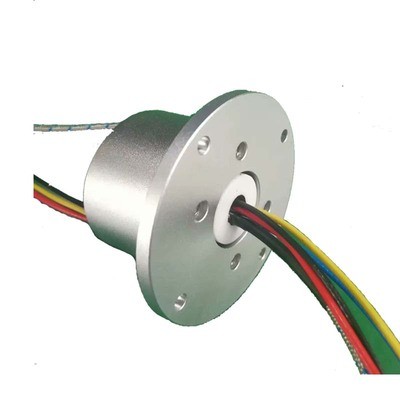

Slip rings are the metal rings that provide continuous electrical contact with the brushes on the fixed contacts. It is generally installed on the rotating part of the machine. Electrical conduction can be achieved by wireless transmission mercury, wiping contacts, infrared transmission, etc.

The slip ring is used in the electromechanical system to connect a fixed system to a rotary system. It is used in various electrical machines to enhance mechanical performance and make the operations simpler. Common features of slip rings include through-hole bore and electrical connectors. Electrical connectors are used for quick disconnection, and the hole is authorized by directing the hydraulic, cooling, pneumatic, etc. lines.

Design, features, and performance are important specifications to keep in mind when looking for slip rings. Important performance specifications to consider when choosing slip rings include operating speed, number of circuits, number of signal circuits or voltage circuits, the maximum voltage of signal circuits, maximum current of signal circuits, the number of power or current circuits, the maximum voltage of the power circuits, the maximum current of the power circuits and the operating temperature. Signal or voltage circuits include a low power signal or circuits, while power or current circuits include high current power or capacity connections.

If you are looking for what specification of the slip ring is applied to the measurement equipment, the specification varies from one type to another. For different types of slip rings, there are some common specifications to be considered for measuring equipment such as insulation resistance, material, strength, and requirements, etc. Let’s have a look at these specifications one by one in detail

Insulation Resistance

It is the leakage resistance of the ring to the ring Ci and the ring to the ground. This depends mainly on the performance of the insulating materials and the separation of the adjacent circuit. For a medium-sized slip ring, it’s better when the least insulation resistance is about 100 mW having a 60% humidity ratio along with 500V voltage. However, for the slip ring with high pressure, higher insulation resistance is required.

Contact Resistance

It is the small electrical resistance between the ring and the contact surface of the brush. Contact resistance can be measured as the direct current d1 between the resistance of the terminal and the consistent conductive ring. The ultimate strength is the contact resistance of brush connection, which is low. It is relatively difficult to measure as it changes with the rotation of the slip ring. In the rotation process, the contact area changes without a base, so the dynamic contact resistance is generally considered to be sound absorption.

Request a quote for our slip rings by providing your details in the form.

Good Dimensional Stability

The material of the joint must have good absorptive as well as outstanding dimensional stability under the settings of the working atmosphere. The insulation resistance decreases when the material is damp. When the temperature changes, the unstable volume, and humidity of the slip rings will have negative effects on the contact resistance and reliability of the operation of the slip ring, which will shorten the service life.

Dielectric Strength

It’s measured by adding an explicit amount of voltage to the circuit that is adjacent to the conductive ring. The current or alternating voltage can be 50 Hz. The high voltage test as well as the insulation examination are an important part of dielectric properties. The failure of the high voltage is the degree of dielectric strength of the feeblest point among the two circuits of installation. Failure usually occurs when there is a narrower air gap, such as along the insulating ring or between the ends of the slip ring. Increasing the purity of insulation could effectually improve the distance from the air opening.

Electrical Requirements

The specific current enables the slip ring engineer to recommend a section unit that is right for brushes, rings as well as the conductive wires. The specified voltage dictates the distances between the rings and the adjacent brushes. It is useful to get the most profitable and smallest practical circumstance so that all circuits do not qualify to the maximum. For instance, if you want 20 circuits then you have to draw three of them ten amps, allocate three circuits to high current. Remember that the overvoltage and tension screws are the leading cause of failure of the slip ring in the system.

Mechanical Envelope

Considering the mechanical envelope is one of the key factors applied to the specification of the slip ring. The available space in the system mainly verbalizes the envelope. The slip ring design expert should have the maximum open space so that all the current filter designs could be considered. It is imperative that the space required for a slip ring is determined in the early stages of system design and that it meets structural and electrical requirements.

Operating Speed

The operating speed of the slip ring is a significant design factor. Nearly all the slip rings could operate effectively at the speeds of 100 rpm, even though numerous applications need operation only a few rpm. Slip rings are used frequently to test the jet turbine engines functioning at speeds above 20000 rpm. The diameter as well as the operating speed, determine the rate of the surface of the ring that is relative to the brush, henceforth the approach to interior design as well as the choice of materials.

Required Rotational Life

Does the unit oscillate or rotate at a constant speed? Determining the environment in which a slip ring operates is a significant factor. The operational temperature range is important in finding the right lubricant. In case that the slip ring is to be exposed to a hostile environment or elements, the cohesive seals should be added in the design. Any unusual vibration or shock should also be identified.

To choose the best slip rings, make sure to consider these above-mentioned slip ring specifications as these are the most important and common specifications of slip ring that are applied to the measurement equipment.

Get in touch with our sales team by filling out the form below.