In the evolving realm of electrical systems, an often-overlooked component plays a pivotal role in the seamless operation of precision instruments: the slip ring. This article delves into the intricacies of slip ring applications in precision instrumentation, addressing user concerns, and unveiling future trends.

Introduction Slip Ring Application in Precision Instrumentation

In the intricate and precise world of electrical systems, slip rings serve as a cornerstone technology enabling the seamless transmission of power and data. A slip ring is a unique electromechanical device that allows for the transfer of electrical signals and power from a stationary to a rotating structure. Essentially, it consists of a metal ring that remains in continuous electrical contact with brushes or similar contact materials as it rotates. This function is critical in systems where parts need to move freely, without hindrance from tangled wires or cables, thus ensuring a continuous electrical circuit. The utility of slip rings doesn’t stop at power transmission; they also play a vital role in transmitting analog and digital signals, including those used for control and monitoring purposes in various applications.

The importance of slip rings transcends general electrical usage, finding a particularly critical place in precision instrumentation. Precision instruments are highly sensitive devices that require exact measurements, often pivotal in fields like medical diagnostics, aerospace, and automated manufacturing systems. The inclusion of slip rings in these instruments is not a matter of convenience but necessity. They facilitate the intricate and often delicate movements of components with unmatched precision, all the while maintaining a stable electrical connection that ensures the accuracy and reliability of the instrument’s readings and operations.

In precision instrumentation, slip rings contribute to the advancement of technology and innovation by allowing for the miniaturization of devices, improving the accuracy of data transmission, and enabling the complex movements required in today’s high-tech applications. Whether it’s a CT scanner that provides detailed images of the body by rotating around the patient or a high-precision robotic arm used in microsurgery, slip rings stand at the helm, ensuring these machines perform their tasks flawlessly. Their role is so ingrained in the functionality of precision instruments that without them, the progress and capabilities of these technologies would be significantly hindered.

Thus, the introduction of slip rings into precision instrumentation signifies a leap toward greater reliability and accuracy in critical applications. Their ability to deliver power and signal integrity across rotating interfaces makes them invaluable in this highly specialized field. As technology advances, the demands on precision instrumentation only grow, placing slip rings at the core of future innovations and applications where precision is paramount.

Slip Ring Application in Precision Instrumentation: Understanding Precision Instrumentation

Precision instrumentation represents a class of instruments and devices engineered with utmost accuracy and sensitivity, designed specifically for applications where minute measurements can have a significant impact. These instruments facilitate the observation, measurement, and analysis of variables within controlled environments or systems with an unparalleled level of precision. Characterized by their ability to provide accurate, repeatable, and reliable data, precision instruments are fundamental to the processes they serve, where the highest standards of measurement are required. This precise nature is achieved through sophisticated design, careful selection of materials, and advanced technological processes that ensure minimal deviation from true values, thereby enabling these instruments to perform tasks that are beyond the capability of standard instruments.

The role and significance of precision instrumentation cut across various critical sectors, profoundly impacting scientific research, healthcare, and technology fields. In scientific research, precision instruments are indispensable. They are used in laboratories for experiments that demand high accuracy, such as those involving quantum physics, materials science, and molecular biology. These instruments are pivotal in gathering data with the precision necessary for groundbreaking discoveries and innovations, enabling scientists to observe phenomena at an unprecedented scale and clarity.

In the healthcare sector, the application of precision instrumentation has dramatically transformed patient care. Diagnostic tools such as magnetic resonance imaging (MRI) machines and computed tomography (CT) scanners rely on slip ring technology for their operational efficacy, providing detailed and precise images that are crucial for accurate diagnoses. Similarly, in advanced surgical procedures, precision instruments equipped with slip rings enable surgeons to perform minimally invasive surgeries with exactitude, enhancing patient recovery times and outcomes.

The technology sector also benefits immensely from precision instrumentation. Whether it’s through the manufacturing of fragile microelectronics, testing and quality control of consumer gadgets, or the deployment of satellites into orbit, the precise measurements and control facilitated by these instruments are critical. They enable the advancement of technology at a rapid pace, supporting the development of smaller, faster, and more efficient electronic devices and systems. Moreover, in the burgeoning field of robotics and automation, precision instruments ensure the accuracy and reliability of robots and automated systems used in manufacturing, logistics, and beyond.

