Turntable slip rings, akin to silent orchestrators, function discreetly yet indispensably in a multitude of electrical applications. These electromechanical devices permit power transmission and data exchange between stationary and rotating components of equipment. The seemingly simple, yet deeply profound operation of these sophisticated devices forms the crux of boundless applications where the need for rotation without hindering electrical connectivity is paramount.

This comprehensive guide aims to illuminate the reader’s understanding, journeying through the intricacies of turntable slip rings. We’ll begin with the fundamentals, elucidating what these devices are and their operational principle. The expedition then unfurls towards the various types of turntable slip rings, elaborating upon each type’s unique attributes, and complementing distinct applications.

The discussion continues to where these slip rings manifest their usefulness, threading through diverse industries such as audio-video broadcasting, manufacturing, and defense. Attention is then diverted towards practical aspects, with a detailed tutorial on installing a turntable slip ring, delicately amalgamated with precautionary notes to circumvent commonly made errors.

Turning the spotlight on longevity and performance sustenance, the guide highlights the indispensability of maintenance and troubleshooting, providing step-by-step actions to ensure your slip ring’s optimal operation.

Next, we navigate towards the purchasing facet, spotlighting crucial considerations when buying a slip ring, from price to quality, brand reputation, and post-purchase support. We will cherry-pick best practices in choosing a reputable supplier and the role of user reviews and ratings in making an informed decision.

The guide concludes by addressing common questions associated with turntable slip rings, delivering comprehensive answers that alleviate confusion, clarify doubts, and ensure a coherent and nuanced understanding of these phenomenal entities.

In essence, this guide aspires to equip readers with a comprehensive understanding of turntable slip rings, fostering confident decision-making when it comes to selecting, installing, and maintaining these devices.

Understanding Turntable Slip Rings: The Basics

Before diving into the practicalities of application, it’s crucial to distill our comprehension towards acquiring a firm grasp of the concept of turntable slip rings.

A turntable slip ring can best be defined as an electromechanical marvel that enables the uninterrupted transmission of power and data signals between stationary and rotating interfaces of a system or equipment. The keyword here is “uninterrupted”, highlighting the slip ring’s primary role of maintaining seamless electrical communication, regardless of the mechanical rotations involved.

However, to appreciate their functionality fully, let’s break down a turntable slip ring into its basic components. At its heart, it typically consists of a rotating part – the ring, and a stationary part – the brush. The ring is usually secured to the rotating component of the system, whereas the brush stays put on the stationary side. Together, the brush and the ring form an electromechanical bridge, providing continuity in a way similar to a stationary electrical connection.

While the assembly might disguise itself in simplicity, an intricate, coordinated operation underpins its core. This choreography of the brush and the ring forms the cornerstone of the working principle of a turntable slip ring. As the system rotates, the ring, firmly attached to it, rotates in tandem. The brush, however, remains static, maintaining contact with the revolving ring without restricting its motion. This continuous contact, despite the mechanical rotation, ensures an unbroken path for electricity to flow, and data to exchange between the rotating and non-rotating components.

In summary, understanding the basics of turntable slip rings helps set the stage for deep dives into typologies, applications, installation, and maintenance. These fundamentals underline the significance of turntable slip rings as a bedrock of modern-day electromechanical applications.

Types of Turntable Slip Rings

Like a well-versed ensemble of versatile instruments, turntable slip rings exist in various forms, each adept at fulfilling specific roles. By delving into the different types, their characteristics, and how they separate themselves from one another, we can empower decision-making and guide the selection of the most appropriate slip ring for a given application.

Four dominant types of turntable slip rings emerge, characterized by their structural and functional properties:

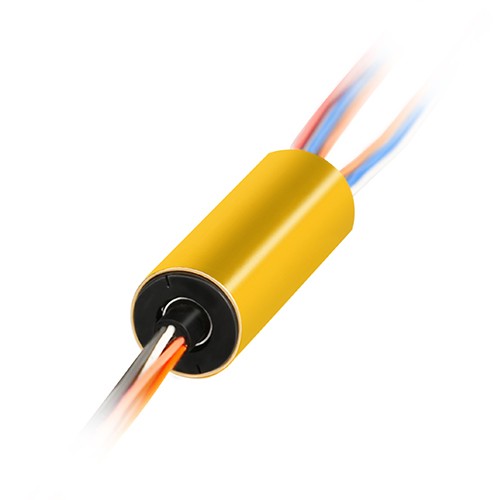

Capsule Slip Rings

Compact and lightweight, these slip rings generally cater to low-current applications where space constraints are significant. Their petite form encapsulates, literally and figuratively, their ability to integrate efficiently into compact assemblies.

