At the intersection of technology and engineering lies an often overlooked but hugely significant component: the slip ring. As electromechanical devices, slip rings facilitate the transmission of power and data from stationary to rotating parts, enabling seamless operation of diverse equipment ranging from wind turbines and radar systems to CT scanners and even cable reels.

However, the functionality of these versatile devices is not just in their engineering design but also in the approach to their installation. Precise and accurate mounting of slip rings is instrumental in guaranteeing their optimal performance, extending their lifespan, and, by extension, enhancing the reliability of the equipment they’re integrated into. An incorrectly mounted slip ring can lead to diminished transmission quality, increased wear and tear, and, in worst-case scenarios, total system failure. Therefore, understanding the intricacies of effective slip ring mounting should be of profound interest to both equipment designers and technical professionals involved in their installation and maintenance.

This guide serves as a comprehensive resource on “slip ring mounting methods,” aiming to illuminate the unique characteristics of various slip ring types and how these influence their successful implementation. We will explore distinct slip ring mounting methods, commenting on their advantages and disadvantages, and discuss considerations critical to their selection. Providing an in-depth look at slip ring mounting methods, this guide is crafted to equip readers with the knowledge required for different mounting scenarios.

By understanding and addressing these factors, you will be better equipped to make informed decisions that optimize slip ring performance and ensure the longevity of your equipment. With this guide, we invite you to broaden your knowledge, enhance your proficiency, and elevate your contribution to the technology and engineering sectors.

Fundamental Slip Ring Types and Their Impact on Mounting Methods

There are countless variations in terms of design and application when it comes to slip ring configuration. Nevertheless, it’s essential to understand the three fundamental slip ring types—Through-bore, Pancake, and Capsule—as these form the core around which most slip ring designs are created.

Through-bore Slip Rings: These slip rings are named after their prominent characteristic—a hollow shaft or center hole—and come in a variety of diameters. This through hole can be utilized to mount additional equipment or to allow the passage of other apparatus like cables, shafts, or pipelines. When mounting through-bore slip rings, special attention has to be paid to secure them firmly, often using flanges or brackets. The nature and burden of the additional equipment passing through the bore can place unique demands on the mounting process to ensure stability and prevent wobble during rotation.

Pancake Slip Rings: Pancake or disc slip rings distinguish themselves with their relatively flat, disc-like design. They are typically employed in scenarios where axial length is a limiting factor due to space constraints, but there’s enough radial breadth to accommodate their disc shape. Mounting pancake slip rings often involves axial methods to ensure secure, flat adhesion and to prevent unwanted displacements during operation. Their shallow depth can be an advantage in reduced spatial demand but requires careful leveling and alignment to minimize mechanical stresses during rotation.

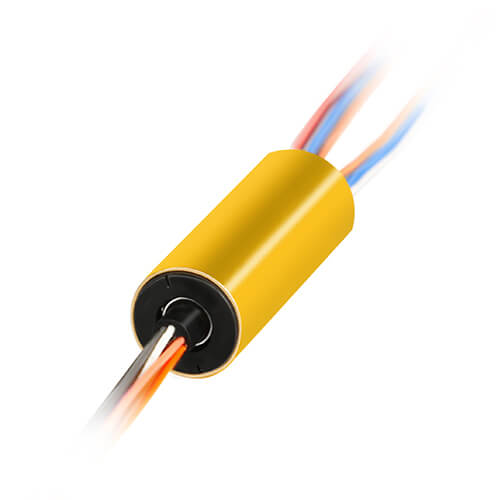

Capsule Slip Rings: These are usually of a more compact design and are often employed in smaller and more enclosed spaces where the overall dimensions of the slip ring assembly are a significant constraint. Capsule slip rings might involve a more diverse range of mounting methods depending on the available space and the device structure. The most common are direct mounting or end-of-shaft mounting.

Each of these slip ring types poses unique challenges and considerations for proper installation. The mechanical structure, available space, and environmental conditions, among other factors, heavily influence the mounting methodology. Therefore, the dynamics of these three types and their interplay with mounting techniques is a core aspect to consider when working with these devices. By understanding these nuances, engineers and technicians can ensure optimal performance and longevity of both the slip rings and the equipment they power.

Common Mounting Methods for Slip Rings

Various mounting methods can be employed when installing slip rings. The choice of a particular methodology often depends highly on the type of slip ring, the mechanical environment of the application, and factors like operation speed, stability, and space availability. Let’s delve into some common mounting methods, and navigate through their application, advantages, and limitations:

Flange-mounted Slip Rings: Flange mounting is a prevalent method of slip ring statement, particularly common for through-bore slip rings. This technique utilizes a flange – a protruding rim, edge, or collar on the slip ring – that is then interconnected with matching hardware on the mountable surface. This method allows secure, robust preparation and enhances the stability of the slip ring. However, it does require more space than other techniques due to the added flange. Besides, flange mounts may demand careful alignment to reduce the potential for strain or warping during operation.

