In the modern industrialized world, the importance of efficient and effective machinery cannot be overstated. One key component that potential users might fail to recognize is the slip ring assembly. From simplifying system operations to improving mechanical performance, these assemblies bridge the gap between stationary and rotating parts. In this comprehensive guide, we aim to enlighten you on everything you need to know about slip ring assemblies.

We invite you to embark on this learning journey on ‘Slip Ring Assemblies’. Whether you consider this for academic knowledge or industrial usage, this guide will supply the in-depth details you may require. Happy Reading!

Table of Contents

- What are Slip Ring Assemblies?

- The Functionality of Slip Ring Assemblies

- Features of Slip Ring Assemblies

- Components of a Slip Ring Assembly

- Different Types Of Slip Ring Assemblies

- Slip Ring Assembly HS Code

- Slip Ring Assembly System

- Crane Slip Ring Assembly

- Purpose of Slip Ring Assemblies

- Price of Slip Ring Assemblies

- How Does Slip Ring Assemblies Work?

- Advantages and Disadvantages of Slip Ring Assemblies

- Material Used to Make Slip Ring Assemblies

- The Dangers of Slip Ring Assemblies: Causes and Solutions

- The lifespan of Slip Ring Assemblies

- Industries that Most Benefit from Slip Ring Assemblies

- How to Determine if Slip Ring Assemblies Are Suitable for My Application?

- Slip Ring Assemblies Manufacturers

- Conclusion

- FAQs About Slip Ring Assemblies

What are Slip Ring Assemblies?

Slip ring assemblies, also commonly known as rotary electrical interfaces, rotating electrical connectors, collectors, swivels, or electrical rotary joints, are devices crucial to industrial machinery. These assemblies provide a method of transferring electrical power and signal from a stationary body to a rotating one, significantly improving mechanical performance, simplifying system operations, and eliminating damages often caused by rotating connections.

The Functionality of Slip Ring Assemblies

In the most basic terms, slip ring assemblies enable the transmission of electrical power and signals from a stationary to a rotating component in a machine. However, the functional utility of these devices goes far beyond this basic explanation. Here’s a detailed point-by-point look at their functions:

- Uninterrupted Transmission: One of the primary functions of a slip ring assembly is to allow for continuous, unrestricted 360° rotation while maintaining the transmission of power or signals. They are designed to facilitate this rotation without causing any disruption or harm to the device, thus improving operational efficiency.

- Transfer of Various Signal Types: Different types of slip ring assemblies can transmit numerous types of signals, including analog and digital signals, high-frequency signals, and bus protocol signals like CAN bus, Profibus, RS-232, RS-485, etc.

- Adaptable to Environments: Depending on the materials used and their design, slip ring assemblies can operate efficiently in different environmental conditions – from the high temperatures experienced in industrial machinery to the cold conditions in wind turbines.

- Supports Multiple Channels: Slip ring assemblies can simultaneously transfer numerous signals or powers without interference to ensure the smooth operation of machinery.

- Reduction of Mechanical Wear: Due to their ability to reduce the wires’ twisting and tangling, slip ring assemblies reduce mechanical wear and tear, thereby enhancing the system’s service life.

- Supports High-Speed Motion: High-speed slip ring assemblies can ensure stable and reliable transmission even at high-speed rotations, unlocking possibilities for applications in areas demanding high-speed operations.

- Compact Design for Space Optimization: Most slip ring assemblies are designed to be compact for installation in tight spaces, thus optimizing the use of space in machinery or equipment.

Each of the above functions contributes to the crucial role slip ring assemblies play in improving and managing machinery efficiency. Their functional capabilities ensure the smooth operation of various types of machines across numerous industries worldwide.

Features of Slip Ring Assemblies

Slip ring assemblies exhibit numerous features, catering to the diverse requirements of various applications across industries. Here’s a detailed list of the key features observed across different slip ring assemblies:

- Durable Construction: Slip ring assemblies are designed to withstand significant wear and tear, ensuring a longer lifespan for the device. They frequently utilize materials like stainless steel, aluminum, or brass that offer exceptional durability and resistance.

- Low Electrical Noise: Quality slip ring assemblies emit minimal electrical noise during operation, ensuring a stable and reliable transmission of power and signals.

- High Rotational Speed: Some slip ring assemblies can support high rotational speeds without compromising their performance, making them suitable for use in demanding applications requiring rapid, continuous rotation.

- Long Maintenance Intervals: By choosing materials with low friction coefficients, some slip ring assemblies are designed for extended maintenance intervals, limiting the need for frequent upkeep.

- Environmental Protection: Some slip ring assemblies come equipped with ingress protection (IP) ratings, offering protection against dust, water, and debris. This feature helps maintain their performance in harsh environments or applications subject to exposure.

