In the world of electronics and electromechanical devices, the slip ring cable holds significant prominence. It serves as a vital component in various industries by providing a reliable solution for transmitting electrical power and data communication across rotary interfaces. As technology evolves and demands for quality power and data connectivity increase, the importance of understanding slip ring cables becomes more crucial. By delving into the types, applications, key features, and maintenance practices for these cables, users can optimize their performance and ensure seamless functionality in different settings. This comprehensive guide will explore everything you need to know about cable slip rings and how to harness their potential in today’s fast-paced world.

What is a Slip Ring Cable?

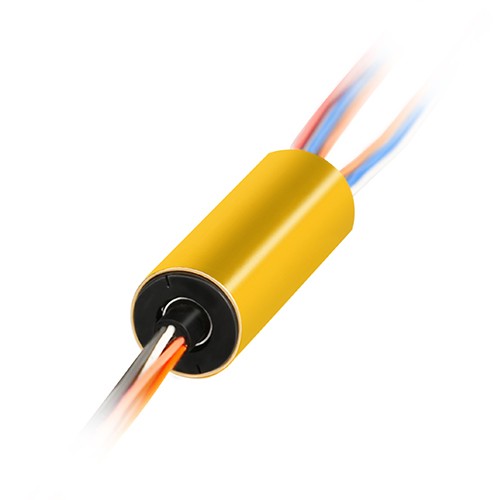

A slip ring cable, often referred to as an electrical rotary joint, rotary electrical interface, or swivel, is a high-performance device that has been ingeniously designed to transfer electrical power and signal from a static to a continuously rotating part. It is an electrical connector that is meant to replace wires that become twisted and eventually break when subjected to perpetual rotation.

The primary anatomy of a slip ring cable consists of rings of conductive material that are mounted on a rotating shaft. Brushes of a similar conductive material ride on these rings. These brushes are fixed, and they slide on the rotating ring, making an electrical connection between the wired, stationary part of the system and the rotating assembly. The cables attached to these brushes are termed slip ring cables. This design helps maintain a continuous and reliable electrical connection, which prevents wiring fatigue and failure, even during constant rotation.

The use of slip ring cables can easily simplify system operations, improve mechanical performance, eliminate damage-prone wires dangling from movable joints, and importantly, solve the twist problem. Thus, they offer a profound advantage in systems where unrestricted, continuous, or intermittent rotation is required.

Types of Slip Ring Cables

Different systems require customized solutions, and slip ring cables are no exception. Multiple types of slip ring cables have been designed, each fulfilling unique requirements and intended for different applications. Here, we talk about some of the most common types:

Capsule Slip Ring

This type of slip ring cable is compact, ensuring its applicability in minimal spaces. It is designed for signals and low-power applications. Its compact nature makes it exceptionally suitable for devices such as CCTV cameras.

Pancake Slip Ring

Pancake slip rings feature a flat disc-like design. They are preferred where the length is restrictive but larger diameters can be accommodated.

Ethernet Slip Ring

As the name suggests, this type of slip ring is primarily designed for data and signal transmission while supporting Ethernet protocols. It is widely used in high-speed data equipment and systems.

Fiber Optic Slip Ring (FORJ)

Ideal for high-speed data transmission over optical fiber, these slip rings, also known as fiber optic rotary joints, offer high resistance to shocks and vibrations.

Wind Turbine Slip Ring

Specifically designed for wind turbines, these slip rings are usually larger, capable of carrying higher currents and withstanding harsh environmental conditions.

These variants cater to a broad range of requirements and specifications. The choice of the type of slip ring cable depends on multiple factors, including the application, the system’s limitations, and the environment in which it will be functioning. Through such a diverse range, slip ring cables extend their versatility, meeting the demands of different sectors, from medical to renewable energy and more.

Slip Ring Cable: Applications

Slip ring cables prove their practicality and adaptability by touching a wide array of industries with their applications. They are used in any system where unrestricted, intermittent, or continuous rotation is needed while transferring power and data. Here are some of the commonplace uses of slip ring cables:

Wind Turbines

In wind turbines, slip ring cables are essential for transmitting power and data from the still nacelle to the rotating blades.

