This article examines the essential role of slip rings in laser-cutting technology. It explores the technical aspects, advantages, types, maintenance requirements, and typical user concerns, and offers insights into real-world applications, all aimed at enhancing your understanding of the integral part these components play.

Introduction to Laser Cutting and the Role of Slip Rings

Laser cutting stands as a technological titan in today’s manufacturing sector, carving out an indispensable niche. This precision-driven process harnesses the power of amplified light to slice through materials ranging from delicate fabrics to robust metals with unparalleled accuracy and speed. The technology’s importance is manifest in its widespread adoption across diverse industries including automotive, aerospace, electronics, and medical devices. It has played a pivotal role in propelling mass production towards a future of finesse and customization, where the only limit to cutting intricate patterns and complex shapes is the imagination of designers.

In the realm of such advanced machinery, slip rings serve as unsung heroes, facilitating the seamless flow of power and information within the rotating parts of laser cutting systems. Imagine the rotating arm of a laser cutter: as it pivots to perform cuts from various angles, traditional wiring would quickly become entangled, leading to potential damage and system failure. Slip rings effectively mitigate this risk by ensuring an uninterrupted electrical connection, delivering power and data signals to the rotating laser head, without the constraints imposed by fixed cabling.

A slip ring assembly typically comprises a stationary graphite or metal brush that rubs on the outside diameter of a rotating metal ring. As the laser cutting head moves, electrical currents and data signals transmit through this brush-ring interface to power the head and control the laser’s movements with surgical precision. This facilitates real-time control of the cutting process, supports data transfer for monitoring purposes, and powers auxiliary components, all vital for the cutter’s operation.

The nuanced role of slip rings transcends mere power transmission; it is about sustaining the lifeline of laser cutting systems – maintaining the flow of electrons and data that choreograph each cut. Their existence within these systems is a testament to human ingenuity in overcoming the physical challenges posed by complex machinery operations. Without slip rings, the dynamism and flexibility of modern laser cutters—required to meet the exacting standards of contemporary manufacturing—would be greatly diminished.

In essence, slip rings bring to laser cutting technologies the dexterity of a conductor’s baton, ensuring that the symphony of manufacturing precision plays on, uninterrupted. It is their silent operation behind the scenes that upholds the reliability and efficiency of these cutting-edge machines, contributing significantly to the technological evolution of manufacturing practices.

Understanding Slip Rings in Laser Cutting Machines

In deciphering the crucial role of slip rings within laser cutting machines, it is first necessary to locate them physically within these complex systems. Slip rings are often found embedded within the rotating joints of the machinery, specifically, where the cutting head assembly intersects with the stationary body of the machine. This location is strategic, and designed to enable seamless communication between the machine’s revolving and non-revolving parts.

At its core, the role of a slip ring in a laser cutter is as a conduit for power and data. Picture a bustling city, with a myriad of cars, buses, and trains all moving in unison, directed by a network of traffic lights. These traffic lights play a pivotal role in maintaining the city’s harmony, ensuring safe and efficient travel for all. Slip rings play a similar role within the confines of a laser cutting machine – they are the traffic controllers of electrical power and data signals.

When the laser cutting machine operates, its cutting head pivots, swivels, and rotates to perform precise cutting actions. As it moves, the slip ring, secured at the pivotal intersection, maintains an uninterrupted electrical connection between the stationary power source and the moving components. The slip ring strategically manages the traffic of electrical power, ensuring it reaches the cutting head without causing a disruption. This process allows for consistent, controlled operation of the laser cutter’s components regardless of their motion relative to the stationary power supply.

Simultaneously, the slip ring assumes the responsibility of a data courier, mediating the flow of control signals and sensory feedback. It channels data commands from the laser cutter’s stationary control systems to the moving cutting head, ensuring the laser accurately follows predetermined cutting paths. Meanwhile, it relays sensor data back to the control system, offering crucial feedback about the cutting process in real-time. This continuous two-way data transmission empowers laser cutters with the precise control they are known for, enabling them to produce intricate designs with surgical precision.

In summary, slip rings function as the critical lifeline within laser cutting machines, ensuring the smooth traffic flow of power supply and data transmission. This silent yet diligent service allows laser cutters to function with remarkable flexibility and precision, making them an asset that is crucial to modern manufacturing versatility. Without them, the dynamic ballet of laser-cutting operations across multiple industries would come to a standstill.