- Wide Temperature Range: Slip ring assemblies are often able to operate within a broad temperature range, making them suitable for various applications exposed to both high and low-temperature conditions.

- Customizable Solutions: Many manufacturers offer customizable slip ring assemblies, catering to the unique requirements of specific applications and industries. These customizations can include options like the number of circuits, material selection, and size adaptations.

- Compatibility with Various Signal Types: Slip ring assemblies can effectively handle various signal types, including analog and digital signals, high-frequency signals, and standardized bus protocols.

- Compact Design: Most slip ring assemblies exhibit a compact design, allowing them to easily be integrated into systems with limited space for installation.

- Simultaneous Transfer of Multiple Channels: Slip ring assemblies often enable the simultaneous transfer of several signals or powers without interference, increasing operational efficiency in complex systems.

These features underline the versatility and effectiveness of slip ring assemblies. By addressing diverse application requirements, they have made their mark as indispensable components in the efficient functioning of machinery across many industries.

Components of a Slip Ring Assembly

Slip ring assemblies typically include the following components:

- Slip ring: The slip ring is the central component of the assembly and consists of a stationary part and a rotating part that are connected by a series of channels or passages. The stationary part is connected to the electrical power or signals source, while the rotating part is connected to the component that needs to be powered or have signals transmitted to or from it.

- Brushes: In brush slip ring assemblies, brushes are used to make contact with the rings to transmit the electrical current or signals. The brushes are typically made of conductive materials, such as carbon, and are mounted on a spring-loaded carrier to maintain contact with the rings.

- Bearings: Bearings are used to support the rotating part of the slip ring and allow it to rotate smoothly and with minimal friction. There are several types of bearings that can be used in assemblies, including ball bearings, roller bearings, and journal bearings.

- Seals: Seals are used to protect the slip ring from contamination and to prevent the transmission of electrical currents or signals to the outside environment. Seals may be made of rubber, metal, or other materials and may be located between the stationary and rotating parts of the slip ring or between the brushes and rings.

- Insulation materials: Insulation materials are used to prevent the transmission of electrical current or signals between the stationary and rotating parts of the slip ring. These materials may be used to insulate the brushes, rings, or other components of the slip ring.

Slip ring assembly is an important component in many applications where a rotating component needs to be electrically powered or have signals transmitted to or from it. They are used to transmit electrical power and signals between stationary and rotating components, allowing for the transmission of power and signals in a wide range of applications.

In general, slip rings that are well-maintained and operated under reasonable conditions can last for many years. However, it is important to regularly inspect and maintain slip rings to ensure that they are functioning properly and to extend their lifespan.

Different Types Of Slip Ring Assemblies

Slip ring assemblies come in various types, each specifically designed to cater to particular needs within special applications. Here’s a detailed narrative highlighting some of the common types of slip ring assemblies:

- Electrical Slip Ring Assembly: The most commonly encountered type of slip ring assembly, the electrical slip ring assembly, is typically used to transfer electrical currents from a stationary component to a rotating component within a machine. These assemblies can handle a range of currents, from low-power signals to high-power applications, across multiple circuits. They have the added advantage of being compatible with a range of signal types, such as analog, digital, or high-frequency signals.

- Fiber Optic Rotary Joint Assembly: Alternatively known as a FORJ, the Fiber Optic Rotary Joint Assembly specializes in transferring light signals instead of electrical ones. These assemblies are designed specifically for situations where high-speed data transfer and low signal attenuation are critical, such as in satellite communication systems, radar systems, and high-resolution cameras.

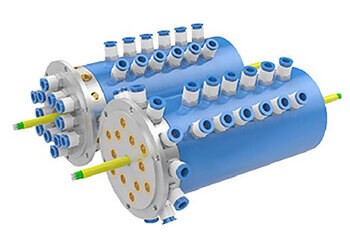

- Hybrid Slip Ring Assembly: A hybrid slip ring assembly combines the capabilities of multiple types of slip rings within a single device. These assemblies incorporate electrical and fiber optic rotary joints or add pneumatic and hydraulic swivels as well. They offer an integrated solution for systems requiring the transmission of power, signals, and media simultaneously and are commonly used in industries such as robotics, marine, and aviation.

- Pancake Slip Ring Assembly: Pancake slip rings feature a flat and disc-shaped design, making them suitable for applications that demand a low-profile installation. They can often be found in applications where vertical space is limited, such as in surveillance cameras, rotating displays, and medical equipment.

- Capsule Slip Ring Assembly: Capsule slip rings are compact and lightweight, designed for use in small-scale applications and devices. Their reduced size makes them a popular choice for applications like CCTV systems, robotics, and rotating display systems.

