In the complex world of mechanics and electronics, where power and data transmission between rotating and stationary components is of the essence, platter slip rings emerge as pivotal elements. They are an ingenious breed of electromechanical device that facilitates the transmission of electrical power or signals across a rotating interface. Featuring a flatter, disk-like design as opposed to the traditional cylindrical shape, these types of slip rings tend to be both space-efficient and adaptable, thereby bringing superior dynamism when integrated into various systems.

The function of platter slip rings is primarily the facilitation of uninterrupted electrical connection while concurrently allowing rotation of the device in which they are integrated. This unique ability plays a crucial role in a broad spectrum of applications. For instance, they find extensive use in radar antennae where they aid in continuous rotation while transmitting vital data to and from the rotating parts. Beyond this, they are also a common feature in packaging machinery, CCTV systems, medical equipment, and wind turbines, where they play a pivotal role in the functioning of these rotating systems. As such, platter slip rings are an emblem of the critical coalescence of mechanical and electrical engineering, enabling seamless interactions between the static and rotating realms.

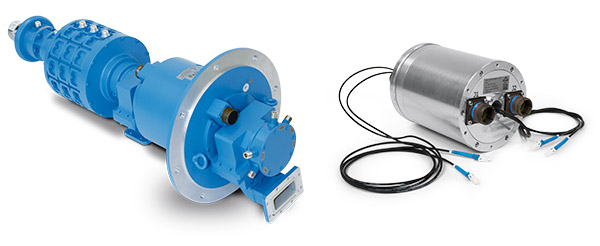

The Structure and Operation Principle of Platter Slip Rings

Within the realm of electromechanical devices, platter slip rings are distinctive due to their unique architecture. Their design deviates from the traditional cylindrical form of slip rings, embracing instead a more flat, disk-like structure. This body, commonly crafted from metals with high electrical conductivity such as copper or silver, houses strategically arranged conductive tracks on its surface. Each of these tracks represents an individual electrical circuit and is assigned one or more brushes, typically made of precious metal alloys, that maintain electrical contact during rotation. In addition, platter slip rings are often outfitted with a center hole, allowing for convenient integration within the mechanical structure of the host device.

The operating principle of platter slip rings embodies the essence of their individualistic design. As the platter – the central rotating part of the slip ring – begins to turn, the brushes retain their position against the conductive tracks. This static yet flexible association allows for an uninterrupted flow of electrical power and data between the stationary and rotating components of the device. What truly makes platter slip rings unique, however, is their ability to handle a significant number of circuits within a limited space. This is due to their planar arrangement of tracks, as opposed to the linear arrangement found in cylindrical slip rings. Furthermore, their compact, lightweight design aids in better heat dissipation and ensures minimal to no impact on the balance of the rotating structure, thereby decreasing wear and prolonging service life.

Advantages of Platter Slip Rings

When exploring the benefits of using platter slip rings, their unique structural design naturally births a plethora of decisive advantages over their traditional cylindrical counterparts. Foremost, their slim profile allows for a considerable amount of weight reduction, working positively towards decreasing stress on the associated rotating mechanism and optimizing the device’s overall performance. Their planar design also enables higher circuit densities, rendering them more compatible with applications that necessitate a larger number of circuits within a constrained space.

Further, the configuration of platter slip rings ensures unrestricted 360° rotation, making them suitable for applications necessitating limitless rotation. Besides, the nature of their design also facilitates superior heat dissipation, leading to higher operating speeds and an extended lifespan—attributes essential for high-performance systems.

To bring these advantages into a real-world perspective, consider their use in medical imaging devices. Platter slip rings in CT scanners support high-speed, continuous rotation, thereby enabling faster scans and improved patient care. In the space industry, their lightweight design proves invaluable for satellites, ensuring less load on the launch vehicle and minimizing energy costs for orbit keeping. Moreover, in wind turbines, their robust design, handling high circuit densities and superior heat dissipation, lends resilience to these hard-working machines amidst fluctuating weather conditions.

Thus, platter slip rings with their litany of attributes prove to be an instrumental advancement in the evolution of electromechanical devices – an upgrade that delivers on the features in the varied fields they serve.

Factors to Consider When Choosing Platter Slip Rings

Selecting the appropriate platter slip rings for any purpose necessitates a careful evaluation of several characteristics and specifications. Firstly, one must consider the number of circuits that need to be handled. The magnitude of power or type and amount of data signals that the device must transfer contribute significantly to making an informed choice. The current and voltage ratings stand as equally important parameters – an incorrect rating could lead to overheating, insufficient power transmission, or even equipment failure. Equally noteworthy is the outer diameter of the slip ring: a parameter that is associated with physical installation space restrictions and must be selected to maintain a harmonious balance with the equipment’s existing design.

The second factor, hinging more on the side of external influences, is the environment within which the equipment operates. The slip ring’s ability to handle variations in temperature, accommodate different humidity levels, and withstand dust or other abrasive elements can drastically affect its service life and operational efficiency. Notably, for slip rings employed in outdoor devices such as wind turbines or radars, weather resistance is an essential parameter.

Lastly, an often overlooked but critical aspect is the reputation of the manufacturer. Ensuring that the platter slip rings are sourced from a reliable and reputable manufacturer goes a long way in guaranteeing product quality, durability, and reliable customer service. Further considering the technical expertise they provide, opportunities for customization to suit unique requirements, and robust after-sales support, including installation assistance and maintenance guidelines, can substantially enhance user experience and overall satisfaction with the product.