Satellite Antennas

These cables are used within satellite antenna systems for stable data transmission during continual rotation.

CT Scanners

In medical imaging machinery like CT scanners, these cables transfer the data between the static part and the rotating gantry of the machine.

Radar Platforms

Radars rely greatly on slip ring cables for sending information about object distance, speed, and direction from the rotating antenna to the static processing unit.

Camera Systems

In professional video capture systems and surveillance cameras, slip ring cables enable 360-degree rotation without the hampering of wires.

Rotary Sensors

These cables provide an effective solution to transmit electrical signals from rotating sensors to static processors.

In vehicles, slip ring cables are used for transmitting signals for controls, sensors, and lighting.

Industrial Machinery

Many manufacturing machines require continual or intermittent rotation while maintaining data and power transmission, making slip ring cables instrumental for such machinery.

Rotating Exhibits in Museums and Trade Shows

These cables are used to allow for power and signal transmission for rotating displays or exhibits, such as in museums or trade shows.

By facilitating constant, sound, and seamless transmission of power and signals, slip ring cables have become an essential cog across industries and applications.

Slip Ring Cable: Performance

The performance of a slip ring cable is a critical factor, especially considering the specific, sophisticated applications it’s designed for. There are several key elements that underline the performance of a slip ring cable:

Longevity

A high-quality slip ring cable often comes with the promise of long-lasting service. It is built to function effectively for millions of revolutions without the need for regular maintenance, depending mainly on the application and environment.

Low Electrical Noise

Electrical noise may lead to unwanted disruptions in data or power transmission. A slip ring cable tends to have a low electrical noise level, making it ideal for situations that require flawless transmission.

Transfer Capacity

Most slip ring cables sport a wide range in terms of both voltage and current ratings. They are adaptable to both high and low-power applications, as well as a variety of signal types.

Transmission Quality

Slip rings are designed to provide high-quality data transmission without loss or interruption. This is absolutely crucial in applications where lossless transmission is imperative, such as in medical equipment or defense applications.

Speed

Depending on the application and the type of slip ring, these components can operate efficiently at various rotation speeds, with some capable of withstanding very high RPMs.

Environment Resistance

The performance of a slip ring cable can also be determined by its resistance to adverse conditions like extreme temperatures, vibrations, pressure, humidity, and even corrosion, making it apt for use across diverse environments.

By excelling in these performance metrics, slip ring cables become the ideal solution for providing unrestrained rotation while ensuring the uninterrupted transmission of power and data, fulfilling the versatile needs of varied applications across industries.

Slip Ring Cable: Key Features

Understanding the key features of a slip ring cable is essential to ensure proper functioning and selecting the appropriate option for a specific application. Some of the essential features include:

Vibration and Shock Resistance

To guarantee the stable operation of a slip ring in dynamic environments, it must be designed to resist vibrations and shock. This is particularly important for applications that deal with heavy machinery or extreme operational conditions.

High Rotary Speed

A robust slip ring cable can work at different rotation speeds and provide consistent performance. High rotary speed capabilities allow them to be used in multiple applications, including those requiring rapid rotations.

Multi-circuit Compatibility

Slip ring cables can support multiple circuits simultaneously. The more complex the application, the greater the likelihood that a slip ring cable will need to transfer different power and signal types concurrently.

Compact Size

In space-constrained applications, compact size is essential. A small slip ring cable allows for easier integration without limiting the performance.

Compatibility with Data Bus Protocols

To meet the increasing demand for data-driven applications, slip ring cables must be compatible with popular data bus protocols such as Ethernet, Profibus, CANbus, and others.

Low Friction

Low friction between the brushes and rings is vital due to the continuous motion during operation. Lower friction contributes to a longer lifespan and enhanced performance.

Temperature Resistance

Slip ring cables must be able to operate in a variety of conditions. This includes being able to withstand extreme temperature fluctuations, which can be critical for applications exposed to harsh environments or outdoor use.

Ease of Integration

A slip ring cable should be easy to integrate within the existing systems, making it adaptable and efficient without imposing undue complexity or difficulty.

By possessing these essential features, slip ring cables can function effectively and reliably in various conditions and adapt to an array of equipment types, making them exceptionally versatile.

