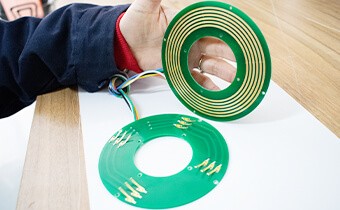

Often known as ultrathin flat slip rings, PCB slip rings are a type of pancake slip ring. It includes two parts, the ring surface, and the brush assembly, and is a common form for flat slip rings. Plating copper and gold are applied to the ring surface circuit board, giving it an ultra-hard and wear-resistant surface.

What Is the Structure of PCB Slip Rings

Where does PCB slip ring come from? Knowing this makes it easier for any customer to understand its reliability. PCB slip rings are made by many manufacturers. Customers expect that each of their PCB slip rings performs well. They are composed of two parts:

The surface: The one which gives it its pancake-like appearance. If there is little space for upward movement, it is flat to occupy horizontal space. Manufacturers use various materials to create the surface, but usually a thick layer of copper and gold is added during the process.

Brushes: A slip ring also contains brushes to transmit signals just like any other slip ring. Depending on the manufacturer, PCB slip rings can have brushes of various materials. Metal alloys can be used for brushes or fibers that are more reliable and are made with the latest technology.

Unique Features of PCB Slip Rings

The PCB slip ring is unique among the other devices due to the materials used in making it. This slip ring features the following characteristics that make it a good choice for customers:

Small-space requirements: When you are installing a slip ring and don’t have a lot of horizontal and vertical space, this pancake-shaped slip ring is ideal because it takes up little space horizontally and vertically. If you are working in a small space but want the system to function normally, it is ideal because it provides a thickness of up to 5.8m.

Friction is low: brushes brush against conductive metal. To make the surfaces and to make brushes, manufacturers use copper and gold. The moving and stationary parts have less friction because rusting is reduced.

Low electric noise: Without friction, a machine or device will not produce any sound when it operates; creating a quiet working environment that is both conducive and productive.

Low torque: Brushes are in direct contact with the metal, causing minimal friction to occur. Therefore, slip rings are suitable for complex machines since they reduce torque.

Maintenance of the slip rig is minimal: The slip rings are not earred because there is no resistance. No lubrication is necessary for the fiber brushes. Because it does not require much maintenance, the customer can use it without incurring much financial outlay.

Moreover, it is coated with gold metal, which keeps it from wearing out. Fiber brushes are also used when transmitting signals to prevent friction between them and the conductive material. PCB slip rings are therefore durable to possess and use.

A customer looking for information on PCB slip rings is best served by knowing how manufacturers manufacture them. A copper or gold coating on the surface, as well as fiber brushes, gives the slip ring durability, flexibility, and is less expensive to maintain, making it both reliable and efficient.

See What We Can Do