The role of slip rings in myriad industries cannot be overstated. These ingenious devices enable the transfer of electrical power and signals across rotating interfaces, paving the way for the smooth functioning of equipment in fields such as robotics, aerospace, wind energy, and manufacturing. Central to these assemblies are slip ring contacts, which form the critical link ensuring seamless transmission. This article aims to discuss and analyze the various types of slip ring contacts and their specific applications in depth, enabling readers to make informed decisions when selecting the contacts best suited to their needs.

As an industry professional with extensive experience in the design and manufacturing of slip rings, my goal is to guide you through the intricate world of slip ring contacts, helping you understand their characteristics, advantages, and limitations, and the factors to consider when choosing contacts for your application. This article is the result of years of hands-on experience, research, and the continuous pursuit to provide reliable, high-performance slip ring solutions to our clients. Combining theoretical knowledge with practical understanding, the article aims to deliver a comprehensive overview of slip ring contacts that is both coherent and grounded in real-world expertise.

By exploring the various types of slip ring contacts and their applications, you will be better equipped to make informed decisions and optimize the performance of your rotating systems. Understanding not only the types but also the nuances of their functionality can make all the difference when it comes to achieving the desired results in your projects.

Understanding Slip Ring Contacts

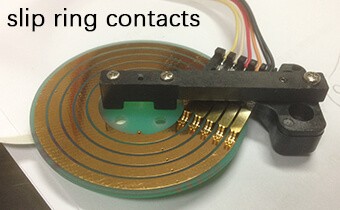

Before delving into the various types of slip ring contacts, it is vital to understand what they are and their fundamental role in the operation of slip ring assemblies. Slip ring contacts are key components situated within the larger body of the slip ring system. They are the point where the static part (stator) transfers electrical current, data, or signal to the rotating part (rotor), thus enabling the unimpeded rotation of machinery or system components while maintaining continuous electrical connectivity.

These contacts come in different forms – from classic metallic brushes to modern fiber optic brushes, each possessing unique properties that make them suitable for specific applications. They form the vital nexus where moving parts connect with stationary parts, providing the electrical continuity necessary for devices to operate without interruption. Without these contacts, the energizing of moving parts within a system or the transfer of important signals would be impractical, if not impossible.

Selecting the right slip ring contact for your application is, therefore, of paramount importance, and directly linked to the optimal performance of the overall system. Choosing the ideal contact can significantly enhance equipment function by minimizing signal interference, reducing maintenance time, increasing equipment lifespan, and improving overall system efficiency. Conversely, making an incorrect selection can lead to frequent breakdowns, higher maintenance needs, and compromised equipment performance. This underscores the importance of a thorough understanding of slip ring contacts, not just for engineers and technicians, but for all stakeholders involved, from project managers to system operators, and end-users.

Types of Slip Ring Contacts

Metal Slip Ring Contacts

Precious Metal Contacts

Precious metal contacts integrate gold, silver, and other precious metals. They provide low electrical resistance and high corrosion resistance, making them the go-to solution for the undistorted transfer of small signals.

Advantages:

- Superior electrical conductivity

- Exceptional corrosion resistance

- Optimal for precise, undistorted signal transmission

Disadvantages:

- High cost due to the use of precious metals

- Not suitable for high-load applications due to metallic softness

Non-Precious Metal Contacts

Non-precious metal contacts commonly use copper, brass, and other similar metals, offering a balance between cost-effectiveness and acceptable conductivity.

Advantages:

- Good electrical conductivity

- Cost-effective

Disadvantages:

- Potential for corrosion over time

- High coefficient of friction, resulting in more wear

Composite Contacts

Graphite and Metallic Brushes

These contacts are a composite of graphite and metal, offering good conductivity and lubrication properties.