Key Advantages of Using Slip Rings in Laser Cutting

The incorporation of slip rings in laser-cutting machines offers a myriad of operational benefits that elevate the capabilities of these sophisticated apparatuses to new heights. At the helm of these advantages is the enhanced flexibility that slip rings offer. When laser cutters are equipped with slip rings, they gain the remarkable ability to execute an extensive array of cutting patterns and shapes seamlessly. This flexibility is not confined to simple two-dimensional designs. With slip rings playing their part, laser cutting machines can venture into the realm of three-dimensional cutting tasks with ease, performing intricate cuts and elaborate engravings that were once thought to be outside the scope of automated production processes.

Slip rings empower laser cutters to rotate their cutting heads through multiple axes, maintaining power supply and signal transmission flawlessly during these maneuvers. This ability to pivot without restraint enables continuous operation—machines can run for longer periods without the need for intermissions to adjust or untangle wires. Such uninterrupted operation is critical in industries where high-volume production is essential, as it directly translates to increased productivity and operational efficiency.

A further advantage of slip rings lies in their role in minimizing wear and tear within the mechanisms of the machines they serve. Rotating joints in any mechanical system are points of vulnerability, subject to the stress of motion, and in a laser cutter, this motion is often rapid and repeated. In traditional setups without slip rings, cables responsible for power and data transmission are prone to twisting and flexing, leading to mechanical strain, insulation failure, or even outright breaks. The incorporation of slip rings negates this strain by eliminating the need for fixed wiring at pivoting points, thus reducing the possibility of cable tangling and subsequent wear. This conservation of the machine’s integrity extends its lifespan, reduces downtime due to equipment failure, and saves on maintenance and repair costs.

In essence, slip rings bring about a revolution in the functionality of laser cutting machines, transforming them into more robust, enduring, and highly versatile tools. They cast aside the limitations imposed by conventional cabling, granting machines the freedom to perform their tasks with greater agility and reliability. This unshackling of movement is not simply a mechanical improvement but a leap forward in production capabilities, enabling the manufacturing industry to meet the exacting demands of modern commerce with confidence.

Types of Slip Rings Used in Laser Cutting Applications

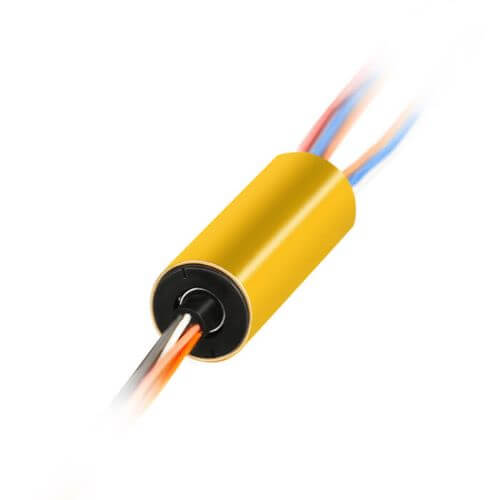

Much like our personal choices depend on the context, finding the most appropriate type of slip ring for a specific laser cutting application hinges on machine design and operational requirements. There are primarily two types of slip rings commonly used in laser cutting machines: capsule slip rings and through-bore slip rings. Each category possesses unique characteristics that make it suitable for different scenarios, and understanding these differences can facilitate an informed selection.

Capsule slip rings, often smaller in size, are enclosed within a protective housing. This design is particularly suitable for compact laser cutting applications where space is at a premium and potential exposure to harsh operational conditions might impact the slip ring’s performance. Due to their smaller footprint and shielding, capsule slip rings ensure uninterrupted signal transmission and electrical continuity even in limited space and harsh manufacturing environments.

Contrastingly, through-bore slip rings feature a central hole that offers unique advantages. This opening allows room for the passage of shafts, pneumatics, or other machinery essentials. They are primarily employed in laser cutting systems with a large central rotating shaft or where multiple devices must pass through the center of the slip ring, maximizing the use of space while also transferring power and data.

The decision to use one type over the other primarily depends on the machine design—its available space, structural configuration, and operational parameters. Nevertheless, the choice isn’t constrained to only these two categories. The beauty of slip ring technology lies in its versatility and the possibility of customization to cater to specific laser-cutting requirements.

