The evolution of modern machinery and electronics demands constant innovations and solutions that cater to dynamic movement, efficiency, and reliability. Among the pivotal components underpinning these advancements, rotary electrical connectors stand out for their critical role in enabling seamless operations across diverse applications. This comprehensive article delves into the nuances of rotary electrical connectors, exploring their mechanism, types, and construction, and addressing the predominant user concerns about durability, maintenance, efficiency, and more.

Introduction to Rotary Electrical Connectors

At the intersection of motion and electrical power transfer, rotary electrical connectors, often termed slip rings, emerge as quintessential components. A “rotary electrical connector” is ingeniously designed to seamlessly transmit electrical power and signals between a static system and a rotating platform. This pivotal role of bridging rotating and stationary parts without hindering the motion or the continuity of the electrical supply defines its essence.

In an age where efficiency, reliability, and seamless integration form the pillars of technological innovation, the rotary electrical connector stands out for its ability to harmonize movement with electrical functionality. This not only enhances the capabilities and flexibility of modern machinery but also opens up possibilities for advancements in design and application.

Understanding the Working Principle of Rotary Electrical Connectors

The seamless interaction between static and dynamic components within machinery relies heavily on the unassuming yet intricate operation of rotary electrical connectors. At its core, the working principle of rotary electrical connector centers on creating a sustainable electrical pathway between a stationary part and a rotating assembly, thereby allowing for the continuous transmission of power and data without the risk of tangling or wear on the connecting cables.

Imagine a carousel ride where the lights and music run without a pause, despite the ceaseless whirling movement. This process is an apt analogy for understanding the operating process of rotary electrical connectors. The rotating base of the carousel, analogous to a slip ring, is in constant circular motion, made possible by a system comprising fixed and rotating contacts, insulation, and housing.

The Operating Process Can Be Visualized in A Stepwise Manner:

Initiation of the Connection: As the machine powers up, the connector initiates an electrical pathway through its stationary conductive brushes (fixed contacts), which are pressed against the rotating surface or ring.

Rotation and Power Transmission: As the device begins to rotate, the rotating ring maintains the electrical flow towards the machine’s rotating part. This uninterrupted current is facilitated by the continuous sliding contact between the brushes and the ring.

The Electrical Pathway: Despite the perpetual rotation, the electrical contact doesn’t falter, mimicking the agility of tightrope walkers, deft at maintaining balance, ensuring the machinery’s reliability and effectiveness.

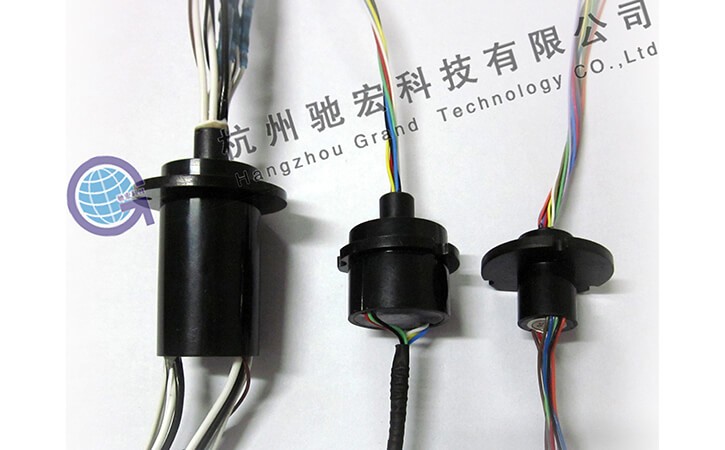

Different Types of Rotary Electrical Connectors

In the diverse ecosystem of machinery and electronic devices, the demand for adaptable and efficient electrical connectivity has led to the evolution of various types of rotary electrical connectors. Each type is designed to meet the specific needs of different applications, varying in construction, capacity, and functionality to solve unique operational challenges.

Applications and Needs: Capsule slip rings are ideal for CCTV cameras, robotics, and medical equipment where size constraints are significant. They address the need for a low-profile connector that can provide reliable transmission of signals and power without compromising on the equipment’s compact structure.

