A slip ring electrical connector is an electrical device that allows for the continuous transmission of power, data, and signals from a stationary component to a rotating component. It comes in a variety of designs and sizes, and choosing the right one for your application is essential for ensuring reliable power transmission.

Why is the Right Slip Ring Electrical Connector Important?

A slip-ring electrical connector is an important component of any rotating electrical device, such as a motor, generator, or fan. It provides a continuous electrical connection between a stationary part and a rotating part, allowing power and data to be transferred from one to the other without interruption. Without a slip ring, the rotating part would be forced to move along with the stationary part, creating a gap in the electrical connection. This gap could cause a disruption in the power supply or data transmission, resulting in lost power or data, and potentially damaging the device. Additionally, slip rings help to reduce electrical noise and wear on the rotating parts, ensuring a longer-lasting and reliable connection.

Choosing the right slip ring electrical connector is crucial for several reasons, particularly in specialized applications such as high-speed slip rings, fiber optic rotary joints (FORJ), and high-temperature slip rings. Here’s why selecting the appropriate slip ring is important:

Performance and Reliability

- Consistent Signal Transmission: The right slip ring ensures that electrical signals and power are transmitted without interruption, which is essential for the smooth operation of rotating systems.

- Durability: High-quality slip rings are built to withstand the specific stresses and conditions of their applications, ensuring long-term reliability and reducing maintenance needs.

Application-Specific Requirements

- High-Speed Operations: For high-speed slip rings, it’s vital to select a connector that can handle the rotational speeds without causing wear or signal degradation.

- Optical Signals: In systems using fiber optic rotary joints (FORJ), the slip ring must be able to transmit optical signals with minimal loss and interference.

- High Temperature: High-temperature slip rings, like the NHG3899 model, need to function reliably under extreme heat conditions without failing or degrading.

Mechanical Compatibility

- Fit and Integration: The slip ring must physically fit into the existing system and integrate seamlessly with other components, ensuring that the overall system design is not compromised.

- Mechanical Stress: The right slip ring can handle the mechanical stresses (such as vibrations, shocks, and rotational forces) encountered in its specific application.

Electrical Specifications

- Current and Voltage Ratings: The slip ring must meet the electrical requirements of the system, including current and voltage ratings, to avoid overheating or electrical failure.

- Signal Integrity: Maintaining the integrity of transmitted signals is crucial, especially in applications involving data transmission, where signal loss or interference can cause significant issues.

Environmental Conditions

- Protection Against Contaminants: In harsh environments, the right slip ring will have appropriate sealing and materials to protect against dust, moisture, and other contaminants.

- Temperature and Humidity: It should be able to operate within the environmental conditions it will be exposed to, such as temperature extremes or high humidity.

Cost Efficiency

- Long-Term Cost Savings: While the initial cost of a high-quality slip ring might be higher, it often results in lower maintenance costs and longer service life, leading to overall cost savings.

- Minimized Downtime: Reliable slip rings reduce the risk of unexpected failures, minimizing downtime and associated costs.

Safety

- Electrical Safety: Properly rated slip rings ensure safe operation, reducing the risk of electrical hazards like short circuits or electrical fires.

- Operational Safety: Reliable slip rings contribute to the overall safety of the rotating machinery, protecting both the equipment and operators.

Selecting the right slip ring electrical connector is essential for ensuring the efficient, reliable, and safe operation of rotating systems across various industrial and commercial applications.

Types of Slip Ring Electrical Connectors

There are several types of slip ring electrical connectors available on the market today. The most common types are electrical slip ring connectors, electrical swivel connectors, and waterproof swivel electrical connectors. Each of these types of connectors has its own unique features and benefits.

Slip Ring Electrical Connector Assemblies

A slip ring electrical connector assembly is an electromechanical device designed to transfer electrical power and signals from a stationary component to a rotating component, or vice versa. These assemblies are essential in applications where continuous rotation is required without interrupting the electrical circuit.