Customization options extend to material compatibility, size constraints, number of circuits, and even the type of transmitted signals. Whether adapting to high-temperature environments with heat-resistant materials or adjusting to compact spaces with reduced-size designs, tailored slip rings can provide the perfect fit. This adaptability makes them exceptionally versatile components, capable of fulfilling a wide range of specifications demanded by cutting-edge laser-cutting machines.

Therefore, selecting the right slip ring for laser cutting applications is about gauging the machine’s needs and picking or designing a slip ring that fits those requirements like a glove. By contributing to the machine’s utmost efficiency and optimal functionality, the correct slip ring type becomes an innovation enabler, helping laser-cutting technology achieve its maximum potential.

Slip Ring Application in Laser Cutting: Technical Specifications and Performance Metrics

The application of slip rings in laser-cutting machines leaves an indelible mark on their operational efficiency and precision. As such, understanding the technical specifications and performance metrics relevant to these applications is pivotal.

Electrical and Mechanical Specifications

The electrical specifications of slip rings are crucial determinants of their performance within a laser cutter. These include aspects such as the number of circuits (which correspond to the number of independent electrical connections a slip ring can facilitate), the current rating (the maximum current that each circuit can safely handle), and the dielectric strength (the ability of a slip ring to resist electric breakdown). Another crucial electrical specification is signal performance, which heavily influences the precision of the transmitted data signals.

Mechanical specifications, on the other hand, focus on attributes related to the physical construction and operation of the slip ring. This includes aspects such as construction materials (which affect the ring’s durability and reliability), operating speed (the maximum allowable rotational speed), size dimensions (relevant for space-constrained applications), and whether the slip ring is a capsule or through-bore type.

Understanding the electrical and mechanical specifications is essential to identify the best-suited slip ring for a particular laser cutting application. These specifications determine how well a slip ring can fit within the machine’s design and perform by the operational demands.

Performance Metrics

When evaluating the performance of a slip ring within a laser-cutting scenario, there are specific metrics that bear significant importance. Durability, reliability, and precision stand out as vital parameters to measure.

Durability pertains to the slip ring’s ability to withstand the rigors of operation within a laser cutter, essentially its lifespan under normal operating conditions. High durability is often achieved by incorporating robust, wear-resistant materials and designs that minimize wear and tear.

Reliability centers around the consistency in the performance of the slip ring. A reliable slip ring maintains steady power delivery and consistent data transmission, ensuring the smooth functioning of the laser cutter despite variations in operational or environmental conditions.

Precision, the third key metric, is of paramount importance in laser-cutting applications. The precision of a slip ring directly influences the precision of the cutter, affecting its ability to make intricate cuts following complex design paths.

In essence, to optimize the use of slip rings in laser cutting, it is necessary to delve deep into the realm of electrical and mechanical specifications, aligning them with the unique requirements of the application. Concurrently, by closely monitoring performance metrics like durability, reliability, and precision, the compatibility and longevity of the chosen slip ring in the laser cutting application can be assured.

Maintenance Requirements for Slip Rings in Laser Cutters

To ensure the smooth functioning and optimal performance of a laser cutting machine, it’s essential to pay close attention to the maintenance requirements of its components. Slip rings are no exception, and adopting regular maintenance practices directly impacts their longevity and effectiveness within the laser cutter. This section delves into some common maintenance practices, troubleshooting techniques, and their relevance in ensuring a well-functioning slip ring.

Common Maintenance Practices

Regular maintenance procedures are necessary to ensure the slip rings perform seamlessly over their service life. Following are some common practices:

- Cleaning: Accumulation of dust, debris, or foreign material on the slip rings can lead to poor electrical contact, increased wear, or even short circuits. Periodic cleaning of slip ring surfaces and brush contacts helps avoid these issues, maintaining uninterrupted power and data transmission.

- Lubrication: Many slip rings require adequate lubrication to minimize friction, wear, and noise during operation. Regular inspection and reapplication of the appropriate lubricant help preserve the smooth functioning and longevity of the slip rings.

- Inspection for Wear: Since slip rings are used in conjunction with brushes, the friction between the pairing can cause gradual wear. Regular evaluation of slip ring surfaces and brushes for wear or damage is essential to maintain performance. Any excessively worn parts should be replaced.

