Silver slip rings have played a pivotal role in numerous applications, primarily due to the sterling properties of silver. This article explores the benefits of these components, comparisons with other materials, their widespread use, and user concerns, and guides procurement and maintenance, before peering into their future.

Introduction to Silver Slip Rings

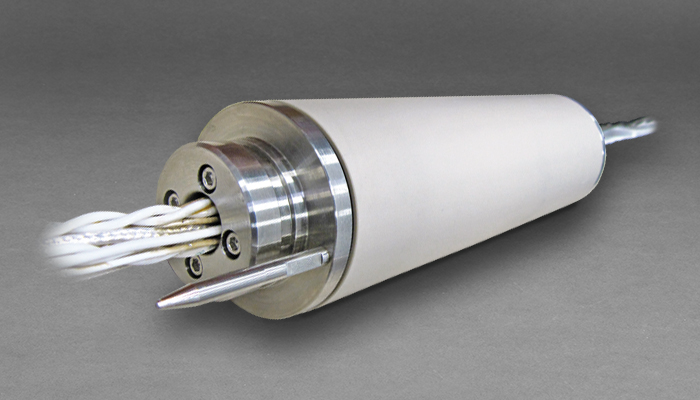

Slip rings, commonly known as rotary electrical interfaces, rotating electrical connectors, or electrical rotational joints, perform a vital function in numerous applications. They facilitate the transmission of power and electrical signals from a stationary structure to a rotating one. Their utility proves indispensable in myriad devices from wind turbines and satellite dishes to MRI scanners and automobile alternators.

However, the efficiency of a slip ring largely depends upon the choice of its construction material. This is where silver – a metal renowned for its array of unique properties – comes to the forefront.

Silver, known for its brilliant luster and malleability in the world of jewelry, is equally celebrated in the realm of electronics and electrical engineering due to its superior electrical and thermal conductivity. With a natural ability to resist corrosion and oxidation, it proves to be an exceptional choice of material for structuring slip rings.

Choosing silver for slip rings transforms them into robust rotary electrical connectors capable of handling high-frequency rotations without significant wear or signal distortion. They become endurance warriors, providing reliable connectivity over extended periods, thus increasing the longevity and serviceability of the systems they power.

Thus, the incorporation of silver as a material in slip rings has set a new standard in their operational efficiency and reliability. It raises the bar in terms of performance under challenging environments, effectively broadening the horizons for their applications.

The subsequent sections of this statement will delve deeper into the properties that make silver slip rings stand apart, their comparison with those crafted from other materials, their prevalent applications, and the associated user concerns, culminating in an insightful guide for prospective customers to make informed decisions.

Properties and Benefits of Silver Slip Rings

When selecting materials for electronic applications, it’s essential to consider the attributes that will enable optimal device functionality. For a component like a slip ring, which plays a pivotal role in ensuring seamless power and data transfer in rotatory systems, material properties can directly affect performance and longevity.

Silver, a precious metal lauded for its sterling properties, is one of the top choices for slip rings. It possesses a unique confluence of characteristics, each of which contributes significantly to the performance enhancement of silver slip rings.

One of silver’s most important properties is its exceptional electrical conductivity. It outpaces all other metals in efficiently transmitting electricity, which is a crucial factor for slip rings given their primary function of enabling electrical communication between stationary and rotating parts.

Thermal conductivity is another prime aspect, and again, silver takes the lead. It swiftly dissipates heat, preventing the risk of overheating, which can negatively impact a slip ring’s performance and lifespan.

Silver’s malleability and ductility further compound its suitability. It can be deftly shaped and structured, making the manufacturing of silver slip rings more precise. The flexibility allows silver slip rings to withstand physical stresses during high-frequency rotations without compromising signal accuracy.

Moreover, silver is highly resistant to corrosion and oxidation. This means that silver slip rings can maintain their functionality even in harsh environments where they are exposed to humidity or other potentially corrosive elements.