End-of-shaft Mounted Slip Rings: An end-of-shaft mounting technique is frequently used for capsule slip rings. In this method, the slip ring is attached at the end of the rotating shaft rather than being placed along its length. While this method is space-saving and allows a more compact design, it could limit the mechanical flexibility of the overall system and might require additional considerations for the mechanical balance of the assembly.

Direct Axial Mounting: Direct Axial mounting involves attaching the slip ring directly onto the rotating shaft. Predominantly used for pancake slip rings, it necessitates precise alignment and calibration. This type of mounting is considered suitable for structures where minimal axial length is a priority. Despite its space-saving advantages, it requires meticulous installation to prevent mechanical stress during operation and could be more prone to misalignment than other methods.

Understanding the unique attributes of each of these mounting methodologies is advantageous for the appropriate planning and implementation of the slip ring. Each method has its benefits and potential pitfalls, and the choice between them depends on the specific needs and constraints of each application.

Factors to Consider When Choosing a Mounting Method

The mounting of a slip ring is a crucial process where multiple factors intersect. These determinants not only influence the ease and success of installation but also contribute to the long-term performance, maintenance, and operational efficiency of the slip ring. Let us delve into these significant factors, their implications, and the considerations they necessitate:

Available Space: The amount of space accessible in the operational setup is a fundamental factor that drives the choice of mounting method for a slip ring. Some methods, like flange mounting, require more space to accommodate the additional hardware. Direct mounting methods are generally more space-efficient but might necessitate specific spatial allocations for proper functioning.

Mechanical Constraints: Every operation setup has its unique mechanical structure and constraints. The design constraints, the need for mechanical balance and stability, and fitting into pre-set hardware configurations can significantly influence how the slip ring should be mounted.

Rotational Speed: The speed at which the rotating components function can impact the suitable mounting method. High rotational speeds require particularly secure and balanced mounting solutions to prevent premature wear or failure.

Environmental Conditions: The prevailing environmental conditions, such as temperature, humidity, and dust, can impact the choice of mounting method. For instance, locations exposed to high humidity may require methods that ensure better sealing against moisture.

Electrical Requirements: A slip ring’s functional requirements, such as voltage, current, and signal type, can dictate the choice of mounting technique. High-voltage applications might necessitate certain mounting practices over others to ensure electrical safety and minimize interference.

Maintenance Requirements: The ease, frequency, and extent of maintenance necessary for the slip ring should be considered. Some mounting methods, while providing a steady and secure mount, might restrict easy access for maintenance. Those that provide for straightforward disassembling and reassembling could prove advantageous in regular maintenance scenarios.

In summary, the method chosen for mounting a slip ring is rarely a result of a single decisive factor. Rather, it is the careful consideration and balancing of a combination of factors that reflect the specific circumstances and requirements of the intended application. Understanding these dimensions and their interplay brings you a step closer to ensuring an optimal slip ring setup and thus a more reliable and efficient operation.

Custom Mounting Solutions for Slip Rings

In many scenarios, employing off-the-shelf slip rings and mounting techniques fulfills the requirements for reliable operation. However, numerous applications may necessitate specialized solutions that exceed the capabilities of standard options. Custom mounting solutions for slip rings can offer tailored, adapted, and enhanced performance to better suit the demands of specific operational environments. In this section, we will explore the reasons behind seeking custom mounting solutions, key design considerations, and the benefits of collaborating with slip ring manufacturers for bespoke achievements.

Off-the-shelf slip rings or mounting methods may not suffice: Unique operational demands or harsh environmental conditions may entail mounting solutions that deviate from conventional methods. Unusual physical dimensions, high-speed rotations, exposure to extreme temperatures, or specific electrical signal requirements can be a few of the circumstances that demand a customized approach to slip ring mounting.

Design considerations for custom mounting solutions: Tailoring a custom mounting solution demands thoughtful analysis of various factors:

- Accurate assessment of physical dimensions and spatial constraints, accounting for any necessary hardware adaptations.

- In-depth understanding of application-specific mechanical forces and potential balancing issues that could arise during operation.

- Detailed knowledge of environmental conditions, including temperature, humidity, and dust, to ensure optimal performance and longevity.

- A comprehensive evaluation of electrical requirements for both power and signal transmission to deliver the desired performance and minimize interference.

- Assessment of the overall system architecture and integration of the slip ring mounting solution into the existing design.

Collaboration with slip ring manufacturers for customized solutions: Partnering with experienced slip ring manufacturers can significantly streamline the process of creating a custom mounting solution. Their expertise and knowledge of both product design and best practices ensure that the tailored solution is aligned with the unique characteristics and requirements of the intended application. Additionally, collaborating directly with manufacturers grants access to their resources, tools, and testing facilities to develop, simulate, and fine-tune the custom solution to the highest standards and quality expectations. This partnership reduces the trial-and-error process and improves the overall design quality and reliability.

