The textile field, as ancient as humanity itself, has experienced immense changes over time. It utilizes a variety of raw materials, from natural fibers like cotton and wool to synthetics such as polyester and nylon, to meet the wide-ranging fabric demands of the contemporary world. The expansive scope of the textile industry, from farming and ginning to spinning, weaving, dyeing, and finishing, involves complex machinery at each production phase.

“Slip Ring Applications in Textile Machines” play an essential role in this multifaceted industry. Slip rings, often recognized as rotary electrical joints, interfaces, or collectors, are electromechanical devices that allow the passage of power and electrical signals from stationary to rotating components. Despite consistent motion, these simple, yet intelligent devices assure seamless electrical connectivity, making them central to the operation of different machinery, including those in the textile sector.

The incorporation of slip rings in textile machinery is noteworthy for their contribution to smooth, uninterrupted operations. They allow necessary rotation during multiple textile production stages, from spinning to weaving, and knitting, without disrupting the electrical connections. Hence, creating a solution to the challenge of interfacing with rotating elements, makes them critical for the functioning of advanced textile machinery.

Slip Ring Applications in Textile Machines

Basics of Slip Ring

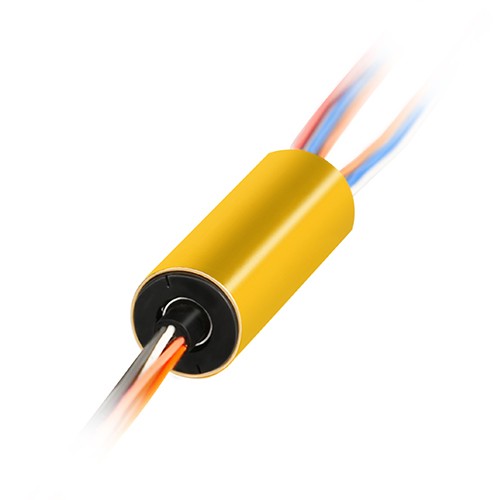

A slip ring, also known as an electric swivel, collector, or rotary electrical interface, is an electromechanical device that allows the transmission of power and electrical signals from a stationary part to a rotating part. Comprising mainly two parts, a rotor, and a stator, it plays a primary role in moving, stationary, and external devices. The rotor, which is the rotating part, is typically connected to the part of the device that needs to rotate, while the stator, the stationary element, is connected to the part that remains static.

The basic working principle of a slip ring depends on electrical conduction and mechanical rotation. The stationary part, or brush, maintains continuous electrical contact with the rotating part, or ring, allowing for electricity and signals to pass through. This transmission is made possible by the pressing of the brush onto a ring. When the ring rotates, electrical currents or signals are transmitted from the stationary part to the rotating part, or vice versa, enabling seamless connectivity even during constant motion.

There are several types of slip rings, each designed to meet different needs and applications. The four most common types are capsule, through-hole, pancake, and mercury slip rings.

Capsule Slip Rings: These are designed for signal and power transmission in compact spaces. They are often used in small precision machines due to their small size and reliability.

Through-hole Slip Rings: These allow for space in the center to provide a clear passage for the shaft of a machine or other equipment. They are typically used in large machinery or equipment.

Pancake Slip Rings: These have conductive material spread out into a disc instead of a ring. They have a flat, disc-like shape to save vertical space, suitable for systems with limited height but ample horizontal space.

Mercury Slip Rings: These use liquid mercury to create an electrical connection. They are usually chosen for their ability to transmit higher amounts of currents and signals and for their reduced noise and wear.

Each type of slip ring, with its own structure and specific features, serves a unique purpose in different settings, optimizing the operational process where continuous rotation and power or signal transmission is a prerequisite.

Crucial Applications of Slip Rings in Textile Machines

Slip rings, due to their ability to provide a crucial electrical connection amidst constant motion, are particularly integral to the smooth functioning of textile machines. These ingenious devices solve the critical challenge of power and signal transmission from stationary to rotating parts, thereby enhancing the overall operational efficiency and productivity of textile machinery.

There are several textile machines where slip rings find their crucial application:

- Spinning Machines: Possibly the most dominant application, spinning machines, which transform raw fibers into yarn or threads, witness an extensive use of slip rings. Here, slip rings facilitate the transportation of power and signals to spin boxes, helping maintain the ceaseless motion that’s essential for the spinning process.