- Mercury-Wetted Slip Ring Assembly: By employing a mercury-wetted contact system, these assemblies boast features such as low contact resistance, long life, and low noise. The use of mercury results in stable electrical connections, making these assemblies suitable for high-precision environments or sensitive signal transmission situations. However, due to the potential risks associated with mercury exposure, they may not be suitable for all applications.

- Through-Bore Slip Ring Assembly: Also called hollow shaft slip rings, through-bore slip rings possess a central hole that allows the passage of other components, such as shafts, cables, or tubing. They are utilized in applications where the rotating component must pass through the assembly, such as in robotic arms, wind turbines, and certain types of cranes.

- Crane Slip Ring Assembly: Tailored for cranes and similar machinery, crane slip ring assemblies are built to satisfy the specific requirements of these applications. They can manage high-current loads, withstand harsh environments, and accommodate the machinery’s rotational movement, ensuring a smooth, efficient operation.

The above types demonstrate the versatility and expansive reach of slip ring assemblies. Depending on your specific application, different variations may be more suitable, and selecting the correct type of slip ring assembly could be vital to the efficient functioning of your machinery.

Slip Ring Assembly HS Code

A Harmonized System (HS) code is a numerical classification system used by customs authorities around the world to categorize imported and exported goods. The slip ring assembly HS Code has several implications for international trade, including its use in tariff determination, customs clearance, and trade statistics. Below is a detailed point-by-point introduction to the Slip Ring Assembly HS Code:

- HS Code: The HS Code for a slip ring assembly may differ depending on the specific country and the slip ring characteristics, such as the material or its function. However, a commonly used HS Code for electrical slip ring assemblies is 8538.90, which represents parts suitable for use with electrical apparatus.

- Classification Basis: The HS Code is assigned based on a product’s characteristics, use, and composition. For example, slip ring assemblies made of different materials or used in different capacities may have different HS Codes.

- Customs Duties Determination: The HS Code for the slip ring assembly is used by customs authorities to identify the correct customs duties or tariffs imposed on the imported or exported item.

- Compliance with Trade Regulations: Using the correct HS Code for a slip ring assembly ensures that companies are complying with international trade regulations and correctly paying import/export duties.

- Trade Data Collection: The HS Code for a slip ring assembly provides logistics, customs, and trade statistics bodies with the ability to track the import and export of this specific item, supporting global trade data collection and analysis.

- Certification and Inspection Requirements: The HS Code given to a slip ring assembly may determine the type of certificates and inspection requirements needed, as some products in certain categories might require special certificates or additional inspections.

- Trade Agreement Benefits: Trade agreements may offer lower tariffs or duty-free trade on certain HS Code categories. By knowing the slip ring assembly’s HS Code, you can verify whether the product falls under these tariff preferences.

Remember, it’s essential to ensure that the correct HS Code for specific slip rings is used in all trade documents. Failing to list the correct HS Code may result in incorrect customs duties, delays in customs clearance, and potential legal issues.

Want to know more about our products? Fill out the form to receive detailed specifications.

Slip Ring Assembly System

A slip ring assembly system allows for the transfer of electrical power, data, or signals from stationary to rotating components within a wide array of applications. These systems are designed to ensure an uninterrupted and smooth transmission while minimizing electrical noise, and mechanical wear and facilitating the rotation of machinery parts. Here’s a detailed point-by-point introduction to slip ring assembly systems:

- System Components: A typical slip ring assembly system consists of multiple parts, including brushes, brush holders, slip rings, a central shaft, and housing or cover. These components work together to facilitate the transmission of power or signals between stationary and rotating components.

- Slip Ring Types: Various slip ring types cater to specific application requirements. Electrical slip rings, fiber optic rotary joint assemblies, hybrid slip rings, and mercury-wetted slip ring assemblies are just a few examples of these specialized systems.

- Transfer Capability: Slip ring assembly systems can transfer a wide range of signals and currents, from low voltage communication signals to high power applications. Their designs also enable the simultaneous transfer of multiple channels without interference.

- Rotation Support: A crucial function of slip ring assembly systems is to enable continuous 360° rotation while maintaining power or signal transmission. This allows for the smooth operation of machinery without disrupting communication or power flow.

- Environmental Protection: Slip ring assembly systems can be designed to withstand harsh environments by incorporating ingress protection (IP) ratings and materials that resist corrosion, high temperatures, and other environmental challenges.

- Size and Shapes: Slip ring assembly systems come in a variety of sizes and shapes, catering to the diverse installation needs of different applications. Compact and pancake slip ring assemblies save valuable space, while through-bore slip rings provide central holes for additional components.

- Maintenance and Durability: Slip ring assembly systems are designed to be low-maintenance and highly durable. The choice of materials and design features help reduce friction, wear, and electrical noise, leading to an extended service life.

- Customization: Manufacturers offer customized slip ring assembly systems to meet the unique requirements of specific applications, with options for varying circuit numbers, material selection, size adaptations, and transmission capabilities.