Advantages:

- Graphite offers excellent lubrication

- Compatible with a diverse range of applications

Disadvantages:

- Generation of dust during operation

- Possible maintenance issues due to dust build-up

Coin Contacts

Ideal for compact installations, coin contacts offer low electrical noise and longer service life with a limited current carrying capacity.

Advantages:

- Minimal electrical noise

- Reduced wear

- Extended service life

Disadvantages:

- Limited current-carrying capacity due to design constraints

Fiber Brush Contacts

Fiber-optic Brushes

Offering high-speed data transmission with negligible electrical noise, fiber-optic brushes are perfect for applications requiring power and data transfer.

Advantages:

- Uninterrupted high-speed data transmission

- Negligible electrical noise

Disadvantages:

- Higher cost

- Limited to specialized use cases

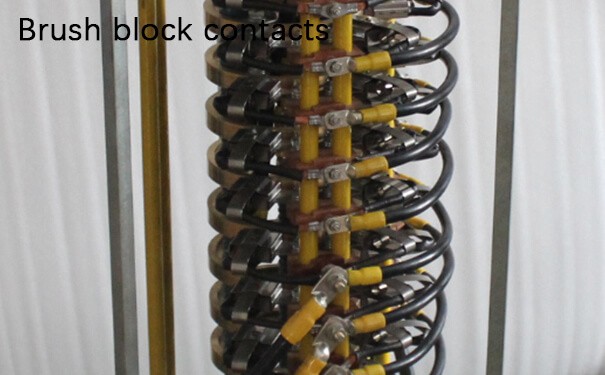

Brush Block Slip Ring

The slip ring of the brush block is known as the slip ring of the carbon brush. It is the earliest slip ring form with a simple configuration and is usually used for the transmission of current and simple signals. It still has advantages in high-power transmission (above 1000A). The conductive block is made of graphite and metal alloy, which is pressed by a spring and can always keep in contact with the conductive ring in case of certain vibrations and impact. It is easy to wear and produces a lot of conductive dust during operation, which needs regular maintenance.

Advantages:

- High carrying power

- Easy to use

- The brush block can be purchased and replaced separately

- Low cost

Disadvantages:

- Regular and continuous maintenance is required

- It can’t transmit precise signals, such as bus signals, thermocouple signals, etc

- It can produce sparks due to dust

- Electrical noise

Wire Brush Slip Ring

It is the most widely used and flexible type at present. The shape and style are changeable. The cap-type slip ring can be a single-wire brush, and the larger through-hole slip ring can be a multi-wire brush. Due to the small contact point, the brush wire is mostly made of gold-plated copper, silver, and other precious metals. There is little wear and dust during the service life, so it can be used maintenance-free.

The metal brush is made of several thin wires, which can provide the best contact quality and service life. No matter it is high power or various complex signals, it can be effectively transmitted.

Advantages:

- It is suitable for most occasions requiring rotary transmission

- Most of the precision signal, high-frequency signal transmission

- Maintenance free use

- Low electrical noise

- It can be configured with hundreds of circuits

- The high degree of customization

Disadvantages:

- High cost

- Low degree of standardization

Liquid Metal Slip Ring

Mercury is usually placed in a metal seal. No brush block or wire is used, and liquid metal is directly used as a medium to conduct electricity or transmit signals. Due to the limitation of RoHS, even though Mercury slip rings have the advantages of long life, low cost, and stable performance, they are only used in a few markets in the world.

Advantages:

- low cost

- Long life

- High current density

Disadvantages:

- It contains harmful heavy metals

- Unable to configure hundreds of circuits

- Low degree of customization

Wireless Transmission Slip Ring

Wireless transmission conductive slip ring is a new type of product (optical fiber slip ring for signal transmission is not discussed for the moment). Based on the principle of capacitive or inductive coupling, the power and signal can be transmitted wirelessly by means of a high-frequency excitation coil without contact between rotating components and static components.

The efficiency of wireless transmission is far less than the others, not only the transmission power is low, but also the distance between the two components is limited, which is the smallest application range among the four kinds of methods.