Pancake Slip Rings

As the name suggests, pancake slip rings possess a flat, disk-like configuration. Ideally suited for applications limited by vertical space or axial height, these slip rings trade spatial height for a larger diameter while prioritizing signal quality and consistency.

Through Hole (or Hollow Shaft) Slip Rings

Augmenting their design with a central aperture, through hole slip rings allows their users to route cables, shafts, or other components through their center. This ability provides flexibility in design and utility, particularly in systems with complex layouts.

High-Frequency Slip Rings

Engineered for high-speed applications, these slip rings boast superior signal integrity and minimal electromagnetic interference even in demanding scenarios. They are the go-to choice for applications where precise, lightning-fast data transmission is non-negotiable.

To discern the aptest choice for a specific application, a thorough understanding of each type’s merits and demerits must be coupled with an acute awareness of the constraints and needs of the application itself.

Consider factors such as:

- Spatial limitations: Understand space constraints in the application, and examine which slip ring format would be the best fit, without compromising performance.

- Current, voltage, and frequency: Assess the requirements for power and data transmission, and ensure that the chosen slip ring is compatible with these parameters.

- Mechanical properties: Evaluate factors like rotational speed, environmental conditions, and system complexity to guarantee optimal performance.

By comprehensively appraising each variable, users can confidently navigate the vibrant landscape of turntable slip rings and zero in on the perfect match for their specific application.

Uses and Applications of Turntable Slip Rings

Turntable slip rings, through their ingenious design and functionality, find themselves at the heart of a myriad of applications spanning several industries. Essentially anywhere a system requires a rotational interface while maintaining uninterrupted electrical transmission, turntable slip rings step in to fulfill this role adeptly.

Audio and Video Industry

The world of broadcasting heavily leans on turntable slip rings for seamless operations. From rotating tables employed by DJs in music production, to advanced audio equipment, and sophisticated 360-degree cameras used in broadcasting, slip rings ensure a continuous, unimpaired transmission of power and data signals without disrupting the system’s rotation. This harmony between rotation and transmission is fundamental to achieving high audio-video quality, making turntable slip rings a pillar within this industry.

Manufacturing Industry

The manufacturing arena, known for its intricately automated frameworks, is a prolific user of turntable slip rings. Robotic arms that often exhibit rotational movements, assembly lines with rotating mechanisms, and other automated systems bank on slip rings for electrically linking their static and rotating components. Specifically in scenarios where rotation, durability, and data transmission converge, slip rings emerge not just as an option but as an operational necessity.

Defense and Military

In defense and military technologies, reliability and precision are nonnegotiable. For systems like radar antennae that rotate while transmitting data, tank turrets that require constant rotation without losing vital data links, or torpedoes using slip rings for guidance and control, these devices come into play. The ruggedness and dependability of turntable slip rings, especially when reinforced with military-grade specifications, make them a critical component of defense technologies worldwide.

In addition to the above, turntable slip rings also find their place in medical imaging devices, wind turbines, amusement park rides, and even space-based applications, showcasing their breathtaking versatility. As an enabler of smooth and reliable electrical transmission amidst rotation, their usage is limited only by the technical constraints of a particular application. These contexts demonstrate the fundamental role of turntable slip rings as a key element in translating scientific possibility into a functional reality.

How to Install a Turntable Slip Ring?

The installation of a turntable slip ring is integral to its performance and longevity. It’s a delicate process that necessitates meticulous attention to detail, and it’s these subtleties that we’ll unravel in this section.

