Embarking on a journey teeming with intricate cables and circuits, this article aims to demystify the pivotal role of slip ring application in robot arms. From factors influencing the choice of slip rings to tackling integration challenges, we’ll unveil key trends and safety standards shaping their application.

Introduction to Slip Ring Application in Robot Arms

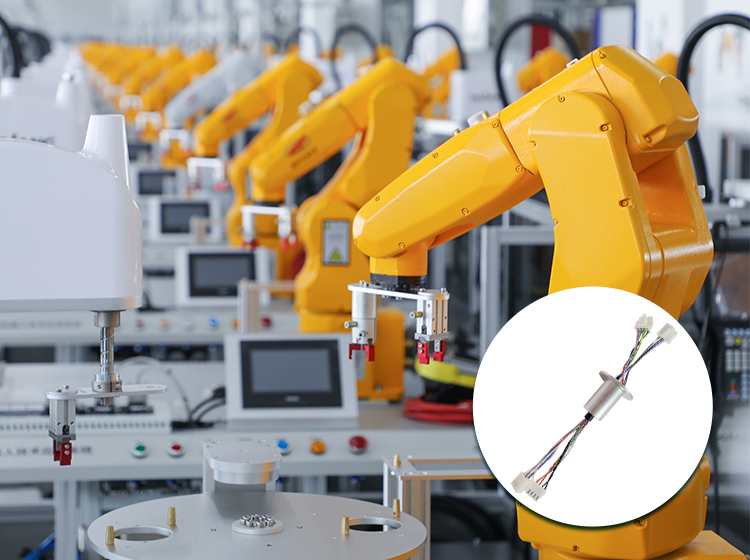

Robot arms, or robotic manipulators, are mechanized and highly sophisticated limbs that perform a variety of tasks that typically require the dexterity and mobility of human arms. These marvels of engineering are widely used across multiple industries—from manufacturing lines where they assemble cars with precision, to the operating rooms where they can assist surgeons with unwavering steadiness. Their applications span even broader, aiding in tasks within laboratory research, materials handling, and even in space stations where they repair satellites.

Within these robot arms, an inconspicuous but critical component takes center stage: the slip ring. Slip rings are electromechanical devices that enable the uninterrupted transmission of power, signals, and data from a stationary to a rotating structure. Imagine the robot arm’s twist and turns, as it bends to perform a task—the slip ring is the element that maintains a constant flow of electricity and communication across these moving joints. Without slip rings, the cables would tangle, signals would be lost, and ultimately, the robot’s functionality would falter leading to operational downtime.

The essence of slip rings lies in their ability to support the robot arms’ complex movements while simultaneously transmitting the necessary energy and digital instructions that spearhead these actions. They ensure that despite the twists and relentless rotations, the arm’s performance remains seamless and efficient. The complexion of modernity in robot arms owes much to the slip ring’s capacity to endure and facilitate this intricate dance of industrial choreography. Therefore, understanding the role of slip rings in robot arms is akin to exploring the heart of robotic motion and efficacy— they are indispensable to turning the electric and data impulses into mechanical grace and productivity.

Types of Slip Rings Used in Robot Arms

The robotic industry utilizes an array of slip ring types, each designed to meet the varied mechanical and electrical requirements of the robot arms. These devices can be broadly categorized into capsule slip rings, pancake slip rings, hollow shaft slip rings, and custom-designed slip rings, each with its unique set of attributes and best-fit application scenarios.

Capsule Slip Rings

The capsule slip ring is a common fixture in compact robot arms, prized for its small, cylindrical shape that integrates seamlessly into the limited space of intricate robotic designs. Its form factor is designed to minimize the impact on the overall arm geometry. Capsule slip rings efficiently conduct electricity and data signals through a series of concentric rings, maintaining consistent connectivity even as the arm pivots and gyrates. By packing multiple circuits into a diminutive space, capsule slip rings are the engineering answer to the demand for high-density transmission capability in spaces where every millimeter counts.

