At the heart of nearly every rotating electrical system is an exquisite technology that does not court the spotlight, yet is instrumental in defining the performance of many machines. This unseen champion is the slip ring brush, a component so discreet and yet so crucial. Nestled within alternators, power generators, wind turbines, and numerous other machinery, slip ring brushes are the little conductors that could. They facilitate the seamless transfer of electrical currents and data from stationary to rotating parts, keeping the wheels of industry turning – quite literally. This article aims to shed some light on these unsung heroes – slip ring brushes. We delve into what they are, their composition, benefits, common problems, and how to troubleshoot them. The objective is to enrich the reader’s understanding of these integral components, their operation, and maintenance. Let’s turn the spotlight on slip ring brushes, the pivotal little conductors driving the world’s rotating electrical systems.

Table of Contents

- What are Slip Ring Brushes?

- What Is the Function of the Brushes in the Slip Ring?

- Advantages of Slip Ring Brushes

- What Are the Brushes on Slip Rings Made Of?

- Slip Ring Brush Specification

- Types of Slip Ring Brushes

- Application of Slip Ring Brushes

- Common Issues and Troubleshooting with Slip Ring Brushes

- How to Maintain Slip Ring Brushes

- Replacement of Slip Ring Brushes

- Installation of Slip Ring Brushes

- Customized Solutions for Slip Ring Brushes

- Conclusion

- FAQs about Slip Ring Brushes

What are Slip Ring Brushes?

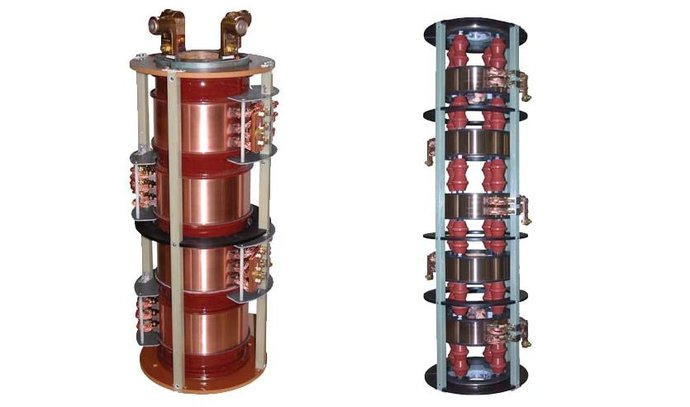

Slip ring brushes are critical components in a device called the slip ring, which is essential for the transmission of electrical power, signals, or data between stationary and rotating parts in various electrical systems. These small, unassuming components may not seem like much at first glance, but their role in facilitating uninterrupted and efficient electrical conduction in devices such as alternators, motors, wind turbines, and cranes is nothing short of impressive.

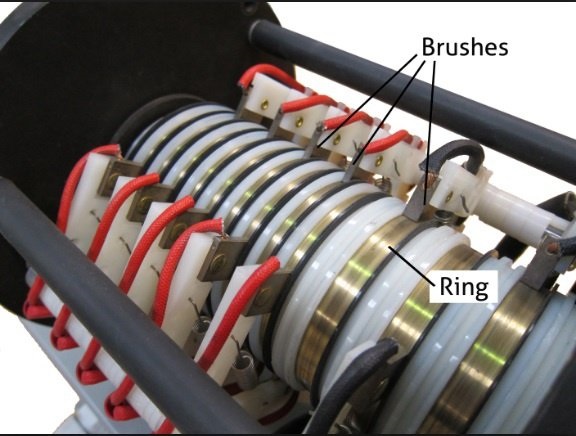

To better comprehend the role of slip ring brushes, it’s crucial to understand the basic structure and function of a slip ring. A slip ring, also known as a rotary electrical joint, consists of two primary components: the stationary stator and the rotating rotor. The stator is electrically connected to the system’s fixed part, while the rotor is linked to the system’s rotating component. Slip ring brushes are positioned between these two parts, establishing an electrical connection as they glide over the rotating surface of the rotor.

