid march of technology, accompanied by escalating expectations in industrial automation, is invigorating a new generation of slip ring innovations. These innovations are not isolated occurrences but are spurred by converging technological trends poised to transform the role, performance, and capabilities of slip rings in future automation landscapes.

Emerging Trends: IoT Integration and Smart Monitoring Features

Two emerging trends are particularly notable: the integration of Internet of Things (IoT) technologies and the incorporation of smart monitoring features into slip ring designs.

The IoT integration opens up a whole new arena for slip ring functionality. An IoT-connected slip ring can play a role far beyond that of a physical transmission link. It can transform into an intelligent device capable of transmitting diagnostic information, operational status, and predictive maintenance data to a centralized management system. This real-time, inbound data can trigger preemptive actions to mitigate failure, minimize downtime, and enhance overall system performance.

Equally transformative is the advent of smart monitoring features in slip rings. Sensors embedded within slip rings can actively monitor parameters like temperature, rotational speed, vibration, and electrical characteristics. Advancements in sensor technology are permitting the integration of these features without a significant increase in size or cost, yet delivering substantial improvements in performance visibility and preventative maintenance capabilities.

Predicting the Evolution of Slip Rings

As industrial automation continues to demand greater reliability, enhanced performance, and real-time diagnostics, slip rings will need to adapt and evolve to meet these escalating demands.

Future slip rings might increasingly exploit wireless technology for power and data transmission. As wireless technologies mature, contactless models could become more prevalent, offering advantages like maintenance-free operation, zero physical wear, and potentially unlimited lifespan.

The expansion of IoT and data intelligence will likely result in ‘smarter’ slip rings. The integration of AI algorithms could enable these devices to self-diagnose and even self-repair minor issues, reducing their need for human intervention. Moreover, they could potentially analyze usage patterns and predict failures, becoming an integral link in the drive toward predictive maintenance.

The pursuit of miniaturization is another potential pathway for the evolution of slip rings. With the relentless push for downsizing machinery and equipment, slip rings that can deliver the same performance in smaller formats, without compromising on power or data handling capabilities, will be in increasing demand.

In addition, the move towards sustainability is shaping the materials and manufacturing processes for future slip rings. Eco-friendly materials that offer lower environmental impact without denting performance, and energy-efficient manufacturing processes, will play a significant role.

In conclusion, the technological transformations sweeping across the automation sector will fundamentally impact the future of slip rings. Driven by IoT integration, smart monitoring features, and an inexorable push for reliability and sustainability, slip rings of the future will embrace a broader role in the high-tech ecosystem. They will evolve from raw data or power transmission elements to intelligent devices, augmenting the performance, reliability, and efficiency of automated systems.

Case Studies and Best Practices in Industrial Automation

The integration of slip rings into industrial automation systems has yielded numerous success stories where their application has been pivotal. Real-world examples showcase the impact of these devices on the success and efficiency of automated processes.

Real-World Examples of Slip Ring Integration

One notable case is that of an automotive assembly line where rotary tables are employed. These tables make use of hefty slip rings that can handle high power loads and multiple signals simultaneously. In a particular instance, the implementation of robust, multi-channel slip rings revolutionized the assembly process by allowing the rotary tables to spin continuously. This led to an increase in production speed and reduced stoppage times, effectively boosting the facility’s throughput and profitability.

Another example can be seen in the realm of wind turbines, which are becoming an increasingly common sight across the globe. Here, slip rings transmit power and data signals from the stationary tower to the rotating blades. The slip rings in this scenario have to endure harsh environmental conditions and significant fluctuating loads due to wind volatility. The successful incorporation of weather-resistant and highly durable slip rings has been critical for reliable operations, resulting in enhanced energy output and lower maintenance requirements.

In the field of medical imaging, particularly MRI machines, slip rings allow for the continuous rotation of the gantry without the tangling of wires. Advanced, non-magnetic slip rings have been developed to be compatible with the strong magnetic fields within MRI machines. Such implementations have ensured uninterrupted electrical connectivity, which is crucial for this equipment’s high-definition imaging capabilities, translating into higher diagnostic accuracy and patient throughput.

Best Practices in Slip Ring Selection, Installation, and Use

Drawing from these and numerous other industry experiences, certain best practices come to light for the selection, installation, and use of slip rings, guided by industry standards and operational wisdom.

In terms of selection, a primary best practice is to assess the operational requirements thoroughly, which include electrical load, data transmission needs, the range of motion, environmental factors, and required lifespan. For instance, heavy industrial use may favor the robustness of traditional contact slip rings, while precision applications, such as in satellites, would benefit from the reliability of contactless variants.

When it comes to installation, it is vital to adhere strictly to manufacturer guidelines. This ensures that the integrity of the product is maintained and the warranty remains valid. Proper installation reduces the risks of malfunction and contributes to optimal performance. For example, aligning and securing the slip ring assembly according to specifications is key to avoiding unnecessary wear or electrical noise.

Use is another aspect where best practices must be observed. Industry standards emphasize the importance of regularly planned maintenance to ensure the longevity of slip rings. It is also recommended to conduct real-time monitoring when possible, to quickly identify and rectify any performance deviations.

Adopting best practices such as these drives operational efficiency, safety, and reliability. By looking to case studies for proof of impact, and to industry standards for guidance, companies can maximize the potential of slip rings as they deploy these devices within increasingly sophisticated industrial automation systems.

Conclusion

To conclude, slip rings are integral to the robust functioning of modern industrial automation systems. Staying informed about advancements in slip ring technology can significantly improve the efficiency and reliability of automation processes.

FAQs about Slip Ring Application in Industrial Automation

As one navigates the role and applications of slip rings in industrial automation, a plethora of questions may arise. This FAQ section addresses the most common queries associated with industrial automation’s use of slip rings.

Q: What is the primary function of a slip ring in industrial automation?

A: A slip ring’s core function is to provide an uninterrupted electrical connection between stationary and rotating parts of an automated system. This allows power and data to be conveyed seamlessly despite movement, enabling full rotational freedom without impeding electrical continuity.

Q: How do I select the right slip ring for my automation needs?

A: The selection of a suitable slip ring depends on several factors:

- Electrical requirements such as voltage, current, and the number of circuits needed.

- Data transmission needs, including signal type and communication protocol.

- Environmental considerations including temperature, humidity, dust, and corrosive conditions.

- Mechanical parameters like the speed of rotation, installation space, and mounting options.

Professional consultation or comprehensive product research is advised to choose the type of slip ring that will perform optimally in your specific operation.

Q: How long do slip rings last?

A: The lifespan of a slip ring depends largely on its construction and the conditions of its use. Traditional, contact-based slip rings have a finite lifespan due to the wear and tear from physical contact. In contrast, contactless slip rings can potentially last indefinitely as they don’t experience physical wear. However, environmental conditions, rotational speed, load conditions, and adherence to recommended maintenance practices can all impact the actual lifespan of a slip ring.

Q: Do slip rings require any maintenance?

A: Yes, maintenance is a key aspect of slip ring management. This mainly applies to contact-based slip rings, which require routine inspection for signs of wear, dirt accumulation, or oxidation on the brushes and rings. Contactless and sealed slip rings require minimal maintenance but still benefit from periodic inspections to ensure optimal performance.

Q: Can slip rings handle data and power simultaneously?

A: Yes, many slip rings are designed as hybrid models that can carry power and various types of signals simultaneously. This allows slip rings to accommodate complex automation processes requiring concurrent power and data transfer.