This article dives deep into the significance of slip rings in the realms of manufacturing and machining. By outlining their applications, benefits, and considerations necessary for their selection, we aim to provide a comprehensive guide that not only addresses common challenges but also looks toward future advancements in slip ring technology.

Introduction: Slip Ring Application in Manufacturing and Machining

In the world of manufacturing and machining, one component often goes unnoticed despite its crucial role – the slip ring. The basic function of a slip ring, sometimes known as a rotary electrical joint, swivel, or rotatory electrical interface, is deceptively simple: it allows for electricity and data signals to be transferred between stationary and rotating parts.

For any machine where part or all of the structure needs to rotate – such as automated assembly lines, wind turbines, or MRI scanners – this is no small task. It’s akin to maintaining a steady conversation while solely revolving on a merry-go-round! This analogy aptly captures how slip rings function as they maintain a steady flow of power and data even while components are in full rotation.

For manufacturing and machining processes, slip rings are paramount. They close the gap between stationary controls and moving machinery, allowing for complex maneuvers and operational smoothness. Imagine a robotic arm in an assembly line, steadily placing components while getting real-time feedback from sensors, and managing multiple tasks simultaneously – none of this would be possible without the continuous power and data transmission provided by slip rings. In essence, they act as the “nervous system” of these versatile machines, making them responsive and highly adaptable.

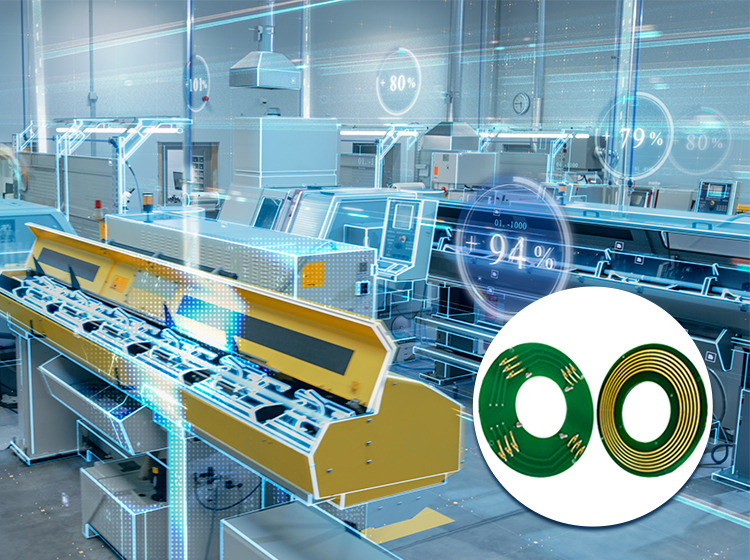

Moreover, slip rings are not just confined to motors or mechanical equipment. In data-driven manufacturing environments, they facilitate the seamless transference of sensor-based data and control signals, enabling real-time monitoring of machine and system performance and opening the doors to Industry 4.0.

Thus, while they might be a small component in the overall machinery, slip rings play an instrumental role in enabling the seamless, efficient operation of manufacturing and machining systems. Their ability to facilitate rotational motion and continuous data and power transmission is what keeps the wheels of the manufacturing sectors constantly turning.

Understanding Slip Rings in Manufacturing

In the intricate landscape of manufacturing, where precision and efficiency are paramount, slip rings emerge as critical components, bridging the gap between motion and functionality. Their basic mechanism hinges on providing a continuous electrical connection between stationary and rotating systems, allowing for an unbroken flow of power and data signals, despite the rotational motion.

At the heart of a slip ring module lie conductive rings and brushes. The rings are connected to the rotating part of the machine and turn with it, while brushes, made of a conductive material, maintain a sliding contact with the rings. As the machinery activates and the component starts its rotational journey, these brushes remain in constant touch with the rings, ensuring an uninterrupted electrical pathway. This setup allows for power to be transferred seamlessly to rotating platforms, enabling functionalities that would otherwise be impractical or impossible due to the constraints of tethered or static wiring solutions.

