PIN slip rings are the substitute for mercury slip rings. Mercury slip rings use liquid metal mercury as the transmission medium. Special sealing technology, insulation, and compact design made them outstanding features like extremely long working life, low electrical noise, and contact resistance. Mercury is a chronic toxic substance. There have great potential threat to both the environment and the operators if leaked. People have been actively searching for alternative products.

What is PIN Slip Ring?

Get Expert Advice on PIN Slip Rings by Filling Out This Form.

PIN Slip Rings - HM Series

Available for Custom, Standard OD 32 mm, 2~5 Rings

GRAND technology has developed innovative PIN slip rings, designed to be environmentally friendly and mercury-free, offering a solution that is compact and cost-effective for industries such as food and packaging manufacturing. These units replace traditional wire connections with PIN connections, simplifying installation. With RoHS and CE approvals, they ensure compliance with international safety standards. Their small form factor allows for the transmission of electrical power and signals in tight spaces, ideal for rotating solutions. The plug-and-play feature enhances usability, making integration easier.

In addition to these advantages, GRAND offers modularized and standardized designs for various applications. For industries that require precise metering and counting, integrating a meter counter into the system ensures accurate tracking of performance and operational efficiency. If you’re looking for a tailored PIN slip ring connector, feel free to contact GRAND to delve into the ultimate solution for your needs.

Feature

- Mercury free, environmentally

- Multi-point brush contact material ensure long life

- Integrated structure design for easy installation

- Standard model supports 2-5rings power or signal (0~20A/ring)

- IP51, IP54 and IP68

- Free maintenance

- Transmitting power and sensitive signals

Options

- Optional for underwater IP65, IP68

- Working speed, current &voltage

- No. of rings

- Housing material

- Protection level (dust and water)

- Working temperature

Model Breakdown

The Future of Slip Rings: Transitioning from Mercury to Non-Mercury Slip Rings

A mercury slip ring is a type of electrical slip ring that uses mercury as the conductive material to create a seamless electrical connection between rotating and stationary components. The liquid form of mercury provides unique benefits, making it especially suitable for high-performance, high-speed applications. While mercury slip ring have been historically important for certain precision-based industries, environmental and health concerns have led to the development of alternative technologies, such as non-mercury slip rings. These non mercury slip ring offer similar performance characteristics but without the associated environmental and health risks, making them a preferred solution in many modern industries.

Key Characteristics of Mercury Slip Rings:

Conductive Mercury: The liquid form of mercury offers a continuous and stable electrical connection, which is crucial for high-speed systems where intermittent contact could lead to performance issues. This is especially beneficial in applications like radar systems, rotating machinery, and aerospace, where uninterrupted power and signal transmission is essential.

Low Friction: One of the standout features of mercury slip rings is their ability to reduce friction between the rotating ring and stationary brushes. The liquid mercury acts not only as a conductor but also as a natural lubricant, minimizing wear and tear. This leads to a longer lifespan and more consistent performance in rotating systems, making them ideal for critical applications like military equipment or high-precision instrumentation.

High Performance: Mercury slip rings excel in applications where high electrical currents are required, and where precise, low-resistance connections are critical. Industries such as aerospace, military, radar, and industrial automation often use these types of slip rings for their high power transmission capabilities and reliable operation in demanding environments.

Drawbacks of Mercury Slip Rings:

Environmental Concerns: The primary issue with mercury slip rings is the toxicity of mercury. If the slip ring fails or is improperly disposed of, it can pose serious environmental and health risks. Mercury is a hazardous substance that can contaminate soil and water, leading to long-term ecological damage. These concerns have prompted governments and regulatory bodies to enforce stricter environmental regulations around the use and disposal of mercury-based products.

Health and Safety Risks: Exposure to mercury vapors can be harmful to human health. If a mercury slip ring is damaged, there is a risk of releasing toxic mercury vapors into the air, which can lead to severe health problems for workers. As such, industries that still use mercury slip rings must follow strict safety protocols to protect personnel, which increases operational costs and complexity.