Slip Ring Cable: Installation

The installation of a slip ring cable should be handled with care to ensure it operates correctly and to extend its lifespan. Let’s look at a general step-by-step installation process:

Preparation

Before installing the slip ring, carefully read the manufacturer’s manual for details regarding the installation process, specifications, and precautions. Gather all necessary tools and ensure the system power is turned off to avoid accidental injuries.

Positioning

Determine the exact position for the slip ring. The position should allow cables to be connected comfortably both from the stationary and the rotating sides. It should also offer sufficient space for subsequent servicing needs.

Mounting

Install the slip ring according to the manufacturer’s instructions – typically, it’s either flange mounting or bore mounting. The mounting should meet the application’s requirements and ensure the slip ring can withstand operating conditions like torque, load, and vibration. Make sure that the slip ring isn’t installed at an angle or misaligned.

Connecting Wires/Cables

Slip ring cables should then be connected according to the wiring diagram provided by the manufacturer. Incorrect wiring may result in the slip ring not operating as anticipated or even damaging the slip ring.

Securing

Confirm the slip ring is securely attached and the wires are tightly connected. Any loose fittings might cause failure or uncertain performance during the operation.

Testing

Once securely installed, perform a test run to ensure the slip ring is functioning correctly. This should include monitoring for any extraneous noises, listening for undue vibrations, and checking the accuracy of data or signal transmission.

Routine Maintenance

Regularly monitor the performance of the installed slip ring. Keep the brushes clean and replace them on schedule. Such routine care can effectively extend the slip ring’s service life.

Note: This general guide may not cover all aspects of slip ring cable installation, each manufacturer will provide specific instructions that should be closely followed to ensure smooth operation and extended service life of the slip ring.

Slip Ring Cable: Maintenance

Regular maintenance of slip ring cables is critical to ensure their longevity and efficient performance. Here are some maintenance tips:

Routine Visual Inspection

Regularly visually inspect the slip ring cables for any signs of wear and tear, blistering, discoloration, or physical damage.

Periodic Electrical Testing

Conduct electrical tests at regular intervals to detect and address any developing faults promptly. This includes checking for variations in voltage and resistance.

Brush Inspection

The brushes should be checked often to ensure good contact with the ring. The pressure of the brush on the ring must be monitored and adjusted as necessary. Replace the brushes once they reach their minimum length as indicated by the manufacturer.

Cleaning

Over time, debris and dust can accumulate on the slip ring, leading to problems like electrical noise or reduced conductivity. Consistent cleaning is required to prevent such issues. Avoid using harsh chemicals or abrasive materials for cleaning as they may damage the cable.

Lubrication

For some slip rings, suitable lubrication might be needed to maintain the smooth functioning of the rotary joint. Always use recommended safe lubricants; inappropriate ones can cause damage or wear.

Temperature Monitoring

Regularly monitor the temperature of the slip ring cable during operation. Excess heat can be a sign of an underlying issue, such as an electrical short or overloaded circuit.

Prompt Repairs

If any issue is detected during routine maintenance or operation, it should be addressed promptly to prevent further complications.

Remember, each slip ring cable will come with its manufacturer’s specific maintenance requirements. It is always advisable to follow those guidelines closely to ensure the effective operation of the cable.

Slip Ring Cable: Troubleshooting

Even with optimal maintenance, you may occasionally experience issues with a slip ring cable. Here are some common issues that might arise and possible ways to troubleshoot them:

Poor Quality Transmission

If there is a noticeable drop in the quality of transmission, visually inspect the slip ring and brushes for debris or scorch marks that might result from sparking. Clean the brushes and slip rings thoroughly as per the manufacturer’s instructions to fix this issue.

Excessive Electrical Noise

This issue is usually due to poor brush contact or worn-out brushes. Examine the condition of the brushes. If they are worn out, replace them. If they appear in good condition, adjust the brush tension to achieve optimal contact with the slip ring.

Overheating

Overheating may point to an overload condition or a frequency mismatch. Check your equipment’s operational demand against the power rating specified by the manufacturer. If everything aligns, contact professionals to check for possible frequency mismatch.

