This article provides a detailed understanding of the use of slip ring applications in scraper machinery, elaborating on their applications, benefits, and future trends while addressing user concerns and frequently asked questions.

Introduction to Slip Ring Application in Scraper

In the diverse arena of heavy-duty industrial machinery, the scraper stands out as an essential piece of equipment. Predominantly used in construction and mining industries, scrapers have been instrumental in altering landscapes through their immense power and functional versatility. Essentially, a scraper is a large machine used for digging, hauling, and dumping soil. The primary operations of this machine fall into a cyclical routine: it digs into the earth with its sharp front edge, collects the loose material into its hopper or bowl, transports the collected material to the desired location, and finally, dumps it.

However, to maintain the scraper’s functionality, certain components are imperative. One such crucial part is the slip ring.

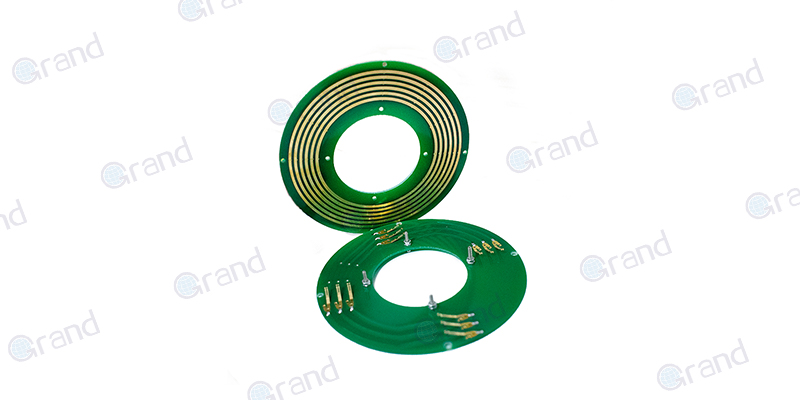

In its simplest definition, a slip ring is a device that allows the transmission of power and electrical signals from a stationary structure to a rotating structure. Without disrupting the flow of power or distorting the signals, this electromechanical device ensures that the rotating parts within the scraper work seamlessly. The utilization of slip rings expands far beyond a single function; they enable the smooth operation of an array of equipment, from wind turbines to CT scanners, and, of course, our present focus, the scraper.

The integration of slip rings within the scraper machinery is essentially what enables it to perform its common operations with maximum efficiency. Whether the scraper is rotating its hopper for another digging cycle or moving its ejector to displace the collected material, the slip ring stands as a silent contributor to the consistent and efficient workings of this heavy-duty machinery.

With a clear understanding of what scrapers and slip rings do, it becomes equally important to connect the dots and understand the fundamental need for slip rings within the operations of scraper machinery. This symbiotic relationship fosters the increased efficiency of scraper operations, leading to enhanced productivity which is key in the fast-paced industrial world. Let us delve deeper into this intricate connection in the next sections.

Scraper Machinery and The Need for Slip Rings

To comprehend the necessity of slip rings in scraper machinery, we must first delve into the multitude of tasks that the scraper carries out and study how it operates.

A scraper is a large, powerful machine designed for digging, loading, hauling, dumping, and leveling operations, making it an indispensable resource in the construction, mining, and agriculture industries. Its basic construction consists of a tractor unit and a rear-mounted receptacle, known as the hopper or the bowl. The bowl is equipped with a cutting edge at the front, used for digging material, and an ejector at the rear to unload the contents. To operate efficiently, scraper machinery relies on the combined efforts of multiple subsystems, including lifting, steering, and traction components. These subsystems require constant coordination, often involving continuous rotation to execute various tasks effectively.

This need for uninterrupted rotation is particularly evident in operations such as loading and unloading of materials. As the scraper digs into the ground, the cutting edge and bowl rotate to collect soil, rocks, or debris. Similarly, while unloading, the bowl rotates upward, and the ejector pushes out the content. These continuous rotations, while necessary, have the potential to disrupt the power flow and signal transmission.

The complications arising from continuous rotation include the tangling and twisting of power cables or signal wires, which could lead to interrupted power supply, data loss, or even the total failure of the system. Additionally, the wear and tear caused by repeated stress on the cables may necessitate frequent maintenance and corresponding downtime, translating into significant losses in productivity and increased operational costs.

Therefore, to address these challenges and maintain seamless connectivity throughout the scraper’s operation, slip rings become an integral part of the system. By providing efficient, uninterrupted power and signal transmission between stationary and rotating components, slip rings prevent cable tangling, ensure smoother operations, and boost the durability and reliability of the machinery. Their application in scraper machinery is essential for overcoming the obstacles posed by continuous rotation, improving operations, and ultimately contributing to enhanced productivity.