In essence, the process of selecting the right platter slip rings shouldn’t be oversimplified. It requires a comprehensive understanding of the product specifications, a thorough evaluation of the operating conditions, and reliance on trustworthy manufacturers to ensure optimal equipment performance.

Maintenance Recommendations for Platter Slip Rings

Ensuring the longevity and optimal performance of platter slip rings is closely linked to an effective and regular maintenance routine. Cleaning is the first and most important step in this procedure. Owing to their operation principle, these slip rings are susceptible to the accumulation of foreign substances such as dust, grime, or oxidation. Without regular cleaning, these substances can increase electrical resistance, leading to data loss or poor power transmission. Therefore, it’s recommended to periodically clean the conductive tracks and brushes with a soft, lint-free cloth, or a brush with soft bristles if necessary, to prevent unnecessary wear and tear on the components.

Alongside cleaning, another critical maintenance aspect is to check the contact pressure between the brushes and the tracks. This needs to be neither too high, which could lead to excess wear, nor too low, which might lead to inadequate contact and inefficient transmission. Following the manufacturer’s recommendations for contact pressure values would be most beneficial in this regard.

Troubleshooting is an equally pivotal aspect of maintaining platter slip rings. Having a clear understanding of common issues can facilitate faster diagnosis and rectification. For instance, a sudden increase in rotational resistance could signal debris accumulation or brush wear. Similarly, intermittent signal transmission might suggest issues with contact pressure. Some issues might necessitate professional help; however, in many cases, a well-informed diagnosis can pave the way towards rectifying the problem and preventing further component damage.

Embracing a proactive maintenance strategy is crucial. Regular cleaning and occasional check-ups, as well as informed troubleshooting when things go awry, can translate into more extended periods of smooth operation and a longer life for your platter slip rings.

Recent Technological Advancements and Future Trends in Platter Slip Rings

The field of electromechanical components, much like any other segment of technology, is an ever-evolving space, with platter slip rings not lagging in this advance. Recent developments have seen these slip rings increasingly incorporating technologies such as fiber optic rotary joints (FORJs) for seamless high-speed data transmission, making them enormously applicable in sectors relying heavily on rapid, uninterrupted data transfer, such as in telecommunications or advanced medical imaging.

Simultaneously, there’s been a growth in the concept of creating hybrid slip rings, which are being designed to accommodate multi-mode functionality, bringing together the transmission of power, traditional electrical signals, and even pneumatic or hydraulic lines. This hybrid trend is a direct response to the increasing complexity of systems they serve, a broadening of capability set to advance in line with technological progression.

Looking towards the future, it’s viable to foresee slip rings integrating further with trending technologies like the Internet of Things (IoT). Embedded sensors could potentially monitor wear and tear in real-time, flagging the need for replacements or maintenance, substantially reducing system downtime, and enhancing operational efficiency.

These advancements present alluring benefits for users. High-speed data transmission opens up new avenues in fields like smart manufacturing and telecommunication, while hybrid slip rings can drastically simplify design complexities. Meanwhile, IoT integration promises a shift towards “smart” maintenance, reducing equipment downtime, and optimizing the lifetime value of devices.

In sum, the future for platter slip rings appears immensely promising. Their progression, shaped by both demand and techno-innovations, is broadening their application portfolio and making them an even more integral part of electromechanical systems.

Conclusion

Understanding the intricate features and operation principles of platter slip rings paves the way for more effective utilization and maintenance of these components. With regular progression in their technology, users can anticipate better performance, adaptability, and efficiency from their platter slip rings in the coming years. The journey of iterative learning and improvement continues!

FAQs about Platter Slip Rings

In the dynamic field of electromechanical devices, platter slip rings often incite numerous queries due to their unique operation principle and adaptability to various applications. Below are answers to a few commonly asked questions.

Q1: Are platter slip rings difficult to install?

A: The process of installing platter slip rings is typically straightforward provided the design and size have been chosen aptly according to your application’s requirements. The manufacturer’s manual generally includes detailed instructions for installation. Nevertheless, professional assistance is recommended for intricate installations or in cases where a device’s functionality can be compromised if not installed correctly.

Q2: Can platter slip rings operate in harsh environments?

A: Yes, many platter slip rings can operate effectively even under harsh environmental conditions. However, the exact resistance to environmental factors such as temperature, humidity, and dust varies depending on the specific slip ring model and the manufacturer’s specifications.

Q3: How often should the platter slip rings be maintained?

A: The frequency of maintenance for platter slip rings depends on the operating conditions and the device’s usage. In general, a routine check every few months is advisable to ensure continued optimal performance. Regular maintenance includes cleaning and checking the alignment and pressure of the brushes.

Q4: What are the signs that a platter slip ring needs replacement?

A: Common signs of needing a replacement include intermittent signal transmission, sudden increases in rotational resistance, visible wear on the brush and track surfaces, or persistent issues despite carrying out routine maintenance and troubleshooting.

Remember, when in doubt, it’s always beneficial to consult with the manufacturer or a technical expert. Regular checks on essential parameters and proactive maintenance can help preempt many potential issues, making the platter slip ring a reliable addition to your system.