In essence, precision instrumentation is crucial in pushing the boundaries of what is scientifically and technologically possible. These instruments serve as the backbone of modern advancements, enabling professionals across various sectors to achieve higher levels of accuracy and reliability in their work. Their integration into various fields underscores a universal truth: the quest for precision and accuracy is fundamental to progress and innovation. As these sectors continue to evolve and grow, the reliance on and importance of precision instrumentation, facilitated in part by the incorporation of slip rings, similarly expands, underscoring its pivotal role in shaping the future.

The Role of Slip Rings in Precision Instrumentation

Within the realm of precision instrumentation, slip rings serve as a fundamental component by facilitating the transfer of electrical power and signals between stationary and rotating parts. This capability is essential in a wide array of precision instruments, where maintaining electrical continuity without impeding mechanical rotation is critical. Slip rings achieve this by incorporating a set of brushes (usually made of a conductive material) that remain in constant contact with a rotating ring or series of rings. As the ring rotates, electrical currents and signals are seamlessly transmitted through this contact point, ensuring a stable and continuous connection that is crucial for the accurate functioning of the device.

The specific need for slip rings in precision instruments stems from their ability to provide an uninterrupted electrical connection in systems requiring rotational movement. Many precision instruments, such as those used in medical imaging, satellite communication, and precision manufacturing, rely on the ability to rotate without losing power or signal integrity. For example, in medical imaging devices like MRI machines, the slip ring enables the rotating part of the scanner to maintain a constant electrical connection with the non-rotating part of the machine, allowing it to produce detailed images of the human body. Without slip rings, the design and functionality of these machines would be severely limited, impacting their precision and effectiveness.

The types of slip rings used in precision instrumentation vary, each offering specific advantages tailored to different applications:

- Mercury-Wetted Slip Rings: These slip rings are known for their near-perfect electrical conductivity and minimal electrical noise, making them ideal for applications requiring high signal integrity, such as in audio and video equipment used in broadcasting. The use of mercury, though, requires careful handling due to its toxicity and environmental impact.

- Fiber Optic Slip Rings: For applications requiring the transmission of large amounts of data at high speeds, such as in advanced communication systems and high-resolution imaging, fiber optic slip rings are preferred. These slip rings use light to transmit data, offering the advantages of immunity to electromagnetic interference, high bandwidth, and the capability to transfer several data channels simultaneously.

- Wireless Slip Rings: Leveraging inductive coupling to transfer power and data, wireless slip rings are ideal for applications where physical contact between the rotating and stationary parts is undesirable. This type is advantageous in environments where traditional contact slip rings may suffer from wear and tear or in applications requiring complete isolation between the rotating and stationary components. Although the efficiency and data rates might be lower compared to direct-contact slip rings, the lack of mechanical wear makes them suitable for high-reliability applications.

Each type of slip ring presents unique benefits tailored to specific needs in the field of precision instrumentation. The selection of a suitable slip ring type is dictated by factors such as signal integrity requirements, environmental considerations, and the mechanical design of the instrument. The incorporation of these various slip rings into precision instruments underscores their versatility and essential role in enabling the advanced functionality and reliability of modern technology systems.

Slip Ring Application in Precision Instrumentation: Case Studies and Applications

Slip rings have been instrumental in enhancing the functionality and performance of various precision instruments across multiple sectors. By allowing for the transmission of power and data across rotating interfaces, these devices have revolutionized the capabilities of equipment in medical diagnostics, aerospace, surveillance, and industrial processes. Here, we delve into real-world examples that showcase the pivotal role of slip rings in precision instrumentation.

Medical Imaging Systems (MRI Machines)

One of the most prominent applications of slip rings is in Magnetic Resonance Imaging (MRI) machines. MRI is a non-invasive imaging technology that produces three-dimensional detailed anatomical images without the use of damaging radiation. Inside an MRI machine, the slip ring’s function is critical for the rotation of the gantry, a component that houses the magnets and coils producing the magnetic field necessary for imaging. The slip rings ensure a continuous power supply and data transmission between the stationary body of the machine and the rotating gantry. This uninterrupted electrical connectivity is crucial for producing high-resolution images of the human body, aiding in the diagnosis and treatment of various conditions.

