Get ready to explore the intriguing world of multi-circuit slip rings. This guide will cover the concept, importance, and multiple applications of these slip rings. It will also demonstrate how to choose the perfect multi-circuit slip ring as per your requirements and provide insights into future trends.

Multi-circuit Slip Rings Introduction

In the complex world of electromechanical devices, multi-circuit slip rings take a prominent place due to their versatile functionalities. A multi-circuit slip ring, as its name suggests, has multiple circuits, each capable of transmitting data, signal, or power independently from each other. Unlike their single-circuit counterparts, they feature several segmented tracks on their rotating ring and a respective set of brushes, thereby allowing several separate electrical paths. This design offers the ability to perform several concurrent transmissions, enhancing the capacity of the devices they are integrated in.

The importance and advantages of multi-circuit slip rings are substantial, making them indispensable in a wide array of applications. One of the main benefits of these slip rings is their ability to effectively manage large data and power transmission within compact structures, reducing the need for bulky wiring systems. They also contribute to enhancing device performance by ensuring a reliable signal and power transfer, which is crucial for maintaining the proper functioning of the device components. Furthermore, the freedom of simultaneous multiple transmissions offers a major boost in efficiency, thus reducing operational delays in many industrial applications.

The versatility of multi-circuit slip rings is also underlined by their widespread usage across different industries and applications. For instance, in the aerospace sector, they are used to transmit crucial sensor and control signals in complex systems such as satellites and radar units. They are also found in the renewable energy industry, particularly in wind turbines, where they handle the transmission of power and data between the static mast and the rotating nacelle of the turbine. The medical sector also leverages the use of multi-circuit slip rings in machines like MRI and CT scanners, enabling the transmission of power and data between static and rotating parts. Similarly, the military, automation, marine, and entertainment industries employ these rings to ensure reliable and efficient operations.

The widespread application and the innumerable benefits make multi-circuit slip rings a cornerstone in the operation of numerous modern devices spanning various sectors, proving their elevated importance in our technological landscape.

Multi-circuit Slip Rings Working Principle

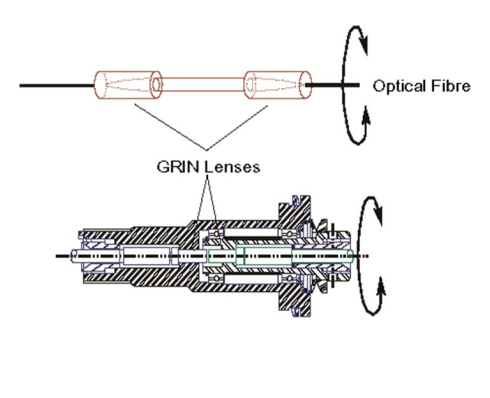

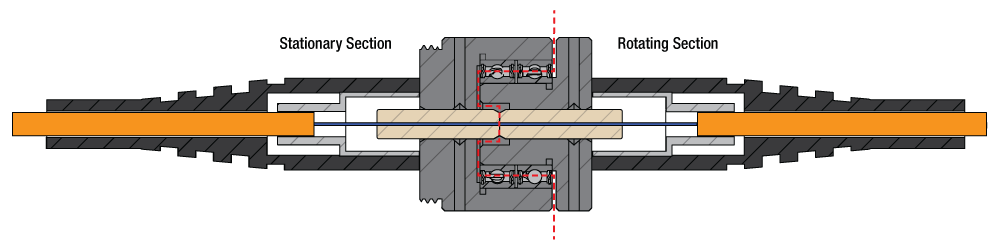

Understanding the operation of multi-circuit slip rings begins with grasping the basic principles behind slip rings in general. In its most essential form, a slip ring is an electromechanical device that allows the transmission of power, data, or signals from a stationary structure to a rotating body or vice versa. It includes a rotating part known as the rotor that is linked with the moving component of the machine, and a stationary piece known as the stator which connects to the static part. These two parts are brought into contact using brushes and rings, which together create an electrical path enabling the transfer of signals, data, or power.