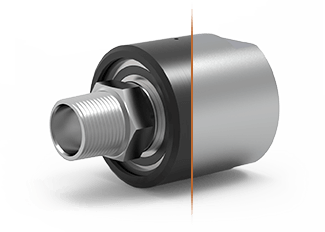

Applications and Needs: This type finds its place in machinery like wind turbines and packaging equipment, where it is necessary to route hydraulic lines, pneumatic lines, or a central rotating shaft through the slip ring. The through-bore design caters to applications requiring integrated systems to pass through the center, facilitating not just electrical connections but also mechanical rotations.

Applications and Needs: Applications requiring large, planar rotations such as satellite dishes and some types of radar assemblies benefit from pancake slip rings. They provide a specialized solution for systems that have adequate space in their diameter but are challenged by axial space constraints.

Applications and Needs: This type is particularly well-suited for applications where minimal wear and tear are crucial, or in environments where physical contact might pose a risk (such as in hazardous or highly clean environments). Wireless slip rings solve the need for contactless operations, extending the life of the system and reducing maintenance needs in critical applications like remote sensors and rotating tanks in process industries.

Applications and Needs: In the age of IoT and connected devices, Ethernet slip rings serve applications requiring high-speed data transmission, such as in advanced communication systems, modern manufacturing automation, and surveillance systems. They address the need for robust data communication capabilities, ensuring that devices remain interconnected and operate seamlessly.

Applications and Needs: Heavy machinery, electric vehicle charging stations, and industrial processing equipment that require the movement of large amounts of power find the high-current slip rings indispensable. They provide a solution for systems where power demand is extensive, ensuring safety, reliability, and efficiency in high-power applications.

The Anatomy of a Rotary Electrical Connector

The rotary electrical connector, often colloquially referred to as a slip ring, is a crucial component within the family of electromechanical devices. Its architecture is a symphony of precision engineering, where each part plays a critical role in ensuring flawless performance. Let’s delve into the structural anatomy and material composition that form the backbone of a rotary electrical connector.

Structure Overview

At its most basic, a rotary electrical connector consists of stationary brush contacts that rub against rotating rings. The contacts are typically made of a hard-wearing, conductive material, and the rings are designed to provide a continuous electrical path as they turn.

Material Composition

Contact Brushes: Usually crafted from precious metals like gold, silver, or copper alloys, these brushes must possess a fine balance of softness for minimal wear on the ring, alongside hardness for durability. They also require excellent conductivity to allow for efficient electrical transmission.

Rotating Rings: Often made from similar materials as the brushes to prevent galvanic corrosion due to material incompatibility, these rings can also be plated with precious metals to enhance performance and extend lifespan.

Insulation Materials: These are key in preventing electrical leaks and shorts. High-quality polymers such as PEEK or Nylon are common, and known for their excellent dielectric properties, resilience to environmental factors, and mechanical strength.

Housing: This external shell is usually composed of robust materials such as aluminum, stainless steel, or engineered plastics. The housing protects against physical damage, dust, moisture, and any other contaminants.

Engineering Behind Robust and Reliable Designs

The engineering prowess behind a rotary electrical connector is exemplified in how these various materials and components come together.

Precision Assembly: The brushes and rings are assembled with exacting precision, ensuring optimal contact is maintained across the full range of motion. This minimizes electrical noise and wear, which could otherwise compromise signal integrity or power transmission.

Balance Between Rigidity and Flexibility: The design must account for the rigidness required to maintain stable electrical contact while allowing flexibility to accommodate any misalignment and prevent undue stress on the components.

Thermal Management: Good design will also consider heat dissipation. Efficient thermal management prevents overheating and ensures the connector’s longevity, especially in high-current applications.

Low Friction Coatings: To reduce the friction between the brushes and the rings, advanced coatings may be applied. This not only helps in reducing wear but also maintains a consistent electrical connection.

