Your Reliable Electrical Slip Rings Supplier in China

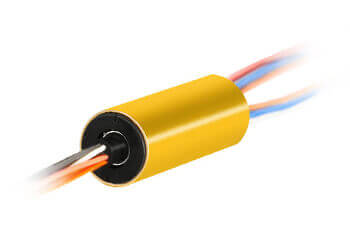

If you are looking for electrical slip rings for transmitting electrical signals, power or data from stationary equipment to rotating equipment, then Grand is your trusted slip ring manufacturer in China.

Provide through hole slip ring, capsule slip ring, ethernet slip rings, miniature slip rings, pin slip rings and other electrical slip rings can be used in wind turbines, robots, medical equipment and monitoring systems.

Slip rings with different parameters and different performances are suitable for different industries and environments. Send us your detailed requirements, and we will have a quick response and quotation.

High Quality Electrical Slip Rings

Electrical slip rings can transfer power or signals from something fixed to a point on a rotating object. It can connect rotating and stationary equipment in any electromechanical system that needs to rotate and can transmit current and signals 360 degrees without limit. The ring body and brushes are the main parts of an electrical slip ring.

Rotating Electrical Connectors Features

- High Electrical Performance: Electrical slip rings offer reliable transmission of power, signals, and data between stationary and rotating parts without any loss of signal or degradation in performance.

- Customizable Configurations: Electrical slip rings come in a range of customizable configurations to suit specific applications, including the number of circuits, current ratings, voltage ratings, and data transfer rates.

- Versatile Applications: Electrical slip rings are suitable for use in various applications, including wind turbines, robotics, medical equipment, packaging machines, and amusement park rides.

- Durable Construction: Electrical slip rings are designed for long-term use and can withstand harsh environments such as extreme temperatures, high humidity, and corrosive substances.

- Low Maintenance: Electrical slip rings require minimal maintenance, making them ideal for applications where maintenance access is limited or restricted.

- Easy Installation: Electrical slip rings are easy to install and require minimal training and expertise to operate.

- Cost-effective: Compared to other methods of transferring signals and power between stationary and rotating parts, electrical slip rings are cost-effective and offer a reliable solution.

How Electrical Slip Rings Work

An electrical slip ring is a critical component used to transmit electrical signals, power, or data between rotating and stationary parts in a system. The key functionality of a slip ring lies in its ability to allow for continuous rotation without losing electrical connectivity, making it an essential device for applications where rotating machinery needs to be powered or communicate signals without the hassle of twisting cables or wires.

At the heart of the design are two main components: the rotating ring (the rotor) and the stationary brushes (the stator). As the rotor rotates, the brushes remain in contact with the rings, transferring electrical signals or power from the rotating part to the stationary part of the system, or vice versa. This design allows a continuous electrical connection to be maintained, regardless of the number of rotations the system undergoes.

In some configurations, these components are assembled into a slip ring assy or slip ring assembly, where all the key parts are mounted together to form a complete working unit. These slip ring assemblies can be customized to suit specific applications, ensuring that the required electrical connections are made seamlessly. In certain specialized setups, pancake slip ring assemblies may be used for applications requiring low-profile designs.

Key Components of Electrical Slip Rings

Rotating Rings (Rotor)

These are typically made of conductive materials like copper, silver, or gold. These rings rotate with the machinery, providing a conductive surface for the electrical contact to occur. The rotating rings are typically mounted on a shaft or rotor assembly, and their design is crucial for maintaining consistent electrical contact with the brushes.

Brushes (Stator)

The brush slip ring is the stationary part that maintains constant contact with the rotating rings. These brushes are typically made from materials like carbon, graphite, or metal alloys. The brushes carry the electrical current from the rotating rings to a fixed point in the system, ensuring that the flow of electricity or signals is maintained even as the rings rotate. Depending on the application, multiple brushes may be used to transfer different signals or currents. Some designs feature brush rings that encircle the rotor for improved durability and stability.

Insulation

To prevent short circuits and ensure safety, the components in the slip ring are insulated from each other. Insulating materials such as ceramics or plastic compounds are used to ensure that the electrical contact remains contained within the conductive parts. Insulation is especially important in systems where high-voltage transmission is involved.

Bearings

Bearings help the slip ring to rotate smoothly and minimize friction, which can wear down the components over time. They support the rotating rings, allowing them to move freely without significant resistance. Ball bearings or roller bearings are commonly used for this purpose.