Limited Use: Due to the environmental and safety concerns, the use of mercury slip rings has become increasingly limited. Many industries are now transitioning to alternative technologies that provide similar performance without the risks associated with mercury.

Alternatives to Mercury Slip Rings:

With the growing awareness of environmental concerns and the push for safer alternatives, mercury slip rings are being gradually phased out in favor of mercury-free technologies. Some of the most common alternatives include:

PIN Slip Rings: PIN slip rings are a popular alternative that use solid or semi-solid contact materials instead of mercury. These slip rings offer similar performance characteristics, such as low friction and high current handling capabilities, but without the environmental hazards. PIN slip rings are used in a variety of industries, including robotics, automation, and food packaging, where space-saving designs and eco-friendliness are important.

Fiber Optic Slip Ring: For applications requiring high-speed data transmission, fiber optic slip rings are another alternative. They use optical fibers to transmit data signals between rotating and stationary components, eliminating the need for conductive materials entirely. Fiber optic slip rings are especially valuable in telecommunications, medical imaging, and military technologies, where high-speed data transfer and electrical isolation are crucial.

Contactless Slip Rings: Another innovative alternative is the contactless slip ring, which uses electromagnetic fields to transfer power and signals without the need for physical contact. These systems are increasingly being used in industries such as automotive and renewable energy, as they eliminate wear and tear altogether.

The Advantages of PIN Slip Rings: A Versatile, Eco-Friendly Alternative to Traditional Slip Rings

PIN Slip Rings are a modern, advanced alternative to traditional slip ring technologies such as mercury or brush-based designs. These slip rings are engineered to provide reliable and continuous electrical power and signal transmission between rotating and stationary components. By utilizing solid PIN contacts, PIN slip rings offer a compact, efficient, and environmentally friendly solution for a wide range of applications.

Key Features of PIN Slip Rings:

Mercury-Free: One of the most significant advantages of PIN slip rings is that they are mercury-free. This not only makes them safer for the environment but also eliminates the health risks associated with mercury exposure. Traditional mercury slip rings can be hazardous if damaged or improperly disposed of, whereas PIN slip rings provide a more sustainable alternative.

Compact Design: PIN slip rings are designed to be smaller and more compact than traditional slip ring technologies. The use of ring and pin contacts allows for a more efficient use of space, which is especially beneficial in applications where space is limited, such as in small machinery or tight installation environments.

Durability: PIN slip rings have fewer moving parts compared to traditional brush-based slip rings, which results in less wear and tear over time. This makes them more durable and long-lasting, providing a reliable solution for systems requiring continuous operation. The reduced mechanical friction between the ring pin contacts and other components results in minimal maintenance requirements and a longer operational life.

High Performance: These slip rings are designed to handle a wide range of electrical signals, from low-power signals to high current applications. The versatility of PIN slip rings makes them suitable for diverse industries, where the needs of the electrical transmission may vary from low signal strength to high-power delivery.

Customizable: One of the key benefits of PIN slip rings is their high level of customization. Manufacturers can tailor the design to meet specific application requirements, such as the number of circuits, power handling capabilities, or the specific environmental conditions in which the slip ring will operate. This flexibility ensures that PIN slip rings can be optimized for each use case.

Applications of PIN Slip Rings:

Rotating Equipment: PIN slip rings are commonly used in machines with rotating components, such as wind turbines, packaging machines, robotics, and industrial automation systems. In these applications, the slip ring provides a continuous connection between the rotating and stationary parts, ensuring that power and data are transmitted smoothly throughout the system.

Food and Packaging Industry: The food and packaging industry often requires equipment that operates in hygienic environments, where contamination risks need to be minimized. The small size and mercury-free nature of PIN slip rings make them ideal for use in food processing and packaging machines, where safety and reliability are top priorities.

Medical Devices: PIN slip rings are particularly well-suited for use in medical devices that require precise electrical connections, such as diagnostic imaging equipment or surgical robots. In these settings, the compact and reliable performance of PIN slip rings ensures uninterrupted power and signal transmission in rotating or moving parts of the medical device.