These brushes are designed to maintain constant and low-friction contact with the rotor while allowing electrical current or data to flow through them seamlessly. They are typically engineered to endure potentially tens of thousands of rotations and countless contact hours, with the ultimate goal of providing a reliable and low-maintenance connection for the electrical system. The material, size, and shape of slip ring brushes may vary depending on the specific application and system requirements, but their fundamental role in securing efficient and continuous electrical transmission remains consistent.

In summary, slip ring brushes are indispensable elements that maintain electrical connectivity across the stationary and rotating parts of numerous electrical systems. They ensure consistent transmission of power, signals, or data, all while minimizing resistance and friction during operation.

What Is the Function of the Brushes in the Slip Ring?

At its core, a slip ring is a rotary electrical interface designed to enable uninterrupted electrical connectivity between stationary and rotational parts of various devices, from wind turbines to alternators. A slip ring system consists of rings and brushes. The ring rotates with the machine’s revolving component, and this is where slip ring brushes come into play.

The slip ring brushes are finely engineered to maintain consistent contact with the rotating slip ring. As the mechanic component spins, the brushes slide on the ring’s conductive material, effectively forming an electrical connection between the spinning rotor and stationary stator.

Each brush applies a controlled degree of pressure on the slip ring. This contact pressure is a key factor in ensuring lower friction, reducing electrical noise, and achieving a reliable electrical connection. Consequently, the slip ring brushes serve as a bridge that facilitates the smooth flow of electrical signals, electric power, or data from the stationary part to the rotating section and vice versa.

Additionally, because the brushes are in constant contact with the slip ring, they also need to cater to variations in the surface speed between the rings and brushes, caused by the difference in radii. Moreover, in some cases, brushes may also play a role in reducing temperature differences in various parts of the slip ring.

In essence, the role of brushes in the slip ring is meticulously multifaceted. From managing electrical connections to contributing to the overall performance of the device, their roles often extend beyond mere conductivity. Their importance to the dynamism and performance of rotating electrical systems cannot be overstated.

Advantages of Slip Ring Brushes

Slip ring brushes offer numerous advantages that make them indispensable in a wide range of electrical systems. Here’s a look at some key benefits:

- Continuous Transmission: Brushes in slip rings make possible the continuous transfer of power, signals, or data from a stationary to a rotating part without interruption. This facilitates rotation without the need for pauses or stoppages.

- Versatility: Thanks to a wide array of materials available for their creation, such as carbon, metal, graphite, and silver, slip ring brushes can be tuned to specific operating environments. This adaptability enables them to cater to disparate industries and applications.

- Durable and Resilient: Owing to their robust design and the wear-resistant materials often used in their construction, slip-ring brushes exhibit high endurance and reliability, providing long-lasting service under continuous operation.

- Efficient Performance: Slip ring brushes are designed to minimize system losses by reducing electrical noise and decreasing energy wastage due to friction.

- Low Maintenance The brushes require minimal maintenance once fitted correctly. Regular inspection and occasional cleaning/replacement are usually adequate for their upkeep.

- High-Speed Operation: Designed for optimal electrical contact with the rotating slip ring, brushes permit high rotational speeds in many applications, like alternators and turbines.

- Simple Design: Brushes are relatively simple in design, meaning they can be easily manufactured, installed, replaced, and maintained.

- Compact: Due to their small size, brushes can be installed in a variety of electrical systems without substantial space requirements.

Each of these advantages makes slip ring brushes a mainstay in rotating electrical machine design, cementing their place as integral contributors to the consistent, efficient operation of many mechanical and industrial systems.

What Are the Brushes on Slip Rings Made Of?

Different machines have different requirements for materials, so slip-ring brushes are also made of different materials.

Here are the most common materials used to make slip ring brushes:

Carbon

Carbon is one of the most popular materials used in slip-ring brushes.