- Check for Proper Brush Contact Pressure: Consistent brush pressure against the slip ring surface is crucial for good electrical contact. Inspecting brush contact pressure and making any necessary adjustments will optimize power transmission.

- Electrical Continuity and Insulation Test: Periodic continuity checks and insulation tests can detect minor issues like poor connections, erratic performances, or possible short circuits before they escalate into severe damage.

Troubleshooting Common Issues

Some common issues associated with slip rings in laser-cutting machinery include:

- Intermittent Signal or Power Loss: This issue may arise from debris accumulation, inadequate brush contact pressure, or worn brushes. Regular cleaning, pressure checks, and brush replacements can rectify these problems.

- Fluctuating Signals or Noise: Poor electrical connections, misaligned brushes, or signal interference can result in inconsistent signal transmission. Ensuring proper alignment of brushes, securing tight connections, and adding shielding to attenuate signal noise can help.

- Overheating: Excessive friction or high current loads could lead to slip ring overheating. Frequent lubrication, verifying current ratings, and distributing high loads across multiple circuits can address this issue.

In conclusion, adhering to regular maintenance practices and troubleshooting common slip ring issues optimizes their performance and extends their service life within laser cutters. Keeping the slip rings in excellent condition is crucial to extract the best performance from the laser cutting machines and maintain operational efficiency and productivity.

Slip Ring Application in Laser Cutting: User Concerns and Considerations

In laser cutting operations, users have certain concerns and considerations when it comes to the application of slip rings in their machinery. These concerns, largely revolving around safety and reliability, as well as efficiency and productivity, significantly influence their choices of specific features, maintenance routines, and troubleshooting practices.

Safety and Reliability Concerns

In any industrial setting, safety is of paramount importance, and laser cutting is no exception. Hence, ensuring that neither slip ring failure nor maintenance procedures compromise safety protocols is an essential consideration for users.

Slip ring failures—due to excessive wear, poor maintenance, or simply age—can lead to unpredictable and hazardous situations, such as sparking, overheating, or total loss of power or signal transmission. These risks could jeopardize both operator safety and material integrity. Users, therefore, must rely on slip rings that are engineered for durability and reliability and meticulously maintained to prevent such potentially harmful scenarios.

Routine maintenance, while essential, must also be carried out in a way that does not compromise safety. Basic safety practices—like disconnecting power before cleaning or maintenance, or inspecting the machine for signs of wear or damage—should be part of every maintenance protocol. Furthermore, slip rings with user-friendly features that facilitate simple and safe maintenance (like easy access design, non-required lubrication, etc.) are highly favored by users.

Efficiency and Productivity Impact

The choice of slip ring can also impact the overall performance of a laser cutter. A well-suited slip ring ensures smooth power and signal transmission, thereby influencing the cutter’s precision and efficiency. Users must consider slip ring specifications—like current-carrying capacity, signal integrity, and resistance to environmental conditions—that align with their specific application’s demands to ensure optimal machine performance.

The downtime associated with slip ring maintenance or failure is another significant concern as it directly affects productivity. Regular maintenance, while necessary, should be as efficient as possible to reduce machine downtime. Consequently, slip rings designed for easy maintenance—like those with removable brushes or a modular design—can ensure quick and straightforward servicing, effectively reducing idle time.

Furthermore, the reliability of the slip ring is essential to minimize the risk of unexpected failures leading to machine downtime and impacting productivity. Hence, users must invest in high-quality, reliable slip rings and follow a preventative maintenance schedule to detect and rectify potential issues before a complete breakdown occurs.

In conclusion, safety and reliability, coupled with efficiency and downtime minimization, are significant concerns and considerations for users when it comes to utilizing slip rings in laser-cutting applications. By addressing these concerns, users can achieve seamless, safe, and efficient laser-cutting operations.

Slip Ring Application in Laser Cutting: Case Studies and Real-World Applications

The application of slip rings in laser cutting operations is widespread and varied. Due to the diversity of the laser cutting spectrum, the use cases succeeded in enhancing operational efficiency and improving cutting precision, marking significant advancements in the industry. This section provides examples of such successful applications and insights from industry experts and users to illustrate real-world implications.

