Dive into the world of stage lighting and discover how slip rings are pivotal in creating mesmerizing lighting effects. We’ll examine the types suitable for stage applications, what to consider when choosing them, state-of-the-art innovations, and how to maintain them effectively.

Introduction to Slip Ring Application in Stage Lighting

Lighting has been a noteworthy aspect of theatrical performances since the ancient Greeks lit torches and fires to perform their late afternoon plays. Fast forward to today, stage lighting has evolved into a complex field of its own, contributing greatly to the mood, atmosphere, and interpretation of performances.

One of the critical innovations that ushered stage lighting into modernity was the introduction of movement. Moving lights, or ‘intelligent fixtures,’ have significantly increased the range of effects possible, giving designers limitless creativity. They can move across multiple axes, create complex patterns, change colors, and dynamically alter their beam shape and size. This phenomenal leap forward would not be possible without an essential, albeit often overlooked, component: the slip ring.

Slip rings, in the context of stage lighting, are devices integrated into rotating fixtures such as moving heads or mirror scanners. Their primary role is to maintain a continuous electrical connection between the rotating part of the fixture (the moving head) and the stationary part (the base), enabling unlimited 360-degree rotations.

Without slip rings, the power cables or control signal wires leading to the moving parts of the light would twist and eventually snap after a few rotations. Slip rings solve this dilemma by providing an electrically conductive path that can rotate indefinitely without tangling wires, all while maintaining a steady flow of power and data.

At their core, these handy devices play an essential supportive role, making it possible for a light show to be as dynamic, complex, and captivating as a director or lighting designer envisions. Whether it’s a rock concert with rapidly changing scenes or a play that requires subtle, shifting lighting effects, slip rings contribute significantly to creating the perfect ambiance.

By enabling dynamic movements and ensuring constant transmission of power and control signals to the moving parts of the lights, slip rings have become fundamental components of modern stage lighting systems. This fascinating exploration of slip rings in stage lighting delves deeper into their types, applications, and innovative technologies revolutionizing this domain. This journey not only highlights the importance of these devices but also illuminates their significant role in bringing alive mesmerizing light spectacles on stage.

Stage Lighting Dynamics & Requirement of Slip Rings

When observing a modern theatrical performance, it becomes evident that static lighting no longer suffices as a medium for communicating atmosphere and emotion. Stage lighting, especially in its broader application to concerts, television, and film, increasingly demands a level of complexity and versatility that can only be delivered by lighting fixtures capable of fluid, 360-degree movement.

These moving lights, following the choreography dictated by lighting controllers, can swivel, rotate, and subtly tilt to spotlight an actor, create dynamic patterns, or wash the stage with color. They can rotate in any direction and are capable of completing countless revolutions. This flexibility is essential to creating engaging and immersive lighting experiences, from the gradual sunrise in a suspenseful opening scene to the intense, strobe-filled climax of a concert.

However, delivering this impressive 360-degree performance without compromising the constant flow of electrical power and control signals to the moving parts of a light fixture presents a significant challenge. If you imagine a wired device being rotated continuously, it becomes apparent that after just a few turns, the cables would become twisted and eventually snap. This is where slip rings come into play.

Slip rings are electro-mechanical devices designed to carry an electric current or signal from a stationary source to a rotating object, without hindering the object’s movement. They consist of stationary conductive brushes that maintain contact with rotating rings. As the light fixture rotates, the electrical current or signal gets transmitted through these rings and brushes, enabling continuous unrestricted rotation.

Slip rings used in stage lighting are often integrated into the base of the unit or directly within the moving yoke structure. This allows power and data to be sent to the critical electrical components like motors, LEDs, lamps, and control electronics in the moving part of the fixture. The rings are made of conductive materials, and the brushes, maintaining a sliding contact, ensure the transmission of power and signals whilst the component is in motion.

In a nutshell, slip rings play an essential role in stage lighting dynamics by supporting the uninterrupted 360-degree movement of lights, while guaranteeing a steady pathway for power and control signals. This function is indispensable in today’s dynamic stage environments, allowing for theatrics-filled performances and contributing majorly to the spectator’s immersive experience.