- Good conductor of electricity

- Low coefficient of friction

- Have a long lifespan

- Withstand high temperatures and friction

- Suitable for use in high-performance machines

Graphite

Graphite is another popular material used in slip-ring brushes. Graphite brushes are commonly used in industrial machines that require continuous operation.

- Excellent electrical conductivity

- Low friction

Metal Alloys

Metal alloys, such as copper or silver, are also used in slip-ring brushes. Metal alloy brushes are commonly used in machines that require high voltage or high current.

- Highly conductive

- Withstand high temperatures

- Ideal for use in high-performance machine

Slip Ring Brush Specification

Types of Slip Ring Brushes

Slip ring brushes come in various types, each designed for specific applications and performance requirements. Here are the main types of slip ring brushes:

- Carbon Brushes:

- Description: Comprising carbon or a carbon compound, these brushes are widely employed due to their high durability, excellent conductivity, and self-lubricating properties. They function well under low or moderate electrical load and contact pressure.

- Applications: Widely used in industrial motors, generators, and wind turbines.

- Graphite Brushes:

- Description: Composed mainly of graphite, these brushes offer excellent lubrication properties and can handle high temperatures.

- Applications: Suitable for high-speed motors and generators, as well as aerospace and automotive applications.

- Metal-Graphite Brushes:

- Description: Constructed from a composite of graphite and metal (like copper or bronze), these brushes combine the low-friction attributes of graphite and the conductivity of metal. They are ideal for heavy-duty operations that require high electrical load capacities.

- Applications: Used in heavy-duty industrial machines, electric vehicles, and power tools.

- Electrographite Brushes:

- Description: These brushes are treated to enhance their electrical properties, providing high resistance to oxidation and corrosion.

- Applications: Ideal for high-load and high-temperature environments, such as steel mills and mining equipment.

- Silver-Graphite Brushes:

- Description: Blending silver and graphite, these brushes ensure low friction and excellent conductivity, making them suitable for high-performance applications involving high-speed data transmission or signal transfers.

- Applications: Commonly used in slip rings for medical equipment, telecommunications, and precision instruments.

- Copper-Graphite Brushes:

- Description: Made with copper to enhance conductivity and mechanical strength.

- Applications: Suitable for heavy-duty industrial applications, including large motors and power generation equipment.

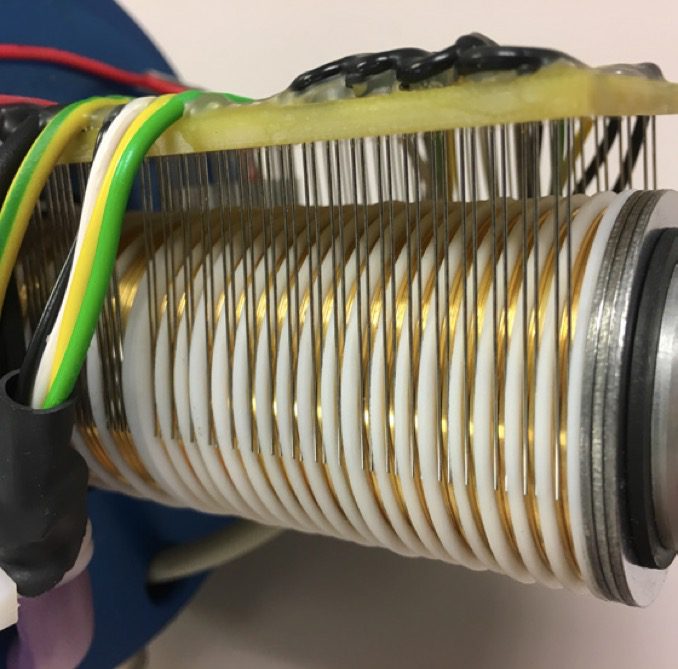

- Metal Fiber Brushes:

- Description: Made from a blend of metal fibers, these brushes offer high durability and excellent conductivity.