Protective Housing and Seals

To protect the internal components from environmental contaminants such as dust, moisture, and other elements, electrical slip rings are often housed in protective enclosures. Seals are used to keep contaminants out while ensuring smooth rotation and minimizing wear on the slip ring’s internal components.

Working Principle of Electrical Slip Rings

Rotating Action

As the rotor (the rotating ring) spins, the stationary brushes maintain continuous contact with the surface of the rotating ring. This allows the transmission of electrical current or data signals across the rotating connection. The slip ring connectors facilitate this transfer, enabling a seamless connection between the rotating and stationary parts.

Electrical Contact

The brushes apply pressure on the rings, maintaining a low-resistance connection that transmits electrical signals or power. The friction between the brushes and rings allows for the reliable transfer of electricity, ensuring that the rotating part can be powered or communicate without interruption. In some configurations, a rong brush (a misalignment-resistant brush) is used to ensure consistent contact, especially in high-vibration environments.

Seamless Transmission

This design enables continuous rotation of the machine while the electrical signals or power are passed from the fixed to the rotating part (or vice versa). It eliminates the need for complicated wiring or connectors that could break or wear out due to constant movement. In many systems, slip ring assemblies are designed to handle multiple channels for power and signal transmission, enhancing the versatility of the device.

In specialized applications, electrical slip ring assembly are used to provide a comprehensive solution for transmitting data, power, and signals through rotating interfaces. These assemblies can include several channels for multiple signal types, making them ideal for applications where high electrical performance and durability are required.

Ring Classification

Rings are classified in various ways depending on their type, function, and application across different industries. Here, we will look at ring classification based on materials, structure, function, and specific uses.

Material-Based Classification

Rings can be classified based on the material used in their construction. Different materials are chosen for their properties, such as conductivity, durability, corrosion resistance, and more.

a. Metal Rings

Copper Rings: Commonly used in electrical applications, copper rings are known for their high conductivity. They are used in electrical slip rings, electrical connectors, and rotating machinery.

Aluminum Rings: Lighter and more cost-effective than copper, aluminum rings are often used in applications where weight reduction is important.

Steel Rings: Steel rings are strong and durable, often used in heavy-duty mechanical systems. They are typically used in industrial applications requiring high strength and resistance to wear.

Precious Metal Rings: Materials like silver, gold, or platinum are used in specialized applications where high electrical conductivity or resistance to oxidation is necessary. They are often used in high-precision electronics.

b. Rubber Rings

Neoprene Rings: Often used in sealing applications, neoprene rings are resistant to oil, weather, and temperature fluctuations.

Silicone Rings: These rings have high flexibility and resistance to high temperatures, making them ideal for medical, automotive, and aerospace applications.

c. Composite Rings

Carbon Fiber Rings: Used in lightweight applications, carbon fiber rings combine strength and low weight. They are often used in aerospace or racing applications.

Ceramic Rings: Ceramic rings are used in high-temperature or abrasive environments due to their heat resistance and wear properties.

Structure-Based Classification

Rings can also be classified based on their shape, structure, and design.

a. Solid Rings

Solid Metal Rings: Typically used in mechanical systems for structural integrity, solid rings are made from a single piece of material, offering high durability and strength.

Solid Rubber Rings: Often used as seals or gaskets, solid rubber rings are designed to prevent leakage and offer cushioning.

b. Hollow Rings

Hollow Rubber Rings: Used in sealing applications, hollow rings are compressible and can adapt to changes in pressure, offering a flexible sealing solution.

Hollow Steel Rings: These rings are often used in bearings, as the hollow center allows for reduced weight without compromising strength.

c. Split Rings

Split Metal Rings: These are rings that are divided into segments to make them easier to install or remove in mechanical systems. They are commonly used in fasteners or as retaining rings.

Split Rubber Rings: Used in sealing applications, split rubber rings can be installed without dismantling the entire system, which is particularly useful for maintenance and repairs.

Function-Based Classification

Rings are also classified by their intended function, which can range from mechanical support to electrical conductivity.

a. Mechanical Rings

Retaining Rings: These are used to secure components within a mechanical assembly. They prevent parts from sliding off a shaft or moving out of place.

Bearing Rings: Used in bearings, these rings allow for smooth rotation or movement of mechanical components, often seen in motors or vehicles.

b. Sealing Rings

O-Rings: These are circular seals made from rubber or other flexible materials. O-rings are commonly used to prevent leakage of fluids or gases between two surfaces.