Wind Turbines

In the renewable energy sector, particularly in wind turbines, slip rings play a vital role. They are used in the hub of the turbine to transmit electrical power, control signals, and data from the nacelle to the rotating blades. The slip ring allows for the transfer of electricity generated by the turbine to the stationary part of the system for storage or immediate use, while also enabling pitch control signals to adjust blade angles for optimal efficiency. The application of slip rings in wind turbines significantly contributes to their efficiency and reliability, enabling them to operate in harsh environmental conditions over long periods without maintenance issues related to power and signal transmission.

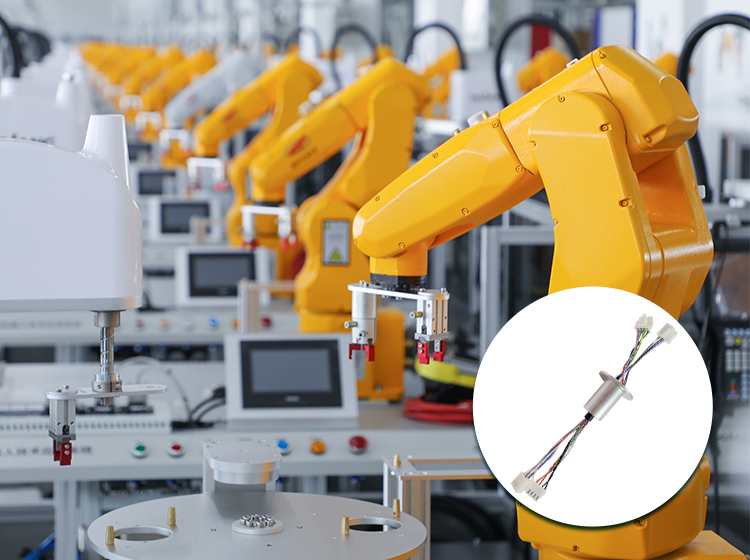

Robotic Arms (Automated Precision Manufacturing)

Robotic arms used in precision manufacturing and assembly lines incorporate slip rings to enhance their flexibility and range of motion. These instruments require the transmission of power and control signals to execute precise movements and tasks, such as assembly, painting, or welding. Slip rings embedded within the joints of robotic arms enable continuous 360-degree rotation, improving operational efficiency and allowing for complex maneuvering required in high-precision manufacturing processes. The contribution of slip rings here is significant, allowing for uninterrupted production lines and reducing downtime caused by cable entanglement or wear and tear.

Surveillance Systems (Pan-Tilt-Zoom Cameras)

Pan-tilt-zoom (PTZ) cameras, widely used in surveillance, security, and broadcasting, rely on slip rings for their operational effectiveness. These cameras must rotate freely to follow movements and cover wide areas without interruption. Slip rings within PTZ systems enable the transmission of power alongside video and control signals between the stationary and rotating parts of the camera, ensuring smooth operation and constant communication. The use of slip rings in these applications not only improves the camera’s performance but also enhances the reliability of surveillance and monitoring systems.

Aerospace (Satellites and Spacecraft)

In the aerospace sector, slip rings are integrated into satellites and spacecraft for various functions, including solar array deployment mechanisms and communication systems. They facilitate the continuous transfer of power, data, and control signals between the stationary and rotating components of these systems, crucial for operation and data transmission back to Earth. The application of slip rings in this context is particularly challenging due to the harsh conditions of space, yet their performance is critical for the success of missions and the reliability of communication networks.

These case studies demonstrate the breadth of slip ring applications in precision instrumentation. From enhancing diagnostic capabilities in medical fields to improving efficiency in renewable energy and enabling the complex movements required in advanced manufacturing and aerospace technologies, slip rings significantly contribute to the advancement and performance of precision instruments.

User Concerns Regarding Slip Ring Application in Precision Instrumentation

The integration of slip rings into precision instrumentation brings a host of benefits, such as enhanced functionality and performance. However, it also raises questions and concerns among users regarding durability, maintenance, and performance reliability. Understanding these concerns is crucial for maximizing the benefits of slip rings while minimizing potential issues.

Common Questions and Concerns:

- Durability: Users often question how long a slip ring will last under continuous operation, especially in harsh environments or high-speed applications. The concern is whether the slip ring will be a weak link in the lifespan of the precision instrument.