The versatility and utility of slip rings stretch across a broad spectrum of manufacturing and machining operations. In CNC machines, for instance, slip rings enable the transmission of control signals and power to the rotating parts of the machinery, facilitating complex cuts, engravings, and other operations with precision. This seamless integration ensures that CNC machines can operate at high speeds and with the precision required for modern manufacturing demands.

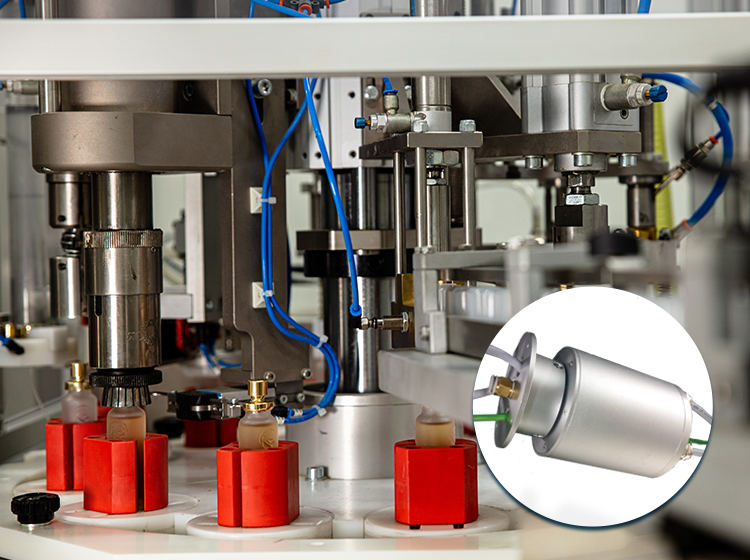

Packaging machinery represents another arena where slip rings find critical application. Many packaging processes involve rotary tables or turntables that must rotate continuously or incrementally to fill, cap, label, or perform quality inspections on products. Slip rings in these machines ensure that power and data can flow without interruption to sensors, actuators, and control systems located on rotating parts of the equipment, enhancing operational speed and efficiency.

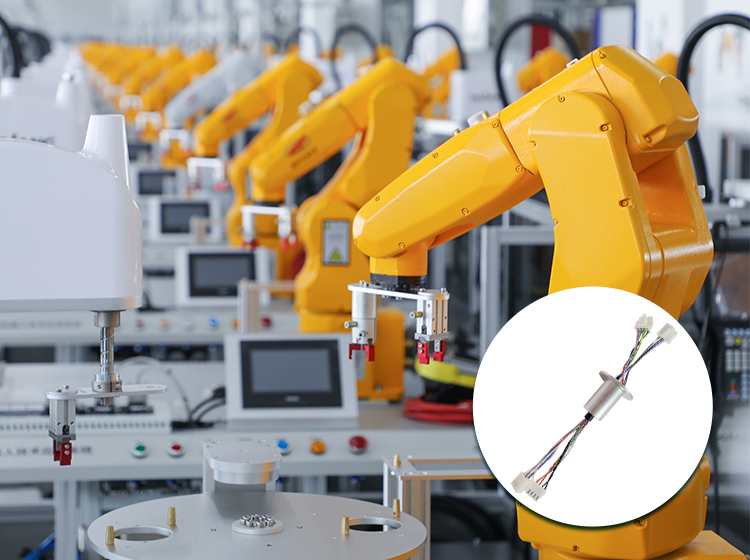

Moreover, industries that require automated assembly lines heavily rely on robotic arms equipped with slip rings. These arms must perform repetitive, precise tasks—such as assembling parts or packing products—while also being able to communicate with central control systems in real-time. By incorporating slip rings, these robotic arms maintain a constant power supply and data exchange throughout their movement, ensuring high precision and efficiency.

Similarly, automated welding equipment, especially those deployed in automotive manufacturing, leverages slip rings for the execution of complex, high-quality welds around the surfaces of rotating parts. This application not only demands the transmission of power but also requires the transfer of control signals and monitoring data to ensure the welds meet stringent quality standards.