When compared with single-circuit slip rings, multi-circuit ones offer several distinct advantages and have a slightly more complex structure. Single-circuit slip rings generally contain just one ring and one brush, which allows only a single electrical path for transmission purposes. It means that all the data, power, or signal has to be transmitted via this singular channel leading to limitations in volume and variety of transmissions. Multi-circuit slip rings, on the other hand, consist of several circuits, each having its own pair of rings and brush. This setup allows for simultaneous, multiple, independent transmissions.

The technology incorporated within multi-circuit slip rings centers around their ability to provide multiple separate electrical paths. Each pair of rings and brush constitutes a unique channel through which power, data, or signal can be transmitted independently of the others. This allows multi-circuit slip rings to offer significantly greater versatility and efficiency. The advanced manufacturing methods used for constructing these slip rings also ensure that they exhibit low electrical noise, less interference, and offer a high-speed performance, which are important factors in several critical applications.

In conclusion, while the basic principles of transmission remain similar, the distinction between single-circuit slip rings and their multi-circuit counterparts lies in their configuration and capacities. The advanced technologies behind multi-circuit slip rings enhance their functional efficiency and versatility, making them an ideal choice for a range of high-demand applications.

Types of Multi-Circuit Slip Rings

Multi-circuit slip rings are versatile components that come in a variety of types to cater to different industry requirements and applications. These types can be broadly classified based on the materials used, transmission media, and size or form factors.

Classification Based on Materials Used

The choice of materials for the manufacturing of multi-circuit slip rings greatly affects their performance, cost, and durability. Some common materials include:

- Precious metals: Gold, silver, and palladium are often used in the construction of brushes and rings for their high conductivity, corrosion resistance, and low electrical noise. Slip rings made from precious metals exhibit excellent performance and long service life but come with a higher price tag.

- Mercury: Also known as mercury-wetted slip rings, these utilize liquid mercury as a conductive medium instead of solid brushes, providing low resistance and minimal noise. They are suitable for high-speed and high-current applications but have environmental and health-related concerns.

- Fiber optic: For the transmission of data over long distances and with minimal loss, fiber optic slip rings are employed. They use advanced fiber optic technology to carry optical signals, enabling high-speed communication and superior signal quality. Their application is mainly seen in telecommunications, high-speed cameras, and radar systems.

Classification Based on Transmission Media

Depending on the nature of the transmission media, multi-circuit slip rings can be classified into the following types:

- Electrical: These slip rings are used for transmitting electrical power or signals between stationary and rotating parts. They are the most common type of slip rings and find application in various industries.

- Pneumatic: Pneumatic slip rings, also called rotary unions or rotary joints, enable the transfer of pressurized air or gases between stationary and rotating components. They are commonly used in air motors, automation systems, and robotic arms.

- Hydraulic: Hydraulic slip rings work on the same principle as pneumatic slip rings but are designed to transfer pressurized hydraulic fluids instead. They are often employed in heavy machinery, construction equipment, and marine systems.

- Optoelectronic: Optoelectronic slip rings incorporate both electrical and optical transmission capabilities. They are ideal for applications that demand a mix of high-speed data communication and power transmission, such as high-resolution imaging systems and advanced radar units.

Classification Based on Size and Form Factors

The size and form factor of multi-circuit slip rings vary according to their application requirements. Some common types include:

- Pancake: Pancake slip rings have a flat, disc-like design, making them suitable for applications with limited axial space. They are commonly found in radar systems, medical devices, and naval equipment.

- Capsule: Capsule slip rings are compact and cylindrical, designed for use in small spaces without compromising performance. They are often used in automation systems, security cameras, and testing equipment.

- Through-bore: Through-bore slip rings feature a central hole or bore, allowing them to be mounted around a rotating shaft or to accommodate other device components. They are widely used in wind turbines, cranes, and heavy machinery.

In summary, the different types of multi-circuit slip rings cater to a wide range of industry needs and applications. Understanding the characteristics, advantages, and limitations of each type helps select the most suitable slip ring for a specific purpose, ensuring optimal performance and durability.