Gasket Rings: Often used in piping or machinery, gasket rings help to create a seal between two flat surfaces and prevent the passage of fluids or gases.

c. Electrical Rings

Slip Rings: In applications like rotating electrical machinery, electrical slip rings are used to transfer power or data from a stationary part to a rotating part without the use of wires that would twist or wear. These electrical slip rings are crucial for maintaining continuous electrical connections in rotating systems.

Ring Connectors: These rings are used to connect wires in a circular form, typically in electrical systems, to ensure reliable and stable connections.

Modular Slip Rings: A modular slip ring mechanism allows for easy customization by adding or removing modules, providing flexibility in design and functionality. Modular slip rings are particularly useful when complex or multi-functional connections are needed.

Hydraulic Slip Ring: Specifically designed for use in hydraulic systems, hydraulic slip rings transmit power or signals between rotating and stationary components in hydraulic machinery, ensuring efficient operation in industrial settings.

Hydraulic Slip Ring: This version of a hydraulic slip ring is particularly used in hydraulic-powered applications, where the slip ring must handle both electrical and hydraulic fluid transmission within a rotating system.

Application-Based Classification

Rings can also be classified based on the industries or sectors in which they are used.

a. Industrial Rings

Conveyor Belt Rings: Used in conveyor systems, these rings are often made from high-strength materials and are designed to withstand harsh operating conditions.

Valve Rings: These rings are used in valves to control the flow of liquids or gases in pipelines.

b. Aerospace Rings

Heat Shield Rings: Used in aerospace, these rings provide thermal protection to high-speed aircraft or spacecraft.

Structural Rings: Used for load-bearing purposes in aircraft, these rings are typically made from lightweight, high-strength alloys.

c. Automotive Rings

Piston Rings: Found in the internal combustion engine of vehicles, piston rings provide a seal between the piston and cylinder wall to prevent leaks.

Suspension Rings: These rings are part of the suspension system, providing support and flexibility for vehicle dynamics.

d. Medical Rings

Orthopedic Rings: Used in medical applications, such as implants or surgical tools, these rings are designed to provide support or flexibility in the body.

Sealing Rings for Medical Devices: Used to prevent contamination or leakage in medical equipment and devices.

Additional Considerations

Tariff Rings: These are rings used to modify or control the costs of certain components or materials, often related to the international trade or procurement of materials.

Signaling Industrial Hydraulics: In systems where both electrical signals and hydraulic power are used, signaling industrial hydraulics involves combining electrical slip rings with hydraulic components to enable communication and power transmission within the same system.

Slip Ring Price: The price of electrical slip rings varies depending on the material, design, and complexity of the system. Manufacturers may offer different pricing based on customization and application needs.

The HS Code for Slip Rings

HS Codes, or Harmonized System Codes, play a crucial role in global trade by classifying products for tariff, tax, and customs purposes. Correct classification ensures that international shipments flow smoothly through customs, with fewer delays and fewer unexpected costs. For example, slip ring HS code is used to properly classify electrical slip rings and their various designs, such as brush slip rings, hydraulic slip rings, and modular slip rings. Similarly, the cylinder assembly HS code is used to classify hydraulic cylinder assemblies and similar mechanical parts, ensuring accurate tariff rates and duties are applied.

HS Code for Slip Rings and Their Uses

Slip rings are essential components in many industrial applications where electrical signals or power need to be transmitted between stationary and rotating parts. These components are commonly used in machinery such as wind turbines, radar systems, rotating equipment, and various automated systems.

HS Code 8544.49 – This code is primarily used for electrical machinery and equipment parts, including slip rings. It covers slip rings that are not classified elsewhere in Chapter 85 and includes a wide variety of electrical slip rings, brush slip rings, modular slip rings, and pancake slip rings.

Specific Components Included:

Electrical Slip Rings: Used to transmit power or data while allowing continuous rotation.

Brush Slip Rings: Components where brushes maintain constant contact with rotating rings to ensure uninterrupted power transmission.

Hydraulic Slip Rings: Slip rings designed for hydraulic systems, incorporating hydraulic fluid to transmit power.

Slip Ring Assemblies: Complete units that combine the rotor (rotating rings) and brushes in a functional assembly for industrial use.