Examples of Successful Slip Ring Applications

- High-Precision Laser Cutting: In a facility specializing in high-precision laser cutting for microelectronics, the application of a high-frequency slip ring significantly enhanced operation. The slip ring was capable of transmitting the necessary power and data signals with minimal electrical noise and resistance variation. Consequently, the precision of the laser cuts greatly improved, and the quality of the microelectronics components skyrocketed.

- Robotic Laser Cutting: A prominent car manufacturer integrated slip rings into its robotic laser cutting assembly line. The high current capacity and reliable signal transmission of the slip rings allowed the robotic arms to undertake complex cutting patterns without interruption. This resulted in reduced production times and increased overall efficiency.

Insights from Industry Experts and User Testimonials

- Insight from Industry Expert: A renowned industry expert in laser technology cited the instrumental role of slip rings in precision laser cutting. He emphasized that robust, high-performing slip rings ensure smooth and reliable data transmission, which is crucial for intricate laser-cutting tasks. Without their contributions, maintaining precision and reliability in demanding laser-cutting applications would be challenging.

- User Testimonial: A user managing an aerospace components production facility shared their experience after upgrading to a custom-engineered slip ring. They reported a marked improvement in their laser cutter’s ability to handle complex geometries and the overall throughput of their operations. The user was particularly pleased with the durability and maintenance ease of the slip ring, reducing downtime and further improving productivity.

In conclusion, the successful application of slip rings in laser cutting operations reveals the significant influence they have on operational efficiency and cutting precision. Through industry expert insights and user testimonials, it’s clear that the thoughtful incorporation of well-suited slip rings delivers practical benefits in diverse real-world applications.

Conclusion

The selection of the right slip ring is paramount for optimal laser-cutting applications. As advancements in slip ring technology continue to emerge, they hold the potential to further enhance the versatility and performance of laser cutting machines.

FAQs about Slip Ring Application in Laser Cutting

Q1: What is a slip ring, and why is it important in laser cutting applications?

A: A slip ring is an electromechanical device that enables the transmission of electrical signals or power between a stationary and a rotating part. In laser cutting applications, slip rings are crucial for supplying power or transmitting control signals to moving components, ensuring accurate, smooth, and efficient cutting operations.

Q2: How does a slip ring contribute to optimized laser cutting performance?

A: Slip rings contribute to optimized laser cutting performance by facilitating uninterrupted power and data transmission. This allows the moving components in the laser cutting machinery, like robotic arms or cutting heads, to operate seamlessly, ensuring precise and efficient cutting operations.

Q3: What factors should be considered when selecting a slip ring for laser cutting applications?

A: When selecting a slip ring for laser cutting, you should consider factors such as:

- Current-carrying capacity, both for power and data signals.

- Signal integrity and bandwidth for data transfer.

- Environmental factors, like temperature, humidity, and dust resistance.

- Required maintenance and ease of servicing.

- Safety features and fail-safe mechanisms.

- Compatibility with the specific laser cutting machinery in your application.

Q4: How often should slip rings be maintained in laser-cutting environments?

A: The frequency of slip ring maintenance depends on factors like the slip ring’s specifications, the laser cutting machinery’s usage intensity, and the working environment. However, as a general rule of thumb, regular maintenance checks—such as cleaning, lubrication, and wear inspections—should be performed every 3 to 6 months. Always consult the slip ring manufacturer’s guidelines for specific maintenance intervals and procedures.

Q5: What are the potential consequences of neglecting slip ring maintenance in laser-cutting machinery?

A: Neglecting slip ring maintenance can lead to several issues, including:

- Reduced performance due to poor electrical contact or increased wear.

- Unplanned downtime brought on by unexpected slip ring failure.

- Safety hazards like overheating, sparking, or complete power loss.

- Increased wear and tear on other components of the laser cutting machinery.

- Reduced longevity and reliability of the slip ring and the entire laser cutting system.

Regular maintenance is essential to avoid these issues and ensure optimal performance and safety of the laser-cutting machinery.

Q6: Can I use a standard slip ring in a highly demanding laser-cutting application?

A: While standard slip rings work well in many applications, they may not be ideal for highly demanding laser-cutting scenarios. In such cases, custom-engineered or specialized slip rings, designed to handle high currents, extreme environments, or precise data transmission, are often recommended. Consult slip ring manufacturers for recommendations and guidance in choosing the perfect slip ring for demanding applications.

See What We Can Do