- Weaving Looms: Modern weaving looms, especially those guided by computer-controlled systems, utilize slip rings to maintain a continuous flow of signals, even during the constant motion of the loom. This unfettered signal communication is pivotal for real-time synchronization, ensuring the correct placement and interlacing of threads.

- Knitting Machines: Whether circular or flat, knitting machines also witness the use of slip rings. They help maintain a constant flow of power and signals, managing the intricate movements of needles and yarn feeders, thus facilitating the creation of seamless knitted fabrics.

In these machines and more, slip rings serve a vital purpose. For spinning machines, they enable the constant spinning motion without disrupting the electrical connections, thereby enhancing the quality and uniformity of the yarn produced. For looms, they assist in maintaining the real-time control of the complex interplay of threads, thereby elevating the precision and efficiency of the weaving process. Similarly, knitting machines, aid in the controlled motion of hundreds of needles, enhancing the quality of the knitted fabric.

By providing an uninterrupted flow of power and signal transmission, slip rings markedly increase the productivity and the operational uptime of textile machines. They also significantly reduce the maintenance downtime and prolong the lifespan of the machinery, thus contributing to cost savings. Considering these aspects, slip rings evidently play a critical role in the textile industry, pushing the boundaries of what’s possible in the world of textiles.

Users’ Concerns About Slip Ring Applications in Textile Machines

For the users of textile machines, understanding the applications and implications of slip rings is essential to harness the full potential and efficiency of the machines. Several concerns are typically associated with the usability and integration of slip rings:

- Reliability and Durability: Given the constant rotation in textile machinery, users often concern themselves with the reliability and durability of slip rings. They need to offer consistent performance and withstand a substantial amount of wear and tear. The longevity of the ring material, the ability to handle electrical loads, and the resistance to corrosive environments are all essential parameters.

- Maintenance Requirements: The maintenance of slip rings is another significant concern. Regular cleaning is necessary to remove dust and grime that can affect performance over time. The slip ring also requires routine lubrication to minimize friction and avoid overheating. Users are often concerned with the frequency and complexity of these maintenance tasks, as excessive downtime can impact productivity.

- Safety Issues: Another important aspect is the safety of the usage of slip rings. The device essentially deals with the transfer of electric current and, therefore, can pose potential safety hazards. Users must be aware of the precautions to take while handling and maintaining slip rings to prevent any accidental mishaps.

- Efficiency and Effectiveness: While users appreciate the importance of slip rings in enhancing process efficiency, they also concern themselves with the efficiency of different types of slip rings. The choice between capsule, through-hole, pancake, or mercury slip rings often hinges on their suitability for specific applications, power requirements, and machine configurations. The right choice of slip ring can significantly impact the performance and longevity of the textile machine.

- Cost: Finally, the cost of slip rings and their installation is a significant concern for users. Apart from the upfront costs, factors such as maintenance costs and potential downtime costs also contribute to the overall investment in a slip ring. Therefore, users evaluate the cost-effectiveness, balancing the initial investment against the expected increase in performance and productivity.

Understanding these nuances equips users to make an informed decision about slip ring selection, usage, and maintenance, which optimizes their textile machine performance and extends its lifespan while ensuring safety and cost-effectiveness.

Installation Process of Slip Rings Applications in Textile Machines

Installing slip rings in textile machines requires adherence to specific guidelines to ensure smooth operation and prevent potential damages. Here is a general process for installing slip rings:

- Preparation: Begin with identifying the type of slip ring best suited for your application. Ensure your textile machine is powered off, and if possible, disconnected from the main power source. Gather all necessary tools for the installation.

- Installation Site Preparation: Clean the location on the machine where the slip ring will be installed. Make sure it’s free of dirt, grease, and contaminants.

- Slip Ring Positioning: Position the slip ring with caution, ensuring it aligns correctly with the machine’s rotating part. The rotation axis of the slip ring should coincide with the rotation axis of the machine to avoid undue stress on the slip ring.

- Attachment: Employ suitable means (clamp, flanges, screws, etc.) to securely attach the slip ring to the machinery. This attachment should be tight enough to prevent slippage but not so tight as to cause deformation.

- Connecting Wires: Connect the wires from the stationary and rotating part to the appropriate terminals on the stator and rotor of the slip ring, respectively. Be sure to follow the manufacturer’s recommendations for secure wire connections.

- Testing: Before integrating it into full operation, test the installed slip ring to ensure proper electrical connections and mechanical rotation.

Here are additional tips and things to avoid throughout the process:

- Before installation, read the installation manual provided by the manufacturer carefully to completely understand the specifics of your particular slip ring.