In essence, slip rings serve as an invisible but indispensable backbone to diverse facets of the manufacturing and machining industries. By allowing for the uninterrupted flow of power and information in rotational mechanisms, slip rings ensure that operations are smooth, equipment runs efficiently, and the output meets the desired standards of quality and precision.

Key Applications in Manufacturing and Machining

In the complex ecosystem of manufacturing and machining, the refinement and advancements in mechanisms often hinge on components unseen to the casual observer. Central to this innovation is the application of slip rings, which facilitate a seamless flow of power and data across rotating interfaces in various equipment. Below, we delve into key applications within the industry that significantly benefit from slip ring technology.

CNC Machines: Precision Through Uninterrupted Connections

CNC (Computer Numerical Control) machines, pivotal in modern machining operations, demand exactitude in tool movements and operations. Slip rings play a crucial role here, acting as conduits for transmitting essential control signals and power between the machine’s stationary and moving parts. These signals ensure that the toolpaths are executed flawlessly, resulting in precise cuts, drills, and engravings necessary for a wide range of manufacturing tasks. The versatility of CNC operations, from sculpting complex components out of metal to intricate woodworking, is largely attributable to the reliability provided by slip rings in maintaining uninterrupted communication and power supply, even amidst high-speed rotational movements.

Robotic Arms: Enabling Fluid Automation on Assembly Lines

In the automation-centric environment of assembly lines, robotic arms are indispensable. Fitted with slip rings, these arms can receive continuous power and transmit data to and from sensors and actuators, all while undergoing full rotation and handling materials, components, or tools. This uninterrupted connectivity ensures that robotic arms can perform complex, repetitive tasks with high precision and reliability, significantly enhancing the efficiency of production lines. From electronics manufacturing where components are delicately placed on circuit boards to automotive assembly lines where parts are mounted and screwed in, slip rings help to achieve harmony of movement and functionality.

Packaging Machinery: Streamlining Operations Through Continuous Rotation

Packaging machinery, often characterized by its high-speed, continuous rotational movements, relies extensively on slip rings. These devices ensure that parts of the machinery, such as filling stations or labeling arms, can rotate without hindrance, maintaining an electrical connection for power and data throughout their motion. This capability is critical for synchronizing various stages of the packaging process, enabling machines to operate at peak efficiency with minimal downtime, thereby accelerating throughput and optimizing operational speed in facilities ranging from food processing to consumer goods packaging.

Automated Welding Equipment: Ensuring Consistency in Weld Operations

In the precision-driven process of welding, especially when dealing with rotating parts commonly found in automotive and aerospace manufacturing, slip rings serve a vital function. They provide a stable electrical connection necessary for the welding apparatus to function seamlessly around the circumference of parts. This consistency is key to achieving high-quality welds with the correct electrical parameters, regardless of the part’s orientation. Additionally, slip rings enable the transmission of control signals and feedback data, allowing for real-time adjustments and monitoring of the welding process, thereby upholding stringent quality standards.

In each of these applications, slip rings transcend their basic function, emerging as linchpins that enhance efficiency, precision, and reliability. By facilitating uninterrupted power and data transmission across moving interfaces, they enable the sophisticated operations necessary in today’s competitive manufacturing and machining landscapes, underscoring their indispensable role in the advancement of industrial technology.

The Impact of Slip Rings in Elevating Manufacturing Outputs

Slip rings, while humble-looking components, play an outsized role in many manufacturing and machining processes. They act as key enablers that drive operational efficiency, ensure reliability in rigorous environments, and provide the flexibility necessary to adapt to diverse machinery needs. Let’s explore each of these crucial benefits in more detail:

Enhanced Efficiency: Catalyzing Smoother Operations and Increased Outputs

The unbroken electrical pathways that slip rings create between the stationary and rotating parts of machinery are a fundamental contributor to smoother operations and increased production rates. By enabling continuous power delivery and communication, they remove the constraints imposed by static wiring, allowing components to move freely and perform their tasks without interruption. Whether it’s the high-speed rotation of a packaging machine or the delicate maneuver of a CNC tool, the presence of slip rings ensures that the necessary data and power flow are maintained, leading to fewer operational hiccups, less downtime, and subsequently higher production rates. This continuous connectivity goes hand in hand with improved efficiency, effectively empowering manufacturing facilities to meet their output targets.