Having established the need for slip rings in scraper machinery, we will now delve into their specific applications and examine their roles in various functional parts of the scraper.

Applications of Slip Rings in Scraper Machinery

The application of slip rings in scraper machinery fundamentally involves resolving challenges associated with continuous rotation. By seamlessly transmitting power and signals from stationary to rotating components, slip rings ensure that various systems within the scraper function properly without the risk of power interruptions or signal distortion due to cable twisting or tangling. Indeed, slip rings serve as the backbone of several operations within the scraper machinery, as highlighted below.

Lifting Mechanism

One critical application area for slip rings is the lifting mechanism of the scraper. This comprises a hydraulic system activated to lift the bowl of the scraper during the digging and unloading processes. As the hydraulic lift rotates, maintaining continuous power and fluid flow can be challenging. Slip rings come in handy here, enabling stable and efficient transmission of electrical power signals to the hydraulic components, thereby ensuring a smooth lifting process.

Steering System

The steering system of a scraper is another critical area where slip rings play a significant role. Through the rotation of the wheels and axle, slip rings help transfer electrical power to activate the steering mechanism, ensuring proper control of the machine during operation. Without the presence of a slip ring, consistent power flow could be interrupted, affecting the maneuverability of the scraper.

Traction Component

The traction component of the scraper, responsible for the machine’s forward and backward movements, also relies heavily on slip rings. Given the constant rotation of the motor and the axles, the use of slip rings guarantees an uninterrupted flow of power, leading to efficient motor operation and overall machine mobility.

In conclusion, detailed scrutiny of slip ring application within scraper machinery illuminates their inherent value. By ensuring an efficient flow of power and signals, slip rings contribute to the robust operation of pivotal machinery components such as lifting, steering, and traction mechanisms. They facilitate smoother operations, improve the reliability of the machinery, and substantially enhance the scraper’s overall performance. The following sections discuss the advantages of using slip rings in scraper machinery in more detail.

Advantages of Using Slip Rings in Scraper Machinery

In the rugged world of heavy-duty machinery like scrapers, the efficient operation of various components can significantly impact overall productivity and functionality. Integrating slip rings into scraper machinery addresses several operational challenges and provides crucial benefits. Below, we examine the specific advantages of using slip rings in scrapers.

Uninterrupted Power and Signal Transmission

One of the primary benefits of using slip rings in scraper machinery is the continuous and efficient transmission of power and signals. Continuous rotation during various scraper operations can lead to power and signal disruptions due to the twisting and tangling of wires. The use of slip rings mitigates these complications by ensuring an unhindered transmission path – a particularly beneficial feature in complex systems like the hydraulic lifting mechanism, steering system, and traction component. The result? A scraper machinery that functions at peak efficiency.

Reduced Downtime

Repeated stress on the delicate power and signal cables from the scraper’s continuous rotation can lead to wear and tear, creating the need for frequent maintenance and thus, increased machinery downtime. With slip rings, these maintenance requirements are substantially reduced. By ensuring a seamless power and signal flow, slip rings eliminate the risks associated with tangled or twisted cables, paving the way for more operational hours and less downtime.

Increased Productivity

With uninterrupted power and signal transmission and reduced downtime, productivity inevitably surges. Slip rings ensure the smooth functioning of various components in the scraper, thereby optimizing its operations. The resulting efficiency allows for faster, more consistent work cycles, directly contributing to heightened productivity levels.

Enhanced Durability and Longevity

Slip rings are constructed to withstand the harsh environments often associated with scraper machinery operation. This robustness lends itself to the durability and longevity of the unit. The use of slip rings reduces the wear and tear on critical components, lowering the risk of premature equipment failure and extending the life of the machinery.

In conclusion, the benefits of using slip rings in scraper machinery make them a game-changer for heavy-duty operations. They not only ensure smoother and more efficient operations but also contribute to the durability and longevity of the machinery. The upcoming sections will further elucidate their successful applications through insightful case studies and explore the potential future direction of slip ring technology in scraper operations.

Case Studies: Slip Ring Applications in Scrapers

Real-life examples of the successful usage of slip rings in scraper machinery operations testify to the undeniable advantages these components offer. Below, we share two case studies shedding light on the challenges faced and how slip rings positively impacted the scraper operations.

Earthmoving Project

In an earthmoving project at a construction site, the project team faced difficulties in maintaining an uninterrupted power supply to the scraper’s hydraulic and steering systems. Continuous rotation of the components led to twisted cables, resulting in power losses and frequent machine downtime for maintenance. As a solution, the team integrated a high-quality slip ring into the scraper machinery.

Upon incorporating the slip ring, the project experienced immediate improvements in operational efficiency. Power delivery to the hydraulic lifting system and steering components became seamless, improving the machine’s overall performance. Ultimately, the slip ring implementation resulted in a significant surge in productivity since the machinery’s downtime was drastically reduced, fostering timely project completion.