By enabling the efficient transmission of power and signals between stationary and rotating components, slip ring assembly systems play a vital role in an array of machinery and equipment. Their versatility, adaptability, and customizable features make them an indispensable solution for numerous industries across the globe.

Crane Slip Ring Assembly

Crane slip ring assemblies are specialized slip rings designed specifically for use in cranes and similar heavy-duty machinery. Their key features and functions are engineered to accommodate the unique requirements of crane applications such as high-current loads, harsh environments, and the rotational movement of various mechanical parts. Here’s a detailed introduction to crane slip ring assembly, highlighting its distinct characteristics:

- High-Current Load Handling: Crane slip ring assemblies are built to manage high-current loads that are frequently found in crane machinery and heavy-duty applications. They can efficiently transmit power and signals to rotating parts without losing performance.

- Rugged Construction: These slip rings are constructed to withstand the harsh environmental conditions, vibrations, and impacts that cranes are often subjected to. Materials such as stainless steel or high-strength alloys are commonly used, which ensure durability and long-lasting performance.

- Adaptability to Motion: Crane slip ring assemblies are designed to accommodate the frequent rotational movement found in crane applications. They enable the smooth transfer of electrical currents between the rotating and stationary parts, facilitating hassle-free movement and operation.

- Maintenance Features: Considering the demanding nature of crane operations, crane slip ring assemblies are often designed to be low-maintenance, reducing the need for frequent upkeep. The use of materials with low friction coefficients and effective sealing helps prolong the maintenance intervals.

- Compatibility with Various Drive Systems: Crane slip ring assemblies can be easily integrated with a range of crane-specific drive systems, including electric motor drives, hydraulic units, and mechanical gearboxes.

- Wide Temperature Range: Given the environments cranes operate in, crane slip ring assemblies are developed to function efficiently across a broad temperature range, making them resistant to potential environmental challenges they may encounter.

- Customizable Options: Manufacturers often offer customization options when it comes to crane slip ring assemblies, taking into account specific application needs such as varying load capacities, additional circuits, and tailored mounting solutions.

- Safety Features: Safety is paramount in crane applications. Crane slip ring assemblies are designed to reduce the risk of electrical faults and mechanical failures, ensuring that equipment operates safely and efficiently.

In conclusion, crane slip ring assemblies contribute significantly to the smooth and safe operation of heavy-duty machinery like cranes. By understanding and catering to their specific requirements through rugged construction, high-current handling, and adaptable motion features, these assemblies play a crucial role in the efficiency and reliability of crane operations.

Purpose of Slip Ring Assemblies

The main purpose of slip ring assemblies is to facilitate the transfer of power, electrical signals, or data between stationary and rotating components within various equipment and machinery.

They play a critical role in the smooth operation of numerous applications and industries. Here’s a detailed point-by-point introduction to the purpose of slip ring assemblies:

- Uninterrupted Transmission: Slip ring assemblies ensure an uninterrupted transfer of electrical signals, data, or power between stationary and rotating parts, maintaining a continuous flow and preventing disruptions in operation or data transmission.

- 360° Rotation Support: By accommodating continuous 360° rotation for the connected machinery parts, slip ring assemblies enhance the range of motion and flexibility of various systems, such as radar antennas, cranes, and wind turbines.

- Wide Range of Applications: Slip ring assemblies cater to a diverse array of applications, from heavy machinery to precision instruments, robotics, and entertainment systems, ensuring the efficient transmission of power and data in diverse situations.

- Compatibility with Various Signals: Slip ring assemblies can handle the development of various signal types, such as high-frequency, digital, and analog signals, making them versatile solutions for multiple needs.

- Adaptability to Harsh Environments: Many slip ring assemblies are designed to withstand harsh conditions, including extreme temperatures, dust, moisture, or vibrations, ensuring a reliable operation in demanding applications and industries.

- Space Efficiency: Slip ring assemblies come in different sizes and shapes, allowing for effective use of space in installations with height constraints, tight spaces, or varying shapes of equipment.

- Low Maintenance Requirement: By utilizing low-wear materials and design features, slip ring assemblies often require minimal maintenance, reducing the need for frequent upkeep and contributing to the system’s longevity.

- Customization: Manufacturers frequently offer customization options, allowing slip ring assemblies to be tailored to the unique requirements of specific applications and industries.

In summary, the purpose of slip ring assemblies is to efficiently manage power and signal transmission, support rotational movement, and ensure smooth operation across a wide range of applications. This flexibility, adaptability, and customization make slip ring assemblies a critical component in many industries worldwide.