The benefits of utilizing silver in slip rings are manifold, as given by these unique properties. When translated into real-world applications, silver slip rings outshine their counterparts through superior operational efficiency and reliable transmission, minimizing signal loss or distortion. Their capacity to withstand high-frequency rotations improves overall system longevity, making them a cost-effective solution in the long term.

In addition, the corrosion resistance ensures that silver slip rings demand less maintenance, providing uninterrupted service over extended periods and trouncing the need for frequent replacements.

Conclusively, the incorporation of silver into slip rings translates into a robust, efficient, and reliable system capable of delivering high performance in diverse applications, thus offering a substantial return on investment for the users.

Silver Slip Rings vs Other Materials

In the realm of electrical engineering, the choice of material for a particular application is influenced by multiple parameters. When it comes to slip rings, materials range from copper and brass to bronze and aluminum, each bringing its unique set of properties to the table. Understanding these properties is vital in evaluating their utility vis-a-vis silver.

Copper, like silver, is an excellent conductor of electricity. It is used extensively in electrical applications due to its relatively low cost. However, when compared to silver, copper’s conductivity is slightly inferior. It is also not as effective in heat dissipation, potentially impacting a slip ring’s performance during high-frequency rotations or in heat-intensive operations.

Brass offers a balance between conductivity and cost-effectiveness and is more resistant to corrosion than copper. However, it falls short of the conductivity and durability offered by silver, which can affect signal integrity and lifespan in more demanding applications.

Bronze, an alloy of copper and tin, is notable for its durability and resistance against wear and corrosion. However, its electrical conductivity is considerably lower than both copper and silver, making it less suitable for high-performance slip rings where signal clarity and strength are paramount.

Aluminum is another choice for many slip ring applications. It’s light, cost-effective, and decent in terms of conductivity. However, aluminum slip rings can be less durable and more prone to wear, particularly in situations involving high rotational speeds or under mechanical stress.

Silver slip rings, when juxtaposed against these other materials, clearly deliver an edge. While silver may be considerably more costly than these alternatives, it excels in terms of conductivity, heat dissipation capabilities, and corrosion resistance. The durability and flexibility of silver support the stability of slip rings during high-frequency operations.

That said, the overarching advantage of silver doesn’t negate the utility of other materials. Depending on the application’s requirements, a different material may be more cost-effective or suitable. For instance, for low-speed operations with a tight budget, copper or brass could be more apt. However, if the application demands high signal integrity, superior performance, and longevity in challenging environments, silver slip rings indisputably emerge as the leading contender.

Applications of Silver Slip Rings

Owing to their unique properties and advantages, silver slip rings have witnessed widespread adoption across diverse industries and applications. Their exceptional electrical and thermal conductivity, corrosion resistance, and durability make them the preferred choice for a multitude of use cases that demand optimal performance and longevity. Let’s examine some prevalent applications and understand why silver slip rings hold an indomitable position in these sectors.

- Power generation and distribution: Silver slip rings find extensive usage in applications involving power generation and distribution, such as wind turbines and energy management systems. Thanks to their superior conductivity, silver slip rings facilitate efficient transmission of electrical signals and power, while their corrosion resistance ensures reliability in challenging outdoor environments.

- Industrial machinery: Silver slip rings are commonly employed in heavy industry machinery such as cranes, robotic arms, and manufacturing equipment. These applications often entail high-frequency rotations and considerable mechanical stress. Silver’s exceptional conductivity and flexibility grant it the ability to endure such conditions, delivering reliable performance with minimal wear and tear.

- Medical equipment: In the medical sphere, silver slip rings are incorporated in devices like MRI and CT scanners, which necessitate accurate signal transmission under demanding circumstances. Enhanced electrical performance, minimal signal distortion, and reliable longevity make silver slip rings an invaluable choice for this equipment.

- Automotive and aerospace: From steering systems in automobiles to antenna systems in satellites and aircraft, silver slip rings play an essential role in automotive and aerospace applications. Given their high-performance electrical connectivity and resistance to extreme temperatures, silver slip rings contribute to the optimization and operational safety of these vital systems.

