Unpack the world of slip ring applications in cranes, from their basic functionality to the nuances of selection, installation, maintenance, and beyond. This article will guide you through a detailed exploration of the vital role of slip rings in cranes, addressing the most frequently asked questions and reflecting on anticipated future trends.

Introduction Slip Ring Application in Cranes

In the world of heavy machinery and construction, cranes hold a special place as indispensable equipment for moving heavy loads and facilitating complex tasks. One crucial component that contributes significantly to their seamless functioning is the slip ring. This simple yet innovative device has redefined crane operations, ensuring they perform at their peak potential. Therefore, understanding the concept and importance of slip rings in cranes can benefit both industry professionals and casual observers.

By addressing the fundamental challenges of power transmission and signal communication between the stationary and the rotating parts of cranes, slip rings have become essential elements in their modern design. Overcoming the limitations of traditional systems prone to tangled cables and downtime, the incorporation of slip rings has led to more efficient, reliable, and precision-oriented processes in crane operations.

As slip rings are heavily relied upon in various crane projects, this introduction discusses their importance, applications, and the overall impact they have on the proper functioning of cranes. From basic concepts to detailed explanations, we begin our journey to better comprehend the role slip rings play in the everyday operations of cranes and their lasting contribution to the industry.

By providing the necessary context and delving into the intricacies of slip ring applications in cranes, we invite you to explore the world of slip rings, arming you with the knowledge required to better understand their significance in crane technology and the considerations that guide their proper usage and maintenance.

Understanding the Basics of a Slip Ring

To begin our exploration of slip rings in cranes, it’s essential to understand the basics of a slip ring itself. Often overlooked, these electromechanical devices are the cornerstone of many intricate machinery operations, including the renowned giants of construction – the cranes.

A slip ring, simply defined, is a device that allows the transmission of power and electrical signals from a stationary structure to a rotating one. Think of it as a bridge that connects two parts of a machine – one that’s fixed and another that rotates – allowing a smooth flow of electrical signals between them.

Fundamentally designed with a rotating ring and stationary brushes, a slip ring helps overcome challenges associated with traditional cable systems where rotational movements could lead to entangled or twisted wires. These devices, though compact, carry tremendous responsibility, playing a pivotal role in the operations of complex machinery.

But how exactly do slip rings work?

The functionality of a slip ring revolves around its basic structure comprising brushes and rings. As the ring rotates, usually connected to the rotational part of the machine, the stationary brushes maintain consistent contact with it, forming an electrical connection. This connection enables the transfer of power or signal from the stationary structure (attached to the brushes) to the rotating structure (attached to the ring) and vice versa.

Through this simple yet effective mechanism, slip rings dissolve any issues stemming from constrained mobility, allowing efficient transmission of power and signals. Understanding this fundamental concept is the basis for unraveling the more complex intricacies of slip ring applications in cranes, setting the scene for a deeper dive into this fascinating world.

The Role of Slip Rings in Cranes

Given the complexity and demands of crane mechanisms, slip rings have emerged as a pivotal component in their design. By facilitating an unobstructed transmission of electrical signals and power through the crane’s rotational and stationary parts, slip rings enhance performance while ensuring the overall durability of these giant machinery pieces.

Cranes, which often require 360-degree limitless rotation to carry out many heavy lifting tasks, could be significantly hindered without the assistance of slip rings. In the absence of these devices, the electrical transmission could face significant disruptions and inefficiencies, sometimes leading to costly downtime and potential safety hazards on-site.

Before the advent of slip rings, traditional systems ran the risk of tangled cables due to the constant rotational motion within the crane operations. These cable bundles, subjected to continuous wear and tear, were prone to failure causing operational hindrances and warranted frequent replacements. The compatibility of these prior systems with high-frequency signals was another core issue, ultimately restricting their effective application.

Enter the slip ring – a solution that addresses these pain points with elegance and efficiency. With their ability to provide an uninterrupted flow of power and signals amidst rotational movements, slip rings have significantly eliminated the risk of cable entanglement, enhancing the lifespan of the overall system.

Additionally, slip rings offered an impressive solution to the signal frequency challenge. Their structure and function allow for a wider range of signal compatibilities, thereby facilitating the transmission of various data types required in contemporary crane operations.

Thus, slip rings stand critical in overcoming the limitations of traditional crane systems. By aiding smooth and efficient operational processes, these devices promote reliable and optimized crane functionality, making them indispensable components in modern crane machinery. Thus, a deeper understanding of the roles they play and their mechanism is crucial for anyone engaged with crane mechanisms and operations.

Types of Slip Rings Used in Cranes

The wide spectrum of crane applications demands an equally diverse array of slip rings. Each type brings something different to the table, addressing unique needs arising from specific crane types and applications. As you traverse deeper into the world of slip rings, you will encounter an eclectic mix, including capsule slip rings, through-bore slip rings, and pancake slip rings, among others.