In conclusion, custom mounting solutions for slip rings can prove an asset in scenarios where standard options fall short of meeting the specific needs of an application. Investing in tailored solutions, while considering all the necessary design factors and collaborating with reputable slip ring manufacturers, can promote the development of an optimized mounting solution that ensures the sustainability, efficiency, and longevity of the operational system.

Mounting-related Best Practices and Tips for Optimal Slip Ring Performance

In understanding the vital role that slip rings play in rotational applications, it becomes clear that their effective mounting and maintenance are steadily linked to their optimal performance and longevity. Toward this end, best practices serve as a useful guide in helping to secure the robustness and efficiency of the slip ring system. Let’s explore some of these practices in detail:

Ensuring Proper Alignment and Minimizing Mechanical Stress: The alignment of a slip ring and how it mounts onto the system plays a vital role in its performance. Incorrect alignment can result in mechanical stress, causing excessive wear or failure of the slip ring or coupled components. It’s essential to pay attention to the correct alignment during installation, using appropriate measuring tools, and conducting necessary tests to optimize the alignment. Additionally, the mounting should also consider any potential thermal expansion or contraction, ensuring enough flexibility in the mounting mechanism to accommodate such variations.

Importance of Keeping the Slip Ring Clean and Well-Lubricated (if applicable): Like any other hardware component, slip rings should be kept clean and free from dust or debris to prevent unnecessary wear and tear. Regular inspection and cleaning should be a part of the maintenance regime. In slip ring designs where lubrication is used, it’s crucial to ensure proper, timely lubrication to minimize friction and prevent overheating. It’s also important to use the correct type of lubricant as recommended by the manufacturer, as inappropriate lubricants can degrade the system and interfere with electrical transmission.

Guidelines for Required Torque and Tightening of Mounting Screws: The mounting screws of a slip ring system are subject to specific torque requirements. Over-tightening can result in excessive stress on the slip ring structure, potentially damaging it or reducing its lifespan. On the other hand, under-tightening can result in a lack of stability and wobbling during operation, leading to inconsistent performance or early failure. Manufacturer guidelines should be thoroughly followed for optimal torque settings, and it’s advisable to use a torque wrench for accurate tightening.

By implementing these best practices, you can improve the operational efficiency of the slip ring, extend its lifespan, and possibly avert premature system failures. Periodic inspections, adhering to the recommended procedures, and maintaining a proactive approach to system upkeep are the keys to achieving and preserving optimal slip ring performance.

Troubleshooting Common Mounting Issues

Regardless of how efficacious the operation setup is, some complications can arise, particularly in the case of improper mounting of slip rings. Recognizing these issues and adopting corrective measures can greatly improve the performance and lifespan of the system. This section addresses some common mounting issues, their associated problems, and guidelines for diagnosing and rectifying these issues.

Warping or Distortion of Components Due to Improper Mounting: Warping or deformation of components often occurs due to inadequate alignment or over-tightening during mounting. This can put an undue mechanical strain on the slip ring and associated parts, leading to irregular operation, premature wear, and possibly, failure. If components appear distorted, it may be necessary to disassemble, inspect for damage, and then properly realign and reinstall the components. Paying attention to the manufacturer’s recommendations for mounting, including the required torque for tightening screws, can prevent such distortion.

Electrical Failures Due to Poor Connections or Misalignment: Improper mounting often causes poor electrical connections or signal interference. Misalignment of contacts or the usage of inappropriate mounting hardware can disrupt signal transfer. When unexpected electrical failures or inconsistent performance occur, it’s crucial to inspect the entire mount set-up for any signs of misalignment or damaged connections. Depending on the findings, correcting the alignment, tightening loose connections, or replacing any damaged components might be necessary to restore proper functioning.

Tips for Diagnosing and Rectifying These Issues: Regular monitoring and periodic system inspections are key actions to identify problems at their inception. Use recommended tests and diagnostic tools to assess the performance of the slip ring system. For mechanical issues, visual inspection and measuring tools can help confirm if components are distorted or misaligned. Electrical issues, meanwhile, can often be isolated using multimeters or oscilloscopes for precise measurements. A clear understanding of the operation setup and the configuration specifics is essential to effectively troubleshooting these issues.

In conclusion, while mounting-related issues can impact the performance and life of slip rings, regular inspections, proactive troubleshooting and diligent adherence to prescribed mounting practices can help circumvent these complications. In some cases, reaching out to manufacturers or expert technical support may be beneficial in diagnosing and resolving persistent or complex issues.

Conclusion

Several factors influence the selection of a slip ring’s mounting method. It isn’t merely about installation but significantly impacts the performance, durability, and maintenance needs of the slip ring. Understanding these essentials arms you with the knowledge to exploit slip rings’ full potential and ensure your projects’ success. Stay curious, keep experimenting, and let innovation drive you.

See What We Can Do