- Ensure the terminals and connecting wires are not subjected to excessive pull or stress that could lead to disconnection or damage.

- Avoid side loads on the rotating part of the slip ring, as it could disrupt electrical continuity.

- Follow a regular maintenance routine to ensure prolonged and efficient functioning.

Proper installation of a slip ring is essential to achieve optimum performance, and each installation step must be carried out with utmost precision and care.

Slip Rings Applications in Textile Machines: Maintenance and Troubleshooting

Routine maintenance and troubleshooting of slip rings are paramount for their continuous and efficient operation within textile machines.

Regular Maintenance Steps and Protocols:

- Cleaning: Regularly clean the slip ring to remove any dust or contaminants. Any build-up can cause excessive wear and tear, affecting electrical conductivity and mechanical rotation.

- Inspection: Regularly inspect the slip ring for any signs of wear and tear, especially on the brushes and rings. Check for uniform wear, groove formation, or plating erosion.

- Lubrication: Lubricate the slip ring as per the manufacturer’s guidelines to alleviate friction and heat generation. Choose the right type of lubricant and follow the prescribed frequency of lubrication.

- Wire and Connection Inspection: Ensure the wires and connections are secure. Loose wires can affect the performance and might lead to severe electrical faults.

Common Issues and Troubleshooting:

- Poor connectivity: If the slip ring does not transmit power or signals efficiently, it may be due to a dirty surface or worn-out brushes. Cleaning or replacing the brushes can solve this issue.

- Overheating: Excessive heat might be due to heavy electrical loading or inadequate lubrication. Users can address this by reducing the load or improving the lubrication.

- Excessive noise: If the slip ring operation is noisy, it may be due to misalignment or worn-out parts. Inspect the slip ring for alignment or replace excessively worn parts.

- Uneven Wear and Tear: If the ring or the brush wears down unevenly, check for misalignment, unstable rotation, or improper pressure between the brush and the ring. Correcting the pressure and alignment can typically solve this problem.

By adhering to a regular schedule of cleaning, inspection, and lubrication, users can prolong the efficient operation of a slip ring. At the same time, staying aware of common issues and their solutions would allow users to troubleshoot effectively and quickly.

Slip Rings Applications in Textile Machines: Case Studies

The application of slip rings in textile machines has revolutionized the industry, providing real-world benefits and significant improvements in production efficiency. Below are two case studies illustrating their benefits.

Case Study 1: Improving Operational Efficiency in Spinning Machines

In a large-scale textile factory utilizing conventional slip rings, the spinning machines’ operational efficiency needed an enhancement. The factory decided to replace the conventional slip rings with an advanced capsule slip ring model. This model was more compact, providing better power and signal transmission and a longer lifespan due to its robust structure and high-quality materials.

The immediate results were a significant decrease in unscheduled downtimes due to slip ring failures, increasing the overall operational efficiency of the spinning machines by nearly 15%. Over time, enhanced yarn quality due to better control of the spinning process was also noted. The return on investment for the new capsule slip ring installations was realized in under a year due to improved productivity and reduced maintenance.

Case Study 2: Cost savings in Weaving Looms

In a medium-sized weaving unit, maintenance costs were climbing high due to the repeated failure of traditional slip rings. The business decided to adopt mercury slip rings, known for their low resistance, high capacity transmission, and minimal maintenance requirements.

After installing mercury slip rings on looms, there was an instant reduction in both the frequency and cost of maintenance, contributing to a yearly saving of around 25% on maintenance costs. The improved control offered by these slip rings also led to better-quality fabrics, thus introducing new market opportunities and higher premium fabric sales for the business.

These success stories exemplify the considerable advantages of implementing suitable slip rings in textile machines, including improved operational efficiency, better product quality, and significant cost savings. It underscores the importance of thoughtful adoption and maintenance of slip rings as a strategic decision for businesses in the textile industry.

Latest Trends and Advancements in Slip Ring Applications

The textile industry continues to enhance productivity, quality, and sustainability with new developments and innovations in slip ring technology. Let’s explore some recent advancements, trends, and potential applications:

- Fiber Optic Rotary Joints (FORJ): The demand for high-speed data transmission between rotating and non-rotating components has led to the development of fiber optic rotary joints. These devices employ optical fibers and are capable of transmitting large amounts of data with minimal signal loss and electrical interference. FORJs have excellent potential in smart textile machines, where large amounts of sensory and operational data must be managed efficiently.