Vibrations or Mechanical Noise

If you notice unusual vibrations or noise, it may be an indication of installation issues such as misalignment or imbalance. Check whether the slip ring is properly fixed and aligned. If the issue persists, the internal bearing might be damaged and require replacement.

Inconsistent Performance

Inconsistent performance could indicate issues like wear, humidity impact, or substandard connections. Regular maintenance checks for cable connections, moisture absorption control strategies, and timely replacement of worn-out components can mitigate this issue.

Remember that troubleshooting should be approached with caution. Always ensure the system is powered off before investigating, and, in case of complex or persistent problems, it’s best to consult professionals or reach out to the manufacturer. These steps can increase the lifespan and maintain the reliability and efficacy of your slip ring cables.

Selecting the Right Slip Ring Cable

Choosing the right slip ring cable is critical, as the selection directly influences the operational efficiency, durability, and maintenance of the system. Here are some key considerations to help guide the selection process:

Application Requirements

Assess the specific needs of your application. Consider aspects such as the type and amount of data to be transmitted, the needed bandwidth, the speed of rotation, operating temperature, and environmental conditions such as humidity, dust, and vibration levels.

Type of Slip Ring

There are several types of slip rings, each suitable for different applications. They include pancake, capsule, through-bore, mercury, and fiber optic slip rings. Understand the benefits and limitations of each type and choose one that best fits your application.

Electrical Specifications

Evaluate the electrical requirements, including the number of circuits, current and voltage ratings, electrical noise tolerance, and signal type. Make sure to pick a slip ring cable that can handle the electrical load without excessive heat or noise generation.

Mechanical Properties

Consider the mechanical requirements such as mounting space, size, weight, and the expected duration and speed of rotation. These factors may affect the choice between a compact and a heavy-duty slip ring, among other things.

Material Quality

The quality of materials used in the slip ring cable—such as the conductivity of the metal used for the ring and brushes and the durability of the encasing material—influences performance and durability.

Maintenance Needs

Some slip rings may require more frequent maintenance than others. Choose a slip ring with maintenance requirements suitable for your operations, bearing in mind the skill level of available personnel and the costs associated with maintenance tasks.

Manufacturer Support and Warranty

Consider the support offered by the manufacturer, including their warranty policy, customer service availability, and any assistance they provide for installation, operation, and maintenance procedures.

Cost Effectiveness

Lastly, take into consideration the total cost, including purchasing price, installation fees, running costs, and anticipated maintenance and repair expenses. The cheapest option may not be the most cost-effective when all these factors are considered.

By considering these factors, you can ensure you select a slip ring cable that is ideally suited to your specific needs, performance requirements, and budget.

Conclusion

Slip ring cables are integral components in numerous applications necessitating the transfer of power, signals, or data between stationary and rotating parts. Proper installation, routine maintenance, efficient troubleshooting, and careful selection are the key aspects of handling these cables. Following the manufacturer’s instructions during installation and maintenance significantly contributes to their longevity and efficiency.

For successful troubleshooting, diagnosis and careful problem analysis are crucial, with professional consultation highly recommended in complex situations. Moreover, thoughtful consideration of factors such as application requirements, slip ring type, electrical and mechanical specifications, material quality, maintenance needs, and cost-effectiveness can facilitate the selection of the most suitable slip ring cable. By understanding these essential aspects, one can optimize the utilization and extend the service life of slip ring cables.

FAQs about Slip Ring Cable

Q: What is the lifespan of a slip ring cable?

A: The lifespan of a slip ring cable heavily depends on its usage and the environmental conditions. In general, with proper care and maintenance, it can last for millions of rotations.

Q: How do you clean a slip ring cable?

A: Cleaning should be done using a non-abrasive, non-residual cleaning agent. Always ensure that the power is disconnected before performing any cleaning or maintenance actions.

Q: What causes a slip ring cable to fail?

A: Some common causes of failure include incorrect installation, continual high rotation speeds, lack of regular maintenance, and abrasive environmental conditions.

Q: Can any slip ring cable transmit both data and power?

A: Yes, some types of slip ring cables are designed to transmit both data and power concurrently. However, it’s crucial to confirm this capability before employing them in dual capacity.