Pancake Slip Rings

In contrast to their cylindrical counterparts, pancake slip rings have a flat, disc-like shape, which makes them ideal for applications where vertical space is restricted, but there is ample horizontal room. They are typified by their larger diameter and shorter height, which translates to a shorter axial length. Rather than being stacked as in the capsule design, the conductive paths in pancake slip rings are spread out flat, akin to the layers of a pancake. This form factor allows easier access for maintenance and can handle higher current capacities due to the greater surface area of each track.

Hollow Shaft Slip Rings

As the name suggests, hollow shaft slip rings are designed with a central void that can accommodate other mechanical elements such as shafts or feed-throughs. This design is especially useful in robot arms that need to pass light, optics, fluids, or additional mechanical linkages through the center of rotation. Hollow shaft slip rings offer not just versatility but also robustness for more demanding applications, allowing a robot arm to multitask, combining rotational movements with through-the-center utilities.

Custom-Designed Slip Rings

No two robots are identical, and often, the one-size-fits-all approach is inadequate for the diverse demands of robotic applications. This is where custom-designed slip rings come into play. They are tailored to specific operational requirements, ensuring that every aspect, from the number of circuits and voltage ratings to the material selection and size, is suited to the robot arm’s designated function. For instance, an ID 7-inch slip ring can be custom-designed to meet the particular needs of robotic systems with larger rotational capacities. This slip ring is engineered to handle higher power or data transmission requirements, making it ideal for robots that need to transmit power and signals over a larger area or across more circuits. Custom slip rings like the ID 7-inch slip ring allow designers to overcome specific challenges, such as extreme environments or unusual motion profiles, ensuring that the robot’s functionality is not compromised by its electrical connections. Custom slip rings can be designed for unique scenarios, allowing designers to overcome specific challenges, such as extreme environments or unusual motion profiles.

Each type of slip ring follows the same principle of enabling rotation while maintaining an electrical connection, yet their distinct designs reflect the versatility and adaptability of robotic technology. They are chosen based on the application’s particular demands, performing under an umbrella of functionalities while specifically catering to the nuanced movement and space constraints of robot arms.

Functions and Advantages of Slip Rings in Robot Arms

Slip rings stand as a beacon of technological proficiency in the realm of robotics, orchestrating an array of functions that pave the way for the efficient and reliable operation of robot arms. From maintaining signal integrity to increasing operating efficiency, these seemingly modest rotary interfaces display impressive versatility.

Continuity of Power and Signal Transmission

At the crux of a slip ring’s functionality is its capability to provide an uninterrupted flow of power and signal transmission, despite the continual rotation of the robot arm. As a robot arm moves, flexes, and rotates; the slip ring ensures a seamless transmission pathway—blending stability with mobility. This constant relay between the static and the dynamic parts eliminates the scenario where cables twist and eventually snap, thus holding paramount significance in the world of robotics.

Enabling Complex Robotic Motion

The power of slip rings extends beyond mere transmission to play a monumental role in facilitating complex robotic movements. They allow a robot arm to perform full 360-degree rotations and more, free from restrictions. This multidirectional freedom allows robots to execute tasks with higher precision, efficiency, and adaptability, akin to manipulating objects in any direction, much like their human counterparts.

Increasing Operating Efficiency and Overall System Reliability

Inextricably linked to their functional role is the positive impact of slip rings on a robot’s operating efficiency and system reliability. A reliable slip ring translates into smooth, uninterrupted operations of the robot arm, minimizing undesirable downtime. Simultaneously, slip rings enable the transmission of various types of signals—data, video, control—which drives multi-faceted efficiency in robotic operations.

Impact on Robot Arm Lifespan and Maintenance Requirements

Equally significant is the slip ring’s influence on the lifespan of a robot arm and its maintenance requirements. By preventing cable twisting and maintaining secure electric connections, slip rings reduce wear and tear on the system, thus potentially extending the robot arm’s longevity. This in turn leads to lower comprehensive maintenance demands, reducing both direct maintenance costs and the indirect cost of operational downtime due to repairs or replacements.

