In the world of electrical engineering and mechanics, understanding key details and making appropriate choices can be crucial aspects for ensuring the successful operation and maintenance of various electromechanical systems. One such vital component, which acts as an essential enabler for diverse applications and is often underestimated by many, is a ‘slip ring’. This article specifically aims to bring to the forefront the importance of one of the critical parameters with respect to slip rings – the slip ring amp data. Furthermore, it delves into the nuances of selecting the apt amp data according to varied operating environments, thereby providing a well-rounded understanding of this intricate subject.

What is Slip Ring Amp Data?

Slip ring amp data refers to the amount of electric current that a slip ring is capable of handling. It is quantified in ‘amperes’ or ‘amps’, a standard unit for the measurement of electrical current. Understanding the amp data of a slip ring is not just about knowing a value, it involves the comprehension of the slip ring’s performance and endurance under varying operational conditions and requirements.

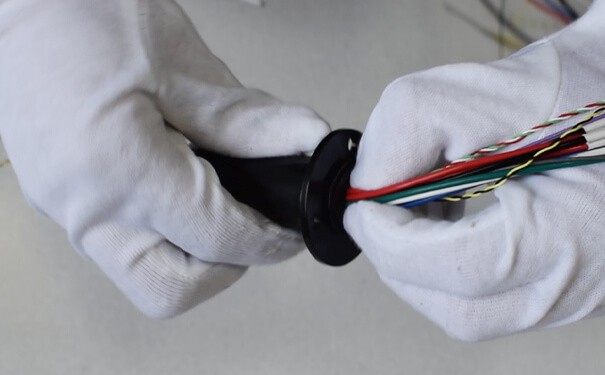

To delve deeper into understanding the slip ring amp data, let’s take a brief look at what a slip ring is. A slip ring is an electromechanical device that is used to seamlessly transmit electrical power and signals from a stationary part to a rotating component within a system. Slip rings thus play an integral role in systems that require consistent electrical transmission, even during continuous rotating movement, such as wind turbines, electric motors, generators, and radar systems, to name a few.

The amp data or the current-carrying capacity of a slip ring is a critical technical aspect that must not be overlooked. It is significant as it reciprocally influences the performance of the mechanism in which the slip ring is utilized. It helps in determining the expected efficiency, operational speed, heat generation, and wear and tear level of the device. Moreover, it affects system specifications like size, weight, and heat dissipation mechanisms.

Recognizing and estimating the slip ring amp data is thus an important practice, as it helps to ensure the proper and safe functioning of the electromechanical device, thereby assisting in predicting its performance and anticipated lifespan. Misinterpretation or neglect of this essential parameter could potentially lead to inadequate performance, operational failures, or even severe damages caused by overloading or overheating.

In summary, slip ring amp data is an essential piece of technical information that defines the permissible electrical current that a slip ring can carry for its effective functioning within a system. This data implicitly impacts the overall performance, reliability, safety, longevity, and efficiency of systems where slip rings are applied.

How to Choose the Appropriate Slip Ring Amp Data?

The right choice of slip ring amp data significantly enhances system efficiency and longevity. The process entails a deep understanding of the system’s requirements and operating conditions. Here is a detailed explanation of the factors to consider while choosing the slip ring amp data:

Load Requirement

The first step in choosing the appropriate slip ring amp data is accurately calculating the total current requirement of your system. Every device or module linked to the slip ring draws a specific amount of current; adding these amounts gives you the total current load. Make sure the amp data of the chosen slip ring is capable of comfortably handling this load. Underestimation could lead to overloading, which often results in device failure or degradation.

Safety Margin

It’s essential to accommodate a safety factor above the estimated load, also known as the safety margin. Electrical systems might experience sudden or unforeseen spikes in current due to various factors. By considering a safety margin, the slip ring can handle such unexpected increases without compromising the system’s operation.

Environments & Duty Cycle

The operating environment and duty cycle influence the demand for amp data for a slip ring. High temperatures can affect the slip ring’s capability to carry current efficiently; hence, in hotter environments, a slip ring with higher amp data may be required. Similarly, a system running in continuous or longer duty cycles needs slip rings that can handle higher current loads regularly.

Device Longevity

Selecting a slip ring with a higher amp rating is advisable to ensure prolonged device life. Operating the slip ring below its maximum capacity reduces wear and tear, thus preserving the rotating contacts. This, in turn, extends the device’s lifespan and reduces the frequency of maintenance and replacements.

With these points in mind, selecting the ideal slip ring amp data becomes an insightful exercise that directly impacts the device’s operational efficiency, durability, and overall performance of the system.

