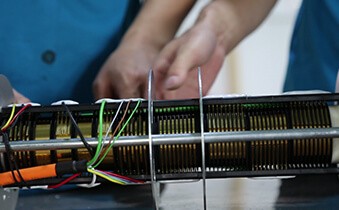

A fiber-type brush electrical slip ring means a fiber-type brush has a sliding contact with an electrical ring for transmitting signals and current.

It has good stability, high precision, low contact wear rate, low dynamic contact resistance, and long life. It is necessary to know the mechanical contact properties of the fiber brush and the electrical ring, the law of dynamic sliding wear, and the electrical contact characteristics of the brush and the electrical ring.

It is very important for the prediction of the life of the fiber brush electrical slip ring and the further extension of the fiber brush electrical slip ring’s life.

The relationship among the deformation proximity, the maximum contact stress, and the load of the single wire brush and the electrical slip ring is derived by the Hertz formula, and the finite element software ABAQUS is used to create the contact model of the single wire brush and electrical slip ring. The finite element solution is obtained to verify the correctness of the theoretical model of a single wire brush electrical slip ring. On the basis of the study of the single wire brush electrical slip ring, the finite element model of the fiber-type electrical slip ring is created and the quasi-static analysis is carried out. Finally, the load distribution coefficient is drawn out to reveal the contact mechanical characteristics of the fiber-type brush electrical slip ring.

Different types of wear mechanisms are classified, which are mainly divided into adhesive wear, abrasive wear, fatigue wear, and corrosion wear. The factors affecting the wear process and their wear laws are described. Based on the mechanism of adhesive wear, the sliding wear model of the single wire brush and the electrical slip ring is created. After that, the sliding wear model of the fiber-type electrical slip ring is further established, and the formula of the relationship between the wear extent, the wear thickness of the fiber-type brush electrical slip ring, and the time are derived. The electric contact theory is expounded from contact resistance, heat conduction theory, and heating of contact spots by current. Based on the electrical contact theory, the electrical contact model of the electrical slip ring is created, the electric potential boundary condition is applied, and the distribution law of the temperature field and the current density of the contact pair of the electrical slip ring and the cloud chart are obtained.

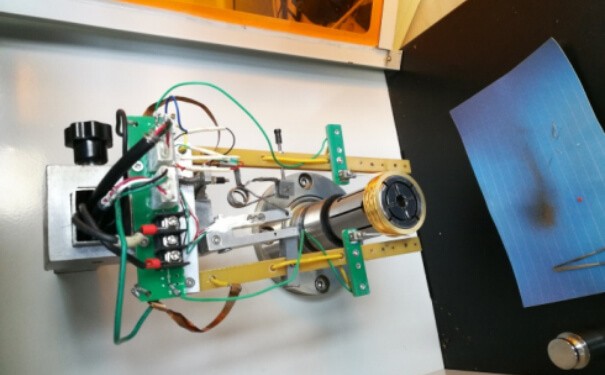

The wear test of electrical contact characteristics is carried out on the electric brush conducting slip ring wear test platform. The contact resistance and friction coefficient of the fiber-type brush conducting slip ring is studied. The micromorphology of the brush and the electrical ring after the test and the composition of the adhesive layer on the surface of the brush wire in the actual working condition are analyzed, and the main wear mechanism of wear of fiber-type electrical slip ring is obtained. It is of great guiding significance to the design, application, and life prediction of the fiber-type brush electrical ring in practical engineering.

Grand Technology test results show that:

- in the process of the accelerated wear test, the results show that the wear state of the left brush wire is light, mainly abrasive wear; the right brush wire is heavy, with inclusions. So the wear state of the brush wire is related to the turning direction of the slip ring.

- Under working conditions, the wear between the electrical ring and the brush wire is mainly adhesive wear.