Key Components of a Slip Ring Assembly:

- Rotor (or Ring):

The rotating part of the slip ring through which electrical contact is made. It spins in sync with the rotating mechanism, allowing current to flow to or from the rotating side. - Brushes (or Contacts):

These are stationary contacts, often made of carbon, graphite, or a metallic alloy, that maintain electrical contact with the rotating ring. The brushes press lightly against the ring to transfer power or signals while minimizing friction and wear. - Housing:

The outer casing protects the internal components from contaminants such as dust, moisture, or vibrations. The housing is designed to withstand the mechanical and environmental stresses associated with the device’s operating conditions. - Wiring (Lead Wires or Terminals):

Wires connect the slip ring assembly to both the stationary and rotating electrical circuits. Some assemblies also feature connectors or terminals for easy integration. - Bearings:

Bearings ensure smooth rotation of the rotor within the housing and reduce friction between the rotating and stationary parts.

Types of Slip Ring Electrical Connector Assemblies:

- Electrical Power Slip Rings:

- Designed for transmitting high currents and voltages.

- Commonly used in wind turbines, industrial machinery, and rotating platforms.

- Signal Slip Rings:

- Used for transmitting data, control signals, and communication protocols.

- These slip rings must minimize electrical noise and interference. They are often used in automation systems, video surveillance, or medical devices like CT scanners.

- Fiber Optic Slip Rings (FORJ):

- These assemblies transmit optical signals, ensuring high-speed data transfer.

- They are ideal for radar systems, subsea applications, or where electromagnetic interference (EMI) is a concern.

- Hybrid Slip Rings:

- A combination of electrical, signal, and fiber optic channels in a single assembly.

- Used in robotics, medical imaging systems, and high-end automation equipment.

Applications of Slip Ring Assemblies:

- Wind Turbines:

Slip rings transfer electrical power from the rotating blades to the nacelle and connect control signals from the stationary side. - Medical Equipment:

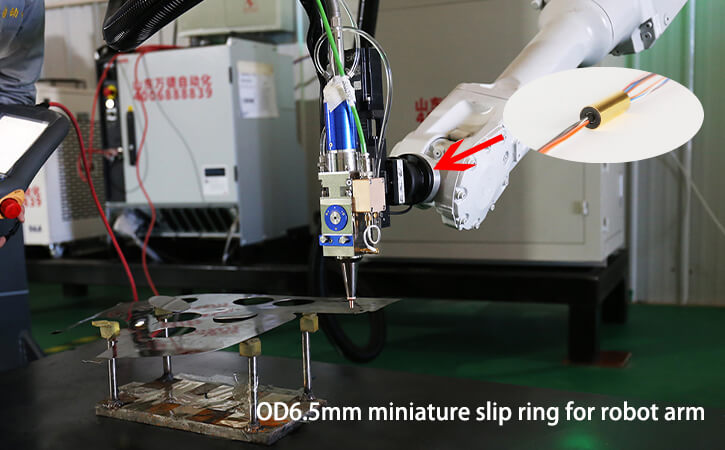

Used in CT scanners and other medical imaging devices to enable continuous data transfer during rotation. - Robotics and Automation:

Ensures uninterrupted communication between stationary and rotating sections of robotic arms. - Aerospace and Defense:

In radar systems, aircraft instrumentation, and rotating antenna systems, slip rings transmit signals reliably despite rotation. - Packaging Machines and Rotary Indexing Tables:

Slip rings are integral in machines that require continuous rotation and electrical connection for sensors, controls, or heating elements.

Advantages of Slip Ring Assemblies:

- Continuous Rotation: Enables power and signal transmission without the need for complex retraction or cable management systems.

- Minimal Wear and Tear: High-quality brushes and rings ensure long service life with minimal maintenance.

- Compact Design: Modern slip rings are compact, allowing for integration in tight spaces.

- Reduced Downtime: Slip rings prevent cable twisting and breakage, reducing machine downtime.

Slip Ring Electrical Connector Specifications

When selecting a slip ring electrical connector assembly, several critical specifications must be considered to ensure it meets the performance and environmental requirements of the intended application. Below is a detailed breakdown of the key specifications:

1. Electrical Specifications

- Current Capacity:

- Defines the maximum current each ring can handle (e.g., 2A, 10A, 500A).

- Higher current ratings require thicker conductive paths or more robust contact materials.

- Typical range: 2A to 500A per channel.

- Voltage Rating:

- Indicates the maximum voltage the slip ring can transmit safely (e.g., 240V, 600V, 1000V).