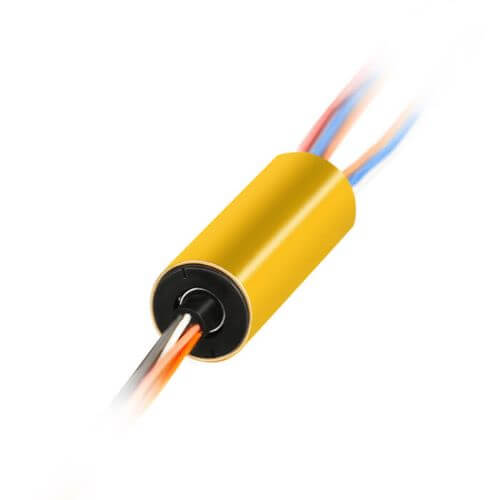

Capsule Slip Rings

Small yet extremely efficient, capsule slip rings are often the preferred choice for cranes requiring compact solutions. These slip rings – known for their flexibility and adaptability – house conductive circuits in a precise, compact form. They are predominantly used in applications where space becomes a crucial factor.

Through-Bore Slip Rings

Distinguished by their central hole, through-bore slip rings offer ingenious solutions where there is a need for a rotational axis to pass through the slip ring. They are notably used in tower cranes and other heavy-duty lifting equipment, allowing for the smooth operation of such high-capacity machinery.

Pancake Slip Rings

These get their name from their flat, disc-like structure, differing significantly from the cylindrical shape of other slip rings. Their unique design makes them an ideal fit for environments with spatial challenges in the vertical direction but ample space in the horizontal direction.

These are just a few types among the array of available slip rings, each with its unique features, advantages, and areas of application within crane operations.

The choice of a specific slip ring is governed by various factors including but not limited to spatial constraints, load requirement, rotation speed, and electrical current transmission needs. For instance, a capsule slip ring might be the go-to for a smaller jib crane, whereas a through-bore slip ring may suit a tower crane better, given its heavy-duty application.

Understanding this diverse landscape of slip rings and accurately matching their specifications to the specific demands of crane operations is vital for achieving optimal performance and efficiency. As we continue our exploration, our comprehension of how these devices impact and improve crane functionality becomes increasingly apparent.

Key Considerations in Choosing the Right Slip Ring for Your Crane

Selecting the right slip ring for a crane is a process of careful deliberation and consideration. Given the pivotal role slip rings play in crane operations, the apt selection can mean the difference between optimal performance and operational hitches.

One key factor to consider is the operating conditions of the crane. For instance, a slip ring to be used in an outdoor crane exposed to harsh weather conditions requires higher durability and protection levels compared to those used within controlled indoor environments. Therefore, considering weather-proof or sealed slip rings for outdoor operations may be imperative.

Load capacity is another major determinant. The power requirements of lifting heavy loads could necessitate the selection of robust, high-current capable slip rings. Similarly, speed and rotation also influence the choice. Cranes requiring high-speed rotation or 360-degree limitless rotation might find slip rings specifically designed for high-speed performance and continuous rotation more suitable.

Beyond these technical considerations, the choice of the manufacturer plays an integral role. The reputation of the manufacturer and the quality of its products directly impact the longevity, efficiency, and reliability of the slip ring. It is always preferable to opt for manufacturers with established credibility, proven product quality, and a history of meeting or exceeding industry standards.

An equally important consideration is after-sales service and technical support. Slip rings are dynamic components subject to wear over time. Hence, having a manufacturer that readily provides technical support for any troubleshooting or complex installations strengthens the overall process. It adds to quality assurance, prolongs the product’s service life, and ensures a smooth and efficient crane operation.

In essence, the right slip ring for your crane isn’t merely about the basic compatibility of specifications. It’s about a holistic analysis of various interdependent factors, from a crane’s operational requirements to a manufactural’s reputation, product quality, and accompanying service. Considering these aspects conscientiously assures an excellent choice, optimizing crane operations for maximum impact.

Installation and Maintenance of Slip Rings in Cranes

The success of a slip ring’s implementation is only as effective as its installation and maintenance – two critical aspects that directly influence its performance and longevity. Therefore, understanding the core tenets of these processes is instrumental.

Installation Process

The installment of a slip ring begins with selecting the appropriate spot within the crane’s structure so it can efficiently serve its function. This spot must accommodate the rotation requirements and allow the seamless transfer of electrical power or signals.

Before initiating the installation, it’s crucial to scrutinize the slip ring and the installation site for any potential damage or dirt. Next, using the appropriate mounting fixtures, the slip ring is fixed securely onto the machinery. It’s vital to follow the manufacturer’s instructions during this process to avoid disorientation or damage.

Once the slip ring is in place, it’s then connected to the machine’s stationary structure and the rotating part by attaching the designated wires and ensuring firm contact. This entire process should be carried out carefully to prevent unnecessary pressure or forced assembly that could damage the slip ring.

Maintenance Routines and Best Practices

Proactive and regular maintenance has proven to be the best strategy for prolonging the service life of slip rings. Over time, due to continuous contact and rotation, wear and tear is bound to occur. By following a routine maintenance plan, this risk can be mitigated to a great extent.