Environmental Sealing: For applications in hostile environments, connectors are sealed from elements that could corrode or otherwise damage the components. This level of protection is reflected in the Ingress Protection (IP) rating of the connector.

User Concerns: Durability of Rotary Electrical Connectors

The durability and service life of rotary electrical connectors are paramount concerns for users across various industries. These connectors play a critical role in the functionality and reliability of equipment, and their failure could lead to significant operational downtimes and maintenance costs. Understanding and addressing these concerns involves delving deep into the factors that affect durability and implementing manufacturing processes that can enhance the longevity of these crucial components.

Solving Durability Concerns

Durability in rotary electrical connectors hinges on three pivotal aspects: material quality, design precision, and environmental protection.

Material Quality: The longevity of rotary electrical connectors is significantly influenced by the materials used. High-quality, wear-resistant materials for both contacts (brushes) and rings ensure minimal degradation over time. For example, gold-plated contacts might offer the best performance in terms of corrosion resistance and electrical conductivity, leading to a longer service life.

Design Precision: The architecture of a rotary electrical connector must account for optimal contact pressure, minimal friction, and efficient heat dissipation. Precision in design minimizes undue wear and tear and prevents overheating, both of which can prematurely age the connector.

Environmental Protection: External factors such as moisture, dust, and corrosive agents can drastically affect the durability of connectors. Hence, incorporating adequate sealing and protective measures, tailored to the operating environment, is crucial for extending their service life.

Recommendations for Enhancing Durability Through Manufacturing Processes

Advanced Plating Techniques: Utilizing advanced plating processes for contact materials can significantly improve wear resistance and reduce oxidation. For instance, applying a multi-layer plating process—starting with nickel for its hardness and finishing with gold for its conductivity and corrosion resistance—ensures durability without compromising performance.

Precision Engineering: Employing state-of-the-art CNC (Computer Numerical Control) machinery for the manufacturing of components ensures high precision and consistency. This reduces the likelihood of defects that could lead to early wear or failure, ensuring that each connector meets the highest standards of quality.

Material Selection: Adopting a rigorous material selection process, prioritizing materials not just for their electrical properties but for their mechanical durability as well, addresses durability from the very foundation. Materials that can withstand high temperatures and resist environmental stressors are preferable.

Environmental Sealing: Implementing sophisticated sealing techniques, such as O-rings and gaskets made from durable materials like Viton or silicone, can protect the connectors from dust, moisture, and other corrosive elements. This is particularly important for connectors used in outdoor or harsh industrial environments.

Quality Control: Integrating comprehensive quality control processes, including tests for wear resistance, electrical performance over time, and resilience under simulated environmental conditions, ensures that only connectors of the highest durability reach the market.

Maintenance Requirements for Rotary Electrical Connectors

Maintaining and ensuring the longevity of rotary electrical connectors is crucial for the seamless operation of machinery and equipment reliant on these components. Despite their designed durability and precision engineering, connectors require regular maintenance and timely repair to function optimally. Establishing a routine maintenance regimen not only extends the service life of the connectors but also prevents unexpected failures that could lead to costly downtimes.

Maintaining and Repairing Rotary Electrical Connectors

Effective maintenance and repair of rotary electrical connectors start with understanding their operation and recognizing signs of wear or failure. Regular, proactive maintenance ensures these components maintain their performance standards over extended periods.

Lubrication: Many rotary electrical connectors require periodic lubrication to reduce friction and wear between the contacts and the rings. Use only the lubricants recommended by the manufacturer since incorrect compounds can degrade materials or cause electrical faults.

Cleaning: Dust, debris, and other contaminants can accumulate on the connector surfaces, leading to poor electrical contact and potential failure. Gentle cleaning with approved solvents and a soft, lint-free cloth can prevent these issues. For connectors in more severe environments, more frequent cleaning may be necessary.

Inspection of Wear and Tear: Regular visual inspection for signs of wear, such as excessive brush wear, corrosion, or damage to insulation, is vital. Early detection of these issues can prompt timely replacements or repairs, preventing more significant problems.