- Rated for AC or DC voltage, depending on the application.

- Number of Circuits (Channels):

- The total number of separate electrical paths within the slip ring.

- Can range from a few circuits (e.g., 2-6) to hundreds, depending on the complexity of the system.

- Insulation Resistance:

- Ensures minimal leakage current between circuits and grounding.

- Measured in megohms (MΩ) at a specific voltage (e.g., ≥500 MΩ at 500 VDC).

- Dielectric Strength:

- The ability to withstand high voltages without electrical breakdown, typically measured in volts AC or DC (e.g., 1000V @ 50Hz for 60 seconds).

2. Mechanical Specifications

- Rotational Speed:

- Maximum allowable rotation speed, typically specified in revolutions per minute (RPM).

- Common range: 50 to 10,000 RPM.

- Torque:

- The resistance to rotation due to the friction within the slip ring.

- Low torque is preferred for smooth operation (e.g., 0.01 Nm to 1 Nm).

- Contact Materials:

- Typical materials include gold-on-gold, silver-on-silver, or carbon brushes, which impact durability and signal quality.

- Gold-plated contacts are often used in signal slip rings for low electrical resistance and reduced noise.

- Bearing Type:

- Ball bearings or sleeve bearings are used to ensure smooth rotation and long service life.

- Mechanical Life:

- The expected number of rotations or operating hours before maintenance or replacement is required (e.g., 10 million rotations or more).

3. Signal and Data Transmission

- Signal Type:

- The slip ring may need to transmit analog, digital, or high-frequency signals.

- Protocols supported: Ethernet, CAN bus, USB, RS232, or video signals (e.g., HD-SDI).

- Bandwidth and Noise:

- For data transmission, slip rings should have high bandwidth and low signal-to-noise ratio (SNR).

- Crosstalk and EMI shielding may be required for sensitive applications.

4. Environmental Specifications

- Temperature Range:

- Defines the minimum and maximum operating temperatures (e.g., -40°C to 85°C).

- Essential for outdoor or industrial applications where extreme temperatures are common.

- Ingress Protection (IP) Rating:

- Specifies the level of protection against dust and water (e.g., IP65, IP67).

- Higher IP ratings are required for marine, offshore, and harsh industrial environments.

- Vibration and Shock Resistance:

- Some applications, such as aerospace or heavy machinery, require slip rings to withstand high levels of vibration and shock.

- Humidity Resistance:

- The slip ring should function reliably in humid conditions, often tested for performance at 95% relative humidity (RH) or higher.

5. Physical Dimensions

- Outer Diameter (OD):

- The overall size of the slip ring, which affects the available installation space.

- Inner Diameter (ID):

- Relevant for hollow shaft designs, allowing other components (e.g., cables, shafts) to pass through.

- Height/Length:

- The length of the assembly, which influences space and integration with other components.

- Weight:

- Important for applications where weight constraints are critical, such as aerospace or robotics.

6. Mounting and Connection Options

- Mounting Type:

- Flange mount, through-bore, or shaft mount options are available based on installation needs.

- Lead Wires or Connectors:

- Slip rings may feature pre-attached lead wires or connectors to simplify integration.

- Connector types: screw terminals, Molex, or circular connectors.

- Cable Length:

- Standard lengths may be provided, or custom lengths may be required for specific installations.

7. Additional Features

- Maintenance-Free Design:

- Some slip rings use self-lubricating materials or special contact mechanisms that eliminate the need for regular maintenance.

- Hybrid Configurations:

- Combines electrical power circuits with signal, data, or fiber optic channels in a single assembly.

- Customization Options:

- Many manufacturers offer custom slip rings to meet specific design, material, or operational requirements.

By considering these specifications, engineers and designers can select the most suitable slip ring electrical connector assembly to ensure optimal performance and reliability in their applications.

2 Wire and 6 Wire Slip Ring Electrical Connector

Slip rings come in various configurations, depending on the number of independent circuits (or wires) required. Two common variants are 2-wire and 6-wire slip ring electrical connectors, each designed for specific applications. Below is a detailed look at both configurations, including their features, applications, and key specifications.