In the grand theater of robotics, slip rings may not take up much physical space, but their role is vast and influential. They act as the linchpins, providing electrical continuity during rotations, enabling complex motions, enhancing operational efficiency, and contributing substantially to the overall life and reliability of robot arms. It’s no understatement to say that slip rings have a profound impact on the performance and life cycle management of robot arms.

Applications of Robot Arms with Slip Rings

Across various sectors and fields, we find the confluence of slip ring technology and robot arms heralding new potentials and capabilities. Let us explore how slip rings in robot arms revolutionize processes in industrial automation, healthcare, collaborative environments, and remote operations.

Industrial Automation

Robotic manipulators armed with slip rings are the workhorses in numerous industrial settings—from automotive assembly lines to electronics manufacturing. They offer high precision and endurance for repetitive tasks, reducing human error and accelerating productivity. The integration of slip rings ensures a smooth flow of power and data, allowing these robots to perform complex, multi-axis movements typical in pick-and-place operations, welding, painting, and more.

Medical Robot Arms (surgical assistance, rehabilitation, etc.)

In the healthcare sector, robot arms serve as surgeons’ sophisticated assistants, providing unprecedented precision inside operating rooms. Robot arms equipped with slip rings become delicate operators that perform intricate maneuvers, from suturing fine blood vessels to inserting thin catheters into blood vessels, enhancing surgical safety and outcomes. Moreover, in rehabilitation centers, robotic arms help patients recover from strokes or injuries, stimulating their muscles and nerves to regain strength and function.

Collaborative Robot Arms (cobots)

Collaborative robots, or cobots, are a massive leap forward in the realm of human-robot interaction. Cobots, armed with slip rings, work hand-in-hand with humans, sharing a workspace and complementing human dexterity with robotic accuracy. Balanced through a perfect symphony of data, power, and signal transmission via the slip rings, these ‘partners’ can perform a range of functions including assembly, packaging, loading, and lab testing.

Remote Operation in Hazardous Environments

There are some environments too hazardous for humans to operate, like deep-sea exploration sites, nuclear plants, and even outer space. In these locations, robot arms with slip rings operate as agile and durable substitutes for human hands. Through remote operation, these robot arms defuse bombs, repair underwater pipelines, and even service satellites—all tasks unimaginable without the reliable and sustained transmission facilitated by slip rings.

Why Universities Are Choosing Custom Slip Rings for Robotics Projects: A 2025 Trend Analysis

Core Focus: Unique experimental requirements driving bespoke solutions.

Analysis:

Modern robotics research (e.g., soft robotics, neuroprosthetics, swarm systems) often involves unconventional architectures. Off-the-shelf slip rings fail to support:Hybrid Power/Data Needs: Projects combining high-voltage actuators with ultra-high-speed data (e.g., real-time neural feedback or LiDAR) require integrated, noise-resistant channels.

Non-Standard Form Factors: Miniaturized surgical bots or biomimetic designs demand slip rings under 10mm diameter or flexible configurations.

Extreme Environments: Underwater, space, or high-radiation labs need materials (e.g., hermetic seals, titanium housings) absent in generic models.

Customization allows researchers to embed sensors, cooling, or fail-safes directly into the slip ring, turning it into a purpose-built subsystem.

Request a callback from our sales team by completing the inquiry form.

From the controlled chaos of an industrial assembly line to the surgical precision within an operation theater, and in the challenging landscapes of hazardous environments, the use of slip rings in robot arms is prolific. They have not only changed the way we approach conventional tasks but have allowed us to innovate, reaching beyond human limitations into a future brimming with extraordinary potential.

Factors to Consider When Choosing Slip Rings for Robot Arms

The selection of an appropriate slip ring for a robot arm is crucial to optimize its capabilities and ensure longevity. Various factors require thorough consideration when making this important choice. Among these considerations are speed and torque requirements, the number of channels and signal types, space and weight constraints, environmental factors, and cost considerations. Delving into these elements can help designers make an informed choice for the perfect slip ring.