Multi-circuit Slip Rings Specifications

Multi-circuit slip ring specifications play a pivotal role in determining their suitability and performance under varying operational conditions. These specifications are broadly divided into electrical and mechanical parameters, besides several considerations for selection and customization.

Electrical Parameters

Key electrical parameters of multi-circuit slip rings include:

- Voltage: This specifies the maximum voltage that the slip ring can safely handle. Choosing a slip ring with a voltage rating that suits the operational needs is crucial to prevent electrical failures.

- Current: The current specification indicates the maximum electric current that the slip ring can transmit without overheating or causing damage.

- Insulation Resistance: It measures the slip ring’s ability to prevent electrical leakage between circuits. A high insulation resistance is preferable for safety and efficiency.

- Noise: This is a measure of the electrical interference or distortions introduced by the slip ring in the transmission. Lower noise levels indicate smoother and more reliable signal transmission.

Mechanical Parameters

Mechanical parameters define the physical and mechanical properties of the slip rings:

- Temperature Range: It specifies the optimal range of working temperatures for the slip rings. Slip rings should be chosen according to the environmental temperature they will be operating in to ensure reliability.

- Speed: This measure describes the maximum rotational speed the slip ring can safely handle while maintaining good performance. The speed rating must align with the speed of the mechanism where the slip ring is installed.

- Operational Life: This indicates the expected service time or the number of rotations the slip ring can perform before failure. A longer operational life signifies a more durable and reliable solution.

Selection and Customization Factors

Choosing the right multi-circuit slip ring involves considering several factors to ensure that it meets the specific requirements of the intended application, which include:

- Number of Circuits: The number of circuits in the slip ring should correspond with the number of independent transmissions needed in the application.

- Material of Construction: The choice of material impacts the cost, performance, and life span of the slip ring. It should be selected based on the operational needs and budget constraints.

- Type of Transmission Media: The transmission media (electrical, pneumatic, hydraulic, or optoelectronic) to be handled by the slip ring should align with the application requirements.

- Size and Form Factor: The slip ring size and design should fit the mechanical constraints of the device it will be integrated into.

The broad range of multi-circuit slip ring specifications offers immense possibilities for customization, ensuring they can be tailored to meet numerous industry-specific needs, therefore helping optimize performance in several different applications.

Multi-circuit Slip Rings Application Examples

The versatility of multi-circuit slip rings makes them an indispensable component in numerous industries, playing a critical role in the seamless functioning of various applications. Here are some examples of industries and applications where multi-circuit slip rings are used to ensure optimal performance:

Aerospace and Defense

In the aerospace and defense industry, slip rings find use in advanced systems requiring high levels of precision, reliability, and durability, such as:

- Radars: Multi-circuit slip rings enable the transmission of power and signals between the rotating antenna and stationary base in radar systems, maintaining continuous communication and data transfer.

- Targeting Systems: In weapon targeting and guidance systems, slip rings facilitate communication between moving and stationary parts, ensuring responsiveness and accuracy in critical moments.

Industrial Automation

The industrial automation sector utilizes multi-circuit slip rings in various applications, including:

- Robotics: Slip rings allow for power and control signal transmission in robotic arms and manipulators, enabling smooth and precise movements while preventing cable twisting.

- Assembly Lines: Multi-circuit slip rings are used in rotating components of assembly lines, ensuring continuous power supply and uninterrupted communication for control and monitoring functions.

Renewable Energy

Slip rings have become a critical component in the renewable energy sector, especially in applications such as:

- Wind Turbines: In wind turbines, multi-circuit slip rings transmit power and data between the stationary nacelle and the rotating hub. They must withstand harsh weather conditions and continuous operation for long periods.

- Solar Panels: Slip rings are employed in solar panel tracking systems to maintain an optimal angle towards the sun, allowing for simultaneous power and signal transmission during rotation.