Advantages:

- No wear

- Maintenance free

- High protection level

Disadvantages:

- It can only transmit a weak current

- Low transmission efficiency

- Low degree of customization

Factors to Consider in Selecting Slip Ring Contacts

Application-specific Requirements

The choice of the contact type revolves around the exact requirements of the application. For instance, systems requiring high-speed data transmission may be best served by fiber-optic brushes, while applications involving small signal transmission might perform best with precious metal contacts. Understanding the specific needs of your application is crucial to make an informed selection.

Electrical Conductivity and Resistance

Electrical conductivity and resistance are key parameters when choosing contacts for power transmission applications. Metals with high conductivity, such as gold for precious metal contacts and copper for non-precious ones, deliver better performance in terms of energy transfer efficiency.

Wear and Service Life

The durability of a contact material directly impacts the service life of the slip ring. For instance, contacts made from softer materials such as gold may wear out faster under high-load applications than their harder counterparts like carbon composite contact materials. Thus, assessing the prospective levels of wear and tear in the intended application is vital.

Contact Pressure, Noise, and Vibration

These aspects can significantly impact the performance of devices. The contact pressure should be sufficient to ensure a reliable electrical connection but not so high as to cause rapid wear. Likewise, low noise and vibration levels are desirable to promote both efficient operation and user comfort in noise-sensitive applications.

Environmental Conditions and Corrosion Resistance

The ability of contact materials to withstand adverse environmental conditions is crucial, especially for slip rings operating in harsh conditions. For those used outdoors or in corrosive atmospheres, corrosion-resistant materials like gold or silver might be the best choice. On another hand, high-temperature applications might need contacts made from materials that withstand extreme heat.

Cost and Maintenance

These are crucial factors affecting ongoing operation and maintenance expenses associated with the use of slip ring contacts. While precious metal contacts may be more expensive, they might present lower maintenance needs and longer service life, which could translate to more cost savings in the long run.

Selecting the appropriate slip ring contact encompasses balancing these considerations to meet your unique working conditions, performance needs, and budget constraints. Comprehensive knowledge on this subject can significantly enhance equipment function, reduce maintenance time, and uplift the equipment lifespan, and overall system efficiency.

Applications and Examples of Slip Ring Contacts

Specific Applications for Each Type of Contact

Precious Metal Contacts:

Due to their superior conductivity and resistance to corrosion, precious metal contacts are most commonly used in sensitive instruments such as medical devices and scientific research equipment, where a slight distortion in the electrical signal could lead to significant inaccuracies.

Non-Precious Metal Contacts:

These are typically used in industrial applications like conventional rotary machines, wind turbines, and power generators, where the focus is on cost-effectiveness and the applications can tolerate some degree of signal distortion or resistance.

Graphite and Metallic Brushes:

Graphite and metallic brushes, with their self-lubrication property and acceptable conductivity, are used extensively in applications like electric motors and alternators, where moderate frictional wear is tolerable.

Coin Contacts:

Coin contacts’ compact design and robust construction make them suitable for installations where space is a constraint, as seen in closed-circuit television (CCTV) camera systems.

Fiber-optic Brushes:

These are predominantly used in data-intensive applications where high-speed data transmission is required without noise distortion. An excellent example is modern network equipment requiring non-interrupted streaming and real-time data communication.

Industry Examples and Case Studies

Aerospace:

In the aerospace industry, slip rings play a critical role in the operation of satellites. Sophisticated configurations are used, typically involving fiber-optic brushes for data transmission, precious metal contacts for power, and mechanical variants to suit the design of the spacecraft.

Wind Energy:

In the wind energy sector, large wind turbines employ slip rings for power generation. Non-precious metal contacts or graphite and metallic brushes are common due to their cost-effectiveness and the large-scale, high-load nature of the application.