- Applications: Used in high-vibration and high-wear applications, such as military and aerospace equipment.

- Composite Brushes:

- Description: Utilizing a combination of conductive and non-conductive materials, these multitasking brushes cater to complex or challenging operational environments requiring superior endurance, resistance against wear, and efficient electrical contacts.

- Applications: Suitable for a wide range of applications, including robotics, automation, and consumer electronics.

- Helical Brushes:

- Description: Designed with a helical structure to improve contact stability and reduce electrical noise.

- Applications: Used in high-precision applications such as radar systems and medical imaging devices.

- Carbon-Ceramic Brushes:

- Description: Incorporate ceramic materials to enhance wear resistance and temperature tolerance.

- Applications: Ideal for high-temperature and high-wear environments, such as furnaces and high-speed machinery.

Each type of slip ring brush is engineered to fulfill a specific set of requirements, providing the flexibility to choose the right brush based on the system’s unique operational milieu. So, the appropriate choice of brush results in improved performance, longer lifespan, and overall operational efficiency of the electrical system.

Application of Slip Ring Brushes

Slip ring brushes have a wide range of applications, primarily ensuring stable transmission of electrical signals and power in rotating connections. Here are detailed descriptions of their applications in different fields:

- Wind Turbines:

- Function: Slip ring brushes are used to transmit current and signals between the wind turbine’s rotor and generator.

- Advantage: They enable continuous rotation of the wind turbine while ensuring stable transmission of electrical energy and signals, enhancing efficiency and extending equipment lifespan.

- Medical Equipment:

- Function: In medical devices like CT scanners and MRI machines, slip ring brushes transmit image data and power.

- Advantage: They allow seamless rotational operation, providing high-quality imaging data and preventing cable tangling issues.

- Robotics:

- Function: Slip ring brushes are used in robotic joints and rotating parts to transmit control signals and power.

- Advantage: They improve the flexibility and precision of robots, enabling complex movements and operations.

- Aerospace:

- Function: Slip ring brushes transmit control signals, data, and power in aircraft and spacecraft.

- Advantage: They ensure stable operation of rotating equipment (such as radars and antennas), enhancing system reliability and safety.

- Industrial Automation:

- Function: In automated production lines, slip ring brushes transmit control signals and power, especially in rotating equipment and robotic systems.

- Advantage: They increase production efficiency and the continuous operation capability of equipment, reducing maintenance and downtime.

- Entertainment Equipment:

- Function: Slip ring brushes are used to transmit control signals and power in rotating stages, camera equipment, and amusement rides.

- Advantage: They provide stable power and signal transmission, ensuring the normal operation of equipment and user safety.

- Military Applications:

- Function: Slip ring brushes are used in military vehicles and weapon systems, such as rotating turrets and radar systems.

- Advantage: They enhance system flexibility and response speed, ensuring reliable operation in harsh environments.

- Marine Engineering:

- Function: In marine exploration equipment and ship systems, slip ring brushes transmit control signals and power.

- Advantage: They ensure stable operation of equipment in harsh marine environments, supporting remote operation and data transmission.

Slip ring brushes are essential components in any scenario requiring rotational connections and the transmission of power or signals. Their reliability, stability, and high efficiency make them indispensable in modern industrial and technological fields.

Common Issues and Troubleshooting with Slip Ring Brushes

The functionality and longevity of slip ring brushes might occasionally be compromised due to various operational or environmental issues.

Some of the most commonly observed problems include:

- Excessive Brush Wear: Excessive wear and tear of the brushes could be an indication of incorrect brush hardness, high friction due to a rough slip ring surface, or an indicator of poor quality brush material.

- Poor Contact with the Ring: Sometimes, the brush might not make good contact with the slip ring. The typical causes could be insufficient spring pressure, an incorrect brush grade, or an improperly seated brush.