Electrical Testing: Performing regular electrical tests to check for continuity, resistance, and potential insulation breakdown can uncover hidden issues that aren’t apparent through visual inspection alone.

Parts Replacement: Worn or damaged components, including brushes, rings, and bearings (if applicable), should be replaced with original manufacturer parts to ensure compatibility and reliability.

Checklist of Routine Inspection and Maintenance Activities

To streamline the maintenance process, a checklist can help ensure that all necessary steps are taken to maintain rotary electrical connectors effectively. Below is a comprehensive checklist:

Visual Inspection: Check for apparent signs of wear, damage, or corrosion on the contacts, rings, and housing.

Lubrication Check: Verify that all moving parts are adequately lubricated per the manufacturer’s recommendations.

Cleaning Regime: Ensure connectors are clean and free of any contaminants that could interfere with operation.

Continuity and Resistance Tests: Perform electrical tests to confirm the integrity of the electrical connections and insulation.

Parts Inspection: Examine brushes, bearings (if applicable), and other wearable parts for signs of wear or degradation.

Environmental Sealing: Inspect seals and gaskets for integrity to prevent environmental damage.

Functionality Test: Operate the connector (if possible) to ensure smooth rotation and consistent electrical performance.

Repair or Replace: Decide whether repairs or replacements of components are needed based on the inspection and test outcomes.

Documentation: Keep records of all maintenance activities, findings, and replacements for future reference and maintenance planning.

Rotary Electrical Connector Efficiency and Performance

Efficiency and performance in rotary electrical connectors are pivotal factors that directly influence the operational capability and reliability of broader systems, such as industrial machineryIndustrial Machinery, medical equipment, and communication devices. The efficiency of these connectors—often defined by their ability to maintain consistent electrical connectivity with minimal power loss and resistance—plays a critical role in optimizing the overall system performance. Poorly performing connectors can lead to energy wastage, signal distortion, and eventually, system failures, thereby emphasizing the importance of high-efficiency components in various applications.

Analyzing the Impact on System Performance

The efficiency of rotary electrical connectors impacts several key aspects of system performance, including energy consumption, signal integrity, and mechanical wear.

Energy Consumption: Efficient connectors minimize electrical resistance, thereby reducing power loss. This is critical in applications where energy efficiency is paramount, directly influencing operational costs and environmental footprint.

Signal Integrity: In systems requiring the transfer of data signals through the connector—such as in telecommunications equipment—maintaining signal integrity is essential. High-efficiency connectors ensure minimal signal degradation, allowing for reliable data transmission without noise or error.

Mechanical Wear: Efficient connectors also exhibit optimized mechanical properties, such as reduced friction and wear between contacts. This leads to longer service lives, less frequent maintenance requirements, and reduced total cost of ownership.

Tips for Optimizing Performance

To ensure the performance of rotary electrical connectors is optimized for a variety of applications, consider the following tips:

Regular Maintenance: Adhering to a schedule of regular maintenance, including cleaning and lubrication, can prevent performance degradation over time. This is particularly important in harsh environments where contaminants can significantly impact efficiency.

Appropriate Material Selection: Choosing connectors with materials suited to the application’s specific requirements can enhance efficiency. For instance, gold-plated contacts might be preferable in scenarios demanding excellent conductivity and corrosion resistance.

Suitable Design Choice: Opting for a connector design tailored to the operating conditions—considering factors like current capacity, rotational speed, and environmental exposure—ensures the system operates at peak efficiency.

Environmental Protection: Implementing protective measures against environmental factors such as moisture, dust, and vibration, either through connector design or supplementary shielding, helps maintain connector efficiency and prolongs lifespan.

Professional Installation: Ensuring that connectors are correctly installed and aligned can prevent mechanical stress and electrical misalignment, which could otherwise hinder performance.

Performance Testing: Conduct regular performance assessments, including electrical continuity, insulation resistance, and thermal analysis, to identify and address issues before they impact system efficiency.

Custom Solutions: When standard connectors do not meet the specific needs of an application, consider custom-engineered solutions designed specifically for optimal performance in unique operating conditions.