Renewable Energy: In renewable energy applications, particularly wind and solar power systems, PIN slip rings are used to transmit electrical power from rotating blades to stationary parts of the system. Their ability to handle high currents and operate in harsh environmental conditions makes them a reliable solution for renewable energy generation systems.

Advantages of PIN Slip Rings Over Other Types:

Environmentally Friendly: Since PIN slip rings are mercury-free, they meet stricter environmental regulations, making them an ideal choice for industries that are governed by sustainability standards. Unlike mercury-based slip rings, which pose significant environmental hazards, PIN slip rings offer an eco-friendly alternative without sacrificing performance.

Ease of Installation: Many PIN slip rings come with a plug-and-play design, simplifying the installation process. This reduces downtime and makes maintenance easier, as fewer specialized skills are required to install or replace the slip ring in the system. This ease of use is particularly advantageous in industries where equipment uptime is critical.

Cost-Effective: The simpler, more streamlined design of PIN slip rings often makes them more cost-effective compared to more complex traditional slip rings, such as those with brush contacts. Additionally, the longer lifespan and reduced maintenance needs of PIN slip rings contribute to lower overall operational costs.

Reduced Maintenance: Because there are fewer moving parts, and the design minimizes friction and wear, PIN slip rings require less maintenance over time. This translates to lower operational costs and less downtime, making them a reliable and efficient option for continuous operations.

Versatility: The ability to handle various electrical currents and signals, as well as the option for custom configurations, makes PIN slip rings suitable for a wide range of applications. Whether it is low-power data signals or high-power electrical transmission, PIN slip rings are adaptable to the specific needs of each application.

3 Wire Slip Ring: For certain applications, 3-wire slip ring offer a compact, efficient solution for systems requiring three-phase power transmission or signal handling. These slip rings are optimized for power transfer in machines with three-phase power, and they ensure stable, low-resistance performance for high-speed applications.

Ring with Pin: In ring with pin designs, the PIN contacts are placed within a ring, ensuring secure and reliable electrical transmission, particularly in systems with high current or rapid rotation. This design offers enhanced durability and performance by minimizing wear and maintaining a solid electrical connection over time. In contrast, pin with ring configurations are typically used in applications where a more compact and efficient design is needed, offering similar performance but with a different structural arrangement that suits specific engineering requirements. Both designs prioritize reliability and longevity, making them suitable for demanding industries.

Slit Rings: For applications requiring a more compact or flexible solution, slit rings can be used in place of traditional full-ring designs. These slit rings maintain electrical continuity while allowing for more flexible integration into various equipment setups.

Grand: Innovating Custom Slip Rings for Modern Industries

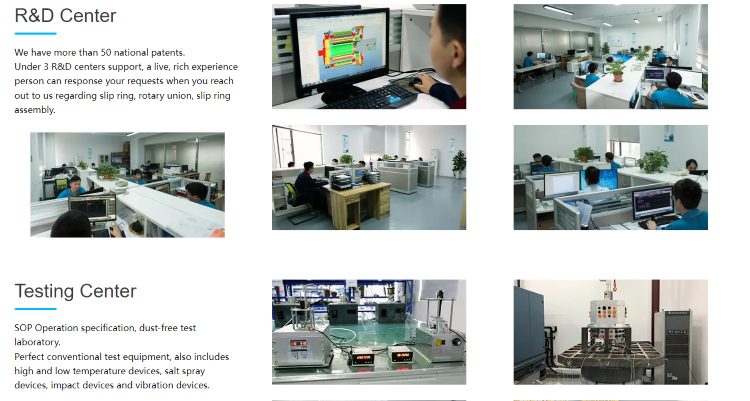

At Grand, we have established ourselves as a leading slip rings manufacturer since 2011, specializing in the design, development, and production of custom slip rings, Rotary Joint, Fiber Optic(FORJ) RF Rotary Joint and so on. Over the years, we have transformed from a specialized manufacturer into a comprehensive solutions provider for industries requiring reliable and high-performance electrical transmission systems. Our 6,000 square meter manufacturing facility is equipped with advanced technologies and automation systems, enabling us to deliver custom engineering slip rings tailored to meet the needs of a wide range of industries, including robotics, aerospace, industrial automation, and renewable energy.

