When we look at any machine type, whether manual or automated, we can see that each part of that machine has its operation to perform. Consider a motor vehicle, where each component contributes to the overall performance of the motor. When we need to transfer electrical impulses in modern machines, we use wires, but what if the path is rotary? In this case, we’re utilizing a device known as a slip ring. “What is a Slip Ring?” you must ask yourself.

What Exactly Is a Slip Ring?

A slip ring is a device that allows electrical impulses to get exchanged between the static part of an electromechanical device and the rotating wick. Sometimes one definition is insufficient to pursue the concept of how any electronic component works. But don’t worry, we are about to reveal everything so you can clarify your question.

Slip Ring Construction:

A slip ring consists of two fundamental components.

Stable or Static Component:

This component remains constant throughout the process.

Rotating or Rotating Part:

This part rotates in a circular motion while it operates.

What is the Function of a Slip Ring?

The metal ring will start rotating and interact with the fixed part between the turns at the start of the revolution. It will pick up signals from this static portion as it interconnects with stationary graphite. As a result, these two critical components of the slip rings provide a secure path for electrical impulses between them.

Types of slip rings

A slip ring is of several types based on its intended use. Here are some of the most common and vital slip ring types are:

Miniature Slip Rings

These rings are typically smaller in size. Slip rings like these are necessary for small rotating devices like CCTV systems.

Pancake Slip Rings

This slip ring stands out from the crowd due to its flat size and negligible height. This type of slip ring is significantly smaller in size than a standard slip ring.

Large Current Slip Ring

Use this type of slip ring when the transmitting current in a device is high. The current rating ranges between 10 A and 500 A in most cases.

Waterproof Slip Rings

These slip rings are shockproof and allow for safe operation in harsh environments.

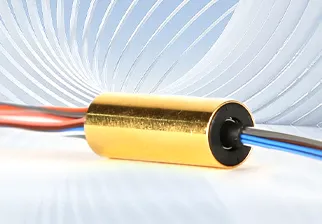

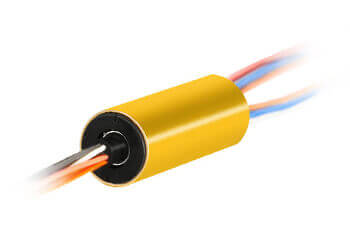

Capsule Slip Rings

These slip rings are helpful in small mechanical assemblies. They are smaller and more conservative in design than other slip rings.

Through Hole Slip Rings

These slip rings have a hole through which any solid object can pass.

Mini Slip Rings

These are slip rings found on small spinning gears. They are typically smaller in size than standard slip rings.

Uses of Slip Rings

Slip rings have a wide range of applications. You can find them in almost all simple machines. However, we have listed some of the most predominant applications for a slip ring.

Power Generation

One of its primary applications is in generators. The slip ring is essential for intensity training in wind turbine generators and various wind turbines like wind turbine slip rings.

Large Cranes

Only a slip ring can provide rotational movement to cranes. As a result, slip rings are crucial in cranes. As a result, the cranes can move the most weight from one location to another.

Motor

This type of slip ring is in mining motors. These expansive motors are in finishing equipment.

See What We Can Do