Types of Slip Rings Used in Stage Lighting

In the vibrant world of stage lighting, slip rings come in various forms and designs, each endowed with unique attributes that make them suitable for specific applications. Here we’ll explore three common types – capsule slip rings, through-bore slip rings, and pancake slip rings – highlighting their unique features, advantages, and the contexts where they shine.

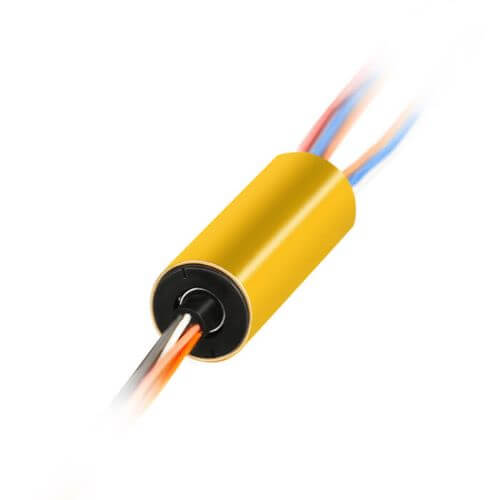

Capsule Slip Rings

Capsule slip rings, also known as miniature or micro slip rings, are small, lightweight, and often built to conserve space. They are generally enclosed within a plastic or metallic housing, which protects the conductive rings and brushes from the surrounding environment. These compact units are perfect for stage light fixtures with limited space, such as LED moving headlights or other compact intelligent fixtures. They’re capable of transmitting both power and data signals, ensuring the smooth operation of these intricate devices.

Through-Bore Slip Rings

Through-bore slip rings get their name from the hollow shaft (the “bore”) in the center of their design. This central hole allows for additional components, such as drive shafts, to pass through the center. These slip rings are highly versatile and can handle multiple circuits, making them perfect for the larger, more substantial moving fixtures we often see in professional concert lighting. Besides, the ample space within the central bore also allows for easier maintenance and provides flexibility for system upgrades.

Pancake Slip Rings

Pancake slip rings, named after their flat and wide shape, feature rings arranged consecutively in a disk-like structure. They are best suited for applications where length is limited, but there’s available axial space. For instance, they could be used in low-profile moving mirrors or scanners, where space restrictions need a minimal profile of the slip ring assembly.

Each of these slip ring types brings a unique set of strengths. Capsule slip rings are valued for their compact footprint, whereas through-bore slip rings are prized for their ability to manage high circuit counts and ease of maintenance. Pancake slip rings, due to their unique flat design, provide a solution for applications with height restrictions.

These variations of slip rings showcase the versatility embedded in the design of these essential components, reaffirming their crucial role in modern stage lighting. The ability to seamlessly integrate into various applications, whether limited by space, accessibility, or circuit numbers, reflects the true prowess of slip rings in catering to the dynamic demands of stage lighting.

Key Selection Considerations for Slip Rings in Stage Lighting

When selecting a slip ring for stage lighting applications, it is crucial to consider a variety of factors that directly influence the slip ring’s performance and ultimately, the overall lighting experience. In this section, we discuss the key selection criteria, including electrical requirements, size and mounting space, rotational speed, reliability, maintenance needs, and the significance of low electrical noise for seamless lighting performance.

Electrical Requirements

It is essential to evaluate the power and signal demands of the stage lighting fixture. Different fixtures require varying amounts of electrical current and signal types. Ensure that the chosen slip ring is capable of handling the current capacities and frequencies needed while providing the required number of circuits for effective transmission of data signals such as DMX or Ethernet.

Rotational Speed

The slip ring should support the rotational speed the stage lighting application demands. High-speed slip ring designs are often required to ensure that they can keep up with the high-speed demands of modern intelligent light fixtures without causing dysfunction or damage.

Size and Mounting Space

Stage lighting fixtures may impose restrictions in terms of available space. Some moving headlights or mirror scanners might have limited mounting space for integrating a slip ring. Choosing a slip ring based on physical specifications such as capsule, through-bore, or pancake designs can help overcome these challenges while delivering the desired performance.