Medical Imaging:

Medical imaging technology, such as CT scanners and MRI machines, requires precise signal transfers and thus uses precious metal contacts for their superior performance.

Expert Recommendations

Selecting the most appropriate slip ring contact is typically dependent on the application in question, and it’s recommended to involve experts in this decision-making process. As a general guideline, considerations should include the nature of the application, performance requirements, environmental factors, and cost.

No single type of contact suits all possible scenarios. Hence, a thorough understanding of each contact’s strengths and weaknesses is vital for making an informed decision. For example, an application demanding high-speed data transmission might be better served by fiber-optic brushes, while a cost-effective, high-load application might be better suited to non-precious metal contacts.

Understanding the way slip ring contacts are used in different industries and applications helps make more informed choices about the best solution for a specific need. By considering the practical demands of your unique application and industry, you can choose a slip ring contact that optimizes performance, durability, and cost-effectiveness.

Need a custom slip ring solution? Contact us by filling out the form.

Industry Examples of Various Types of Slip Ring Contacts

Automotive Manufacturing

In the automotive manufacturing industry, slip ring contacts are crucial for robotic arms used in assembly line processes. Generally, non-precious metal contacts or graphite and metallic brushes are used for these applications, as they provide a balance between acceptable conductivity and cost-effectiveness.

Offshore Drilling Platforms

Offshore drilling platforms use slip ring contacts for transferring data, power, and control signals to underwater equipment, such as remotely operated underwater vehicles (ROVs). The harsh marine environment requires contacts with high corrosion resistance, making precious metal contacts the ideal choice. However, graphite and metal brushes with adequate protective coatings could also be used in some cases.

Amusement Parks

Amusement parks use slip rings in a variety of applications, such as rotating signs, Ferris wheels, and roller coasters. Depending on the specific needs of the ride or attraction, slip ring contacts might range from non-precious metals for cost-effective power transmission to fiber-optic brushes for smooth data transmission related to control systems.

Defense and Aerospace

Defense and aerospace applications, including radar systems, missile guidance systems, and UAVs (Unmanned Aerial Vehicles), demand sophisticated and reliable slip ring contacts. Precious metal and fiber-optic contacts are common choices in these scenarios for their high conductivity, low electrical noise, and resistance to environmental factors.

Expert Recommendations for Choosing the Most Suitable Slip Ring Contact

To determine the best slip ring contact for a specific application, consider the following recommendations:

- Analyze the application requirements: The primary consideration should be the specific requirements of the application, such as data transmission, power requirements, and signal integrity.

- Consider environmental factors: Environmental conditions, such as temperature, humidity, and exposure to corrosive elements, should be taken into account when choosing a slip ring contact material. This will help ensure that the contract can withstand long-term usage in challenging conditions.

- Assess wear and service life: Evaluate the anticipated wear, the required service life, and the maintenance costs of different contact materials based on the intended application. This can help you strike the right balance between performance, durability, and cost.

- Consult with experts: Consult with slip ring manufacturers and engineers who have experience in your industry and application. They can provide valuable insights into the best contact type for your specific needs, taking all the factors mentioned above into consideration.

- Be prepared to customize: Finally, be prepared to work with manufacturers and engineers to design a custom slip ring solution that meets your unique requirements. This might involve a hybrid approach, combining multiple contact types to achieve the desired performance.

By carefully considering these expert recommendations, you can make an informed decision about the most suitable slip ring contact for your specific application, ensuring optimal performance, reliability, and longevity.

Innovations and Trends in Slip Ring Contact Technology

Latest Advancements in Slip Ring Contact Materials and Designs

One of the significant advancements in slip ring contact technology is the development of higher conductivity and more durable materials. These include the use of novel alloys or composite materials, which possess superior corrosion resistance or self-lubrication properties. For example, the growing adoption of silver-graphite material, known for its excellent conductivity and low friction, is evident in more demanding applications.