Maintenance of slip rings primarily involves regular inspections for signs of wear or damage, ensuring cleanliness to avoid dust or debris accumulation, and checking the secure fixing of the slip ring.

For slip rings with brushes, an additional aspect of maintenance is the periodic replacement of brushes since they are prone to wear faster than other parts. However, the replacement cycle varies based on the type of the slip ring and application, and the manufacturer’s recommendation should be followed.

One of the best practices to follow is to maintain a comprehensive maintenance log. This can assist in tracking the performance of the slip ring over time and more accurately predicting when replacements or repairs may be required.

Both the processes of installation and maintenance, when performed with due diligence and as per recommendations, ensure the efficient performance and longevity of slip rings, contributing to the seamless operation of crane machinery.

Innovations and Future Trends in Slip Rings for Cranes

The landscape of slip rings for cranes is continually evolving, shaped by new technological advancements, changing market demands, and innovative applications. Looking ahead, several innovations and trends stand to significantly impact this field.

Nanotechnology

Nanotechnology, the manipulation of matter at the atomic and molecular level, could dramatically change slip ring design and performance. With its ability to enhance robustness and minimize friction, nanotechnology can contribute to greater functionality and operational life of slip rings in cranes. Reduced wear and tear would translate to fewer maintenance requirements, potentially revolutionizing this crucial component’s cost-effectiveness and efficiency.

Wireless Power Transmission

Another anticipated advancement is wireless power transmission. Embracing such cutting-edge technology could eliminate the need for physical contact between the stationary and rotating parts. This elimination of contact reduces the risk of wear and tear, leading to enhanced durability and ensuring smoother, uninterrupted operations.

Sensor Technology and AI-Based Predictive Analysis

The incorporation of sensor technology combined with advanced AI-based predictive analysis models ushers in an era of smart slip rings. These systems can monitor and analyze the performance and health of the slip ring in real time, predicting potential failures before they occur. This proactivity can significantly enhance the operational efficiency of the crane, mitigating downtime due to unexpected issues.

Advanced Material usage

Lastly, the exploration and use of advanced materials in slip ring production, such as novel conductive materials or high-grade plastics, can increase their lifespan, capacity, and overall utility. These advancements promise to enhance the slip ring’s resilience to harsh operating conditions and heavy-duty applications, making it an excellent fit for cranes and similar machinery.

In summary, the future for slip rings in crane technology seems poised for profound and exciting transformation. The vertical will witness momentous changes enabled by advancements in nanotechnology, wireless power transmission, AI, sensor technology, and novel material use. As we move forward, embracing these trends will be integral to maximizing slip rings’ potential and paving the way for more efficient, reliable, and futuristic crane operations.

Conclusion

Understanding the application of slip rings in cranes is both essential and beneficial. This exploration not only equips you with the necessary knowledge but also paves the way for more informed, efficient, and innovative operations. The horizon of slip rings in cranes emerges as promising and exciting, promising unprecedented advancements in the field.

FAQs about Slip Ring Application in Cranes

The world of slip rings for cranes can be a complex landscape to navigate, with numerous factors and considerations to account for. Compiled below are some frequently asked questions and their respective answers, intended to facilitate a deeper understanding of slip ring applications in cranes.

Q: What are the main functions of a slip ring in cranes?

A: Slip rings in cranes are primarily responsible for transmitting electrical power and control signals between the stationary and rotating parts of the crane machinery. They ensure the crane operates smoothly, providing continuous transmission of power and signals without interruption while the crane is in motion.

Q: How do I choose the right slip ring for my crane?

A: The selection of an appropriate slip ring depends on several factors, including the crane’s operating conditions, load capacity, rotation speed, electrical current transmission needs, and space constraints. Beyond these considerations, it’s crucial to choose a reliable manufacturer known for producing high-quality products and offering after-sales support and technical assistance.

Q: Are there different types of slip rings? How do I know which best suits my crane?

A: Yes, there are a variety of slip ring types, each designed to suit specific operational needs or address unique challenges. Some common types include capsule slip rings, through-bore slip rings, and pancake slip rings. The best match for your crane hinges on its specific requirements, which may vary based on its operation, load capacity, and rotation flexibility needs. Consulting with a slip ring provider or a technical expert can guide you in determining the optimal choice.

Q: How does one ensure slip rings’ proper installation and maintenance in cranes?

A: Proper installation involves positioning the slip ring in an appropriate spot within the crane’s structure, ensuring it is securely connected to the stationary and rotating parts. Always follow the manufacturer’s instructions during installation. In terms of maintenance, it’s essential to follow a regular inspection schedule, replace brushes (where applicable), maintain cleanliness, and ensure secure fixing, ultimately prolonging the slip ring’s service life and enhancing efficiency.

Q: How will new technology shape the future of slip rings in cranes?

A: Emerging technologies such as nanotechnology, wireless power transmission, sensor technology, AI-based predictive analysis, and advanced materials promise significant changes in the slip ring landscape. This evolution will translate to more efficient, durable, and cost-effective slip ring designs, and usher in a new era of crane operations with enhanced performance and minimal downtime.

See What We Can Do