The unsung heroes behind smooth power transmission in rotating systems.

In the intricate world of electrical engineering, the quest for seamless power transmission in rotating systems has led to the invention of remarkable devices known as electrical slip ring brushes. These unsung heroes play a crucial role in maintaining uninterrupted electrical connectivity in rotating machinery, ensuring smooth operations and reliable performance. Today, we dive into the realm of electrical slip ring brushes, unraveling their ingenious design and the impact they have on various industries.

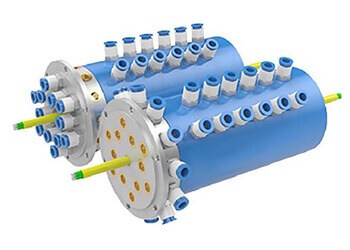

The Brushed Connection: Electrical slip ring brushes serve as the vital link between stationary and rotating components in a wide range of applications. They enable the transmission of electrical power from a fixed source to a rotating part, ensuring uninterrupted electricity flow even during continuous rotation. By utilizing a combination of brushes and rings, these devices establish a frictional contact that maintains a steady electrical connection, allowing for the transfer of power and signals across the rotating interface.

Enabling Seamless Power Transmission: The primary function of electrical slip ring brushes is to facilitate the smooth transmission of electrical power in rotating systems. As the brushes make contact with the rings, they create a conductive path that allows electrical current to flow from the stationary side to the rotating side. This seamless power transmission is essential in applications such as wind turbines, rotating machinery, and electrical generators, where continuous and reliable power delivery is critical for optimal performance.

The Ingenious Brush Design: Electrical slip ring brushes are meticulously engineered to ensure efficient power transmission while minimizing wear and tear. The brushes are typically made of high-quality carbon or graphite materials, known for their excellent electrical conductivity and durability. The brushes are designed to exert a controlled amount of pressure against the slip rings, ensuring reliable contact and minimizing the risk of electrical arcing or signal loss. This precision engineering allows the brushes to maintain a consistent and reliable electrical connection, even in demanding environments.

Versatility and Adaptability: Electrical slip ring brushes exhibit versatility and adaptability, making them suitable for a wide range of applications. They can be designed to accommodate various voltage and current levels, allowing for compatibility with diverse power requirements. Additionally, the number of brushes and rings can be customized to meet specific application needs, ranging from just a few to dozens or more. This flexibility enables electrical slip ring brushes to cater to a broad spectrum of industries, including manufacturing, automation, robotics, and renewable energy.

Ensuring Longevity and Reliability: To ensure long-term performance and reliability, electrical slip ring brushes require regular maintenance and periodic replacement. The brushes may wear down over time due to friction and continuous use, which can lead to degraded performance and potential electrical issues. However, advancements in brush materials and designs have significantly improved their durability and lifespan. Manufacturers often provide guidelines and recommendations for proper maintenance and brush replacement, allowing users to maximize the longevity and reliability of their electrical slip ring systems.

Advancements in Brush Technology: The field of electrical slip ring brushes continues to witness advancements in technology and materials. Researchers and manufacturers are continuously exploring innovative brush materials that offer enhanced conductivity, reduced friction, and improved wear resistance. These advancements aim to further optimize the performance of electrical slip ring brushes, ensuring even smoother power transmission, increased efficiency, and prolonged service life.

The importance of electrical slip ring brushes cannot be overstated. Their ingenious design and reliable performance enable seamless power transmission in rotating systems, ensuring the smooth operation of critical machinery across various industries. As technology continues to evolve, electrical slip ring brushes will continue to play a crucial role in driving innovation, efficiency, and reliability in rotating systems.

In the quest for uninterrupted power and smooth operations, electrical slip ring brushes remain the unsung heroes that silently enable the seamless transmission of electrical energy, revolutionizing industries and powering progress in the ever-evolving world of engineering.

See What We Can Do