Rotary unions are used to transfer fluid or gas from a stationary supply line to a rotating device. One type of rotary union, the Pneumatic rotary union, is used to transmit compressed air, which is necessary for pneumatic systems.

How Does a Pneumatic Rotary Union Work

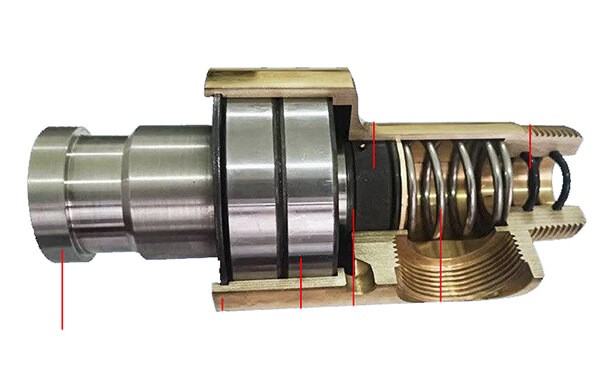

Rotary joints are used to transport steam, pressure, air, and other media. It is a sealing device that connects the gas input from the pipeline to the rotating equipment and then discharges. Pneumatic swivel unions work by swirling compressed air through a fixed point without leaking. A rotary union has two main components: the rotor and the stator. The rotor is the rotating element mounted on the shaft of a rotating machine, while the stator is the stationary part connected to a compressed air source. The rotor and stator contain channels through which compressed air flows.

When the machine turns, the rotor turns with it. The compressed air flowing through the channels in the stator is then delivered to the channels in the rotor without any leakage. Pneumatic swivels can deliver up to 10,000 psi of compressed air and can rotate at up to 10,000 rpm.

Simple rotary joints are divided into one-way flow type and two-way flow type. The one-way flow type does not use an inner tube, and the liquid enters through one end and exits through the other end. The two-way flow type has two forms: inner tube rotation and inner tube fixed. The inner tube rotary type is mostly used for gas transmission.

There is a combined rotary joint whose working principle and structure are based on a pneumatic rotary joint and an electric slip ring. Electric slip rings are used to transmit electricity or signals. The functional parts are the stator and rotor. Through the contact of the stator brush wires with the rotor rings, rolling friction conducts current between the two elements. The electric ring can be composed of multiple metal rings to provide multiple power supplies.

Features of Pneumatic Rotary Union

Pneumatic Rotary Unions come in different sizes and designs to fit various industrial applications. Here are some features of the pneumatic rotary union:

High Speeds: Pneumatic Rotary Union can operate at high speeds up to 10,000 RPM.

Low Torque: They have low torque requirements due to the low friction seals.

Compact Design: Pneumatic Rotary Unions have a compact design and can fit into small spaces.

Low Maintenance: They require low maintenance due to the durable materials used in construction.

Applications of Pneumatic Rotary Union

Pneumatic rotary union is used in various industrial applications, such as:

Machine Tools: Pneumatic rotary union is used in machine tools to transfer compressed air to the rotary spindle, which powers the cutting tool.

Robotics: Pneumatic rotary union is used in robotics to transfer compressed air to the rotating joints of the robot, which allows it to move.

Packaging: Pneumatic rotary union is used in packaging machinery to transfer compressed air to the rotating parts of the machine, which allows it to perform various tasks such as filling, sealing, and labeling.

Textile Industry: Pneumatic rotary union is used in the textile industry to transfer compressed air to the rotary spindle, which powers the spinning and weaving machines.

What to Do When a Rotary Adapter Leaks

First, check the overall concentricity, check the size and accuracy, and adjust the connection with the rotating end.

Check whether the vibration is large due to low accuracy, and whether the appropriate equipment needs to be rectified.

If there is dirt or slurry again, it is necessary to add a decontaminator or filter screen.

If the working pressure, temperature, speed, and other mechanical parameters are not suitable, the rotary joint needs to be redesigned.

Pneumatic Rotary Union is a vital component in various industrial applications that require compressed air to be transmitted through rotating machinery. With its high-speed operation, low torque requirements, and low maintenance features, it is a popular choice in machine tools, robotics, packaging, and the textile industry.

See What We Can Do