Cost of Rotary Electrical Connectors

The cost of rotary electrical connectors encompasses more than just the initial purchase price. It involves a comprehensive consideration of installation expenses, ongoing maintenance requirements, and the operational impact over their lifecycle. For organizations relying on these connectors for critical operations, understanding these costs in detail is essential for effective budgeting and operational planning. By breaking down these costs and conducting a thorough cost-benefit analysis, users can make informed purchasing decisions that align with both technical requirements and financial constraints.

Breakdown of Costs

Purchase Price: This is the upfront cost of acquiring the connector, which varies significantly based on the connector’s specifications, materials, and design complexity. High-performance connectors, especially those tailored for specific applications or environments, generally command higher prices.

Installation Costs: Installation involves not only the physical integration of the connector into the system but also potential modifications to accommodate the new component. These costs can include professional fees for technicians, as well as downtime required to integrate and test the new connectors.

Maintenance and Repair: Regular maintenance involves cleaning, lubrication, and inspection to ensure optimal performance. Additionally, parts may need to be repaired or replaced over time, contributing to the total cost of ownership. The frequency and cost of these activities largely depend on the operating environment and application intensity.

Operational Impact: This includes potential downtime or reduced system efficiency due to connector failures or inefficiencies, which can have significant financial implications, especially in critical or high-throughput applications.

Cost-Benefit Analysis for Purchasing Decisions

To navigate the purchasing decision effectively, a cost-benefit analysis that considers both direct and indirect costs versus the anticipated advantages is essential.

Long-Term Reliability vs. Initial Cost: While high-quality connectors may have a higher initial price, their reliability and longer service life can reduce the frequency and severity of system downtime, leading to cost savings over time.

Performance Efficiency: Connectors that maintain optimal performance under varying conditions can enhance system efficiency, leading to energy savings and potentially more consistent operation, which are important considerations for high-demand applications.

Maintenance Requirements: Low-maintenance connectors, though possibly more expensive upfront, can offer savings in terms of reduced repair costs and downtime, particularly in critical systems where maintenance access is challenging.

Customization Needs: For specialized applications, the benefits of custom-engineered connectors (designed for specific operational requirements) need to be balanced against the higher cost and potential longer lead times compared to off-the-shelf solutions.

Future-Proofing: Investing in connectors that can accommodate future upgrades or changes in application requirements can provide long-term savings by minimizing the need for complete system overhauls.

Solve the Problem of Wear and Replacement of Rotating Electrical Connectors

Rotating electrical connectors, integral to many systems, endure wear due to their moving parts and electrical loads. Gradual wear can lead to decreased performance, potential failures, and unplanned operational disruptions. Therefore, implementing a proactive maintenance strategy that includes vigilant monitoring and timely replacement of these connectors is crucial for the uninterrupted performance of equipment. This strategy not only anticipates potential issues but also extends the lifespan of the overall system.

Guidance on Monitoring Rotary Electrical Connector Wear and Scheduling Replacement

Regular Inspections: Conducting scheduled inspections of rotating electrical connectors can reveal early signs of wear, such as excessive brush wear, degradation of slip rings, or corrosion. These inspections should be more frequent in harsh operating environments or high-cycle applications.

Performance Metrics: Monitoring key performance indicators, such as electrical resistance, insulation breakdown, or noise levels, can offer insights into the connector’s condition. Deviations from established baselines may signal impending wear or failure.

Condition Monitoring Systems: Advanced monitoring systems using sensors can continuously assess the health of rotating electrical connectors, providing real-time data on temperature, vibration, and electrical characteristics that prelude wear-related issues.

Wear Patterns and Predictive Analysis: Documenting wear patterns and utilizing predictive analytics can help forecast the likely lifespan of a connector based on historical data and usage patterns. This enables the scheduling of replacements before actual failures occur.

Manufacturer’s Recommendations: Adhering to the replacement schedules suggested by connector manufacturers is a baseline for maintenance. Their insights take into account the design limits and tested operating cycles of the connectors.