- Low-maintenance Slip Rings: Recognizing the industry’s need to reduce downtime, manufacturers are developing low-maintenance slip rings. These rings feature extended-life brushes, improved contact materials, and advanced sealing techniques, making them resistant to harsh environments and requiring minimal maintenance.

- Wireless Slip Rings: As the demand for contactless power and data transmission grows, wireless slip rings have emerged as an innovative alternative. These devices utilize inductive coupling or magnetic resonance to transfer power and data between rotating and stationary parts, eliminating the need for physical contact. Wireless slip rings have the potential to further reduce maintenance costs and improve operational efficiency in textile machines.

- Compact and Customized Slip Rings: As textile machines become more sophisticated and compact, the slip rings accompanying them must also adapt. Manufacturers are increasingly focusing on developing compact, customized, and integrated slip rings that can meet precise requirements while occupying minimal space.

- Environmentally Friendly Slip Rings: With increased global attention to sustainability and environmental impact, eco-friendly slip ring materials, designs, and processes are gaining traction. Developments such as biodegradable materials, low-CO₂ emission manufacturing, and energy-efficient slip rings demonstrate commitment to responsible textile industry practices.

These advancements in slip ring applications and related technologies signify a bright future for the textile industry. With better data transmission, less maintenance, improved efficiency, and higher sustainability standards, these innovations pave the way for increasingly smart, optimized, and environmentally responsible textile production processes.

Conclusion

Slip rings play a crucial role in the operational efficiency of textile machinery. These devices enable seamless transfer of electrical power and signals between stationary and rotating parts, significantly contributing to the overall performance of the machinery. Without them, the complex movements needed in processes such as spinning, weaving, and knitting would be challenging if not impossible.

The importance of proper installation cannot be underestimated. Installation needs to be performed with precision and accuracy to ensure optimal functionality and longevity of the slip ring. Misalignment or incorrect connections can lead to inefficiencies and possible equipment damage. Regular maintenance, including cleaning, inspection, lubrication, and checks for wear and tear, also extends the operational life of slip rings and minimizes unplanned downtimes.

Staying abreast of advancements and trends in slip ring technology is another crucial aspect. The textile industry continues to evolve, with an increasing focus on automated and smart operations, sustainability, and data-driven manufacturing. The new wave of slip ring advancements, from Fiber Optic Rotary Joints, low-maintenance and wireless slip rings, to compact and environmentally friendly designs, promises improved efficiency, cost savings, and environmental responsibility.

In conclusion, the humble slip ring is a key player in the textile industry. Its careful selection, proper installation, routine maintenance, and continuous upgrading with new technologies will not only enhance machinery performance but also contribute significantly to more intelligent and sustainable textile production processes.

FAQs About Slip Ring Applications in Textile Machines

Q: What does a slip ring do in a textile machine?

A: A slip ring is a device that enables the transfer of power and signals between fixed and rotating parts. In textile machines, they are essential in processes that involve constant movement, such as spinning and weaving. They ensure seamless operation and higher productivity.

Q: What type of slip ring is best for textile machines?

A: The type of slip ring depends on the specific requirements of a machine, including power and signal transmission needs, physical constraints, and environmental conditions. Generally, textile machines might use traditional, capsule, or mercury slip rings. Consultation with the slip ring manufacturer or supplier is typically required to choose the most suitable option.

Q: How often should a slip ring be maintained in a textile machine?

A: The maintenance frequency depends on factors like the operating conditions, quality of the slip ring, and manufacturer’s guidelines. A good rule of thumb is to perform an inspection and cleaning every 3 to 6 months. However, it might be more frequent in harsh operating conditions.

Q: What are the signs of a worn slip ring?

A: Increased noise, poor connectivity, or excessive heat generation may indicate a worn slip ring. Visual signs may include discoloration or uneven wear and tear. Regular inspections can help identify these issues before severe problems occur.

Q: What are the latest trends in slip ring technology for textile machines?

A: There are several exciting advancements including Fiber Optic Rotary Joints for high-speed data transmission, low-maintenance slip rings for reduced downtime, wireless slip rings for non-contact power and data transfer, compact and integrated slip rings for modern, streamlined machinery, and eco-friendly slip rings for sustainable practices.

These FAQs provide an overview of essentials about slip rings in textile machines – their function, selection, maintenance, signs of wear, and current advancements. They should be helpful for those interested in understanding and optimizing the role of slip rings in the textile industry.

See What We Can Do