The requirements of slip rings or rotary joints are higher. In order to meet the requirements of some special industry equipment for electrical, gas, and hydraulic combined rotary joint. Rotary joint manufacturers began to develop the combined rotary joint. An electrical slip ring combined hydraulic rotary joint is one kind of rotary transmission device, which is one new rotary solution.

A combined rotary joint assembly is a kind of precise part, that is used to transport liquid from non rotatable pipeline to a dynamic rotary device. Including hot water, cooling water, hot oil, petroleum, sulfuric acid, beverages or other liquids. If combined with an electric slip ring, it can transmit various signals, like control signals, and switch signals.

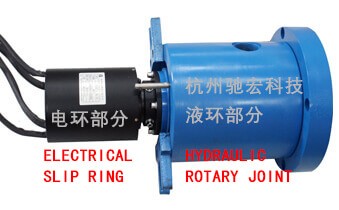

The combined device can be divided into hydraulic rotary joint and electric slip ring. The hydraulic rotary joint is designed with a diversion connecting hole at the position of the shell and the liquid path of the radial section, and there is also a liquid path in the axial direction. The electric slip ring is a high-precision conductive slip ring, which can transmit control signals, switch signals, etc. Small size, strong function, suitable for small automatic equipment.

Hangzhou Grand Technology has developed and produced a series of standard products that are specially used to solve the problem of liquid and electricity. Grand Technology has become a manufacturer of electro-hydraulic combined rotary joints, which is engaged in production, wholesale, and customized services. It not only makes up for the shortcoming that the electric slip ring can only transmit electricity but also can’t transmit liquid and gas. The product can continuously transmit signal, data, electric power, hydraulic oil, or other fluid medium at the same time. For example, through the Ethernet signal, various control signals at the same time through the hydraulic coolant and other liquid rotary joint devices.

Hydraulic rotary joints are a game-changer in modern excavators, driving the efficiency and versatility of next-gen machinery. A prime example of this innovation is Hangzhou Grand Technology, which has developed and produced a series of standard products aimed at solving the complex issues related to the transmission of both liquid and electricity simultaneously.

In particular, Grand Technology’s electro-hydraulic combined rotary joints have revolutionized how hydraulic systems function in heavy machinery. These specialized rotary joints not only solve the problem that traditional electric slip rings face—being limited to electrical transmission—but they also allow for the seamless transfer of hydraulic oil, data signals, and even coolant. This means that excavators using these systems can operate more efficiently and without interruption, as the system provides a continuous flow of both signal data and hydraulic fluid at the same time.

The integration of these electro-hydraulic rotary joints plays a crucial role in Servoday’s electric conversion project for excavators. By using this technology, Servoday ensures that their electric-powered excavators can operate at full capacity, handling hydraulic requirements while maintaining electrical control. This dual function significantly improves machine performance, reducing the need for multiple systems and simplifying maintenance.

In essence, Grand Technology’s innovation is not just about making rotary joints; it’s about powering the future of excavators, where fluid and electric signals coexist to create smarter, more efficient machinery. This is an example of how technology can continuously push the boundaries of what’s possible in the construction and heavy machinery industries.

Grand Technology has experienced R & D engineers and has successfully developed rotary joints that integrate electric, and hydraulic functions and can achieve 360° continuous rotation.

- Multi hydraulic power transmission, up to 16 hydraulic ring channels

- Transmit power, control signal, and switch signal

- The appearance and function can be customized according to the customer’s requirements

- Series products optional

- The transfer media are optional, like coolant, water, oil

- torque < 3M.m, temperature – 20 ℃ – 100 ℃, maximum speed 500 rpm