How a Proactive Approach Prevents Downtime and Extends Equipment Life

Anticipatory Interventions: A proactive approach involves scheduling maintenance and replacement activities ahead of projected wear-out periods. This forethought prevents unexpected breakdowns and the cascading effects on connected systems.

Optimized Maintenance Schedules: By integrating wear monitoring into regular maintenance schedules, replacements can be planned during less critical operational periods, thus mitigating the impact on production or service availability.

Enhanced System Reliability: Proactive wear management maintains connector performance at optimal levels, contributing to the overall reliability and efficiency of the system.

Cost-Effective Operations: Unplanned downtime or emergency replacements are often more costly than scheduled maintenance. Proactive measures allow for better budgeting and allocation of funds, reducing overall expenditure.

Extended Equipment Lifespan: Systematically addressing wear not only assures the functionality of the rotary connectors themselves but also protects associated equipment from secondary damage due to electrical faults or mechanical misalignment.

Improved Safety and Compliance: Ensuring connector integrity through proactive replacement can also be integral to compliance with safety regulations, especially in critical applications such as medical devices or transportation systems.

Historical Data Utilization: The analysis of historical wear and replacement data can fine-tune maintenance intervals, further refining the proactive replacement strategy and enhancing lifecycle management.

Choose the Right Rotary Electrical Connector

Rotary electrical connectors play a vital role in many different industrial applications, allowing the transmission of power and signals between stationary and rotating parts. Given their importance, it is crucial to select a connector that properly fits the operational requirements and environment. The right choice involves considering various key specifications and features and exploring customization options to meet specific demands.

Key Specifications and Features to Look for When Choosing a Rotary Electrical Connector

Electrical Characteristics: Depending on the application, connectors may need to accommodate varying levels of electrical currents, voltages, and number of channels (circuits). It is key to consider the electrical capacity of the rotary connector to ensure it matches the load requirements.

Signal Integrity: For applications transmitting data or sensitive signals, noise immunity, signal-to-noise ratio, and data transmission rates are crucial considerations to maintain signal integrity.

Mechanical specification: Factors such as size, weight, and mounting options need to align with the physical constraints of the application. These attributes should be compatible with existing equipment and installation spaces.

Rotational Speed: Some applications require high-speed rotation while others may operate at lower speeds. Not all connectors can handle a wide range of speeds, so rotational speed compatibility is important.

Environment and Durability: Connectors used in harsh environments should have appropriate environmental resistance such as corrosion resistance, temperature tolerance, and IP rating for dust and waterproofing.

Maintenance Requirements: Select a connector that aligns with your maintenance capabilities. Some designs necessitate frequent care, especially in demanding environments, while others may be virtually maintenance-free.

Concept of Customization Options and How They Suit Specific User Requirements

Despite the broad range of standard rotary electrical connectors available, some applications may require customization to address unique requirements. Manufacturers may offer a variety of customizable options that can be tailored to individual user needs.

Material Selection: Depending on the environmental conditions and performance requirements, customers can choose specific materials for the housing, connectors, and other components to enhance durability, safety, or noise reduction.

Design Alterations: Customization could include changes to the design like the pattern of the connections, the addition of extra channels, or unique mounting arrangements.

Integration with other Systems: Some applications may require the connector to be integrated into a more complex system. Manufacturers can sometimes design and build connectors that directly integrate with existing equipment, reducing installation complexity.

Special Performance Requirements: Customization options can include enhancements to performance, such as improved signal transmission, increased rotational speed capability, or superior environmental resistance.

Considering custom options could offer better long-term value, though they may have higher upfront costs and longer lead times compared to standard connectors. However, when specific challenges need solving, or the application demands the highest levels of performance and reliability, a customized rotary electrical connector could be the most appropriate solution.

Choosing the right rotary electrical connector involves a comprehensive examination of both technical requirements and environmental factors, and perhaps exploring customization options. By focusing on these areas, users can select a connector that not only performs optimally and reliably but also fits perfectly within the constraints and needs of their unique application.