2-Wire Slip Ring Electrical Connector

A 2-wire slip ring is the simplest configuration, providing two independent paths for transmitting either power or signals between the rotating and stationary parts.

Key Features:

- Simple Design:

Only two conductive paths, typically used for DC power or low-complexity signals. - Compact Size:

Due to fewer channels, the design is lightweight and space-efficient. - Cost-Effective:

Suitable for simple systems, with lower manufacturing costs compared to multi-channel slip rings.

Applications:

- DC Power Transmission:

Transmits power to low-voltage motors or lighting on rotating parts (e.g., rotating camera platforms). - Basic Signal Transmission:

Used in simple sensor systems or rotating indicators. - Rotating Lights or Displays:

Powers rotating LED signs or simple lighting elements in kiosks or advertising systems. - Robotic Joints:

Provides power to small motors or sensors on single-axis robotic joints.

Typical Specifications:

- Current Capacity: Up to 10A per channel.

- Voltage Rating: 24V – 250V AC or DC.

- Rotational Speed: Up to 300 RPM.

- IP Rating: Optional IP65 for dust and water protection in outdoor use.

6-Wire Slip Ring Electrical Connector

A 6-wire slip ring provides six independent electrical paths, making it suitable for more complex systems where multiple power lines or signal channels are required.

Key Features:

- Multi-Channel Capability:

Supports multiple circuits, making it ideal for transmitting different signals or power levels simultaneously. - Versatility:

Can handle a combination of power, control signals, and communication protocols. - Compact Hybrid Designs:

Some 6-wire slip rings offer both power and data transmission within the same assembly.

Applications:

- Robotics and Automation:

Used in robotic arms to transfer control signals, sensor data, and power to rotating end-effectors. - CCTV and Surveillance Systems:

Transmits power and video signals to rotating cameras on platforms or drones. - Packaging Machines:

Provides power and control signals to rotating tools or motors in industrial equipment. - Medical Equipment:

Transfers power and control signals in rotating imaging devices like dental chairs or CT scanners. - Ethernet or Data Communication:

Supports communication protocols like CAN bus or RS232, alongside power circuits.

Typical Specifications:

- Current Capacity: 2A – 30A per channel (depending on wire type and insulation).

- Voltage Rating: 24V – 600V AC/DC.

- Rotational Speed: Up to 1000 RPM.

- Wire Configuration: 6 independent wires with dedicated insulation for signal isolation.

- IP Rating: IP65 or higher for industrial or outdoor applications.

- Signal Noise Protection: Some designs include shielding to minimize EMI (Electromagnetic Interference).

Comparison Between 2-Wire and 6-Wire Slip Rings

| Specification | 2-Wire Slip Ring | 6-Wire Slip Ring |

|---|---|---|

| Number of Channels | 2 | 6 |

| Applications | Power for simple systems, basic sensors | Robotics, CCTV, medical devices, automation |

| Current Capacity (per wire) | Up to 10A | 2A – 30A |

| Voltage Rating | 24V – 250V | 24V – 600V |

| Size and Complexity | Compact and lightweight | Larger, with more intricate wiring |

| Cost | Lower | Higher, due to more wires and complexity |

| Rotational Speed | Up to 300 RPM | Up to 1000 RPM |

Both 2-wire and 6-wire slip ring electrical connectors serve different needs. A 2-wire slip ring is ideal for simple applications, offering power transfer in a compact and cost-effective design. In contrast, the 6-wire slip ring provides greater versatility, suitable for applications that require multiple power and signal lines, such as robotics, automation, and medical devices. Selecting the right type depends on the electrical load, number of circuits, and the complexity of the rotating system.

Factors to Consider While Selecting Electrical Slip Ring Connectors

When selecting electrical slip ring connectors for your application, there are several important factors to consider.

Circuits and Wires

The first factor to consider is the number of circuits and wires you need. Electrical slip ring connectors come in a range of sizes and can accommodate different numbers of circuits and wires. It is important to select the right size for your application as per your need.

Material

The material used for the electrical slip ring connector is also important. This can range from plastic to metal and will determine the durability and longevity of the connector. It is also important to consider the environmental conditions the connector will be exposed to, as some materials may be better suited than others.