Here are step-by-step instructions on installing a turntable slip ring:

- Preparation: Begin by fully understanding the installation instructions specified in the slip ring’s manual. Gather essential tools and materials and clean the area around the installation site to avoid contamination.

- Slide the Slip Ring onto the Shaft: Carefully slide the slip ring onto the rotating shaft of the system. Ensure that the slip ring is oriented correctly as per the system’s design.

- Secure the Slip Ring: Once the slip ring is positioned accurately, secure it properly using set screws or other fixtures specified in the manual. Tighten these fixtures to the recommended torque.

- Attach the Wiring: Connect the slip ring’s leads to the corresponding system power and data lines. It is crucial to match the connections precisely as per the manual to avoid misconnections.

- Test the Setup: After installation, rotate the system manually to check for any obstruction and test the electrical connections to ensure correct power and data transmission.

During the installation, areas to tread cautiously include:

- Handling: Slip rings comprise delicate components. Handle them with care to avoid inflicting any damage.

- Installation Directions: Incorrect orientation or forced installation can lead to mechanical failure or compromised performance.

- Wiring Connections: Incorrect or loose connections can cause malfunctions and potentially damage the system.

Common errors during installation often spring from superficial oversight or lack of technical understanding. These mistakes include misaligning the slip ring, over-tightening set screws, not following the manufacturer’s instructions, and not testing the system after installation.

In essence, precision, patience, and cognizance of the manufacturer’s instructions are paramount to the successful installation of a turntable slip ring. With these aspects addressed, the installed slip ring positions itself to deliver the optimal performance it was engineered for.

Understanding Turntable Slip Rings: Maintenance and Troubleshooting

Regularly maintaining and inspecting turntable slip rings ensures their durability and optimal performance. Like finely tuned instruments, their welfare hinges on routine checks, an in-depth understanding of their operation, and precisely directed remedial actions when things go wrong.

Importance of Maintenance and Routine Checks

Periodic maintenance checks can ward off unforeseen problems while also prolonging the slip ring’s life. Failure to maintain these devices can result in a host of issues, including electrical noise, intermittent signals, poor contact, or even complete shutdowns. Besides, it’s worth noting that regular maintenance is often easier, less time-consuming, and more cost-effective than troubleshooting or replacing a malfunctioning slip ring.

Maintaining Turntable Slip Rings

Here’s a general guide on how to maintain turntable slip rings:

- Inspect Regularly: The simplest form of maintenance is a regular visual inspection. Look for visible signs of wear, corrosion, or dust build-up, and address these issues promptly.

- Clean Carefully: Dust can impair rotational movement or degrade contact points. Use a soft cloth or compressed air to gently clean the slip ring. Avoid abrasive materials or harsh cleaning agents, which can damage the components.

- Check Connections: Ensure that all electrical connections are secure. Loose connections can lead to electrical noise or intermittent signals.

- Lubricate: If recommended by the manufacturer, use the specific lubricant to keep the rotating parts moving smoothly. Ensure it’s done sparingly and correctly to avoid attracting dirt or causing slip.

Common Problems and Their Solutions

- Intermittent Signals or Electric Noise: This is often caused by a loose connection or worn contact points. Check and tighten all connections, and consider replacing the contacts if worn excessively.

- Reduced Mobility or Excessive Heat: Dust, dirt, or insufficient lubrication can cause this. Clean the mechanism and apply lubricant if advised by the manufacturer. If the problem persists, there may be internal component damage requiring professional attention.

- Complete loss of connection: This could be caused by total wear of the contact points or significant internal damage. Often, a complete replacement is the best course of action in this case.

In conclusion, nurturing turntable slip rings with routine maintenance is the secret to extending their life and enhancing their performance, while a clear understanding of common problems and their solutions assists in efficient troubleshooting. This combination equips users better to manage these essential devices and ensure a seamless operation of their respective applications.

Understanding Turntable Slip Rings: Buying Guide

Choosing the right turntable slip ring can be a complex task given the wide range of options available in the market. It’s these choices that we attempt to simplify in this section, highlighting some key considerations when making this important purchase.