Reliability

As slip rings play a critical role in a stage lighting system’s smooth operation, it is essential to opt for solutions known for their durability and reliability. High-quality brushes, conductive materials, and superior workmanship can reduce the likelihood of premature failure, ensuring consistent performance throughout the fixture’s life.

Maintenance Needs

Regular maintenance is crucial for the longevity and seamless operation of slip rings. It is essential to factor in access for cleaning, and lubrication, and to replace worn-out components. For instance, through-bore slip rings are known for offering easier maintenance access due to their hollow center design.

Low Electrical Noise

Consistently maintaining low electrical noise levels is important for the optimal performance and control of stage lighting systems. Slip rings with low electrical noise ensure minimal interference with nearby sensors, cables, and control equipment, safeguarding the delicate systems that govern today’s sophisticated stage lighting fixtures.

Taking these factors into account will lead to a well-informed selection of a slip ring that’s best suited for your specific stage lighting application. By focusing on electrical requirements, rotational speed, size, mounting space, reliability, maintenance, and minimizing electrical noise, one can better optimize stage lighting performance and gain control, ensuring that the show will go on without a hitch.

Technological Advancements in Slip Ring Design for Stage Lighting

Slip ring technology, much like the dynamic field of stage lighting it supports, continues to advance, evolving its potential for even more complex and powerful light shows. The latest innovations in materials, signal integrity, and cutting-edge designs stand testament to this progress. Moreover, the rise of contactless or even wireless slip rings is capturing industry interest due to its unique potential benefits. Let’s explore these advancements in detail.

Improvements in Materials & Signal Integrity

Traditional slip ring technology often relies on precious metals like gold or silver for their superior conductivity properties. However, the high cost and wear rates associated with these metals have catalyzed research into alternative materials. Today, the industry has seen the advent of advanced composite materials that offer a solid balance between high conductivity, durability, and cost-effectiveness. These novel materials contribute to extended lifespan, reduced maintenance needs, and overall superior performance of slip rings.

Furthermore, today’s high-tech stage lighting systems require the transmission of increasingly complex digital signals. To cater to these requirements, advancements in signal integrity, such as design enhancements for shielding and impedance matching, have been made. These innovations help maintain the accuracy of digital signals amidst the physical strain of rapid, continuous rotation, resulting in smoothened motion controls and more precise lighting effects.

Contactless & Wireless Slip Rings

The unprecedented rise of contactless or wireless slip rings is a ground-breaking development in slip ring technology. Conventionally, slip rings relied on physically touching components (rings and brushes) to facilitate signal transmission. However, this physical contact results in wear over time, requiring regular maintenance and eventual replacement.

Contactless slip rings, on the other hand, leverage magnetic fields or wireless techniques to transmit power and data across a small gap, eliminating the need for physical contact. This innovation results in drastically reduced wear, promoting a longer lifespan and virtually zero maintenance needs. In terms of performance, contactless slip rings show considerable potential in handling high-speed rotations and superior signal integrity, making them highly suitable for complex and demanding stage lighting applications.

In a nutshell, these technological advancements have led to a revolution in slip ring design for stage lighting. From new materials and signal integrity solutions to contactless and wireless technologies, these innovations offer a glimpse into the future of stage lighting, bringing forth a new era of mesmerizing and magnificent light shows.

Case Studies: Successful Applications and User Experiences

In the world of stage production, the integration of slip rings into lighting systems not only enhances the show’s dynamism but also revolutionizes the reliability and management of these systems. Below, we present real-world examples where slip rings have significantly impacted stage lighting operations, focusing on the positive experiences of the professionals behind the scenes.

Real-World Applications of Slip Rings in Stage Lighting

Broadway Musicals: Bringing Dynamic Scenery to Life

On the Broadway circuit, slip rings have played a pivotal role in achieving seamless transitions and dynamic set changes. For instance, in a critically acclaimed musical, capsule slip rings were integrated within the rotating base of massive set pieces, allowing them to transmit power and control signals for embedded lighting without tangling the wires as the scenery rotated. This application demonstrated the slip rings’ effectiveness in providing uninterrupted electrical connectivity in a highly demanding theatrical environment.