Voltage and Current

The voltage and current requirements of the application will also impact the selection of an electrical slip ring connector. It is important to select a connector that can handle the voltage and current requirements of the application.

Size and Weight

The size and weight of the connector are also important factors to consider. If the connector needs to fit in a tight space or needs to be light enough to be used in a mobile application, then the size and weight should be taken into account.

Waterproofing

Finally, waterproofing is an important factor to consider when selecting an electrical slip ring connector. If the connector will be exposed to moisture or other liquids, then a waterproof swivel electrical connector may be necessary.

Wind Turbines

- Blade Pitch Control: Slip rings transmit power and control signals to the blades, allowing for the adjustment of blade angles to optimize energy capture and protect the turbine during high winds.

- Yaw Control: They enable the rotation of the nacelle to keep the blades facing the wind.

Medical Equipment

- CT Scanners: Slip rings allow continuous rotation of the scanner’s gantry while transmitting power and data, enabling high-speed imaging.

- MRI Machines: Used for transmitting signals in devices requiring constant rotational motion.

Radar Systems

- Rotating Antennas: Slip rings ensure uninterrupted power and signal transmission to the rotating radar antennas, essential for consistent radar operation.

Robotics

- Robotic Arms: They provide electrical connection for motors and sensors in rotating joints, allowing for complex movements and functionality.

- Automated Machinery: Used in various types of automated and robotic systems for seamless power and data transmission.

Industrial Machinery

- Packaging Equipment: Slip rings transmit control signals and power to rotating parts in packaging machines, ensuring continuous operation.

- Rotary Tables: Used in CNC machines and other industrial equipment to provide precise control of rotating workpieces.

Aerospace and Defense

- Gyroscopes: Slip rings provide power and data connections to the rotating elements of gyroscopes, used for navigation and stabilization.

- Turrets and Weapon Systems: They enable the transfer of power and control signals to rotating turrets and weapon systems on military vehicles.

Telecommunications

- Rotating Cameras: Slip rings are used in PTZ (Pan-Tilt-Zoom) cameras to provide continuous power and signal transmission during 360-degree rotation.

- Satellite Communication: In satellite dishes that rotate to track signals, slip rings maintain a stable connection.

Entertainment and Simulation

- Amusement Rides: Used in rides with rotating components to provide power and control signals, ensuring safe and reliable operation.

- Simulators: In flight and driving simulators, slip rings enable the transmission of data and power to moving parts, enhancing the realism of the simulation.

Renewable Energy

- Solar Trackers: Slip rings are used in solar panel systems to maintain electrical connections while the panels rotate to follow the sun.

Oil and Gas

- Drilling Rigs: Slip rings are used in rotating drilling equipment to transmit power and data signals, essential for monitoring and control.

- Offshore Platforms: Used in various rotating equipment on offshore oil platforms.

Marine

- Ship Cranes: Slip rings provide power and control signals to cranes and winches on ships, allowing for efficient loading and unloading operations.

- Marine Propulsion Systems: Used in azimuth thrusters and other rotating propulsion systems.

Agriculture

- Irrigation Systems: Slip rings in rotating irrigation equipment ensure continuous power and control signal transmission, improving efficiency and coverage.

Automation and Process Control

- Rotary Sensors: Slip rings are used in sensors that require continuous rotation, providing power and data transmission.

- Rotating Conveyors: Used in manufacturing and process control systems where conveyors need to rotate.

These applications demonstrate the versatility and critical importance of slip ring electrical connectors in enabling efficient and reliable operation across a wide range of industries.

Wind Turbines

- Blade Pitch Control: Slip rings transmit power and control signals to the blades, allowing for the adjustment of blade angles to optimize energy capture and protect the turbine during high winds.

- Yaw Control: They enable the rotation of the nacelle to keep the blades facing the wind.

Medical Equipment

- CT Scanners: Slip rings allow continuous rotation of the scanner’s gantry while transmitting power and data, enabling high-speed imaging.

- MRI Machines: Used for transmitting signals in devices requiring constant rotational motion.

Radar Systems

- Rotating Antennas: Slip rings ensure uninterrupted power and signal transmission to the rotating radar antennas, essential for consistent radar operation.

Robotics

- Robotic Arms: They provide electrical connection for motors and sensors in rotating joints, allowing for complex movements and functionality.