- Brush Noise and Arcing: This usually happens when there is a high electrical load, usage of a wrong brush type or size, or rapid changes in operational parameters.

- Overheating of Brushes: Overheating is often the consequence of high rotational speeds, excessive current, or the utilization of an incorrect brush material.

- Dust Accumulation: Certain brushes, like those made of carbon, tend to produce dust that can accumulate and disrupt the efficient functioning of the system.

Troubleshooting Measures for Slip Ring Brushes

Knowing the problems is just the first step. Addressing them effectively requires precise troubleshooting methods:

- Excessive Brush Wear Troubleshooting: Investigate potential causes of excessive wear and consider solutions like using an appropriately hard brush, smoothing the slip ring surface, or replacing poor-quality brushes.

- Poor Contact Troubleshooting: Improve the level of contact with the slip ring by increasing the spring pressure, reseating the brush properly, or by utilizing the correct brush grade.

- Brush Noise and Arcing Troubleshooting: Address brush noise and arcing by either choosing a brush that can handle higher load operations, verifying the brush size, or adhering to operational controls to prevent abrupt changes in parameters.

- Overheating Troubleshooting: Counter overheating issues by selecting an appropriate brush material, restraining the speed, and load within permissible limits, and increasing cooling measures (like forced air or water cooling).

- Dust Accumulation Troubleshooting: Periodic inspection and cleaning of the slip ring and brushes can help prevent dust build-up. You can also consider using brushes that produce less dust.

Regular maintenance and inspection are crucial for smooth operation. If complex or persistent issues arise, it is recommended to seek advice from professional technicians or manufacturers.

How to Maintain Slip Ring Brushes

Prolonging the lifespan and optimizing the performance of your slip ring brushes requires a well-planned and meticulous maintenance routine. Here are some steps to guide you:

Regular Inspection: Regularly inspect slip ring brushes and their housings for any signs of wear, mechanical damage, or accumulation of dust and debris. Also, check for signs of aberrant heating, arcing, or noise during operation. Being proactive and fixing minor issues early can prevent costly repairs or replacements down the line.

- Cleaning: Regular cleaning of the slip ring and brushes helps counter dust buildup and ensures optimal performance. Use specific cleaning solutions recommended by the manufacturer or a dry, lint-free cloth for light cleaning jobs.

- Proper Seating of Brushes: Make sure the brushes are properly seated in their holders and are in full contact with the slip ring surface to guarantee an efficient transfer of electrical signals. Misaligned brushes can lead to inefficiencies and rapid wear.

- Optimal Spring Pressure: Ensure the brushes are under the correct spring pressure to facilitate good contact with the slip ring, but not so much pressure that it causes premature wear. Follow the manufacturer’s instructions to determine the ideal pressure.

- Replacement: Regularly replace the brushes depending on their wear level and the manufacturer’s recommendations. Overused brushes can lead to slip ring damage and system failures.

- Timely Lubrication: Depending on the system, some slip ring brushes require occasional lubrication to reduce friction and extend their lifespan. Always use the lubricants recommended by the manufacturer and avoid over-lubrication, which can cause dust and debris to gather around the brushes.

- Ambient Conditions Monitoring: Keep an eye on the operating environment. Excessive moisture, high temperatures, or corrosive conditions can negatively affect the brushes’ performance and lifespan. Seek professional advice for suitable solutions if such adverse conditions prevail.

Remember, while regular maintenance is key to optimizing the performance of slip ring brushes, extremely worn-out or damaged brushes often require replacement. Always follow the manufacturer’s instructions and don’t hesitate to consult professionals if in doubt or tackle complex issues.

Replacement of Slip Ring Brushes

Proper replacement of slip ring brushes is vital for maintaining the optimal performance of an electrical system. Overused brushes can cause slip ring damage and system failures. The replacement process generally involves the following steps:

- Consult Manufacturer Guidelines: Always refer to the manufacturer’s instructions for recommendations on when to replace the brushes and for brush selection. Each system is designed differently and requires specific brushes in terms of material, hardness, and dimensions.