Reliability and Durability: Upholding Dependability in Rigorous Environments

Often, manufacturing environments are subject to harsh conditions – high temperatures, dust, moisture, and mechanical stress are common. Thankfully, slip rings are designed to withstand these conditions, being made of robust materials and having designs that minimize wear and tear. Consequently, their reliability even in demanding scenarios reduces frequent breakdowns and maintenance needs, preventing costly production downtimes and repair expenses. Because of their robust construction, slip rings can provide consistent service over long periods, a quality that’s particularly appreciated in industries where failure can result in a significant loss of time and resources.

Flexibility: Adapting to Diverse Machining and Power Needs

Slip rings showcase versatility in their capacity to adapt to different types of machinery, as well as a wide range of data and power needs. Their designs can be customized to handle varying power requirements, from low-voltage sensor signals to high-current power feeds. In addition, slip rings can be engineered to carry a variety of data types, including digital data for control signals and analog data for sensor feedback. Whether in a minuscule assembly robot, a hefty wind turbine, or an intricate MRI machine, slip rings can be tailored to the specific requirements of almost any rotating machinery. This flexibility is critical in our increasingly complex and digitized manufacturing landscape.

In essence, slip rings significantly enhance the capabilities of manufacturing and machining facilities. By driving efficiency, assuring reliability in challenging environments, and exhibiting great flexibility, they pave the way for smoother operations and continuous innovation in the manufacturing sector.

Selection Criteria for Slip Rings in Manufacturing

The selection of slip rings is a pivotal decision in the design and operation of manufacturing equipment, impacting everything from the efficiency and reliability of machinery to its adaptability in diverse environmental conditions. As manufacturers seek to achieve higher levels of precision and output, understanding the nuances of choosing the right slip ring becomes critical. Here are key factors to consider, underscoring the tailored approach needed for optimal performance.

Key Considerations for Slip Ring Selection

Electrical Current Capacity: Essential for ensuring that the slip ring can handle the power needs of the machinery, the electrical current capacity must be matched with the operational requirements of the equipment. Overlooking this factor could lead to inefficient power transfer or, worse, potential damage to the slip ring or the machine itself.

Number of Circuits: The complexity and functionality of manufacturing machinery often necessitate the transmission of multiple signals and power streams simultaneously. Thus, the number of circuits within a slip ring becomes a crucial consideration. Selecting a slip ring with an appropriate number of circuits ensures seamless multitasking capabilities for the equipment, supporting various operations without compromise.

Environmental Tolerance: Given the harsh conditions prevalent in many manufacturing environments – including exposure to dust, moisture, extreme temperatures, and corrosive substances – the environmental tolerance of slip rings must not be overlooked. The material composition and design of the slip ring should be suitable for the specific conditions it will face, ensuring longevity and reliability.

The Cruciality of Application-Specific Choices

In the diverse world of manufacturing and machining, the ‘one-size-fits-all’ mantra holds little value, especially when it comes to selecting slip rings. Different applications bring unique challenges and requirements, from the high-speed data and power transfer needed in precision CNC machining centers to the robust and durable designs necessary for heavy industrial equipment operating in adverse conditions.

Understanding the specific operational needs – whether it involves high-speed data communication, significant power loads, or operation in challenging environmental conditions – is paramount. Moreover, considering future scalability and technological advancements in manufacturing processes is crucial. The selected slip ring should not only meet current needs but also accommodate potential future demands, ensuring a degree of future-proofing.

In essence, the selection of slip rings is a nuanced decision that significantly affects the performance, reliability, and efficiency of manufacturing machinery. Balancing these criteria with the specific demands of the intended application ensures that equipment operates at peak efficiency, minimizing downtime and maximizing output. The strategic selection of slip rings, therefore, is not merely a technical consideration but a strategic one, laying the foundation for operational excellence in the manufacturing sector.