Price of Slip Ring Assemblies

The price of slip ring assemblies can vary greatly due to their diverse range of applications, materials used, complexity, and customization requirements. Here’s a detailed point-by-point introduction of the factors that influence the cost of slip ring assemblies:

- Size and Dimensions: Different sizes and dimensions influence the cost of the assembly. Larger, more complex assemblies tend to cost more due to the increase in material and production requirements.

- Material Used: The type of material used in the assembly significantly affects its price. High-quality materials, such as precious metal contact materials, can increase the cost due to their superior electrical characteristics and durability.

- Specification and Performance: The specifications and performance parameters of the slip ring, like the number of circuits, signal types and power rating, data transmission speed, and IP rating, can affect the price of the assembly.

- Customization: Custom-designed slip ring assemblies can command higher prices due to the additional design, engineering, and production work required to meet specific customer requirements.

- Volume and Quantity: The quantity of slip ring assemblies ordered can heavily influence the price per unit. Price per unit typically goes down with an increase in volume due to economies of scale.

- Brand and Quality Assurance: Well-known brands with a reputation for high quality, reliability, and solid warranty terms often charge more for their products than lesser-known manufacturers.

- Application: The specific applications for which a slip ring assembly is designed can also affect its cost. Assemblies for use in demanding environments or specialized industries might be more costly due to their enhanced build quality, engineering, and components.

- Delivery and Shipping: The cost of delivery, shipping, and potentially import/export duties can add to the final price of the assembly and can depend on factors like delivery speed, destination, and product weight.

In conclusion, the price of slip ring assemblies can vary widely based on several factors. It’s essential to weigh these factors carefully and understand the needs of your specific application to find the solution that offers the best value for your investment.

How Does Slip Ring Assemblies Work?

Slip ring assemblies are designed to transmit electrical signals, data, or power between stationary and rotating components. They ensure continuous transmission while facilitating the smooth rotation of machinery parts. Here’s a detailed point-by-point introduction to how slip ring assemblies work:

- Main Components: A slip ring assembly consists of several key components: slip rings, brushes (or brush blocks), brush holders, central shaft, and housing or enclosure. These parts work together to facilitate electrical transmission between the stationary and rotating parts.

- Slip Rings: Slip rings are circular conducting rings usually made from copper alloys, precious metals, or graphite. They are mounted on and rotated with the central shaft connected to the rotating component.

- Brushes: Brushes are stationary conductive elements, typically made of precious metal alloys or graphite materials, that press against the slip rings. The brushes usually have built-in springs to maintain contact pressure, ensuring proper transmission and reducing wear.

- Brush Holders: Brush holders securely position the brushes, evenly distributing contact pressure on the slip rings. These holders are designed to allow the brushes to move freely, accommodating the slip ring rotation.

- Central Shaft: The central shaft functions as the slip ring assembly’s core and physically connects the rotating component. The slip rings are mounted on this shaft, allowing them to rotate with the component.

- Housing: The housing or enclosure of the slip ring assembly contains and protects its internal components while allowing the central shaft to rotate. It also provides a secure location for the brush holder and wiring connections to the stationary part.

- Transmission Process: As the slip ring rotates with the central shaft, the brushes remain in constant contact with the slip rings, creating an electrical circuit. The rotating motion of the shaft thus does not disrupt the electrical flow, ensuring continuous transmission between stationary and rotating components.

- Minimizing Noise and Wear: To reduce wear and maintain the efficiency of the assembly, the brushes and slip rings are often made of low-wear materials. Meanwhile, the brush contact pressure, positioning, and housing design help minimize electrical noise and maintain a smooth signal transmission.

By enabling constant electrical transmission between stationary and rotating components, slip ring assemblies make it possible for a wide array of machinery and equipment to operate smoothly, from industrial machinery and renewable energy systems to medical equipment and communication devices.

Advantages and Disadvantages of Slip Ring Assemblies

Like any mechanical or electrical components, slip ring assemblies come with their own sets of advantages and disadvantages. Understanding these helps inform the best application for slip ring assemblies and highlights areas for future technological improvement.

Advantages of Slip Ring Assemblies

- Uninterrupted Transmission: They allow for the continuous transfer of power, data, and signals between stationary and rotating parts without interruption, which is vital in numerous applications.

- 360-degree Rotation: Enables unrestricted 360-degree rotation of machinery and equipment parts, enhancing functionality and range of motion.

- Versatility: With a wide range of sizes, capacities, and custom options, they can be adapted to virtually any application, from industrial equipment to consumer electronics.

- Multi-channel Capability: Their design can accommodate multiple electrical circuits for simultaneous transmission of power, signals, and data.

- Durability: Many are made of robust and long-lasting materials, making them durable and reliable in various environments, even under long service life and harsh conditions.

Disadvantages of Slip Ring Assemblies

- Maintenance: Due to the physical contact between the brushes and slip rings (in traditional designs), wear and tear can occur over time, which may require maintenance or replacements.