Medical Equipment

Medical equipment often requires precise and reliable transmission of power and data. Some applications that use multi-circuit slip rings include:

- CT Scanners: Slip rings in CT scanners are used to transmit power and data between the stationary control system and the rotating gantry that houses the X-ray source and detectors.

- MRI Machines: In MRI machines, slip rings enable data transmission and synchronization between the rotating gradient coils and the stationary control systems, ensuring accurate imaging.

Entertainment

The entertainment industry also benefits from the use of multi-circuit slip rings in various applications:

- Cameras: Slip rings are used in rotating camera systems, such as 360-degree cameras or remote-controlled pan-tilt-zoom cameras, to transmit power and control signals, while preventing cable entanglement.

- Amusement Park Rides: In amusement park rides, slip rings are used to transfer power, control signals, and lighting effects between stationary and rotating components, contributing to the safety and thrilling experience for riders.

These examples illustrate the extensive use of multi-circuit slip rings across several industries. Their ability to provide reliable, efficient, and continuous transmission of power and signals is vital in applications where precision, durability, and high performance are paramount.

Multi-circuit Slip Rings Challenges and Solutions

Despite their relevance and widespread use, multi-circuit slip rings face several challenges, including wear and maintenance issues, operation in harsh environments, integration with other components, and maintaining high-quality transmission. Let’s delve into these challenges and their respective solutions:

Wear and Maintenance

Due to their nature, multi-circuit slip rings are subject to wear and tear over time. As the slip ring rotates, the brushes in contact with the rings can wear out, leading to performance degradation.

Solution: Regular maintenance and inspection can help prolong the service life of slip rings. Additionally, using slip rings manufactured from high-quality materials can reduce wear and increase durability. Some designs also feature easy brush replacement mechanisms to simplify maintenance.

Dealing with Vibration and Harsh Environments

Slip rings often need to operate in challenging conditions, including high-vibration environments and exposure to harsh elements like dust, water, or extreme temperatures.

Solution: To mitigate these challenges, slip rings can be designed with robust materials and sealing mechanisms to withstand harsh conditions. Moreover, some slip rings use advanced design techniques to minimize the effects of vibration, contributing to more stable performance.

Integration with Other Components and Systems

Integrating slip rings with various system components and equipment can be a complex task, requiring careful consideration to avoid performance issues.

Solution: Customizable slip rings are available to cater to specific sizing and mounting needs, allowing for better integration into diverse systems. Furthermore, consulting with slip ring manufacturers during the design phase can help ensure seamless integration.

Noise Reduction and Interference Minimization

Noise and interference can degrade the quality of power and signal transmissions, negatively impacting system performance.

Solution: Using precious metal contacts, shielding techniques, and impedance matching can help minimize electrical noise and interference. Advanced slip rings may also use fiber optics for data transmission, virtually eliminating electrical noise.

Ensuring High-Quality Signal and Power Transmission

Maintaining high-quality signal and power transmission, especially in applications requiring high-speed data transfer or high-current power, can be challenging.

Solution: Utilization of sophisticated materials and design techniques can help. For instance, gold-on-gold contacts are known to provide reliable transmission with minimal loss. For high-speed data, optoelectronic slip rings provide excellent signal integrity. Meanwhile, larger contact surfaces and improved thermal management designs can handle high-current power transmission.

In conclusion, while multi-circuit slip rings do present challenges, a combination of innovative design approaches, advanced materials, and regular maintenance can effectively address these issues, ensuring reliable and efficient performance for a wide range of applications.

Choosing the Right Multi-Circuit Slip Ring

Selecting the right multi-circuit slip ring involves several considerations. It requires an accurate understanding of operational requirements, comparison between different manufacturers, compliance with industry standards, and cost-effectiveness. Here’s an expansion on how to go about these:

Assessing Needs and Requirements

The initial stage in selecting a suitable slip ring lies in the detailed assessment of your needs and requirements. This includes understanding the application where it will be utilized and defining the parameters such as the number of circuits, required current, voltage, speed, and data transfer rates, compatibility with transmission media, and environmental conditions.