- Maintenance: Another common concern revolves around the maintenance requirements of slip rings. Users are interested in knowing how frequently maintenance should be performed, what it involves, and how complex it is.

- Performance Reliability: Users are understandably concerned about the reliability of slip rings in transmitting power and data without interference or loss, particularly in critical applications like medical imaging or aerospace.

Addressing Concerns:

- Manufacturing Standards: Manufacturers address these concerns by adhering to rigorous manufacturing standards that ensure the durability and reliability of slip rings. This includes the use of high-quality materials resistant to wear and environmental damage, precision engineering practices that minimize contact resistance and ensure a stable connection, and designs that are tailor-made for specific applications and their unique demands.

- Safety Measures: Safety measures are integral to the design and operation of slip rings. This includes the implementation of fail-safes to prevent catastrophic failure, insulation to protect against electrical hazards, and shielding to prevent electromagnetic interference that could affect performance.

- Testing Procedures: Before deployment, slip rings undergo extensive testing to ensure they meet performance expectations. This includes operational testing under various conditions, life cycle testing to assess durability, and stress testing to identify potential failure points. These tests are designed to ensure that the slip ring will perform reliably over its intended lifespan.

Maintenance and Handling Tips:

- Regular Inspection: Periodically inspect the slip ring for signs of wear, damage, or contamination. This allows for the early detection of issues that could affect performance or lead to failure.

- Proper Cleaning: Follow the manufacturer’s guidelines for cleaning the slip ring. This typically involves removing debris and contaminants that could interfere with electrical contact. It’s important to use the correct cleaning agents and methods to avoid damage.

- Avoid Overloading: Ensure that the slip ring is not subjected to electrical loads beyond its rated capacity. Overloading can lead to overheating, increased wear, and reduced lifespan.

- Qualified Personnel: Maintenance and repairs should be carried out by qualified personnel who understand the intricacies of slip rings and the precision instruments in which they are used. This ensures that the slip ring is handled correctly and maintains its performance and reliability.

- Environmental Protection: If the slip ring is used in a harsh environment, take additional protective measures. This might include using protective enclosures to shield the slip ring from contaminants, moisture, or other environmental factors that could cause damage.

By addressing these concerns through high manufacturing standards, rigorous testing, and proper maintenance practices, users can significantly enhance the durability, reliability, and overall performance of precision instruments featuring slip rings. This ensures that these instruments can perform their critical functions effectively, supporting advancements across a wide range of sectors.

Slip Ring Application in Precision Instrumentation: Future Trends and Predictions

The role of slip rings in precision instrumentation is poised to evolve with technological advancements, shaping the way they are used and integrated into various domains. These advancements will influence not only the performance and capabilities of slip rings but also open new avenues for their application.

Influence of Technological Advancements:

- Material Science Innovations: Ongoing research in material science promises to yield more durable and reliable slip rings. New materials that can withstand higher electrical loads, more extreme temperatures, and more aggressive environmental conditions are on the horizon. The development of wear-resistant coatings and self-lubricating materials may increase the longevity and reduce the maintenance requirements of slip rings.

- Miniaturization: As precision instruments become smaller and more compact, the demand for equally miniature slip rings increases. Advances in microfabrication and nanotechnology are likely to make smaller, lighter, and highly efficient slip rings that can fit into tighter spaces without compromising performance.

- High-Speed Data Communication: Next-generation precision instruments will require even faster data transfer rates. This need could lead to more sophisticated slip ring designs that can handle higher bandwidths, enabling applications such as real-time high-resolution video streaming or lightning-fast data collection from sensors.

- Wireless Power Transfer (WPT): Wireless technology may complement or, in some contexts, replace traditional slip rings. With WPT, there would be less dependence on physical contact for power transmission, which would greatly enhance the lifespan and reliability of the system by eliminating wear and tear on moving parts.

Potential Growth Areas and Emerging Trends:

- Renewable Energy: As the world continues to shift towards sustainable energy sources, wind turbines and other renewable energy technologies that require robust slip rings for power and data transmission will likely see a significant increase in demand.