Slip Ring Application in Manufacturing and Machining: Challenges and Solutions

Despite the immense benefits slip rings bring to manufacturing and machining applications, integrating them into systems can be met with technical challenges. Understanding these challenges and identifying solutions paves the way for optimal functioning, enhanced lifespan, and consistent performance under varying operational conditions. Here, we address common issues and propose representative solutions.

Common Challenges in Slip Ring Integration

Electrical Noise: As devices that establish moving electrical connections, slip rings are inherently prone to generating electrical noise. This can interfere with the signal quality, leading to inaccuracies in data transmission between machine parts.

Wear and Tear: Given their mechanical nature, continuous rotation inevitably leads to wear and tear of the slip rings, affecting their durability and, by extension, their effectiveness in maintaining uninterrupted power and data transmission.

Proposed Solutions and Best Practices

Mitigating Electrical Noise: The key to dealing with electrical noise lies in the choice of slip ring and proper system design. Opt for high-quality models designed to minimize electrical noise through the use of optimal contact materials and shielding techniques. Additionally, consider integrating noise filtering and isolation techniques when designing the system to further minimize the effect of generated noise.

Addressing Wear and Tear: Regular maintenance is paramount, including cleaning and replacing worn-out parts. The quality of the slip ring selected also plays a pivotal role. Opting for slip rings made from durable, wear-resistant materials and featuring sealed designs can boost the lifespan and maintain consistent performance.

What becomes clear from these challenges and their solutions is the importance of a holistic approach to integrating slip rings into manufacturing systems. Simply adding a slip ring without due consideration to its quality, suitability for the specific operational environment, and maintenance requirements can lead to suboptimal performance and frequent downtime. Instead, understanding the intricacies of these challenges and proactively integrating solutions can ensure the longevity of the slip ring, optimize performance, and ultimately enhance the overall efficiency of manufacturing and machining operations.

Slip Ring Application in Manufacturing and Machining: Future Outlook

The world of manufacturing and machining thrives on the back of technological advancement and innovation. As we edge deeper into the era of the smart industry, improvements in slip ring technologies play a definitive role. They facilitate seamless, efficient operations, offering promising prospects for the future of the manufacturing sector. Let’s delve into these technological advancements and consider their potential impacts.

Contemporary Technological Advancements in Slip Ring Technology

Wireless Data Transmission: One of the breakthroughs in slip ring technology is the integration of wireless data transmission facilities. Traditionally, slip rings relied on physical contact for transferring power and data from stationary to rotating parts. The advent of wireless technology brings a new dimension, allowing for data exchange without the need for direct contact thereby reducing wear and tear.

Smart Monitoring Features: Modern slip rings are not just all about power and data transmission. The integration of smart sensing and monitoring features offers predictive capabilities, allowing pre-emptive maintenance activities. This propels the shift from a reactive to a proactive approach, minimizing the downtime of manufacturing processes.

Future Implications of these Advancements on Manufacturing and Machining Processes

The leap into wireless transmission and the adoption of smart monitoring in slip rings comes with a host of advantages that could revolutionize manufacturing and machining operations:

Extended Operational Lifespan:

The shift from physical connections to wireless transmissions reduces physical wear, leading to longer-lasting equipment. Coupled with predictive maintenance from smart monitoring, reliability is improved, preventing unexpected malfunctions and extending the lifespan of the manufacturing units.

Efficiency in Maintenance Procedures:

The introduction of smart monitoring allows for the early detection of potential malfunctions long before they escalate into significant issues. As such, maintenance procedures become more efficient, focusing on prevention rather than resolution – saving time and resources for other processes.

Enhanced Integration with Industrial IoT:

The integration of wireless and smart technologies in slip rings aligns with the broader trend of the Industrial Internet of Things (IIoT). This could result in complete, interconnected manufacturing processes with real-time data sharing and analysis for improved decision-making.

Energy Efficiency and Sustainable Processes:

Wireless data transfers and automated monitoring are likely to streamline manufacturing processes, leading to less energy consumption. As industries move toward green manufacturing, these improvements support sustainability, reducing energy costs and environmental impact.