Amp Data of Different Types of Slip Rings

The amp data varies among different types of slip rings as each type is designed for distinct applications:

Through Hole Slip Ring

Through hole slip ring is a kind of slip ring with a hole in the center. Same meaning as a through-bar slip ring, sometimes called a hollow shaft slip ring. Through hole slip ring totally meets with continuous transmission of power, signals, weak current, high current, and high voltage under 360-degree unrestrained rotations. Low torque, low electrical noise, low loss, and easy maintenance as the main features.

The process of manufacturing and principle are similar to other slip rings. Power, signals, and other data are transmitted from the fixed position to the rotating position through the contact between the brush and the contact. Gold brush and contact will increase the working life. The basic technical parameters of a hole/bore slip ring mainly include bore outer diameter, bore inner diameter, length, circuits, voltage, current, maximum speed, etc. The length is variable and can be customized arbitrarily, while the outer diameter and inner diameter have some standard dimensions in through hole electrical slip rings industry. The number of circuits is the one core parameter for this series of products, the larger the number of circuits, the more complex the manufacturing process, and the higher the price cost.

Model | Picture | No. of Rings | ID(mm) | OD(mm) | Rated Current | Rated Voltage | |

1-12 | 12 | 33 | 2A | 0~240V | |||

1-24 | 12 | 54 | 5A | 0~240V | |||

1-10 | 20 | 60 | 2A~10A | 0~380V | |||

1-48 | 25.4 | 78 | 2A~10A | 0~380V | |||

1-48 | 38.1 | 99 | 2A~15A | 0~380V | |||

1-10 | 50 | 75 | 2A~12A | 0~380V | |||

1-72 | 50 | 120 | 5A~20A | 0~380V | |||

1-96 | 60 | 135 | 5A~20A | 0~380V | |||

1-96 | 70 | 155 | 5A~20A | 0~380V | |||

1-96 | 80 | 180 | 5A~20A | 0~380V | |||

1-96 | 90 | 190 | 5A~20A | 0~380V | |||

1-96 | 100 | 203 | 5A~20A | 0~380V | |||

1-96 | 120 | 250 | 5A~20A | 0~380V | |||

1-96 | 150 | 300 | 5A~20A | 0~380V | |||

1-96 | 180 | 332 | 5A~20A | 0~380V | |||

1-96 | 200 | 350 | 5A~20A | 0~380V | |||

1-96 | 250 | 407 | 5A~20A | 0~380V | |||

1-96 | 300 | 490 | 5A~20A | 0~380V | |||

1-96 | 400 | 632 | 5A~20A | 0~380V |

Capsule Slip Ring

Capsule slip rings are often offered in a compact size with flange-like miniature slip rings, used for electrical power transmission and data transfer between a stationary and a rotating part. Capsule Slip Rings also have the rotor, stator, brush block, bearing, and housing. They are easily installed and widely used in small and medium-sized equipment, such as speed dome cameras, intelligent toys, stage lights drones, etc.

Miniature slip rings

A miniature slip ring assembly is specially designed for small installation spaces. Also called a small slip ring, mini slip ring, compact slip ring, or micro slip ring. A miniature slip ring is the extension of a capsule slip ring and through the through-bore slip ring. The miniature package units have been designed to offer an economical and compact solution for signal and power transmission between the rotor and stator side. Shaft or flange are the two main mounting methods.

PIN Slip Rings

PIN slip rings are the substitute for mercury slip rings. Mercury slip rings use liquid metal mercury as a transmission medium. Special sealing technology, insulation, and compact design made them outstanding features like extremely long working life, low electrical noise, and contact resistance. Mercury is a chronic toxic substance. There have great potential threat to both the environment and the operators if leaked. People have been actively searching for alternative products.

Model | Picture | No. of Rings | OD(mm) | Rated Current | RPM | IP | |

2 | 32 | 20A | 0~400 | IP54 | |||

2 | 32 | 20A | 0~400 | IP65 | |||

2 | 32 | 20A | 0~400 | IP68 | |||

3 | 32 | 5A/20A | 0~400 | IP54 | |||

3 | 32 | 5A/20A | 0~400 | IP65 | |||

3 | 32 | 5A/20A | 0~400 | IP68 | |||

4 | 32 | 5A/20A | 0~400 | IP54 | |||

4 | 32 | 5A/20A | 0~400 | IP65 | |||

4 | 32 | 5A/20A | 0~400 | IP68 | |||

5 | 32 | 5A/20A | 0~400 | IP54 | |||

5 | 32 | 5A/20A | 0~400 | IP65 | |||

5 | 32 | 5A/20A | 0~400 | IP68 |

High Temperature Slip Ring

The slip ring can work stably under a 100~250℃ high-temperature environment, even above 250℃.

