Slip-ring varieties proliferate — and the propelled segments come in bore sizes from a large portion of an inch to numerous feet in diameter. Take an example of clinical imaging machines intended to support domesticated animals. In any case, choices go past an insignificant scale. So how do OEMs and configuration engineers pick among standard and custom choices … and what are different alternatives past the most across-the-board varieties of electromechanical and fiber-optic slip rings? Let’s find out.

Standard Slip Rings

Companies offer slip rings as standard product offerings. This means that these slip rings are easily manageable and are of standard sizes, that one can easily use them in machines. These slip rings are easily installable and can be mounted anywhere and have much simpler connections. These standard slip rings can be used as a rib, strung rotors, mounted on a pole, or fitted into a pole’s inner bore. These standard slip rings can also come in handy for secondary purposes. They can ensure slip-ring installation alignment for things to work properly. Sometimes there are cases when the shafts need to be aligned so that these things work properly. The circuitry options of these slip rings can vary from one slip ring to another just to make these things work with every machine. These slip rings are designed to satisfy voltages and amperage, i.e., AC or DC.

Where can Standard Slip Rings be Used?

Only an engineer can give a satisfying answer to this question. Only he knows that you need ten channels or individual circuits in place of a slip ring. He can best analyze the situation and tell whether a slip ring might come in handy instead of wires or not. There are some other aspects to consider too, and it is the job of an engineer to clearly analyze the facts and ultimately make the final decision. He might end up ordering a slip ring that is slightly bigger than needed. But in the end, there is a chance that it might suffice the needs of the machine but end up being an overbuilt item. On the other hand, engineers have no knowledge upfront about how many dedicated circuits will be needed or how many Ethernet connections a machine might need.

NOTE: There is one factor that slightly confuses the engineers. They get puzzled over a basic thing that an Ethernet cable has 4 one-hundred MB Ethernet runs, which means that it has four secondary wires too. While there is another metal braid present that is necessary for shielding. This metal braid is also counted as an additional circuit. Therefore the slip ring manufacturing companies count these as five circuits and make it a standard for preparing an Ethernet line while the engineers take these as 4 wires. At the end of the day, due to poor communication and issues like these underscore the significance of market education, things get out of hand. Due to these issues, engineers end up rethinking how to fit the designs with a slip ring. It also sheds light on the need for there must be involvement of both the slip ring manufacturers and design engineers to keep these issues at bay.

Custom Slip Rings

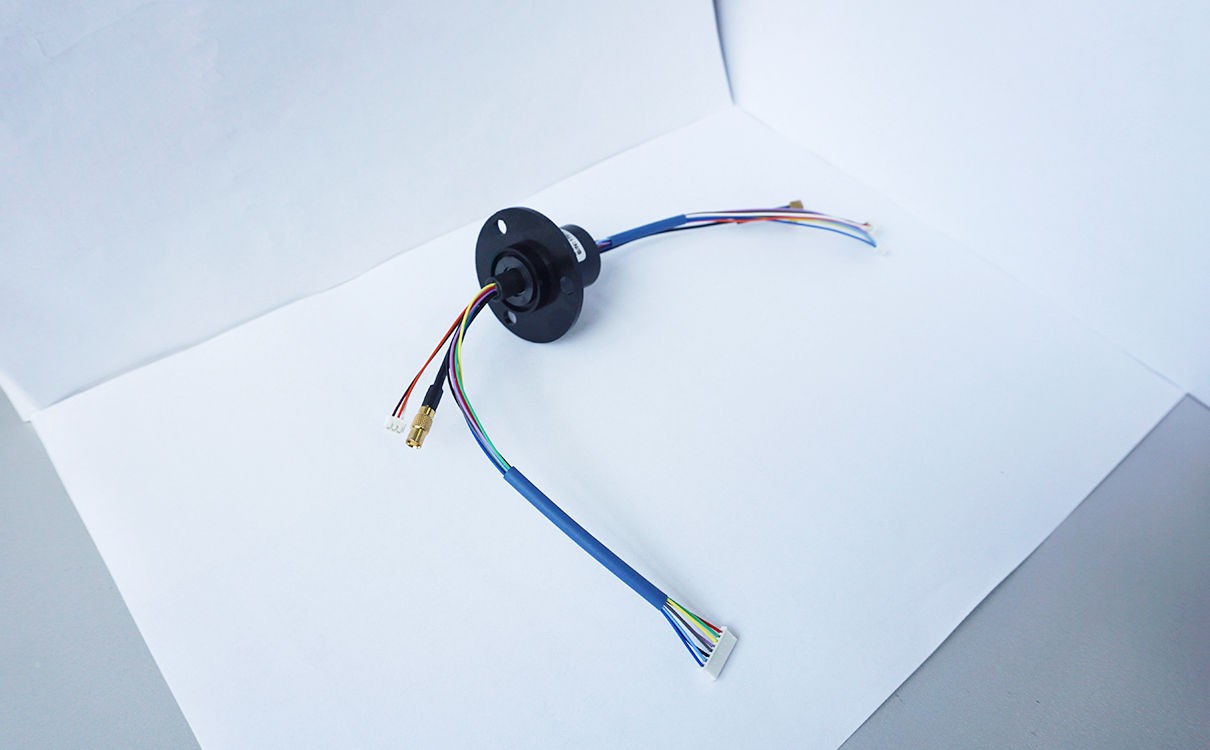

There are numerous cases where an engineer tried to fit a standard slip ring inside a machine, but all his efforts went in vain. This is partly because there are many things to consider while ordering a slip ring, yes far more things that your design engineer considers at first. Custom slip rings are the best answer to these problems and allow the engineers to communicate with the manufacturers to get the required product according to their specifications. There are some additional benefits of ordering custom slip ring, and that is, custom slip rings have a variety of connection circuits and multi-trace types. These rings have plenty of feedback devices and heaters, too, if and when needed. There is also a shielding for EMC present. Custom-built slip rings are also advantageous when there is a fear of high temperature, and can withstand extremely hot conditions. If you are concerned about any of these things, you need not worry because engineers at Grand Slip Ring Manufacturers are always available to cater to your needs.

NOTE: The best thing about custom-built rings is that these products take customization in very high regard. From simple installations to zero maintenance, you can order whatever you like. Don’t shy away from spending money on these components, to ensure that these things work at their maximum.

Mercury-wetted Slip Rings

There is another kind of slip ring in the market that is making people fond of themselves at a much higher pace. It runs of liquid. In the mercury-wetted slip rings, there is a liquid metal present inside the rotating shaft that helps in rotating connections. Mercury, being toxic, is a heavy metal that cannot be used in every other place and boldly not in the food and beverage processing companies. There is an advantage to these slip rings, and that is, mercury-wetted slip rings have a longer life, and they can transmit data and power at a much faster pace. These are no-noising rings and reduce the unnecessary noise made by the components.

Pro Tip: While considering buying a standard slip ring or ordering a custom slip ring, consider what will be the right choice for your needs. Many companies are offering these slip rings at much lower costs. While ordering these products from the vendors, keep in mind to consult with the design engineer who has prior knowledge about these things. Keeping a design engineer in the loop might be handy and will be helpful if something bad happens. However, it is advised that you don’t negotiate on the quality of these items and order what is feasible for you. It must also be kept in mind to use slip rings instead of commutators, as the former is a continuous ring while the latter is a segmented product.

See What We Can Do