- Automated Machinery: Used in various types of automated and robotic systems for seamless power and data transmission.

Industrial Machinery

- Packaging Equipment: Slip rings transmit control signals and power to rotating parts in packaging machines, ensuring continuous operation.

- Rotary Tables: Used in CNC machines and other industrial equipment to provide precise control of rotating workpieces.

Aerospace and Defense

- Gyroscopes: Slip rings provide power and data connections to the rotating elements of gyroscopes, used for navigation and stabilization.

- Turrets and Weapon Systems: They enable the transfer of power and control signals to rotating turrets and weapon systems on military vehicles.

Telecommunications

- Rotating Cameras: Slip rings are used in PTZ (Pan-Tilt-Zoom) cameras to provide continuous power and signal transmission during 360-degree rotation.

- Satellite Communication: In satellite dishes that rotate to track signals, slip rings maintain a stable connection.

Entertainment and Simulation

- Amusement Rides: Used in rides with rotating components to provide power and control signals, ensuring safe and reliable operation.

- Simulators: In flight and driving simulators, slip rings enable the transmission of data and power to moving parts, enhancing the realism of the simulation.

Renewable Energy

- Solar Trackers: Slip rings are used in solar panel systems to maintain electrical connections while the panels rotate to follow the sun.

Oil and Gas

- Drilling Rigs: Slip rings are used in rotating drilling equipment to transmit power and data signals, essential for monitoring and control.

- Offshore Platforms: Used in various rotating equipment on offshore oil platforms.

Marine

- Ship Cranes: Slip rings provide power and control signals to cranes and winches on ships, allowing for efficient loading and unloading operations.

- Marine Propulsion Systems: Used in azimuth thrusters and other rotating propulsion systems.

Agriculture

- Irrigation Systems: Slip rings in rotating irrigation equipment ensure continuous power and control signal transmission, improving efficiency and coverage.

Automation and Process Control

- Rotary Sensors: Slip rings are used in sensors that require continuous rotation, providing power and data transmission.

- Rotating Conveyors: Used in manufacturing and process control systems where conveyors need to rotate.

These applications demonstrate the versatility and critical importance of slip ring electrical connectors in enabling efficient and reliable operation across a wide range of industries.

What to Look for in a Quality Slip Ring Connector

1. Durability: Look for a slip ring connector that is designed to stand up to wear and tear of frequent use. It should be made of a durable material that can withstand shock, vibration, and other environmental factors.

2. Electrical Integrity: A quality slip ring connector should be designed to provide reliable electrical connections with minimal signal loss. Look for connectors with high-quality contacts and gold-plated contact points for improved conductivity.

3. Low Maintenance: A good slip ring connector should be designed to require minimal maintenance. This includes features such as sealed designs, corrosion-resistant materials, and low-friction components to ensure reliable performance over time.

4. Compatibility: Make sure the slip ring connector you choose is compatible with your system’s existing components and meets all applicable electrical standards.

5. Cost: Quality slip ring connectors can vary widely in price depending on the features and materials used. Consider what features you need and look for a product that meets your needs without breaking the bank.

6. Ease of Installation: Select a slip ring connector that is easy to install and requires minimal maintenance.

7. Quality: Check for high-quality components and materials used in the construction of the slip ring connector.

Tips for Installing an Electric Slip Ring Connector

1. Ensure that the electric slip ring connector is compatible with the application before installation.

2. Make sure that the area around the connector is clean and that there is adequate ventilation to prevent overheating.

3. Secure the connector to the application to prevent it from vibrating or shifting during operation.

4. Make sure the electrical connections are tight and free of corrosion.

5. Check for any potential sources of interference to prevent electric shock or damage to the application.

6. Test the connector for proper operation before and after installation.

7. Monitor the connector for signs of overheating or wear and tear during operation.

8. Make sure to follow all safety procedures when installing and operating the connector.

Conclusion

Choosing the right electrical slip ring connector for your application is essential for ensuring reliable power transmission. It is important to consider the operating environment, the number of circuits required, and the durability and reliability of the connector when selecting a slip ring electrical connector. With the right slip ring electrical connectors, it is possible to ensure reliable power transmission over long periods of time.

See What We Can Do