Speed and Torque Requirements

The operational speed and torque of a robot arm play a pivotal role in determining the ideal slip ring. The slip ring must be able to handle the required speed without wearing out or compromising its contact quality. Higher speeds typically demand specialized materials and lower contact pressure. Furthermore, a slip ring with adequate torque matching the robot arm’s demands can ensure optimal performance and reduced wear on the system.

Number of Channels and Signal Types

The number of channels (circuits) and the specific types of signals—like data, video, or control—are key factors influencing the selection of slip rings. It is crucial to consider the robot arm’s connectivity requirements to ensure seamless and accurate communication when making rotations. The slip ring should be designed to handle the desired number of channels as well as any mixed-signal applications that may be necessary.

Space and Weight Restrictions

Depending on the design and geometry of the robot arm, space, and weight constraints can significantly influence the choice of a slip ring. Compact systems might favor capsule slip rings, while pancake slip rings could be suitable for systems with height limitations. It is essential to balance these restrictions with performance parameters to ensure that the slip ring does not hamper the robot arm’s overall capability.

Environmental Factors and Durability Concerns

Robot arms operating in harsh environments, such as extreme temperatures, high humidity, or corrosive atmospheres, necessitate slip rings capable of withstanding these conditions. The slip ring’s materials, contact surfaces, and sealing methods should be designed for durability and resistance to premature wear and tear. It’s critical to ensure that the chosen slip rings can maintain reliable electrical and mechanical performance over the anticipated lifetime of the robot arm.

Cost Considerations

While performance factors reign supreme, cost cannot be ignored. Balancing a slip ring’s performance and durability with its price point is essential to maximize the investment in the robot arm. It is necessary to weigh the slip ring’s cost against its expected lifespan, operational expenses, and replacement or maintenance expenses.

Selecting the right slip ring for a robot arm is a complex equation, incorporating various factors that can influence the robot’s efficacy, durability, and overall performance. Thoroughly considering speed, torque, channels, space and weight restrictions, environmental factors, and cost can guide designers in choosing a slip ring that will uphold the robot arm’s functionalities and enhance its life cycle management.

Slip Ring Application in Robot Arms: Integration Challenges and Solutions

Introducing slip rings into the sophisticated ecosystem of a robot arm presents an intricate set of challenges. These range from ensuring seamless joint operation with various components to managing cables and achieving a harmonious balance between the robot arm’s performance and dimensions. Here, we delve into these integration challenges and explore pragmatic solutions that facilitate the effective use of slip rings in robotic systems.

Integration with Other Components (Motors, Sensors, etc.)

Slip Ring to Component Symbiosis: The Interaction Puzzle

The robotic arm’s performance is contingent on the seamless integration of slip rings with motors, sensors, and control units. This integration challenge often lies in ensuring slip rings do not introduce electrical noise or disruptions that can interfere with the precise control of the robot.

Solutions: Coordination and Customization

Custom-designed slip rings, developed through close collaboration between manufacturers and robotics engineers, can address unique electrical and mechanical requirements. Electromagnetic compatibility (EMC) considerations and superior shielded cables can mitigate interference issues, ensuring reliable signal transmission and smooth operation.

Cable Management and Strain Relief

Controlled Chaos: The Cable Conundrum

As the robot arm articulates, cables traveling through it experience stress, which can compromise their integrity. Effective strain relief and cable management are crucial to preventing snags, twists, and tension that compromise function.

Solutions: Meticulous Routing and Anchoring

Employing flexible cabling, designing with ample bend radiuses, and using articulated cable carriers can ensure cables move smoothly without undue stress. Additionally, strategic placement and secure anchoring of cables within the robot structure prevent overextension or tangling.

Achieving Optimal Balance Between Performance and Size

The Compact Performance Equilibrium: A Delicate Trade-off

There is a delicate trade-off between the size of a slip ring assembly and the performance required by the robot. Larger slip rings may accommodate more channels or higher power transmission but can encroach on the arm’s agility or increase its footprint unnecessarily.

Solutions: Ingenious Design and Material Advances

Advances in materials and engineering can help achieve slimmer profiles without sacrificing performance. Using high-grade, low-resistance materials can allow more compact designs while maintaining signal integrity and power delivery.