- Automation and Robotics: In the industrial sector, automation is quickly becoming the standard. Robots with intricate slip rings will be crucial to ensure uninterrupted performance with minimal maintenance, capable of continuous operation in smart manufacturing environments.

- Aerospace Application: Space exploration and satellite technology are rapidly advancing fields where slip rings could have a significant impact. The development of space-grade slip rings that can survive the rigors of space travel could enhance communications systems or enable new capabilities in space vehicles and equipment.

- Medical Technology: Medical devices, particularly imaging equipment like MRI and CT scanners, strive for greater precision and resolution. The evolution of slip rings will parallel this development, leading to more reliable diagnostic equipment capable of handling increased data flow and supporting complex movements during imaging procedures.

- Defense and Security: Highly reliable slip rings are crucial for defense and security applications, such as radar systems, surveillance drones, and other remotely operated vehicles. As these systems become more advanced, the slip rings they utilize will also need to meet higher standards of reliability and data integrity.

As we look to the future, the intersection of refined materials, miniaturization, high-speed communication, and wireless capabilities will be the cornerstone of slip ring innovation. By continuing to adapt to the needs of various precision instruments, slip rings will play an indispensable role in the advancement of technology across numerous industries. The emphasis on sustainability, performance, and reliability will steer the development of slip rings, ensuring their continued relevance and utility in an ever-evolving technological landscape.

Conclusion

The application of slip rings in precision instrumentation unequivocally underscores their significance in the progression and reliability of critical technological and scientific advancements. As the sector continues to evolve, the adaptation and innovation of slip rings will remain crucial. Continued research and development are essential to meet the growing demands and to address user concerns efficiently.

FAQs about Slip Ring Application in Precision Instrumentation

Q1: What is the role of a slip ring in precision instrumentation?

A1: A slip ring is a device that enables the transmission of electrical signals or power from a stationary part to a rotating component in precision instruments. Depending on the specific application, this may include power, control signals, or data.

Q2: In which sectors are slip rings commonly used?

A2: Slip rings are widely used in several sectors, including medical diagnostics (MRI machines), renewable energy (wind turbines), industrial automation (robotic arms), surveillance (PTZ cameras), and aerospace (satellites and spacecraft).

Q3: What factors influence the durability and reliability of slip rings?

A3: The durability and reliability of slip rings are influenced by several factors, including the quality of materials used, manufacturing standards, operational conditions (temperature, load, speed), and the level of maintenance.

Q4: How frequently do slip rings need maintenance?

A4: The frequency of maintenance depends on the specific application and environmental conditions. However, regular inspections are recommended to ensure optimal performance and longevity. Please consult the manufacturer’s guidelines for specific maintenance schedules.

Q5: How are slip rings tested for quality assurance?

A5: Slip rings undergo rigorous testing procedures to ensure performance and reliability. This includes operational testing under various conditions, life cycle testing to assess durability, and stress testing to identify potential failure points.

Q6: What considerations should be kept in mind while handling precision instruments with slip rings?

A6: Important considerations include following manufacturer guidelines for cleaning, ensuring the slip ring is not overloaded, having maintenance and repairs handled by qualified individuals, and providing protection against harsh environmental conditions.

Q7: What are future trends in slip ring technology for precision instrumentation?

A7: Future trends include material science innovations for enhanced durability, miniaturization, advancements in high-speed data communication, and wireless power transfer. These factors will considerably influence the design and performance of slip rings in precision instrumentation.

Q8: What are some potential growth areas for slip ring application?

A8: Potential growth areas include renewable energy, automation and robotics, aerospace, medical technology, and defense sectors. With continuous technological advancements, we expect to see an increased demand for high-performance slip rings in these areas.

Q9: Can slip rings be customized for specific precision instruments?

A9: Yes, slip rings can be customized in terms of size, material, and electrical specifications to meet the unique requirements of various precision instruments.

Q10: What maintenance is required for slip rings in precision instruments?

A10: Regular inspection, cleaning, and lubrication (if applicable based on the type) are key to maintaining slip rings. Specific procedures may vary based on the slip ring design and application.

Q11: How do environmental conditions affect slip ring performance in precision instruments?

A11: Environmental conditions such as dust, moisture, and temperature can impact slip ring performance. Protective enclosures and materials suited to the operating environment can mitigate these effects.

See What We Can Do