There’s also a trend towards designing slimmer and more compact slip rings for applications where space is at a premium. Additionally, the constant pursuit of longer service life and reduced maintenance has led to innovations like seamless contact surfaces and the use of advanced lubricants to minimize wear and tear.

Adoption of New Technologies: Nanotechnology and Smart Materials

The integration of nanotechnology in the development of new slip ring contact materials has opened up possibilities for improving conductivity, friction resistance, and wear resistance. For instance, by manufacturing contacts coated with nano-scale layers or additives, engineers are creating materials that can significantly enhance performance, durability, and overall service life.

Furthermore, the adoption of smart materials, such as electro-rheological fluids, can introduce variable stiffness in slip ring contacts. This can adaptively conform to the irregularities of the contact surface, reducing vibration, noise, and contact resistance, and increasing service life.

Future Trends and Potential Impact on Performance

The push towards digitization and the increased demand for high-speed data transmission are influencing the trends in slip ring contact technology. For instance, we foresee a growing demand for hybrid slip rings that can carry both power and high-speed data in industries like telecommunications, aerospace, and defense.

Another promising direction is the development of wireless slip rings or ‘contactless’ slip rings, which eliminate physical contact altogether. These make use of electromagnetic or optical technologies to transmit power and signals between the rotating and stationary components, eliminating issues associated with wear and tear.

Finally, with the increasing prevalence of IoT (Internet of Things) and Machine Learning technologies, more intelligent and self-monitoring slip rings may come into play. These could offer real-time diagnostics and predictive maintenance capabilities, significantly reducing maintenance costs and improving system reliability.

In conclusion, the future of slip ring contact technology is evolving rapidly, driven by continuous innovations and advancements. As new materials and designs come to the forefront, we can expect to see slip rings capable of higher performance, greater efficiency, and extensive service life.

Conclusion

Understanding the differences among various slip ring contacts is crucial for ensuring optimal performance. Readers are encouraged to apply the knowledge from this article in choosing and maintaining slip ring contacts in their applications.

FAQs about Slip Ring Contacts

Q: What are slip ring contacts?

A: Slip ring contacts, also known as ‘brushes’, are an essential part of a slip ring assembly that transfers electrical signals, data, and power between a stationary and a rotating component in a device or a system. Depending on the application, slip ring contacts can be made from different materials, including precious metals, non-precious metals, graphite, and fiber-optic materials.

Q: How do slip ring contacts work?

A: Slip ring contacts work by maintaining a continuous electrical connection between stationary and rotating parts. When the machine or device operates, the contact (brush) allows power or signals to be passed along its length by touching the rotating ring, while the current or data is transferred to or from the stationary part.

Q: What materials are used in slip ring contacts?

A: The choice of material largely depends on the application. Precious metals like gold and silver are known for their excellent conductivity, low resistance, and corrosion resistance. They are often used in sensitive applications that require precise signal transfers. Non-precious metals and graphite materials are used for their cost-effectiveness and decent conductivity. Fiber-optic brushes – made of fibers that transmit light – are used for high-speed, noiseless data transmission.

Q: How do I select the right slip ring contact for my application?

A: Choosing the right slip ring contact involves considering several factors such as the nature of the application, the environmental conditions, and the expected service life. Ideal contact material should offer required conductivity, minimal resistance, and appropriate durability, and must be cost-effective for your specific usage. It’s highly recommended to involve experts in this selection process for an informed decision.

Q: What are the latest trends in slip ring contact technology?

A: Advancements in contact materials and designs, adoption of nanotechnology and smart materials, and increased data transmission demands are shaping the future of slip ring contact technology. Trends also point towards hybrid slip rings for simultaneous power and data transfer, ‘contactless’ slip rings for eliminating physical wear and tear, and intelligent slip rings with IoT and Machine Learning for real-time diagnostics and predictive maintenance.

Ready to learn more about our slip rings? Complete the form below to get started.