Cirque du Soleil: Enhancing Aerial Performances

Cirque du Soleil’s productions are synonymous with innovation and excellence in performance art. In one of their celebrated shows, through-bore slip rings were utilized in complex aerial apparatuses to preserve the beauty and grace of the performances. These slip rings enabled the incorporation of lighting elements into the spinning apparatuses used by the acrobats, adding an extra layer of visual spectacle without compromising safety or performance.

Touring Concerts: Facilitating Spectacular Light Shows

For touring music artists, pancake slip rings have been crucial in crafting unforgettable light shows. On a recent world tour, the lighting designer utilized these slip rings to create a series of low-profile moving head fixtures. Despite the rigors of constant transportation and reassembly, the slip rings’ reliability and durability stood out, ensuring outstanding performance night after night.

User Experiences from Industry Professionals

Light Technicians’ Enhanced Efficiency

Light technicians working on touring shows have repeatedly highlighted how slip rings have streamlined their setup and tear-down processes. The advent of plug-and-play solutions with slip rings has allowed for quick assembly, reducing labor hours and the potential for connection errors.

Designers’ Creative Freedom

Lighting designers share a consistent appreciation for the freedom slip rings have afforded them. The ability to rotate set pieces and fixtures indefinitely without cable-binding has opened new avenues for creative lighting designs—some designers have even attributed the success of their most innovative lighting concepts to the capabilities provided by advanced slip ring technologies.

Stage Managers’ Reliability Appreciation

Stage managers are tasked with ensuring the smooth execution of performances and have praised the reliability improvements that slip rings contribute. Contactless slip ring solutions have especially been lauded for drastically reducing technical issues, which is paramount during live performances where every second counts.

These case studies serve to illustrate not only the practical functionality of slip rings in diverse stage lighting scenarios but also the significant enhancements they bring to users at all levels of production. The professionals who operate and interact with these systems daily stand as testaments to the impact that well-integrated slip ring technology can have on the art and science of stage lighting.

Maintenance & Troubleshooting Slip Rings in Stage Lighting

In stage lighting applications, slip rings play a crucial role in the seamless operation of equipment. However, like all mechanical elements, slip rings may encounter issues and require proper maintenance to ensure their functionality, reliability, and longevity. This section covers common troubles a user may face with slip rings and offers troubleshooting advice. Additionally, it discusses standard maintenance practices for the best performance.

Common Issues & Troubleshooting Tips

Stage lighting comes with its unique set of challenges, and slip rings are no exception. Here are some of the difficulties users may face and troubleshooting tips:

Intermittent Signals or Power Loss

Common culprits of these issues are debris accumulation on the slip ring surfaces or worn-out brushes. Cleaning the slip ring surfaces and replacing worn brushes usually resolve these issues. The use of compatible cleaners and periodic brushing can help in debris removal.

Noise or Vibrations

Excessive noise or vibrations often point to alignment issues or worn-out components. Checking the alignment of the slip ring assembly and inspecting for faulty components can alleviate these problems. If required, components should be replaced to restore the best possible functioning of the assembly.

Overheating Issues

If the slip ring gets excessively hot during operation, it may be due to overcurrent, incorrect installation, or a lack of ventilation. Users should verify that they are not overloading the slip ring’s rated capacity, ensure proper installation, and allow for adequate ventilation.

Standard Maintenance Practices

The maintenance of slip rings plays a vital role in prolonging their life and ensuring flawless performance. Below are some standard maintenance practices:

Scheduled Cleaning

The accumulation of foreign particles can adversely impact the slip rings’ functioning. Therefore, users should adhere to regular cleaning schedules. Non-conductive cleaners are typically used to clean both rings and brushes.

Frequent Inspection & Brush Replacement

Over time, the brushes on the slip ring wear down and need replacing. Routine monitoring to check the condition of brushes is essential, and if the wear is significant, brush replacement should be carried out.

Ensuring Proper Alignment

Proper alignment of the brush and the ring is fundamental to the slip ring’s functionality. Routinely checking and maintaining alignment can prevent damage and enhance the slip ring’s lifespan.