Mining Operation

In a mining operation, a scraper was utilized to efficiently transport large quantities of material. However, the complicated wiring setup, coupled with the machine’s continuous rotation, led to frequent cable tangling and data signal loss. This issue caused an array of problems, including impaired steering and reduced mobility, affecting the overall productivity of the operation.

To address these challenges, the site engineers decided to implement an advanced electrical slip ring. The slip ring effectively managed the data transmission between stationary and rotating components, thereby eliminating signal loss and facilitating smooth steering and mobility functions. As a result, the scraper’s operational efficiency improved significantly, allowing for increased productivity and a more effective resource allocation process in the mining operation.

These case studies demonstrate the tangible benefits of slip ring application in scraper machinery. The integration of slip rings reduces downtime, enhances operational efficiency, and ultimately, boosts productivity. As technology continues to evolve, it’s essential to remain abreast of the latest trends and innovations in slip rings to maximally harness their benefits in heavy-duty machinery operations.

Challenges and Solutions in Slip Ring Applications in Scrapers

While slip rings offer many benefits for scraper machinery operations, their integration and utilization can also present certain challenges. It is essential to be aware of potential problems and have preemptive solutions lined up to make the most of these critical components.

Integration Complexity

Slip ring integration can be complex due to the size, shape, and specific requirements of different scraper machinery. Fitting a slip ring into an existing unit may require modifications, which may lead to significant downtime.

Solution: To tackle this, it’s crucial to do proper planning and customization. When procuring slip rings, ensure they are tailor-made to fit the machine’s specifications. Many reputable manufacturers offer customizable slip rings that can seamlessly integrate with various machinery types without requiring major alterations.

Environmental Impact

Outdoor heavy-duty operations expose the slip ring to harsh environmental conditions, like dust, dirt, extreme temperatures, and moisture. These factors can damage the slip ring, impeding its performance.

Solution: To counter this, consider using slip rings designed for harsh environments. These specialized slip rings are built with robust materials that can withstand extreme conditions and feature protective casings that shield the internal components from environmental damage.

Wear and Tear

Persistent rotation in scraper machinery can lead to wear and tear on the slip ring, prompting potential signal transmission problems and reduced service life.

Solution: Regular maintenance and inspection of the slip ring components can help mitigate this issue. Additionally, employing slip rings with long-lasting contact materials like gold or silver can increase the lifespan and performance reliability.

Signal Interference

In instances where the slip ring simultaneously transmits power and data or multiple data types, signal interference can occur, which can distort the information being transmitted.

Solution: Use advanced slip rings designed to handle multiple signal types simultaneously without interference. Many of these slip rings feature shielding and separation methods to maintain signal integrity.

In conclusion, while challenges can arise when using slip rings in scraper machinery, with knowledge and forethought, these can be effectively managed. Leveraging customized slip rings, dealing proactively with environmental factors and wear and tear, and using advanced models can greatly enhance the effectiveness and longevity of slip rings in scraper operations.

User Concerns about Slip Ring Applications in Scrapers

When considering the integration of slip rings into scraper machinery, operators may have several questions and concerns related to the cost, maintenance, adaptability, durability, and training associated with this technology. Addressing these concerns helps users make informed choices and mitigate potential challenges.

Cost and Investment

The cost of procuring slip rings and integrating them into scraper machinery is a primary concern. Users may be hesitant to make this investment, especially if there’s a limited understanding of the long-term benefits and return on investment.

Response: While integrating slip rings might require an initial investment, their long-term benefits in operational efficiency, reduced downtime, and increased productivity make it a wise decision. Many manufacturers offer a range of slip ring options with different pricing tiers to cater to various budgets and requirements.

Maintenance

Users might be concerned about the maintenance requirements of slip rings, assuming that their complex nature might necessitate frequent, skill-intensive servicing.

Response: Modern slip rings are designed for minimal maintenance needs. Regular functional checks and basic maintenance are often sufficient to maintain optimal performance. Additionally, manufacturers typically provide comprehensive maintenance guides and customer support to aid users in ensuring that their slip rings function smoothly.

Adapting Existing Machinery

Concerns regarding the adaptability of slip rings to existing machinery systems and associated downtime are common among users.

Response: Reputable slip ring manufacturers offer customizable options suited to individual machine specifications, facilitating seamless integration with minimal modifications. Proper planning, technical support from manufacturers, and collaboration can ensure the slip ring installation process is smooth and efficient, with little downtime.

Durability Under Harsh Conditions

Users may be concerned about the durability and lifespan of slip rings, especially in scraper machinery that operates under harsh environmental conditions.

