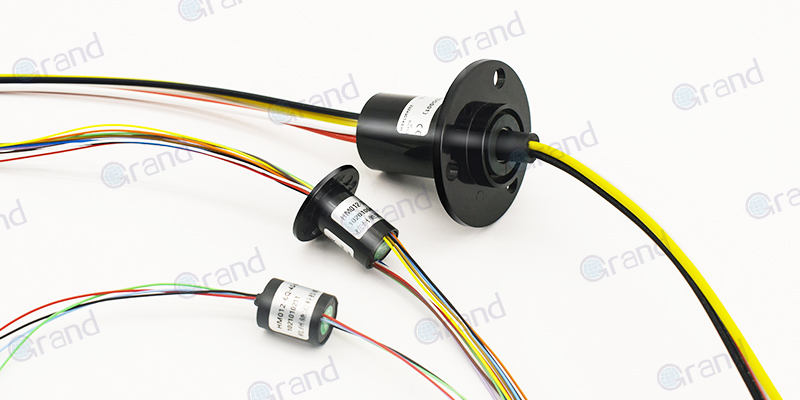

The robotics labs of leading universities are buzzing with increasingly ambitious projects—from bio-inspired swarm robots to precision surgical arms and agile autonomous drones. As these projects push technical boundaries, a critical trend has emerged in 2025: the shift from off-the-shelf slip rings to fully customized solutions. Here’s why academia is driving this demand and how it’s accelerating innovation.

The Limitations of Standard Slip Rings in Cutting-Edge Research

Off-the-shelf slip rings often fall short in advanced robotics due to:

Space Constraints: University robots prioritize miniaturization (e.g., nano-drones, endoscopic tools). Standard slip rings can’t fit micro-scale designs.

Hybrid Power-Data Demands: Projects increasingly merge high-power actuators (24–48V) with high-speed data (EtherCAT, USB3.0, HDMI). Generic units lack optimized integration.

Unconventional Motion Profiles: Robots with multi-axis rotation or continuous 360° tilting (e.g., robotic joints) require slip rings that withstand complex torque and vibration.

A 2024 MIT study found 68% of robotics teams modified commercial slip rings—adding cost, weight, and failure points.

Why Customization is Winning in Academia

Precision-Tuned Performance

Custom Slip Rings solve project-specific challenges:

Signal Integrity: Shielding against EMI from motor drives or wireless systems is critical for sensor-heavy bots (e.g., LiDAR-equipped rovers).

Material Science: Researchers specify biocompatible coatings for surgical robots or titanium housings for marine drones.

Hybrid Designs: Combining electrical circuits, Fiber Optic Rotary Joints, fluid/gas rotary joint (e.g., for pneumatic grippers) in a single unit.

Cost Efficiency Through Innovation

Paradoxically, custom units reduce long-term costs:

Durability: Tailored brushes/contacts extend lifespan (e.g., gold-gold contacts for low-torque lab arms).

Modularity: Reusable across multiple projects (e.g., a slip ring for drone gimbals adapted for agricultural sensing bots).

Grant Compliance: Custom designs meet funding requirements for “novel engineering solutions.”

Enabling Interdisciplinary Research

Custom slip rings bridge domains:

Neuroscience + Robotics: Brain-computer interface (BCI) robots need ultra-low-noise signal transmission.

Space Robotics: Vacuum-rated, radiation-hardened slip rings for lunar rover prototypes.

Soft Robotics: Stretchable conductive elements for deformable structures.

The 2025 Customization Process: Fast, Agile, Collaborative

Leading manufacturers now offer:

Digital Co-Design Platforms: Universities share CAD models via cloud tools for real-time prototyping.

Rapid Iteration: 3D-printed prototypes delivered in 72 hours (vs. 6-week lead times for standard units).

Academic Discount Structures: Volume pricing for multi-lab consortia (e.g., ETH Zurich + EPFL joint projects).

Example: UC Berkeley’s “RoboFly” project used a 5-mm diameter custom slip ring transmitting power and HD video, enabling untethered flight in confined spaces.

Impact: Accelerating Research Breakthroughs

Custom slip rings empower next-gen robotics:

Autonomous Drones: Continuous rotation slip rings allow 360° surveillance without yaw limitations.

Haptic Surgical Robots: Transmitting force feedback data with zero latency.

Swarm Robotics: Micro slip rings (<10g) enable collective behavior in palm-sized bots.

“Our custom slip ring was the enabler for a 12-DOF robotic arm. Off-the-shelf options added 300g and limited rotation—ours weighs 90g and handles unlimited rotation.”

— Dr. Elena Torres, Robotics Lab Lead, Imperial College London

The 2025 Co-Design Ecosystem

► Digital Twin Workflow

Lab uploads CAD model + motion profile

AI simulator predicts:

Thermal hotspots at 5,000RPM

EMI susceptibility map

Fatigue failure points

72-hour rapid prototyping

► Academic-Specific Services

Modular Kits (Carnegie Mellon’s “SlipRing Lego”):

Stackable power/data/fluid modules

Reconfigurable for drones → rovers → arms

On-Demand Upgrades (MIT’s Mars Drone):

Phase 1: 12 circuits

Phase 2: Added 8-channel thermocouple module

Domain-Specific Breakthroughs Enabled

► Medical Robotics (Johns Hopkins)

Challenge: Steerable endoscope needing:

5DOF articulation

4K imaging @ 30fps

Electro-surgical power

Custom Solution:

0.8mm fiber-optic rotary joint (FORJ)

Slip ring with plasma-resistant contacts

Result: 92% reduced lumen space occupation

► Space Robotics (Caltech JPL)

Europa Ice Penetrator:

Requirements:

-270°C to +150°C operation

Radiation hardening (100kRad)

100m-depth pressure rating

Custom Achievement:

Ceramic-on-ceramic contacts

Hermetic laser welding

0 outgassing

The Road Ahead: Emerging Trends

Integrated Sensing: Slip rings with embedded temperature/vibration sensors for predictive maintenance.

Sustainable Materials: Biodegradable polymers for eco-conscious projects.

AI-Optimized Designs: Generative AI suggests topology-optimized structures for weight/performance gains.

In 2025, custom slip rings are no longer luxury items—they’re essential tools for university robotics. By solving the “interface problem” between static and rotating systems, they free researchers to focus on breakthroughs rather than compromises. As labs tackle grand challenges—from deep-sea exploration to personalized medical robots—the partnership between academia and slip ring innovators will remain pivotal, turning theoretical concepts into tangible, spinning, soaring reality.

See What We Can Do