Modular Slip Rings: Customizable slip ring assemblies designed for specific industrial applications that require modular setups for easy assembly or replacement.

These components play a crucial role in industries such as signaling, industrial hydraulics, aerospace, and energy generation, where systems often involve rotating machinery that needs to maintain electrical connectivity without complex wiring that could twist or wear out.

How HS Codes Affect International Trade

HS Codes, or Harmonized System Codes, play a crucial role in global trade by classifying products for tariff, tax, and customs purposes. Correct classification ensures that international shipments flow smoothly through customs, with fewer delays and fewer unexpected costs. Here’s an expanded look at how HS Codes affect electrical slip rings, hydraulic slip rings, cylinder assemblies, and other industrial components in the context of international trade.

Determine Tariffs and Duties

When goods cross borders, customs authorities rely on HS Codes to determine the appropriate tariff rates and customs duties that apply to the products being imported or exported. Each HS Code corresponds to a specific duty rate based on the product’s classification. Misclassifying a product with an incorrect HS Code can lead to the wrong tariff being applied, resulting in:

Overpayment of Duties: A product may be classified under a category with higher tariffs, resulting in unnecessarily high costs.

Underpayment of Duties: On the other hand, misclassification might lead to underpayment of duties, which can result in fines, penalties, or confiscation of goods if discovered during a customs audit.

For example, the HS Code for electrical slip rings may have a different tariff rate than a related component, such as a hydraulic slip ring. Ensuring the correct classification helps businesses avoid costly tariff errors.

Simplify Customs Clearance

One of the key functions of the HS Code is to expedite the customs clearance process. When products are shipped internationally, customs authorities use the HS Code to quickly assess what the goods are, their country of origin, and their classification for regulatory purposes. If the correct HS Code is used:

Faster Processing: Customs officers can easily identify the product’s classification and calculate any applicable taxes or duties, allowing goods to clear customs more quickly.

Reduced Risk of Delays: Misclassification or ambiguity about a product’s HS Code can lead to delays as customs authorities may need additional information or clarification before approving the shipment. Incorrect classifications often trigger customs examinations, further slowing down the process.

For example, a cylinder assembly may be quickly processed under an accurate HS Code 8412 for hydraulic systems, while a misclassified part could cause unnecessary holdups in the clearance process.

Avoid Additional Costs

Incorrect classification of goods, whether it be electrical slip rings, hydraulic slip rings, or cylinder assemblies, can result in several additional costs. These can include:

Penalties and Fines: Customs authorities may impose penalties for incorrect tariff classification, especially if misclassification is deemed intentional or if it leads to significant revenue losses for the government.

Storage Fees: If shipments are held up at customs due to misclassification, additional storage fees may be incurred. This is especially true for goods that are required to undergo physical inspection or further documentation checks.

Legal Costs: If the misclassification leads to legal disputes or audits, businesses could face high legal fees to resolve the issue. Delays caused by misclassification could also lead to operational disruptions, affecting production schedules and delivery timelines.

For example, a hydraulic slip ring incorrectly classified as a non-hydraulic component could trigger fines and delays, affecting overall supply chain efficiency.

Regulatory Compliance and Trade Agreements

HS Codes also play a crucial role in complying with international trade agreements and regulatory standards. Many countries and regions have trade agreements that provide duty-free or reduced-duty status for certain products. To qualify for these benefits, goods must be correctly classified under the appropriate HS Code.

For instance:

Trade Agreements: Under agreements such as NAFTA (North American Free Trade Agreement), EU Customs Union, or ASEAN Free Trade Area, products that meet certain criteria may be eligible for reduced tariffs or preferential treatment. Misclassifying these products could cause a company to lose these benefits.

Regulatory Compliance: Products in certain categories, such as electrical components (like electrical slip rings) or hydraulic systems (like hydraulic slip rings), may be subject to specific safety or environmental regulations. Accurate HS Code classification ensures compliance with these regulations, avoiding the risk of fines or product recalls.

Improved Supply Chain Efficiency

Using the correct HS Code for slip rings, cylinder assemblies, and similar components can contribute to smoother and more efficient global supply chains. The more accurately products are classified:

Reduced Risk of Return Shipments: Incorrect HS Codes could lead to products being rejected or returned, especially if the product does not meet local regulations or standards.

Streamlined Ordering and Inventory: Accurate classification allows businesses to forecast and manage inventory more effectively, particularly when dealing with international orders and suppliers. When products are correctly classified, it is easier to identify them in inventory systems and streamline the ordering process.