- Signal Quality: Noise can be introduced due to the sliding contact between brushes and slip rings, affecting the quality of signals, especially in high-speed, high-frequency, or data transmission applications.

- Environmental Sensitivity: Dust, moisture, extreme temperatures, or corrosive substances can affect performance, particularly in assemblies that aren’t sealed or protected adequately for the environment.

- Cost: Custom, high-frequency, or high-power slip ring assemblies can be expensive due to their complexity and the specialized materials used.

- Size Constraints: Their size and length may pose limitations on integration, especially in instances where space is constrained.

While slip ring assemblies have some disadvantages, innovations continue to mitigate these issues. For example, contactless slip ring assemblies (aka rotary transformers or induction couplers) can address problems with wear, noise, and environmental effects. Therefore, understanding the application’s specific needs will lead to a suitable choice from an array of slip ring options.

Material Used to Make Slip Ring Assemblies

The materials used in the construction of slip ring assemblies are crucial in determining their performance, durability, and application suitability. Here’s a detailed, point-by-point description of the commonly used materials in the manufacturing of slip ring assemblies:

- Slip Rings: The main conducting rings, also known as ‘slip rings’, are typically made from high-quality conductive metals. Copper is a common choice, often in the form of copper alloys, due to its excellent electrical conductivity. For demanding or high-performance environments, precious metals like gold, silver or palladium may be used owing to their superior electrical properties and reduced contact noise.

- Brushes: Just like slip rings, the brushes also need to be conductive and durable. Graphite (carbon) is generally used for larger, higher-current applications, whereas precious metals like gold, silver, or palladium are used in small, low-current assemblies due to their superior electrical properties and minimal noise.

- Brush Holders: The brush holders need to be electrically insulating and often are made up of plastic or other non-conductive materials.

- Enclosure or Housing: The enclosure or housing of the slip ring assembly is often made with robust and durable materials such as aluminum or stainless steel. This is to protect the internal components from environmental factors and mechanical damage.

- Sealants: For slip ring assemblies used in harsh or outdoor conditions, sealants may be used to provide protection against dust, moisture, or corrosive elements. The type of sealant or coating used will depend on the specific environmental requirements of the application.

- Bearings: The bearings used for the rotating shaft in the slip ring assembly are often made from steel or other strong metals to withstand operational stress and ensure smooth rotation.

- Wires and Cables: The electrical wires and cables used within and coming from the slip ring assembly are typically made from highly conductive materials like copper, and are insulated with materials such as PVC, rubber, or heat-resistant polymers.

Each of these materials plays a crucial role in the functionality, reliability, and longevity of the slip ring assembly. The choice of material depends on the specific application, operating conditions, and performance requirements of the assembly.

The Dangers of Slip Ring Assemblies: Causes and Solutions

Slip ring assemblies, while providing critical functions in many mechanisms, also come with potential hazards. These hazards can be mitigated or prevented by understanding their causes and applying appropriate measures. Below are some dangers commonly associated with slip ring assemblies, their causes, and effective solutions:

1. Electric Shock

Cause: Direct or unwanted contact with the powered parts of the slip ring assembly could result in electric shock.

Solution: Always de-energize and isolate the assembly before performing any maintenance or inspection. Also, make sure to use properly insulated tools and personal protective equipment (PPE) when handling these assemblies.

2. Overheating and Fires

Cause: Overloading of the slip ring assembly that surpasses its intended capacity can cause overheating and potentially start a fire.

Solution: Always make sure that the assembly is operated within its designated capacity limits. Regularly observe the assembly for any signs of discoloration or unusual temperature rise indicating excessive heat generation.

3. Mechanical Failures

Cause: Improper operation, irregular maintenance, or using the assembly beyond its life expectancy can lead to mechanical failure.

Solution: Perform regular maintenance as guided by the manufacturer. Replace worn-out parts and retire the assemblies that have exceeded their life expectancy.

4. Equipment Malfunction or Damage

Cause: Poor quality signals or power fluctuations can cause malfunctions or damage to the linked equipment.

Solution: Use slip rings with noise reduction features and suitable signal processing for the intended application to ensure consistent and clean data transmission.

5. Environmental Hazards

Cause: Substandard assemblies or those not designed to handle a specific environment (extreme temperatures, dust, humidity, etc.) can fail and might cause accidents.

Solution: Use slip ring assemblies designed for specific environmental conditions or with specified IP ratings for dust and water resistance.

6. Noise and Vibration

Cause: A worn-out or poorly mounted slip ring assembly can cause excessive noise and vibration.

Solution: Regularly maintain and inspect assemblies for wear and tear. Make sure assemblies are correctly mounted and balanced to minimize noise and vibration.