Solutions for Common Technical Challenges

Troubleshooters’ Toolbox: Anticipating and Addressing Issues

Common technical challenges with slip rings include signal disruption, wear and tear, and maintenance demands. These require proactive and innovative solutions.

Solutions: Advanced Materials and Predictive Maintenance

Utilizing contact materials with higher durability can reduce maintenance frequency and extend the lifespan of slip rings. Predictive maintenance techniques, such as real-time monitoring of slip ring performance, can forecast failures before they occur, minimizing downtime.

Through intelligent design and by addressing the aforementioned challenges with innovative solutions, the integration of slip rings into robotic arms can be optimized. These advances aim to create a harmonious balance between technological sophistication and reliability, ensuring the robotic system operates at peak efficiency with minimal complications.

Trends in Slip Ring Technology for Robot Arms

The integration of slip rings into robot arms is a burgeoning field, continually evolving with the advancements in engineering, material science, and digital technology. Present trends are shaping the destiny of robot arms and their efficiency in automation, medical assistance, and other fields. Emerging trends include the development of contactless slip rings, the application of advanced materials, the integration of the Internet of Things (IoT), and increasing modularity and customization in design.

Contactless Slip Rings and Their Benefits

Ethereal Exchange: The Rise of Non-Contact Transmission

Contactless slip rings, or wireless slip rings, represent a major stride in the field. These rely on magnetic induction or radio frequency to transmit electrical signals and power, eliminating physical contact and therefore reducing friction and wear.

Benefits: Bridging Gaps Without Contact

Unhindered by physical contact or the need for lubrication, these slip rings can offer significant advantages in terms of maintenance requirements and service life. They can support higher speeds, withstand a broader range of environmental conditions, and dramatically reduce the risk of downtime, resulting in enhanced overall performance and reliability.

Advances in Materials Science and Their Impact on Slip Ring Performance and Longevity

Reinventing Metal: Material Innovations in Slip Rings

Innovations in materials science hold the potential to revolutionize slip ring performance and longevity. The incorporation of enhanced materials for contact surfaces contributes directly to increased efficiency and lifespan of the slip ring.

Impact: Performance Uplift and Extended Lifespans

Advanced materials, such as engineered alloys or advanced composites, can reduce electrical noise, increase current-carrying capacity, and resist corrosion. These advancements translate into cleaner signal transmission, higher power density, improved robustness, and an extended operational lifecycle for slip rings in robot arms.

The Role of IoT and Connectivity in Slip Ring Applications

Power of Connectivity: IoT Meets Slip Rings

The advent of IoT technology has given rise to connected slip rings that can share real-time operational data, allowing for predictive maintenance and a new level of control in their applications.

Role: Preemptive Action and Enhanced Control

Connected slip rings capture and communicate data about their operational health, enabling the identification of performance anomalies that may signal impending failure. This opens the door for preemptive maintenance, reducing downtime and enhancing system productivity.

Customization and Modularity in Slip Ring Design

The Freedom to Adapt: Customized and Modular Designs

With the diverse range of robotic applications, there is an increasing shift towards customization and modularity in slip ring design. This flexibility allows for tailored solutions to meet the specific requirements of each application.

Traces of Adaptability: Modular and Made-to-order Solutions

Modular slip rings offer the freedom to configure the required number of circuits, power ratings, or communication channels. This modularity, combined with customization possibilities, can perfectly meet changing demands and future-proof robotics applications.

These trends highlight how advancements in slip ring technology are catering to the ever-evolving demands put forth by robot arms applications. The balance of technology, material innovation, data connectivity, and design flexibility is pivotal in pushing the frontiers of efficiency and performance in robotics.

Compliance and Safety Standards for Robot Arm Slip Rings

A paramount factor to consider in the integration of slip rings into robot arms involves compliance with the globally accepted safety and performance standards. These rules serve as benchmarks to assure consistency, safety, performance, and user trust. They cover a wide range of aspects, including material quality, manufacturing processes, performance parameters, and safety considerations. Let’s explore the critical standards in the field and their relevance to obtaining optimal performance and securing user trust.