As a forward-thinking company, we have always prioritized innovation and quality. By combining our expertise with cutting-edge technology, we have successfully developed custom sliprings for demanding applications where high speed, high current, and compact designs are essential. Our commitment to continuous improvement and customer satisfaction has earned us a solid reputation as a trusted partner for companies across the globe.

Certifications, Patents, and Military-Grade Standards

One of the cornerstones of our success is our unwavering commitment to quality and industry standards. We are proud to hold certifications including ISO9001, RoHS, CE, and GJB9001B, all of which demonstrate our adherence to stringent international standards for manufacturing, safety, and environmental responsibility. These certifications ensure that our custom slip rings and rotary joints meet the highest levels of quality, performance, and compliance.

In addition to our certifications, we have been granted more than 50 national patents for our innovative designs and solutions. These patents cover a range of technologies, including advanced slip ring assemblies and custom engineering slip rings. Our ability to continuously innovate and protect our intellectual property has allowed us to stay ahead of the curve in the rapidly evolving electrical transmission industry. Moreover, many of our products are designed to meet military-grade specifications, ensuring they can withstand the harshest conditions. Whether in aerospace, defense, or industrial machinery, our products deliver superior performance, even under extreme temperatures, vibrations, and other challenging environments.

Environmental Responsibility and the Shift from Mercury Slip Rings

As the mercury slip ring market continues to evolve, we are proud to lead the shift away from traditional mercury slip rings in favor of safer, eco-friendly solutions. While mercury slip rings have historically been a staple for delivering smooth, low-resistance electrical connections, the environmental and health risks associated with mercury have led many industries to seek out mercury-free alternatives. The growing concerns surrounding mercury’s toxicity and its impact on both human health and the environment have prompted global regulatory bodies to enforce stricter guidelines and standards.

In response to these challenges, Grand has been at the forefront of developing custom slip rings and custom engineering slip rings that offer similar performance to their mercury counterparts without the associated environmental hazards. Our commitment to producing mercury-free solutions ensures that our products meet the latest industry standards for safety and environmental responsibility, making them an ideal choice for industries that require high-performance, reliable electrical transmission systems while adhering to strict environmental regulations.

Expertise in Custom Engineering Slip Rings and Applications

As specialists in custom slip rings, we understand that each application comes with its own unique challenges. Our team of engineers and designers works closely with clients to develop custom engineering slip rings that meet their exact specifications. Whether it’s designing a slip ring assembly for high-power applications, creating compact solutions for space-constrained environments, or developing systems that can operate under extreme conditions, we have the expertise and resources to deliver exceptional results. Our custom slip rings are used in a wide range of industries, including:

Surveillance & Video:

For surveillance and video equipment that involves rotating platforms or cameras, our custom slip rings ensure stable power and data transmission, even during high-speed rotations, allowing for continuous monitoring and uninterrupted video feed.

Wind Turbine:

Our custom slip rings are crucial in wind turbines, transmitting power from the rotating blades to stationary systems. Designed to withstand extreme weather and demanding environments, they ensure efficient energy generation and reliable performance in renewable energy systems.

Stage Lights:

In stage lighting systems, our slip rings facilitate reliable power and signal transmission to lighting rigs and equipment, ensuring smooth operation during performances and enabling dynamic lighting changes without interruption.

Entertainment Equipment:

For entertainment technology that requires constant movement, such as rotating video screens or stage effects, our custom slip rings provide seamless electrical connections, ensuring high performance and reliable operation in high-speed environments.

Packing Machine:

In the packing machine industry, where continuous, automated operations are essential, our custom slip rings support stable power and signal transmission between rotating and stationary parts, enhancing production efficiency and minimizing downtime.