Innovation in Rotary Electrical Connector Technology

With technological advancements and the increasing demand for higher performance and reliability, the field of rotary electrical connectors is undergoing significant transformation. Innovations in design and materials are extending the capabilities of these connectors to meet the ever-evolving demands of a broad spectrum of industries, from medical and defense to communication and automation.

Demonstrates the Latest Advances in Rotary Electrical Connector Design and Materials

Design Enhancements:

Modular Systems: New connector designs are focusing on modularity to allow for easier customization and scalability. This means that individual components or modules can be replaced or upgraded without the need to change the entire system.

Contactless Connectivity: Magnetic induction and capacitive coupling are being used to create contactless rotary connectors, mitigating wear and tear and significantly improving longevity and reliability in data and power transmission.

Integrated Electronics: Smart connectors with integrated sensors and circuitry that can provide real-time feedback on the connector’s status, health monitoring, and predict maintenance schedules, are becoming common.

Practical Applications of Rotary Electrical Connectors

Key Points of the Case Study

- Durability Against Harsh Conditions: Slip rings are designed to withstand the extreme environments in which wind turbines operate, often withstanding fluctuations in temperature, humidity, and exposure to the elements.

- Continuous Transmission: The slip ring ensures uninterrupted transfer of power and signals, which is critical for the real-time adjustments needed for optimal turbine efficiency.

- Maintenance Schedules: Given the high costs of maintenance for wind turbines, especially offshore ones, the slip rings used must have extended life spans and low maintenance requirements.

This case study demonstrates the importance of rotary electrical connectors in renewable energy and exemplifies how selecting the right connector can drastically affect performance and operational costs.

Different Industries Where These Connectors Are Making a Difference

Medical Industry: In medical equipment, rotary electrical connectors are found in CT scanners, and MRI machines, where they facilitate the transmission of power and data within the rotating parts of the machinery, allowing for uninterrupted imaging processes.

Military and Defense: Military turrets, radar platforms, and communication systems rely on these connectors to maintain power and data flow as they rotate, ensuring constant operational readiness and strategic communication integrity.

Manufacturing and Automation: Rotary connectors are key in robotic arms and turntable applications, offering power and control signals through continuous motion, leading to increased productivity and precision in manufacturing processes.

Aerospace: In the aerospace sector, they are used in both the rotating parts of an aircraft, such as radar and weapon systems, and ground support equipment, enabling the reliable transfer of monitoring and control signals.

Marine and Subsea: For underwater remotely operated vehicles (ROVs) and equipment, rotary connectors must resist pressure and corrosion, providing critical power and telemetry data through the rotary interface.

Conclusion: The Future of Rotary Electrical Connectors

These are quintessential components playing pivotal roles across a multitude of applications—from powering the rotational movement within wind turbines to enabling precise data transmission in medical imaging equipment. Their versatility and functionality underscore the innovative strides in areas as diverse as renewable energy, healthcare, defense, and manufacturing. As we’ve explored, these components not only facilitate essential mechanical operations but also ensure the seamless flow of electricity and data across stationary and rotating interfaces, enabling modern technological marvels to perform optimally.

The Importance of Rotary Electrical Connectors:

Rotary electrical connectors stand at the crossroads of innovation and reliability, integrating seamlessly into devices that touch upon nearly every facet of modern life. Their specific application in enhancing the capabilities of renewable energy sources, supporting cutting-edge medical diagnostics, and ensuring the reliability of defense systems highlights their critical role. As technologies evolve, the function of these connectors transcends traditional boundaries, pushing the envelope of what’s possible in mechanical and electrical engineering.

Commitment to Innovation and Quality

Innovation at the Core: The future of rotary electrical connectors is indelibly marked by a commitment to innovation. This entails a continuous quest for materials that offer better performance and durability, designs that accommodate higher speeds and more compact spaces, and technologies that enable smarter, more efficient connections. Innovation also means embracing new manufacturing techniques, such as 3D printing, to create connectors with complex geometries or integrated components that were previously inconceivable.