In retrospect, the evolution in slip ring technologies underscores the push towards optimized, predictive, and green manufacturing processes. Innovations offer a pathway to improved efficiency and reliability, critical for maintaining competitive edges in the market. The integration of wireless data transfer and smart monitoring features within slip rings is poised to usher in the next generation of manufacturing competence, laying the groundwork for the future of the manufacturing industry.

Conclusion

Summarizing the crucial role of slip rings in enhancing the operational efficiency and reliability of manufacturing and machining, this concluding section encourages reflection on the discussed factors and forthcoming trends, urging readers to consider how slip rings might be integrated or upgraded within their production environments.

FAQs about Slip Ring Application in Manufacturing and Machining

Q: How do slip rings improve CNC machine operations?

A: Slip rings enable CNC machines to consistently transmit control signals and power across rotating parts, ensuring precise and smooth tool movements.

Q: Can slip rings operate effectively in harsh manufacturing environments?

A: Yes, with proper selection based on environmental tolerance and maintenance, slip rings can reliably function in extreme conditions.

Q: What should I consider when selecting a slip ring for my manufacturing setup?

A: Key considerations include the slip ring’s electrical current capacity, number of circuits, environmental resistance, and compatibility with the machinery’s operational demands.

Q: Are there new technologies in slip rings that could benefit my manufacturing process?

A: Absolutely, advancements such as wireless communication and smart monitoring are set to significantly enhance slip ring functionality, offering predictive maintenance capabilities and improved operational efficiency.

Q: What is a slip ring, and why is it crucial for manufacturing and machining processes?

A: A slip ring is an electromechanical device that allows for the transfer of power and electrical signals from a stationary structure to a rotating one, ensuring continuous operation without hindering the rotation. In manufacturing and machining, slip rings are indispensable for machinery that requires electrical power and data transmission across rotating interfaces, such as turntables, wind turbines, and rotary tables, enabling complex movements and operations.

Q: How do slip rings help in improving the efficiency of manufacturing processes?

A: Slip rings enhance manufacturing efficiency by providing a reliable and uninterrupted power supply and data transmission to rotating parts of machinery. This ensures that processes can run continuously without interruption for maintenance or due to power/data transmission issues, significantly reducing downtime and increasing overall productivity.

Q: What types of slip rings are most commonly used in manufacturing and machining?

A: Varieties of slip rings used in manufacturing include pancake slip rings, through-bore slip rings, and wireless power transfer units, each suited for different applications. Pancake slip rings have a flat disc shape suitable for limited axial space, while through-bore slip rings provide a central hole for mounting and are ideal for applications requiring a clear passage through the center. Wireless slip rings, though not traditional slip rings, facilitate power and data transfer to rotating platforms without direct contact, reducing wear and maintenance.

Q: What challenges are frequently encountered with slip rings in industrial applications?

A: Common challenges include electrical noise, which can disrupt data transmission, and physical wear and tear, which affects the longevity and reliability of the slip ring. Ensuring consistent performance amidst various operational stresses also poses a significant challenge.

Q: Can slip rings transmit data wirelessly, and how does this impact their application?

A: Yes, newer slip ring technologies incorporate wireless data transmission features, significantly impacting their application by reducing mechanical wear and maintenance needs. This advancement enables more reliable data transmission, particularly in environments where traditional physical contacts could degrade due to exposure to contaminants or extensive use.

Q: How can the lifespan of a slip ring in a manufacturing setting be maximized?

A: Maximizing the lifespan of a slip ring involves selecting the correct type of slip ring for the specific application, ensuring proper installation, and adhering to a maintenance schedule that includes regular inspections, cleanings, and immediate replacement of worn components. Using high-quality slip rings designed for industrial applications can also greatly contribute to extending their operational life.

Q: Are there any new developments in slip ring technology that could influence future manufacturing processes?

A: Recent developments in slip ring technology, such as the integration of smart monitoring systems and advancements in materials for reduced wear and enhanced electrical conductivity, have the potential to greatly influence future manufacturing processes. These innovations could lead to longer maintenance intervals, improved reliability, and higher efficiency in operations.

See What We Can Do