Robotic Arm:

Our custom slip rings play a pivotal role in robotic systems, ensuring precise and continuous transmission of power and signals between stationary controllers and moving robotic arms, enabling automation in manufacturing and assembly processes.

Construction Machinery:

For construction machinery such as cranes and excavators, our slip rings provide reliable electrical transmission between rotating components, ensuring smooth operation and preventing breakdowns even in demanding construction environments.

Medical Devices:

In medical devices, where precision and reliability are paramount, our custom engineering slip rings help ensure consistent power and data transmission in rotating medical equipment, improving the accuracy and safety of diagnostic and treatment systems.

Marine:

Our custom slip rings are used in marine applications, such as radar systems and underwater equipment, to transmit electrical power and signals reliably in challenging, high-moisture environments, ensuring safety and efficiency in marine operations.

Cable Reel:

For cable reels that require constant rotation, our slip rings provide reliable power and signal transmission through rotating cables, ensuring seamless performance in applications like offshore rigs, wind turbines, and entertainment venues.

Automation:

In industrial automation, where machines and systems continuously rotate, our custom slip rings ensure that power and data are transmitted consistently across moving parts, supporting a wide range of applications from factory automation to testing systems.

Measuring Equipment:

Precision measuring equipment benefits from our custom slip rings, which ensure stable electrical connections for accurate data transmission between rotating sensors and stationary components, maintaining high measurement accuracy in testing and analysis systems.

Military:

For military applications, our custom slip rings provide secure, high-performance electrical connections for radar systems, communication equipment, and other critical military technologies, ensuring reliable operation in extreme conditions and sensitive environments.

Radar & Antenna:

Our slip rings are essential in radar and antenna systems, transmitting power and data between rotating antennas and stationary equipment. Designed to handle high-speed rotations and critical communications, they provide secure and uninterrupted connections for defense, weather monitoring, and communication applications.

Strategic Partnerships and Global Reach

Throughout our growth, Grand has built strong relationships with leading companies and research institutions across Asia and Europe. Our collaborations with industry giants such as Panasonic, SIEMENS, SAMSUNG, and HUAWEI have been instrumental in enhancing our technological capabilities and expanding our global reach. These strategic partnerships allow us to stay at the forefront of industry developments, continually improving our product offerings and expanding the range of custom slip rings and rotary joints we offer.

Additionally, we work closely with universities and research institutions to stay on top of emerging trends and integrate the latest technologies into our products. By leveraging these collaborations, we ensure that our customers have access to the most advanced and reliable solutions available.

Advanced Testing and Manufacturing Capabilities

At Grand, we understand that reliability is paramount. That’s why we have invested heavily in our testing center, which is equipped with a wide range of equipment to conduct rigorous performance and reliability tests. Our testing facilities include high and low-temperature chambers, salt spray testing, impact resistance machines, and vibration devices. This comprehensive testing process ensures that every custom slip ring we produce meets the highest standards of quality and durability.

Our manufacturing process is equally advanced. We utilize a combination of skilled labor and automation to enhance production efficiency, repeatability, and product consistency. By integrating automation into our workflow, we have been able to reduce lead times, improve quality control, and increase overall productivity, ensuring that our clients receive the highest-quality products within the shortest possible time frame.

A Commitment to Innovation and Customer Satisfaction

At Grand, we are driven by a passion for innovation and a commitment to delivering the highest-quality custom slip rings and rotary joints. We believe that every project is an opportunity to push the boundaries of what is possible, and we work tirelessly to ensure that our products meet the exact needs of our clients. Our focus on customer satisfaction, combined with our technical expertise and advanced manufacturing capabilities, makes us a trusted partner for industries around the world.

Additionally, we work as belt clip pin ring assembly suppliers China to provide specialized solutions for clients looking for high-quality, durable, and customizable pin ring assembly products. Whether you’re looking for a custom slip ring for industrial automation, renewable energy, or medical applications, we are here to deliver the expertise and reliability you can trust.

FAQs about PIN Slip Rings

What is the difference between a collector ring and a slip ring?