- Preparation: Before beginning the replacement process, disconnect power to the system, ensure that no electrical or mechanical components are active, and assemble the required tools, materials, and safety gear.

- Access Brush Assembly: Locate the brush assembly, which typically consists of brushes, brush holders, and springs. Remove any housing, covers, or guards that shield the assembly, making sure to keep track of all the components you remove.

- Inspect Slip Ring Condition: Prior to replacing the brushes, inspect the surface of the slip ring for any signs of wear or damage that might necessitate resurfacing or replacement.

Remove Old Brushes: Carefully remove the worn-out brushes from their holders. Depending on the system, this may involve releasing the spring tension holding the brushes in place or unscrewing any fasteners that secure the brushes. - Clean Brush Holder and Slip Ring: Clean any debris, dust, or contaminants from the brush holder and the slip ring. Use a lint-free cloth or a soft brush to remove loose dust and debris. For more stubborn contaminants, use a cleaning solution recommended by the manufacturer.

- Install New Brushes: Install the new brushes into their holders, ensuring correct orientation and alignment with the slip ring. If the brushes are spring-loaded, apply gentle pressure and re-engage the springs to secure the brushes in place. In systems with fasteners, make sure to tighten them appropriately without over-tightening.

- Check Brush-Slip Ring Contact: Verify that the new brushes are in full contact with the slip ring, ensuring optimal electrical conductivity.

- Reassemble Components and Test: Reassemble any housing, covers, or guards that were removed during the process. Restore power to the system, perform a visual and audio inspection, and test the system to ensure proper functionality.

- Maintain Records: Document the date of the replacement, the type of brushes used, and any observations made during the process. This information will be invaluable for future maintenance or troubleshooting.

Always exercise caution during the replacement process and follow the manufacturer’s guidelines. If you are uncertain about any steps or encounter any issues, seek assistance from a qualified professional.

Fill out the form below to request specifications and pricing for Slip Ring Brushes.

Installation of Slip Ring Brushes

Slip ring brushes play a crucial role in transmitting electrical signals, making their correct installation paramount for the smooth functioning of the system. Here are detailed steps to guide you through the installation process:

- Preparation: Before starting, gather all the required tools and new brushes. Make sure the new brushes are correct in terms of material, hardness, and dimensions, aligning with the manufacturer’s specifications. Remember to disconnect the power to the system and ensure that no moving or electrical components are active.

- Access Brush Assembly: Locate the brush assembly area which is typically covered by a housing or guard. Remove these protective components to access the brush assembly, which generally consists of the brushes, brush holders, and springs.

- Remove Existing Brushes: If replacing brushes, carefully remove the old ones from the brush holders. Typically, this involves releasing the spring tension that holds the brushes. Be cautious while releasing springs to avoid injury.

- Clean Brush Holder and Slip Ring: Always maintain cleanliness in the brush assembly area. Use a lint-free cloth or a soft brush to clean any dust, debris, or contaminants from the brush holder and slip ring. For stubborn contaminants, apply a cleaning solution recommended by the manufacturer.

- Install New Brushes: Position the new brushes in the brush holders. Ensure they are correctly oriented and aligned with the slip ring surface. If the brush assembly utilizes spring-loading, gently apply pressure on new brushes and engage the springs to secure the brushes. If the assembly uses fasteners, properly tighten them without overdoing them, as excessive pressure might damage the new brushes.

- Verify Contact: After installation, check that the new brushes make full contact with the surface of the slip ring. The brushes should slide smoothly over the slip ring surface, achieving optimal electrical conductivity.

- Reassemble the Housing and Test: Place any guards, covers, or housing back over the assembly, ensuring they’re secured correctly. Then, restore power to the system, and conduct a visual and auditory check during operation to ensure everything functions as expected.