ISO and IEC Standards

Ubiquitous Guides: International Standards for Global Assurance

The International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) provide numerous standards relevant to industrial automation and electronics. For instance, IEC 60204-1 covers the safety of electrical equipment in machines, including those used in slip rings. ISO 10218-1 and -2 provide safety requirements for industrial robots and their integration.

Conformity: Universal Assurance and Interoperability

Adherence to ISO and IEC standards ensures the slip rings can deliver reliable and safe performance under globally recognized norms. It also facilitates international trade and assures the compatibility and interoperability of components coming from different manufacturers.

Safety Regulations Specific to Robot Arm Applications

Tailored Protocols: Preserving Safety and Performance

Robot arm applications often call for industry-specific safety regulations, including those for electrical equipment in medical technology or food production. Such rules may also include specifications for areas like control reliability, emergency stop functions, and effective energy isolation.

Risk Mitigation: Averting Hazards, Guaranteeing Safety

These safety regulations guide the design, installation, operation, inspection, and maintenance to ensure operational safety. Compliance reduces the risk of failures that could lead to hazardous situations, ultimately making robot arm applications reliable and safe.

The Importance of Adhering to Industry Standards for Optimal Performance and User Trust

The Bedrock of Trust: Why Standards Matter

Adhering to industry standards serves more than just regulation – it is critical for maintaining optimal performance, minimizing risks, and fostering user trust. Standards guide the design and manufacturing processes, ensuring compatibility, interoperability, and safety.

Tools for Trust: Compliance and Confidence

When slip ring manufacturers conform to standards, they demonstrate a commitment to quality, safety, and performance. This adherence fosters customers’ trust, as compliance signals a product’s reliability, safety, and capacity to deliver as promised.

In summary, compliance with internationally recognized standards and industry-specific safety rules is essential in producing slip rings that harmonize safety, reliability, and performance. Adherence to such standards is not only a regulation necessity but a potent tool for winning customer confidence in the highly competitive world of robotics.

Conclusion

Slip rings, though hardly visible to the naked eye, play a colossal role in the world of robotics. As they continue to shape and navigate robotics’ future, their importance grows in tandem. Indeed, the evolution of robotics is deeply intertwined with the quiet but persistent revolution in slip ring technology.

FAQs about Slip Ring Application in Robot Arms

Q: What is the main function of a slip ring in a robot arm?

A: A slip ring in a robot arm primarily serves to provide electrical continuity in a rotational or moving component, allowing seamless power and signal transmission. This enables the robot arm’s joints to rotate freely while maintaining electrical connection, ensuring smooth operation and enhancing mobility.

Q: How scalable is the design of a slip ring for different robot arm applications?

A: The design of a slip ring is highly scalable, as a function of the wide-ranging applications of robot arms. Ranging from micro-slip rings for minimally invasive surgery robots to larger, more robust versions for heavy industrial robotic arms, slip rings come in diverse sizes and specifications to meet varied requirements.

Q: Does the incorporation of a slip ring affect the performance (speed/accuracy) of a robot hand?

A: When integrated correctly, a slip ring does not hamper the performance of a robotic hand. Instead, by facilitating 360° rotation without cable twisting issues, it enhances functionality and agility. Early collaboration with slip ring providers can ensure the component’s design perfectly aligns with the motion and data transfer requirements of the robot.

Q: Are there potential wear and tear issues due to the constant movement of a slip ring in a robot arm?

A: Like any other rotating component, slip rings are subject to wear and tear. However, the impact of wear and continuous movement can be substantially mitigated through precise design, appropriate material selection, and regular maintenance. Further, innovations such as contactless slip rings are promising in reducing wear and enhancing lifespan.

Q: How challenging is maintenance for slip rings used in robot arms?

A: Maintenance for slip rings used in robot arms can vary based on the type of slip ring used, environmental conditions, and operational hours. Properly designed and well-built slip rings require less frequent maintenance. Advancements in predictive maintenance techniques leveraging IoT can streamline maintenance processes and predict issues before a failure occurs.

See What We Can Do