Considerations When Buying a Turntable Slip Ring

Here are the aspects to contemplate before investing in a turntable slip ring:

Price: This is often the first consideration, but remember that the cheapest option isn’t always the best. Balance cost against performance, durability, and features, and weigh your budget against the slip ring’s intended use and expected lifespan.

Quality: A high-quality slip ring ensures better performance and longer product life. Look for materials that are resistant to wear and corrosion, and construction that indicates durability. This may include how the ring and brushes are paired, how they are enclosed, and what materials are used.

Brand Reputation: Not all brands are created equal. Some brands are known for their product reliability, consistency, and superior performance. Research different brands’ reputations in the market before making a decision.

Manufacturer Support and Warranty: Good customer support can be invaluable for installation, maintenance, and troubleshooting. Also, a solid warranty offers a safety net against premature failure.

Choosing the Right Supplier

When choosing a supplier, consider factors like their reputation, the range of products they offer, their knowledge and experience within the industry, their commitment to quality and customer service, and their ability to provide after-sales support or value-added services.

Users’ Reviews and Ratings

Customer reviews offer valuable insights into the product’s performance, reliability, and the manufacturer’s customer service. Pay particular attention to reviews that speak about the same context in which you’ll be using your slip ring. Ratings can also provide a quick, at-a-glance view of how the product stacks up against others.

In summary, buying a turntable slip ring is not just about finding a device that fits into your budget, but it’s about balancing costs with quality, brand reputation, and manufacturer support. An aspect that is often overlooked, but vital, is perusing user reviews and ratings as they provide practical insights on real-time usage of the product. With these points in mind, picking the perfect turntable slip ring becomes an easier, more manageable exercise.

Conclusion

Turntable slip rings serve a critical function in various applications. By understanding their types, uses installation processes, and maintenance needs, users can maximize the performance and durability of their slip rings. Always choose a reputable supplier and prioritize quality and service to get the most from your purchase.

FAQs about Turntable Slip Rings

Here, we address common questions users may have about turntable slip rings, shedding light on some of the fundamentals and nuances surrounding these devices.

Q1: What is a turntable slip ring, and what are its functions?

A: A turntable slip ring is an electromechanical device that enables the transmission of electrical signals and power between stationary and rotating components of a system. It is designed to maintain a continuous flow of electricity, data, or both, while a component rotates, ensuring smooth functionality in various applications.

Q2: What are the different types of slip rings?

A: Slip rings can be classified based on several criteria, including their design, contact technology, and application. Common types include through-bore slip rings (a central hole for the shaft), capsule slip rings (compact, space-saving design), pancake slip rings (flat and used in systems with limited height), and high-frequency or optical slip rings (using radio frequency or optical technology to transmit signals).

Q3: In which industries are turntable slip rings utilized?

A: Turntable slip rings find applications across a multitude of industries, such as audio and video, manufacturing, defense and military, energy production, amusement parks, medical imaging, and even space technology. They are used in any system that requires a rotational interface while ensuring uninterrupted electrical transmission.

Q4: How do I clean and maintain my turntable slip ring?

A: Regular visual inspection, careful cleaning with a soft cloth or compressed air, ensuring secure connections, and applying suitable lubrication (if recommended by the manufacturer) are key steps to maintaining your turntable slip ring. It’s important to be gentle during the cleaning process to avoid damaging any of the slip ring components.

Q5: Can I replace a worn-out turntable slip ring with any other slip ring type?

A: Replacing a worn-out slip ring with a different type is highly discouraged. It’s crucial to pick a replacement that is compatible with your system in terms of specifications, size, and functionality. Consult the manufacturer or an expert to choose the correct slip ring for your application.

Q6: My slip ring is generating electrical noise. What should I do?

A: Electrical noise can stem from worn contact points, loose connections, or other issues. Begin by checking and tightening all connections and inspecting the contact points. If the problem persists, consult the manufacturer or a technician to identify the root cause and execute the appropriate corrective measures.

Armed with the above answers, users can deepen their understanding of turntable slip rings and feel well-equipped to manage their usage, installation, and maintenance of these essential devices. Knowledge of their multifaceted applications and the ability to navigate common issues can empower users when making future decisions involving turntable slip rings.

See What We Can Do