Unwavering Quality: The commitment to quality is paramount, given the critical roles these connectors play. Enhanced testing methodologies and adherence to stringent global standards ensure that these connectors can reliably perform in the most demanding conditions. Quality also implies a dedication to sustainability, ensuring that the materials and processes used in manufacturing connectors minimize environmental impact.

Custom Solutions: Acknowledging the unique demands of various industries, manufacturers are increasingly offering custom-designed solutions. This tailored approach ensures that specific application requirements are met, be it in terms of size, capacity, or environmental resilience, fostering innovation in application-specific contexts.

Smart Connectivity: Looking ahead, rotary electrical connectors will undoubtedly become smarter. Integrating sensory capabilities and diagnostic tools directly into the connectors will facilitate real-time monitoring, predictive maintenance, and a deeper understanding of operational efficiencies and anomalies. Such advancements will not only extend the lifespan of the connectors themselves but also the systems they empower.

Global Collaboration: The future shines brightly with possibilities spurred by global collaboration. Partnerships across industries and academia promise to drive forward innovations in materials science, engineering, and data analytics, furthering the possibilities for rotary electrical connectors.

FAQs about Rotary Electrical Connector

What Should I Consider When Selecting A Rotary Electrical Connector for My Application?

- Electrical Requirements: Assess the voltage and current that the connector needs to transmit, and whether it needs to handle signals, power, or both.

- Operating Environment: Determine if the connector needs to withstand exposure to elements like moisture, dust, chemicals, or extreme temperatures, and consider the required IP rating.

- Mechanical Constraints: Reflect on the physical space available, required rotation speed, expected lifecycle, torque level, and the number of rotations.

- Certification and Standards Compliance: Ensure the connector complies with relevant industry standards and certifications.

How Do I Install A Rotary Electrical Connector?

Understand Specifications: Before installation, review the product’s manual for technical specifications and installation procedures.

Align Correctly: Make sure the stationary and rotating interfaces align properly to prevent undue stress and ensure a smooth rotation.

Connect Securely: Follow the manufacturer’s guidelines for securing electrical connections, which may involve soldering wires or securing with set screws.

Test Before Use: Perform functionality tests to confirm that the connector is installed correctly and that there is consistent power and signal quality during rotation.

Can Rotary Rlectrical Connectors Be Repaired or Do They Need to Be Replaced When They Malfunction?

- Repairability: Some connectors are designed with repairable parts, such as replaceable brushes or contact rings. In these cases, the malfunctioning component can be exchanged.

- Replacement: However, if a connector is sealed or designed as a non-serviceable unit, it may need to be entirely replaced once it malfunctions beyond a simple repair.

How Long Do Rotary Electrical Connectors Typically Last?

- Varies by Use: The lifespan can highly vary depending on the usage conditions, such as rotational speed, duty cycle, and environmental factors.

- Manufacturer’s Rating: Most manufacturers provide an estimated lifespan, often reported in the number of rotations or hours of operation, under specified conditions.

Are There Custom Options Available for Rotary Electrical Connectors?

- Manufacturer Services: Many manufacturers offer customizable options, including specific electrical configurations, materials, and integration features.

- Consultation: Discussing the specific application with a manufacturer is recommended to determine what custom solutions could be tailored to meet special requirements.

What Kind of Maintenance Do Rotary Electrical Connectors Require?

Maintenance Needs:

- Routine Inspection: Regularly inspect connectors for signs of wear or damage, especially in applications that involve high speeds or heavy loads.

- Cleaning: Some environments may necessitate periodic cleaning to remove debris or contaminants that could affect performance.

- Lubrication: Depending on the design, some connectors might need lubrication to maintain smooth operation and extend the connector’s life.

How Does Rotational Speed Affect The Selection of A Rotary Electrical Connector?

Rotational Speed Impact:

- Speed Rating: Ensure that the connector is rated for the maximum operational speed of your application.

- Faster Operations: High-speed applications may require connectors with low inertia and minimal contact resistance to prevent overheating and ensure long-term reliability.