Response: Investing in slip rings designed for rugged outdoor applications is key. These slip rings are made from robust materials and feature protective casings, ensuring durability even under challenging circumstances. Moreover, selecting slip rings with long-lasting contact materials can also enhance their service life.

Training for Operation and Maintenance

Using and maintaining slip rings efficiently may require specialized training, raising concerns about potential additional costs and workforce competency.

Response: Most slip ring manufacturers offer comprehensive training resources, guides, and customer support to help users understand the operation and maintenance process. An initial investment in training will quickly pay off in terms of efficiency and cost savings in the long run.

Understanding and addressing common user concerns is essential to maximizing the benefits of slip ring applications in scrapers. Evaluating cost-to-benefit ratios, following maintenance best practices, selecting the right slip ring models to meet specific needs, and investing in appropriate training will ensure successful implementation and optimal performance.

Future Trends and Innovations in Scraper Slip Rings

The technological landscape of slip rings for scraper machinery continues to evolve. Innovations aim to further streamline operations, enhance efficiency, and reduce maintenance and operational costs. Let’s explore anticipated advancements in slip ring technology and how these could transform scraper operations in the future.

Smart Slip Rings

The rise of Industry 4.0 and the Internet of Things (IoT) is expected to bring about smart slip rings that can self-monitor and send real-time performance data. Through this technology, issues can be identified and rectified before they escalate and interfere with operations, reducing downtime and potentially increasing machinery lifespan.

The integration of smart slip rings is likely to lead to predictive maintenance strategies instead of reactive ones, fostering increased operational efficiency.

High-Speed Data Transmission

With operations becoming increasingly data-driven, the demand for high-speed data transmission is expected to increase. Advanced slip rings capable of handling higher bandwidths and promoting faster data, video, and sensor signal transmissions will enhance the multifunctionality of scrapers.

Robust Materials

Conventional slip rings often suffer from wear and tear due to continuous friction. The future may see slip rings incorporating materials eliciting minimal friction, such as advanced ceramics or nanotechnology-derived substances. This development could prolong the service life of slip rings and further reduce maintenance needs.

Energy-Efficiency

Alongside meeting operational needs, environmental concerns are driving the development of more energy-efficient slip rings. Future slip rings could incorporate technologies to reduce power loss, consume less energy while maintaining high performance, and have a lower environmental impact.

Wireless Slip Rings

While physically connected slip rings are the norm, wireless technology could make a breakthrough in the slip ring sector. The development and refinement of contactless or wireless slip rings will eliminate mechanical wear, reducing maintenance needs and facilitating continuous, unhindered operation.

The future of slip ring technology is promising, with trends centered around minimizing maintenance, optimizing efficiency, improving versatility, and reducing environmental impact. These advancements are poised to contribute significantly to the operational efficiency and productivity of scraper machinery, making the most of this powerful, heavy-duty equipment.

Conclusion

Slip rings play an indispensable role in the smooth & efficient operation of scraper machinery. While challenges and concerns may exist, their superior performance, improved longevity, and promising future make them an investment worth considering.

FAQs about the Slip Ring Application in Scraper

When considering the integration of slip rings into scraper machinery, users may have several questions about its application, functionality, and benefits. Here are some frequently asked questions about slip ring applications in scraper machinery.

Q1: What are slip rings and why are they used in scrapers?

A: Slip rings are electromechanical devices that allow the transmission of power and electrical signals from a stationary structure to a rotating one. In scrapers, they play a crucial role in enabling uninterrupted, smooth rotation while maintaining electric connectivity.

Q2: What are common challenges when integrating slip rings into a scraper machine?

A: The most common challenges include integration complexity due to differing machine specifications, wear and tear from regular operation, susceptibility to environmental conditions, and potential issues like signal interference.

Q3: How can I address the issue of wear and tear on slip rings?

A: Regular maintenance and inspection of the slip ring components are key. Utilizing slip rings made from long-lasting contact materials can also significantly increase their lifespan.

Q4: Are slip rings difficult to maintain?

A: No, modern slip rings are designed for low maintenance — basic cleaning and periodic checks usually suffice. Further, most manufacturers provide detailed maintenance guides and customer support.

Q5: Can slip rings reliably operate under harsh environmental conditions?

A: Yes, slip rings especially designed for harsh environments feature protective casings and are built from materials that can withstand severe weather conditions, dust, and other environmental factors.

Q6: What kind of training is required to operate and maintain slip rings in scraper machinery?

A: Some degree of training is beneficial to understand how to operate and maintain a slip ring system effectively. Most manufacturers offer training resources and guides to assist with this.

Q7: What are the future trends in scraper slip rings?

A: Trends are leaning towards smart slip rings that offer real-time performance data, slip rings capable of high-speed data transmission, usage of robust and frictionless materials, energy-efficient models, and potentially even wireless slip rings.

See What We Can Do