- Document the Installation: Note down the date, type of brushes installed, and any significant observations. These records can come in handy during future maintenance or troubleshooting.

As always, adhere to safety precautions and follow manufacturer guidelines while carrying out the installation. If unsure at any given point, do not hesitate to seek professional help.

Customized Solutions for Slip Ring Brushes

Slip ring brushes come in various materials, grades, and sizes that cater to a wide range of applications. While standard solutions meet requirements for most electrical systems, certain applications may require custom-designed slip ring brushes. Here are a few circumstances where customization might be necessary:

- Unique Operational Conditions: Not all applications operate under ‘normal’ conditions. Some may be exposed to extremes of temperature or pressure, corrosive environments, high levels of shock or vibration, or other unique operating conditions. Custom-made slip ring brushes can be designed to withstand such challenges.

- Specific Electrical or Mechanical Requirements: Depending on the details of the electrical system, you may need brushes of specific sizes or shapes, different grades of material, or unusual mounting arrangements. A customized solution can ensure that these necessary parameters are met.

- Space Limitations: Sometimes, space constraints require slim, compact brush designs that will fit into the system without compromising performance.

When customizing slip ring brushes, here are a few solutions to consider:

- Custom Materials: Slip ring brushes can be made from several materials like copper, carbon, silver graphite, etc., to cater to different conductivity, hardness, and resilience levels.

- Custom Sizes: The brushes can be made to exact dimensions to fit within a specific assembly or housing.

- Special Features or Components: Depending on the application, brushes can be designed with unique features, such as special shunts, special terminals, or differentiated brush holders.

- Innovative Designs: Custom brushes can leverage unique designs that help overcome physical space constraints while ensuring high performance.

Keep in mind that customization typically comes at a higher cost and may take more time to deliver than standard brushes. However, these additional costs and time can be offset by improved system performance, reduced maintenance needs, and prolonged lifespan.

For best results with customized slip ring brushes, consult with a seasoned brush manufacturer who can understand your requirements and design a solution that fulfills your specific needs.

These professionals can use their experience and expertise to help you adapt standard designs or create entirely new solutions that provide optimal performance in your unique application.

Conclusion

In conclusion, slip ring brushes are vital components in a myriad of electric systems. Whether it’s managing the electric current in a power generator or facilitating data transmission in an alternator, slip ring brushes ensure the efficient operation of these systems. Even though they are subject to wear over time, proper maintenance can extend their lifespan significantly. The choice of slip ring brush will depend on the specific system requirements, but the fundamental role they play in promoting efficient and continuous power or data transmission remains constant.

FAQs about Slip Ring Brushes

Finally, here are a few frequently asked questions about slip ring brushes:

Q: How to extend the life of slip ring brushes?

A: Regular inspection, proper installation, maintaining the correct pressure, and using suitable quality brushes can significantly extend their life.

Q: Why does the choice of brush composition matter?

A: Material choice directly affects the brush performance and wear rate, and it needs to be ideal for the operating environment of the electrical system.

Q: What are the signs of a failing slip ring brush?

A: Excessive sparking, increased noise, and decreased system performance are common indicators of a failing brush.

Q: What Is the Purpose of Slip Ring Brushes?

A: Slip ring brushes provide electrical contact between stationary and rotating parts of an electrical machine.

Q: Can Slip Ring Brushes Be Replaced?

A: Yes, slip-ring brushes can be replaced. However, the replacement process may vary depending on the specific machine and its requirements.

Q: When to Replace Slip Ring Brushes?

A: The lifespan of slip ring brushes varies depending on the specific machine and its usage. Best to consult the manufacturer’s guidelines for specific instructions on when to replace slip-ring brushes.

Q: What do the brushes do in the slip ring?