- Marine applications: The marine sector leverages silver slip rings in equipment such as radar systems, winches, or communication devices. Operating in a corrosive saltwater environment, silver’s natural corrosion resistance and durability become paramount in maintaining operational efficiency and reliability.

- Telecommunications: In an industry where signal clarity is mission-critical, the remarkable electrical conductivity of silver slip rings renders them ideal for telecommunications equipment. Examples include high-speed data communication systems and microwave transmission equipment, which rely on the seamless handling of multiple signal channels without interference.

These examples demonstrate how silver slip rings have come to dominate across diverse industries, aided by their enhanced properties and consequential benefits. While each application poses its distinct set of challenges, the attributes of silver—including its superior electrical performance, strength, and resistance to environmental wear—have proved invaluable, making silver slip rings a natural choice for an extensive array of applications.

Silver Slip Rings User Concerns and How to Address Them

When selecting silver slip rings, users may have various concerns regarding quality, cost, durability, maintenance, and repair. Addressing these concerns upfront is paramount to assure users of the suitability and practicality of their investment in silver slip rings.

- Quality: To guarantee superior performance and longevity, users need the assurance that the silver slip rings are manufactured to high-quality standards. To address this concern, it’s crucial to opt for well-established and reputable manufacturers, backed by accreditations and certifications that validate their adherence to industry benchmarks. Seeking testimonials or reviews from other users can further help in eliminating quality-related doubts.

- Cost: The initial investment in silver slip rings might appear more substantial than that of other materials, raising concerns about the cost-efficiency of the purchase. However, it’s essential to consider the long-term benefits that silver slip rings offer, such as reduced signal loss, minimal wear and tear, and extended service life, contributing to lower maintenance and replacement costs. In applications where performance and longevity are critical, silver slip rings justify the premium investment.

- Durability: Durability is crucial for slip rings, especially in demanding operating environments and under high-frequency rotations. Silver slip rings are inherently more durable due to their malleability and flexibility to withstand mechanical stress. Ensuring that the slip rings comply with industry-specific standards or utilizing custom designs tailored to unique environments can further bolster their endurance against wear and tear.

- Maintenance: While regular maintenance checks are essential for the optimal performance of any slip ring system, silver slip rings have a natural advantage due to their corrosion resistance and minimal wear. Consequently, they demand comparatively less frequent maintenance, translating to reduced downtimes and cost savings. By following recommended maintenance schedules and guidelines provided by manufacturers, users can ensure the upkeep of their silver slip rings even more efficiently.

- Repair: Although silver slip rings are robust and durable, repair or replacement may occasionally be necessary. To address this concern, users should collaborate with manufacturers or distributors that provide reliable after-sales support, including repair services or replacement parts. Comprehensive warranty coverage can further alleviate concerns around potential repair expenses while ensuring a prompt resolution in case of malfunction or damage.

In summary, the concerns of silver slip ring users are valid, but by adopting a proactive approach and seeking quality products and services, they can rely on these advantages to deliver heightened performance and longevity. The long-term benefits of silver slip rings, vis-à-vis operational efficiencies, service life, and reduced maintenance, make them an optimal choice for numerous industrial applications that demand the utmost in reliability and performance.

Guidance for Purchasing and Maintaining Silver Slip Rings

Identifying high-quality silver slip rings and maintaining them accurately are two fundamental aspects that users need to navigate effortlessly to leverage the potential of silver slip rings. Here, we provide some practical suggestions to guide users in purchasing and maintaining their silver slip rings.

Choosing Silver Slip Rings

- Research manufacturers and suppliers: Start with thorough research on potential suppliers and manufacturers. Opt for those with a solid industry reputation, well-established clientele, and industry-acclaimed certifications.

- Review product specifications: Examine the detailed product specifications to ensure they meet your application requirements. Look out for key features such as high electrical conductivity, superior thermal management, and corrosion resistance.

- Quality assurance: Ensure the slip rings have undergone rigorous quality testing and comply with industry standards. High-quality silver slip rings typically tout this information prominently.