Remember, the key to safely operating and maintaining slip ring assemblies lies in understanding their limitations and potential hazards, implementing proper safety procedures, and regularly monitoring their condition. Always refer to manufacturer guidelines for operating parameters and safety instructions.

The lifespan of Slip Ring Assemblies

The lifespan of slip ring assemblies can vary significantly depending on several factors including the quality of the components, the operational environment, the load it carries, and maintenance practices. Here’s a detailed explanation:

- Quality of Components: High-quality components, manufactured to precise industry standards, can ensure a long lifespan for slip ring assemblies. Premium materials used in slip rings and brushes, such as precious metals, can result in lower wear and longer service life.

- Operational Environment: The environment in which the slip ring assembly operates can greatly affect its lifespan. For instance, assemblies operating in harsh or corrosive environments, extreme temperatures, or exposed to dust or moisture will typically have a shorter lifespan unless designed and protected appropriately for these conditions.

- Load Carried: The electrical load carried by the slip ring assembly also impacts its lifespan. Units constantly operating at high power outputs, or at the limits of their voltage or current capacities, are likely to experience accelerated wear and shorter lifespans.

- Maintenance Practices: Regular maintenance can significantly prolong the lifespan of slip ring assemblies. This includes regular inspection for wear and tear, cleaning of slip rings and brushes, and ensuring that the assembly is adequately lubricated (if required).

- Type of Slip Ring Assembly: The type of assembly also affects its lifespan. For example, contactless slip rings (like rotary transformers or induction couplers) typically have longer lifespans than traditional slip ring assemblies due to the absence of physical wear between components.

In general terms, a well-manufactured and maintained slip ring assembly in a suitable environment can last several years. Some high-quality assemblies have been reported to last for over 100 million revolutions. Always refer to specific manufacturer’s guidelines for a particular assembly’s expected lifespan and maintenance requirements.

Industries that Most Benefit from Slip Ring Assemblies

Slip ring assemblies are incredibly versatile devices that find use in a wide array of industries. These devices facilitate the transmission of electrical power, data, or signals between stationary and rotating parts of equipment. Here are some of the significant industries that most benefit from these assemblies:

- Wind Energy: In wind turbines, slip ring assemblies transfer electrical power from the rotating nacelle to the stationary grid. They can also transmit control and sensor signals between the stationary and rotating parts of the turbine.

- Industrial Manufacturing: In various rotating equipment used in assembly lines, packaging, and automated machinery, slip ring assemblies are crucial for power transfer and signal communication. MRI machines and CT scanners in medical imaging are also significant users.

- Defense and Aerospace: In radar systems, slip ring assemblies are used to connect the stationary and rotating parts of the radar antenna. They’re also used in gun turrets, targeting systems, and satellites for power and data transfer.

- Automotive Industry: Slip rings are used in electric vehicles for power transmission to rotating parts. They are also used in the steering wheel for enabling the connection of electrical components such as airbags, controls, and more.

- Maritime Industry: On board ships, slip ring assemblies are used in propulsion systems, radar systems, winches, and other rotating equipment for power transmission and communication signals.

- Entertainment Industry: In rotating stages, lighting systems, and cable reels, slip ring assemblies enable seamless power and signal transmission.

- Renewable Energy: Beyond wind energy, slip rings are also used in concentrating solar power plants where they enable the tracking system to follow the sun’s movement.

- Telecommunications: In satellite communication systems, slip ring assemblies help maintain the connection between stationary and rotating parts, transmitting power and data.

These are just a few examples; the adaptability of slip ring assemblies allows for their use in practically any industry where there is a need for power, data, or signal transmission between stationary and rotating systems. As such, they continue to be relevant and essential in evolving technologies and applications.

How to Determine if Slip Ring Assemblies Are Suitable for My Application?

Selecting the right type of slip ring assembly for your application requires a detailed understanding of your operational requirements, environmental conditions, and technical specifications.

Here are five key factors to consider:

- Type of Transmission: Identify whether you need to transmit power, data, signals, or a combination thereof. The type of transmission required will help determine the specific model of slip ring assembly, as different models offer varied capabilities for transmission.

- Power and Signal Requirements: Evaluate the voltage and current your application will require. Review signal types (analog, digital, or both) and required data rates for signal transmission. This information will help select an assembly that can handle your application’s power and data needs safely and efficiently.

- Rotational Speed: Consider the rotation speed of the application. Some slip rings are designed for slow rotations, like in wind turbines, while others cater to high-speed rotations, such as in certain industrial machinery.

- Environment: The operational conditions are also crucial. For instance, if your application operates in a harsh, dust-filled, or corrosive environment, you would need a slip ring assembly designed to withstand these conditions. High or low-temperature environments would require special materials that can operate within these temperature ranges.