Lubrication

Some slip ring designs require lubrication to operate smoothly. Users should follow manufacturer instructions for the type and frequency of lubrication.

Maintaining slip rings, while requiring a meticulous approach, is not overly complex. With proper care and a proactive approach, users can ensure that the slip rings in their stage lighting systems keep the show going, just as brilliantly, for a much longer time. They will also be well-prepared to troubleshoot common issues, ensuring swift resolution and minimal downtime.

Conclusion

The integration of slip rings into stage lighting rigs has revolutionized performance art, bringing boundless energy and creativity to production designs. As we look to the future, the evolution of slip ring technology promises an even brighter era for the spectacle of stage lighting.

X. FAQs about Slip Ring Application in Stage Lighting

Q: What considerations should I have in mind when choosing a slip ring for stage lighting?

A: When selecting a slip ring for stage lighting, important factors include mechanical compatibility with the lighting fixture, the ability to handle the required power and signal types, the number of circuits, durability, and ensuring a low level of electrical noise to not disrupt control systems.

Q: How often do slip rings in stage lighting need maintenance?

A: The maintenance schedule for slip rings can vary, but typically, they should be checked at least annually. It also depends on the operating environment and usage; more frequent checks may be necessary in demanding conditions.

Q: Can slip rings transmit DMX and other control signals for stage lighting?

A: Yes, modern slip rings can transmit DMX and other digital control signals used in stage lighting. They are designed to maintain signal integrity even as the lighting fixture rotates continuously.

Q: How do you select the best slip ring for a moving headlight?

A: When choosing the appropriate slip ring for a moving headlight, consider the following factors:

- Voltage and current ratings: Ensure the slip ring can handle the required voltage and current levels for the specific application.

- Number of channels: Account for project requirements and ascertain that the slip ring possesses the necessary number of power and signal channels.

- Dimensions and mount compatibility: Verify that the slip ring’s dimensions are compatible with the moving headlight, especially in cases where space is constrained.

- Rotation speed: Opt for a slip ring that supports the desired range of rotation speeds without compromising transmission quality.

- Signal integrity: Select a slip ring with adequate shielding and impedance matching, especially if the application involves complex digital signals.

Consulting the moving headlight’s manufacturer guidelines and engaging with slip ring suppliers during the selection process can also assist in identifying the most suitable solution.

Q: How often should slip rings in stage lighting be serviced?

A: The servicing frequency of slip rings in stage lighting depends on usage patterns, the specific operating environment, and the slip ring’s material and design quality. As a general guideline, every 3 to 6 months, slip rings should be inspected for wear, alignment, and debris accumulation. For more demanding applications or harsher environments, inspection intervals should be shortened.

Q: What affects the lifespan of slip rings in stage lighting applications?

A: Several factors can impact the lifespan of slip rings:

- Quality of materials: High-quality materials, such as advanced composite materials or precious metals, usually allow for extended lifespans.

- Mechanical stress: Prolonged exposure to high rotational speeds, vibration, or misalignments may reduce the slip ring’s lifespan.

- Environmental factors: Debris, dust, and corrosive environments can negatively influence slip ring durability and necessitate more frequent maintenance or replacements.

- Maintenance practices: Adhering to proper maintenance schedules and procedures can significantly extend the slip ring’s lifetime and performance quality.

Q: Can slip rings transmit both power and data simultaneously?

A: Yes, slip rings can transmit both power and data simultaneously. In stage lighting applications, they often transmit power to lighting elements while also transmitting control signals for the lighting system. Slip rings are designed with separate channels for power and signal transmission, ensuring that each transmission is handled efficiently and accurately.

Q: Are contactless slip rings a reliable choice for stage lighting applications?

A: Contactless slip rings have shown considerable potential as reliable solutions for stage lighting applications. By eliminating physical contact between components, they significantly reduce wear and extend the device’s lifespan. Furthermore, their ability to handle high-speed rotations and maintain superior signal integrity makes them particularly suitable for intricate and demanding stage lighting scenarios.

See What We Can Do