Power Slip Ring Market Overview

The power slip ring market refers to the global market for electrical components that allow the transmission of electrical power and signals between stationary and rotating parts in industrial and commercial applications. Power slip rings are crucial in systems where continuous rotation is required without losing electrical connectivity, such as in wind turbines, cranes, radar systems, rotating machinery, and industrial robots. These components are used in industries like aerospace, energy, automotive, and manufacturing.

Additionally, slip ring assemblies manufacturers play a critical role in designing and producing complete slip ring units that integrate the rotating rings and brushes, essential for efficient power transmission in rotating systems. Our company, Grand, offers a wide range of slip rings and slip ring assemblies designed for various industrial applications. You can explore our full range of products and services by visiting grandslipring.com.

In parallel, the conductive slip ring market continues to grow as industries demand more efficient, reliable, and customizable slip ring solutions. As the market for power slip rings, custom sliprings, and modular slip rings expands, companies are increasingly focusing on developing conductive slip rings to meet the evolving needs of automation, renewable energy, and other high-tech applications.

Key Market Drivers

Increasing Demand for Renewable Energy

The growing need for renewable energy sources, such as wind power, is a significant driver for the power slip ring market. Wind turbines rely on power slip rings to transmit electrical power from the rotating blades to the stationary grid.

Advancements in Automation and Robotics

As industries embrace automation and robotics for manufacturing and assembly, the demand for power slip rings is rising. Power slip rings are vital for transmitting power to robotic arms, rotating conveyors, and automated assembly lines without the risk of tangling or wear from constant movement. This growing demand has led to the development of custom engineering slip rings tailored to specific automation needs.

Growth in Aerospace and Defense

The aerospace and defense sectors also contribute to the market growth as power slip rings are used in radar systems, satellite communication systems, and other mission-critical equipment where continuous electrical connection is essential.

Miniaturization and Customization

Increasing demand for miniaturized and highly customizable slip rings has driven manufacturers to develop more compact and efficient designs. Custom sliprings, including conductive slip rings, allow for unique configurations to meet the specific requirements of various applications, such as those in high-precision machinery or sensitive electronics.

Types of Power Slip Rings

Standard Power Slip Rings

These are the most commonly used power slip rings in industrial applications where the main purpose is to transmit power between stationary and rotating components.

Modular Power Slip Rings

These slip rings allow for customization by adding or removing modules as required. They offer flexibility for different power transmission needs, especially in complex systems like robotics and automated machinery.

Pancake Power Slip Rings

These are flat, compact slip rings used in space-constrained applications, such as wind turbines or small robotics, where a low-profile design is necessary.

Hydraulic Power Slip Rings

These slip rings incorporate hydraulic components to provide power transmission to systems that use hydraulic fluid. They are used in heavy-duty machinery and equipment where both electrical and hydraulic power are required.

Regional Market Insights

North America

The North American power slip ring market is driven by the increasing demand for renewable energy, particularly wind energy. The region’s strong industrial base also supports the use of power slip rings in automation and aerospace applications.

Europe

Europe is another key market, with countries like Germany and the UK leading in wind turbine installation and automation systems. The European market is also supported by advancements in automotive and robotics industries, which require efficient power transmission systems.

Asia-Pacific

The Asia-Pacific region, especially China and India, is experiencing rapid growth in power slip ring adoption due to expanding manufacturing sectors, the rise of automation, and increasing demand for energy-efficient solutions.

Latin America and Middle East & Africa

Emerging economies in Latin America, as well as growing infrastructure projects in the Middle East and Africa, are expected to drive the demand for power slip rings in the coming years.

Challenges and Opportunities

Challenges

High Manufacturing Costs: Power slip rings can be costly to produce, especially when high-precision and custom designs are required for specialized applications.

Environmental Factors: Exposure to harsh environmental conditions, such as dust, moisture, and extreme temperatures, can affect the performance and lifespan of power slip rings.

Opportunities

Integration with IoT: The integration of power slip rings with IoT (Internet of Things) technologies for predictive maintenance and system monitoring presents a significant opportunity for the market.

Growing Adoption in Electric Vehicles (EVs): As electric vehicles gain popularity, the need for reliable and efficient power transmission systems, including power slip rings, will continue to rise.