- Maintenance and Durability: Evaluate if regular maintenance of the assembly will be possible. If maintenance will be challenging due to the assembly’s placement or operation, consider slip ring assemblies that require less maintenance or have longer service lives, such as contactless slip rings.

- Size Constraints: Consider the physical space available for integrating the slip ring assembly into your application. Make sure you match the size of the assembly to fit within the physical constraints of your system.

- Budget: Lastly, consider your budget. Premium models with advanced features or made with expensive materials may offer superior performance but also come with a higher price tag.

After evaluating all these factors, consulting with a manufacturer or a distributor specializing in slip ring assemblies can provide valuable guidance. They can take into consideration your specific requirements and suggest the most suitable alternatives. Always ensure that the selected slip ring assembly matches your needs and operational demands to ensure optimal performance and longevity.

Slip Ring Assemblies Manufacturers

Many manufacturers around the globe specialize in producing high-quality slip-ring assemblies. These companies often offer customizable solutions, meeting the varying requirements of different industries and applications.

| No. | Manufacturer | Website |

|---|---|---|

| 1 | Hangzhou Grand Technology | https://www.grandslipring.com/ |

| 2 | Moog | https://www.moog.com/ |

| 3 | Schleifring | https://www.schleifring.de/ |

| 4 | Cobham | https://www.cobham.com/ |

| 5 | Stemmann-Technik | https://www.stemmann.com/en/home |

| 6 | Mersen | https://www.mersen.com/ |

| 7 | GAT | https://www.gat-mbh.de/ |

| 8 | Morgan | https://www.morganelectricalmaterials.com/en-gb/ |

| 9 | Cavotec SA | https://www.cavotec.com/ |

| 10 | LTN | https://www.ltn-servotechnik.com/ |

If you want to know about other well-known slip ring manufacturers in the world, you can read Top 10 Slip Ring Industry Key Manufacturers 2023, Top 10 Slip Ring Manufacturers In the USA Market 2023, and Top 10 Slip Ring Manufacturers in China.

Conclusion

As a critical component for enabling the rotation of electronic and electrical components, slip ring assemblies are of paramount importance in numerous applications. Their use helps enhance equipment efficiency by ensuring uninterrupted and high-quality transmission of electrical signals and power. The lifespan, functionality, and versatility make slip ring assemblies an indispensable asset in industries requiring constant mechanical rotation.

Request a quote for our slip rings by providing your details in the form.

FAQs About Slip Ring Assemblies

Q: What are some key considerations when selecting a slip ring assembly?

A: Factors such as the required rotational speed, type and amount of data or power to be transmitted, environmental conditions, and specific application requirements should be considered.

Q: How are slip ring assemblies maintained?

A: Regular inspection, cleaning, and replacement of worn-out components form the core of slip ring maintenance.

Q: What materials are commonly used in slip ring assemblies?

A: Slip ring assemblies are constructed using a variety of materials. Some common materials include copper and its alloys for slip rings, graphite or precious metals (e.g., gold, silver, or palladium) for brushes, plastic or non-conductive materials for brush holders, and aluminum or stainless steel for housing. The choice of material depends on the specific application and operational requirements.

Q: How long do slip ring assemblies typically last?

A: The lifespan of a slip ring assembly depends on factors such as the quality of components, operational environment, electrical load, and maintenance practices. A well-maintained, high-quality slip ring assembly in a suitable environment can last several years. Some high-quality assemblies have been reported to last for over 100 million revolutions. Always consult the manufacturer’s guidelines to estimate individual assembly lifespan and maintenance requirements.

Q: In which industries are slip ring assemblies primarily used?

A: Slip ring assemblies are versatile devices used in numerous industries. Key industries where they find applications include wind energy, industrial manufacturing, defense and aerospace, automotive, maritime, entertainment, renewable energy, and telecommunications. They are utilized wherever there is a need to transmit electrical power, data, or signals between stationary and rotating parts of equipment.

Q: How do I determine if a slip ring assembly is suitable for my application?

A: When selecting a slip ring assembly, consider factors such as the type of transmission required (power, data, or signals), the required power and signal characteristics, rotational speed, operational environment, maintenance and durability needs, physical size constraints, and your budget. Consult with a manufacturer or distributor to help select the most appropriate slip ring assembly for your specific requirements.

Q: Are there different types of slip ring assemblies for various applications?

A: Yes, there are various types of slip ring assemblies designed for specific applications and requirements. These include traditional assemblies with physical contact between brushes and slip rings, and contactless slip rings that rely on magnetic induction or optical transmission. Different slip ring assemblies cater to different transmission requirements, rotational speeds, operating environments, and maintenance needs.

Note

Please note that the contents provided in this guide are based on general knowledge about slip ring assemblies. For specific applications, consulting with a slip ring assembly manufacturer or specialist is highly recommended to ensure the most accurate and beneficial information.

See What We Can Do