A: Brushes in a slip ring play a critical role in maintaining electrical contact between the stationary and rotating components. They are typically made of conductive materials like graphite or metal-graphite and are designed to press against the rotating slip ring. As the slip ring rotates, the brushes slide along its surface, facilitating the transfer of electrical signals or power across the rotating interface. This setup is essential in various applications, such as wind turbines, medical imaging equipment, and industrial machinery, where continuous rotation is required. The brushes ensure that the electrical connection remains stable, allowing for the seamless transmission of power and data without interruption. Despite the benefits, brushes are subject to wear and tear over time due to friction, necessitating regular maintenance or replacement to ensure the slip ring’s optimal performance.

Q: What is the difference between a slip ring and a brush?

A: A slip ring and a brush are complementary components used together to enable electrical connection in rotating systems, but they serve distinct functions. A slip ring is a rotating electrical connector that allows for the transmission of power and electrical signals from a stationary component to a rotating one. It typically consists of a cylindrical assembly with conductive rings. The brush, on the other hand, is a stationary component made of conductive material such as graphite or metal-graphite. It maintains contact with the rotating slip ring, facilitating the transfer of electrical current or signals. The key difference lies in their roles: the slip ring provides the rotating conductive path, while the brush maintains the physical connection to transfer electricity across the stationary and rotating parts. Together, they ensure continuous electrical connectivity in devices that require rotational movement, such as wind turbines, medical scanners, and industrial machinery.

Q: What are slip rings and brushes?

A: Slip rings and brushes are essential components used in rotating electrical systems to ensure continuous electrical connectivity between stationary and rotating parts. A slip ring is a mechanical device comprising one or more conductive rings, which rotate with the machine’s rotating part. These rings provide a path for electrical signals and power to be transmitted across the rotating interface. Brushes, on the other hand, are stationary components made of conductive materials like graphite or metal-graphite. They are designed to press against the slip ring’s surface, maintaining a continuous electrical connection. This setup allows for the transmission of electrical power and signals in applications where the components need to rotate freely, such as in wind turbines, medical imaging equipment, and industrial machinery. The brushes ensure that despite the continuous rotation, there is no interruption in the electrical connection, enabling the efficient and reliable operation of these systems. Regular maintenance is required to keep the brushes and slip rings in good condition, as wear and tear from friction can affect performance over time.

Q: Why brushes are used in slip ring induction motor?

A: Brushes are used in slip ring induction motors to facilitate the introduction of resistance into the rotor circuit. This configuration allows for better control of the motor’s starting current and torque characteristics. In a slip ring induction motor, the rotor windings are connected to external resistances through brushes and slip rings. By adjusting these resistances, it is possible to control the motor’s starting torque and limit the inrush current, making the motor suitable for applications that require high starting torque or frequent starting and stopping. The brushes maintain contact with the rotating slip rings, ensuring that the external resistances remain connected to the rotor circuit during operation. This setup also provides the ability to adjust the motor’s performance characteristics dynamically, improving its efficiency and operational flexibility. Once the motor reaches its operational speed, the external resistances can be short-circuited, and the brushes and slip rings can be bypassed, allowing the motor to operate like a standard squirrel-cage induction motor. This versatility makes slip ring induction motors ideal for heavy-duty applications such as cranes, elevators, and conveyors.

Q: Where can I buy PCB slip ring brushes?

A: You can purchase PCB slip ring brushes from various specialized suppliers and manufacturers who offer a wide range of slip ring products. One option is to explore online marketplaces like Alibaba, Amazon, or eBay, where numerous vendors list their products. Additionally, you can visit the websites of companies that specialize in slip ring technology, such as Moog, Mercotac, and Schleifring, which provide detailed catalogs and direct purchasing options. For tailored solutions and bulk orders, contacting manufacturers directly is advisable. Companies like your own, which specialize in slip ring products, often offer customized solutions to meet specific requirements. Ensure you check for product specifications, quality certifications, and customer reviews to make an informed decision. Additionally, attending trade shows and industry exhibitions can provide opportunities to connect with suppliers and see the products firsthand.