Market Forecast

The power slip ring market is expected to witness steady growth in the coming years, driven by technological advancements, increasing automation in industrial processes, and the rise of renewable energy projects worldwide. As industries strive for more efficient and reliable power transmission systems, demand for advanced power slip rings will continue to grow. Additionally, the demand for custom engineering slip rings and conductive slip rings will increase as companies continue to adopt more specialized and customized solutions for complex systems.

FAQs about Electrical Slip Rings

How to Choose a Slip Ring?

Need detailed information about the application’s operating parameters, including total circuits, the voltage and amperage of each circuit, working speed, working temperature, installation methods, signals type, and the protection level. Please check our standard slip rings for start or just reach out to our experts.

What is the Difference Between a Commutator and a Slip Ring?

Slip ring and commutator both are used to maintain electrical circuit continuity between a static and a rotating system. The most important difference is commutator can convert dc to ac or ac to dc but an electrical slip ring cannot.

How do Electric Slip Rings Work?

Electric slip rings work by using brushes to maintain a continuous electrical connection between a rotating part and a stationary part through a set of conductive rings, allowing signals and power to be transmitted without the need for wired connections.

What is a Slip Ring Used For?

Some parts need under 360° unrestrained continuous rotation, but the wires are to be connected to the rotating parts. Electrical slip rings can avoid the wires to be twisted.

What does an electrical slip ring do?

An electrical slip ring is an electromechanical device that allows the transmission of electrical power and signals from a stationary component to a rotating component. In systems where continuous rotation is required, slip rings maintain electrical contact, ensuring that the power and signals can be transmitted without interruptions. They are widely used in applications such as wind turbines, industrial machinery, robotics, and radar systems. The slip ring works by using a rotating contact, typically made of brushes and rings, which allows the uninterrupted flow of current and data through the device, even as the connected parts rotate relative to one another. This ability is critical for maintaining consistent performance in rotating systems, where traditional wiring would become tangled or break due to movement.

What is the problem with the slip ring?

While electrical slip rings provide essential functionality in many applications, there are some common problems users may encounter. One of the primary issues is wear and tear. As slip rings are in constant motion, the brushes that maintain contact with the rotating rings can wear out over time, leading to electrical failures, signal interference, or loss of power transmission. Another challenge is the accumulation of dust, dirt, or debris, which can cause electrical resistance and short-circuiting. In addition, the performance of slip rings can be affected by environmental factors such as temperature fluctuations, humidity, and corrosive conditions. These issues can reduce the lifespan of the slip ring and result in costly repairs or replacements. Regular maintenance, proper sealing, and selecting the appropriate materials for the specific operating environment are critical to extending the lifespan and improving the reliability of slip rings.

What is the difference between a collector ring and a slip ring?

Although both collector rings and slip rings serve similar functions in transmitting electrical power and signals from a stationary part to a rotating one, they are used in different contexts and have subtle differences in design. A collector ring is typically a stationary ring mounted on a rotating system that works in tandem with brushes to provide electrical contact. It’s more common in simpler or low-speed systems, where only power needs to be transmitted. On the other hand, a slip ring generally refers to a more sophisticated device that not only transmits electrical power but can also handle signals, data, or even fluid transfer in more complex systems. Slip rings can feature multiple rings, each carrying different signals or power paths, and are designed for higher-speed and higher-performance applications. Essentially, while both serve the purpose of ensuring electrical contact during rotation, slip rings offer greater versatility and reliability for high-precision applications.

How do you make an electrical slip ring?

Making an electrical slip ring involves several key steps, beginning with the design and selection of materials suitable for the intended application. The process generally starts with choosing conductive materials like copper for the rings and brushes, ensuring high-quality electrical performance and low wear resistance. The components are then assembled with a rotor (the rotating part) and a stator (the stationary part) in a way that allows the brushes to maintain continuous contact with the rings. The next step is to incorporate insulation materials to prevent electrical shorts between components. After assembly, the slip ring is tested for durability, conductivity, and performance under real-world conditions, such as rotational speed and load. Some slip rings are customized with features like sealing for harsh environments, or they may be designed for specific applications, such as high-frequency data transfer. Precision engineering is essential for ensuring the slip ring operates reliably over time.

Contact Our Team

Electric Slip Rings: Composition, Types, and Purchase

What is a slip ring? What is an electric slip ring? What is the function of slip ring? Click on the article to know the answers to these questions and also understand why slip rings are expensive, and explore how to buy electric slip rings.