Solution: Engage pertinent staff such as maintenance, engineering, and operational personnel to gather comprehensive input on the desired slip ring’s performance and features. Make a list of the key specifications required for your application.

Comparing Manufacturers and their Offerings

Once the key requirements are identified, the next step is to look into various manufacturers, comparing their offerings and reputations.

Solution: Evaluate the manufacturers based on their expertise, quality of products, customer reviews, and support services. Research their offerings in detail, considering factors like the design, materials used, technology employed, and the level of customization available.

Compliance and Certifications

Compliance with industry standards and certifications is critical to ensure the quality and safety of slip rings. They validate the manufacturer’s claim of the product’s performance and reliability.

Solution: Check if the manufacturer’s products meet the necessary industry standards, and if they carry relevant certifications. For example, a CE mark shows compliance with EU safety standards, while an ISO 9001 certification indicates adherence to stringent quality management systems.

Costs and Warranties

Lastly, striking a balance between cost and performance is vital when choosing a slip ring. While initial cost is important, focus should also be put on overall life-cycle costs, including maintenance expenses and potential downtime costs.

Solution: Compare the prices from different manufacturers for similar specifications. However, remember to not compromise quality for cost, as a lower-cost product may result in higher maintenance or replacement costs in the future. Also, consider the warranty offered by the manufacturer as it’s an indicator of their assurance of the product’s robustness and longevity.

By considering these four main areas – needs and requirements, manufacturer offerings, compliance and certifications, and costs and warranties – you’ll be able to make a well-informed decision when choosing the right multi-circuit slip ring for your specific application.

Multi-circuit Slip Rings Future Trends

Looking ahead, multi-circuit slip rings are expected to evolve in response to emerging technological developments and changing industry demands. Here are some probable future trends concerning slip ring technologies:

Advancements in Materials Science

As new materials with enhanced electrical, mechanical, and thermal properties emerge, multi-circuit slip ring designs may incorporate these for improved performance and longevity.

Context: The use of advanced materials can lead to less wear and increased durability, thereby reducing the need for maintenance and prolonging their operational life. Furthermore, these materials could enhance the electrical properties of slip rings, ensuring greater reliability in signal and power transmissions.

EtherCAT and Other Communication Protocol Support

With the ever-growing reliance on real-time communication and Industry 4.0 applications, multi-circuit slip rings may need to accommodate contemporary communication protocols like EtherCAT, Profinet, and Ethernet/IP.

Context: Adopting these protocols would enable seamless integration of slip rings into modern automated systems, ensuring high-speed data transfer and improved interoperability across various connected devices and operations.

Miniaturization and New Design Possibilities

As industries demand more compact and lightweight solutions, miniaturization of slip rings may emerge as a significant trend.

Context: Smaller and lighter slip rings can enable new design possibilities, particularly for industries such as aerospace, defense, and robotics, where weight and size constraints are critical. Miniaturization can lead to innovations in slip ring design, allowing for better integration and overall system performance in space-limited applications.

Integration of Newly-Developed Technologies

As advancements are made in other fields, there will likely be an increased focus on integrating novel technologies into multi-circuit slip ring components.

Context: For example, integrating fiber optic technology can further improve data transmission speeds and reduce interference. Similarly, developments in optoelectronics and the incorporation of wireless connectivity within the overall slip ring systems may result in innovative new designs that improve efficiency and simplify maintenance.

In conclusion, multi-circuit slip rings are poised to evolve along with technological advancements and industrial demands. By adopting cutting-edge materials, supporting modern communication protocols, focusing on miniaturization, and integrating new technologies, the future of multi-circuit slip rings appears promising, offering enhanced performance and flexibility for numerous applications.

Conclusion

Multi-circuit slip rings undeniably play a significant role in today’s technologically advanced world. It’s crucial to understand their importance, applications, and operation while opting for the right slip ring based on individual needs and industry requirements. As we move ahead, multi-circuit slip rings will continue to evolve and integrate with diverse modern frameworks, making them a technological mainstay.