Model | No. of Rings | ID(mm) | OD(mm) | Rated Current | Rated Voltage | |

1-12 | 12.0 | 33.0 | 2A | 0~240V | ||

1-24 | 12.7 | 54.0 | 5A | 0~240V | ||

1-10 | 20.0 | 60.0 | 2A~10A | 0~380V | ||

1-48 | 25.4 | 78.0 | 2A~10A | 0~380V | ||

1-48 | 38.1 | 99.0 | 2A~15A | 0~380V | ||

1-72 | 50.0 | 120.0 | 5A~20A | 0~380V | ||

1-96 | 60.0 | 135.0 | 5A~20A | 0~380V | ||

1-96 | 70.0 | 155.0 | 5A~20A | 0~380V | ||

1-96 | 80.0 | 180.0 | 5A~20A | 0~380V | ||

1-96 | 90.0 | 190.0 | 5A~20A | 0~380V | ||

1-96 | 100.0 | 203.0 | 5A~20A | 0~380V | ||

1-96 | 120.0 | 250.0 | 5A~20A | 0~380V | ||

1-96 | 150.0 | 300.0 | 5A~20A | 0~380V | ||

1-96 | 180.0 | 332.0 | 5A~20A | 0~380V | ||

1-96 | 200.0 | 350.0 | 5A~20A | 0~380V | ||

1-96 | 250.0 | 407.0 | 5A~20A | 0~380V | ||

1-96 | 300.0 | 490.0 | 5A~20A | 0~380V | ||

1-96 | 400.0 | 632.0 | 5A~20A | 0~380V |

PCB Slip Ring

PCB slip ring is a kind of pancake slip ring, also called ultrathin flat slip ring. A common form of flat slip rings and made up of two parts, ring surface and brush assembly. The ring surface circuit board with an ultra-thick copper layer, then copper plating, and hard gold plating, so the PCB slip rings have high hardness and wear resistance features.

High Voltage/High Current Slip Ring

High-current slip rings and high-voltage slip rings are used for communication devices, large machining centers, antenna radar systems, large cranes, mining machines, and large cable reels. High voltage sometimes requires more than 2,000 volts and high current sometimes requires 500 amperes.

Model | ID(mm) | OD(mm) | No. of Rings | Max Rated Current | |

50 | 135 | 4 | 280A | ||

66 | 202 | 20 | 500A | ||

70 | 176 | 8 | 100A | ||

75 | 185 | 98 | 1000A | ||

75 | 190 | 4 | 400A | ||

80 | 180 | 3 | 250A |

Conclusion

The importance and nuances of understanding the slip ring amp data cannot be overstated as it governs the core functionality and efficiency of numerous electromechanical systems. Recognizing its role as a significant parameter in the construction and operation of a device enables us to make informed decisions, which directly impact the performance, safety, and longevity of the overall system.

A diligent selection of the appropriate amp data strengthens the foundation of reliable system operations. It prevents system failures induced by overloading, and most importantly, it extends the product lifespan by reducing undue stress on the slip ring. In other words, understanding and selecting the apt slip ring amp data is like investing in the “health” of the system, leading to lower maintenance costs and prolonged usage.

Moreover, taking into account factors like load requirements, safety margins, environmental conditions, and duty cycles while deciding on the slip ring amp data creates a more holistic approach toward system design and operation. It ensures more than just avoiding catastrophic mishaps; it provides an opportunity to optimize system operation, thereby improving overall efficiency.

In the end, a profound understanding of the slip ring amp data enables engineers and technicians to make decisions that imbue their designs with reliability, safety, and efficiency, and facilitate seamless coordination between the system’s stationary and moving components. Essentially, a grasp of slip ring amp data converts challenges into opportunities, making it an indispensable factor in the realm of electrical and mechanical engineering.

FAQ about Slip Ring Amp

Q1: Can a slip ring handle more than its stated amp data?

While a slip ring may momentarily bear a surge in current above its rated amp data, consistent exposure can degrade its performance and reduce its lifespan.

Q2: Are there any signs of inappropriate slip ring amp data usage?

Symptoms such as excessive heat, noise, or intermittent performance could indicate inappropriate amp data usage in the slip ring.

Q3: Can I change my slip ring amp data post-purchase?

The amp data of a slip ring is fixed during the manufacturing process and cannot be altered afterward. Always ensure to select the correct amp data during purchase.

A prudent understanding of slip ring amp data and making informed choices can save you from any unwarranted electrical mishap and enhance device longevity.

See What We Can Do