- Consider customization: Depending on your application, you might require slip rings with specific configurations or features. Many reputable manufacturers offer customization services to meet these bespoke requirements.

- After-sales services and warranty: Assess the after-sales support, including warranty policies, repair, and replacement services. It helps ensure that your investment is protected and any future repair needs are addressed.

Maintaining Silver Slip Rings

- Adhere to manufacturer guidelines: Following the maintenance guidelines provided by the manufacturer is the first step towards prolonging the lifespan of your silver slip rings. This could involve visual inspections, cleaning procedures, or periodic testing.

- Schedule regular checks: Schedule routine maintenance checks to detect early signs of wear and tear or any operational inefficiencies. This proactive approach can prevent potential downtime or costly repairs.

- Provide proper training: Ensure that professionals handling the slip rings are adequately trained in their upkeep and troubleshooting. Proper knowledge can prevent mishandling that might lead to premature damage to the slip rings.

- Opt for professional maintenance services: Consider professional maintenance services from the supplier or third-party specialists, especially for more complex applications or setups. These experts are often better equipped to identify potential issues and suggest timely solutions.

By following these guidelines, users can select high-quality silver slip rings that best align with their needs, and effectively maintain them, thereby optimizing their performance and extending their lifespan. Proper purchasing decisions coupled with diligent maintenance practices can significantly enhance the return on investment, making silver slip rings a valuable asset in a variety of applications.

Silver Slip Rings Future Trends and Predictions

The realm of silver slip rings is dynamic, constantly shaped by technological advancements and the emergence of new applications. While silver slip rings have already established an indelible mark across various industries, the future presents exciting prospects in terms of novel technologies and applications.

Advancements in Silver Slip Ring Technology

- Smart connectivity: In line with the Industry 4.0 revolution, we may see silver slip rings incorporate smart features such as IoT (Internet of Things) integration that enables remote monitoring and in-depth operational analysis. These advancements could lead to predictive maintenance capabilities, reducing downtime and improving overall system efficiency.

- Miniaturization: As industries trend towards compact and streamlined products, silver slip rings are likely to follow suit. Future advancements may include the development of smaller, more efficient slip rings that can deliver the same high electrical performance in a significantly reduced package.

- Enhanced durability: Ongoing research and development efforts aimed at further enhancing the durability and resistance features of silver slip rings. This could involve advanced coating technologies or innovative manufacturing techniques to augment their suitability in extreme operating conditions.

- Sustainable manufacturing: With a global emphasis on sustainability, we can predict more environmentally friendly production methods in the fabrication of silver slip rings – methods that will minimize environmental impact without compromising the product’s performance and durability.

Potential New Applications and Innovations

- Renewable energy systems: Silver slip rings could find extensive usage in renewable energy systems like solar panels and offshore wind turbines. Their superior conductivity and durability would ensure optimal power transmission and withstand harsh environmental conditions, respectively.

- Autonomous vehicles and drones: The rise of autonomous vehicles and drooffersffer potential new applications for silver slip rings. Their high-quality signal transmission capabilities could play an integral role in the reliable operation of these vehicles’ sensors and communication systems.

- Advanced healthcare devices: With continuous advancements in medical technologies, silver slip rings could find innovative uses in state-of-the-art healthcare devices such as robotic-assisted surgical systems or next-generation imaging platforms where precision and dependability are paramount.

- Space applications: As space exploration sees renewed vigor, demand for durable and efficient silver slip rings in spacecraft communication systems, scientific instruments, and satellite antennas can be expected to surge.

In a nutshell, the future of silver slip rings looks promising, underpinned by advancements in technology and the discovery of new applications. Given their intrinsic benefits and adaptability, silver slip rings will continue to remain crucial components in myriad sectors shaping our present and future.

Conclusion

Embracing silver slip rings corresponds to choosing superior performance, reliability, and versatility. While understanding the associated costs and care needs is essential, the promising future of silver slip rings makes them a compelling consideration for a multitude of applications.