A collector ring and a slip ring both serve the purpose of transferring electrical signals or power between rotating and stationary components, but they operate differently and are used in different applications. A collector ring typically refers to a simpler, mechanical contact system that is often used in low-current applications. It consists of a stationary ring that maintains contact with a brush or contact surface as it rotates. These systems are typically used in less demanding applications where precision and high durability are not as critical.

In contrast, a slip ring is a more sophisticated device designed for transferring electrical power and signals between rotating and stationary parts while allowing continuous rotation. Unlike a collector ring, slip rings are usually composed of multiple rings, often in conjunction with brushes that slide across the rings’ surfaces. Slip rings are used in more advanced applications, such as in wind turbines, robotics, medical equipment, and military systems, where high current, high precision, and reliability are required. The main difference is that slip rings offer greater performance and are built to handle more complex and demanding electrical transmission tasks.

What is the purpose of the slip rings?

The primary purpose of slip rings is to enable the transmission of electrical signals and power from stationary components to rotating parts or vice versa, without any interruption. This continuous connection is essential in systems that involve rotational motion, such as wind turbines, robotic arms, radar systems, stage lights, and medical devices. In such systems, the rotating parts, like antennae or rotating machinery, need a constant flow of power or data to operate, and the slip ring ensures that this transmission occurs smoothly as the components rotate.

Slip rings help avoid the need for complex wiring systems that could get tangled or damaged due to constant movement. They allow for reliable, efficient electrical connections, minimizing wear and ensuring consistent performance even in high-speed or harsh environments. This is especially important in industries like automation, telecommunications, military, and aerospace, where high-performance systems are critical, and downtime or failure is unacceptable.

Why are slip rings so expensive?

The cost of slip rings can vary based on several factors, but they tend to be more expensive than simpler electrical connectors due to their complexity and the materials required for their production. One of the primary reasons for the high cost of slip rings is their construction. They are often made from specialized materials that are durable and capable of handling high current, high-speed rotation, and environmental stresses. These materials, such as gold, silver, and specialized alloys, help ensure smooth electrical conduction and a longer lifespan, but they are more expensive than standard metals.

Another factor contributing to the cost is the precision engineering required for custom slip rings. Many slip rings are designed for specific applications, meaning they must be carefully manufactured to meet the exact requirements of the system they are used in, such as the number of circuits, current capacity, size, and environmental conditions. Research and development (R&D) costs also add to the price, especially for industries like aerospace, medical, and military, where slip rings must meet stringent standards.

Lastly, slip rings are designed for high reliability and long operational life, making them a significant investment for industries that require non-stop performance, such as renewable energy, robotics, and automated systems.

What is the alternative to a slip ring connector?

While slip rings are commonly used for electrical power and signal transmission in rotating systems, several alternatives may be used depending on the application and specific requirements. The most common alternatives include:

Brushless Slip Rings: These use magnetic fields or optical systems to transfer power and data without physical brushes or contacts. While they are often more expensive than traditional slip rings, they offer the advantage of no wear and tear, leading to longer lifespans and reduced maintenance. Brushless systems are ideal in environments with high speeds, such as automotive and renewable energy systems.

Wireless Power Transfer: Inductive coupling or wireless power transfer (WPT) technologies can be used as an alternative in applications where physical connections may be undesirable. This method uses electromagnetic fields to transfer power without any physical contact, reducing wear and tear. It is increasingly used in medical devices and some consumer electronics.

Fiber Optic Slip Rings: For high-speed data transmission applications, fiber optic slip rings offer an alternative. They use optical fibers to transmit data signals between rotating and stationary components. This system is ideal for applications where high-speed data transmission is required, such as in telecommunications, military, and medical imaging.

Rotary Transformers: For certain applications, rotary transformers can be used to transfer electrical energy from stationary to rotating parts. These transformers use magnetic fields to transfer power, making them suitable for high-power applications, such as in military or industrial machinery.

Request a quote for custom FIBER OPTIC ROTARY JOINT (FORJ) designed for your requirements.