This article presents an extensive look at squirrel cage induction machines (SCIMs), exploring their fundamental principles, construction, and the pivotal role they play across various industries. We will delve into operational mechanisms that make SCIMs the motor of choice for countless applications, investigate their efficiency, and control, and address current challenges and future innovations in the field.

Introduction to Squirrel Cage Induction Machines

A Squirrel Cage Induction Machine (SCIM) is a type of AC electric motor, specifically an induction motor, distinguished by its particular rotor design—the squirrel cage. Resembling a cylindrical squirrel cage, the rotor consists of conducting bars shorted together at each end by conducting rings. This simple design, with no winding on the rotor, makes it almost maintenance-free and robust.

SCIM, derived from Nikola Tesla’s original induction motor patent in 1888, has maintained its relevant position within the field of electrical engineering. Accredited for its simplicity, reliability, and ruggedness, SCIMs permit the economical conversion of electrical energy into mechanical energy, thereby performing the core function in various rotary applications.

There’s a high likelihood you encounter a device powered by a SCIM daily. The significance of these machines in industries and applications is vast, spanning sectors of all sizes and scales. Deeming them indispensable components, industries such as manufacturing, transportation, HVAC, oil & gas, white goods, and more employ SCIMs. They provide motion and process control with benefits including easy speed regulation, smooth operation, and superior per-unit torque production.

SCIMs also serve in domestic appliances like fans, washing machines, and refrigerators, subtly rendering our lives convenient. Their significance lies not only in their heavy-duty, high-power industrial or infrastructure applications but also in quieter, lower-power household usage.

Despite being more than a century old, the fundamental architecture of SCIMs remains prevalent, though several efficiency-improving adaptations have been implemented over time. As we delve deeper, further understanding the basics, principles, working, applications, efficiency, challenges, and future of SCIMs will reinforce their importance, popularity, and contribution in the realm of electrical machines.

Squirrel Cage Induction Machines: Basic Principles and Construction

The basic principle on which a Squirrel Cage Induction Machine (SCIM) operates is the concept of induction, where an electromotive force (EMF) is induced from a varying magnetic field. This induction is the consequence of Faraday’s law of electromagnetic induction. In the context of SCIMs, when an alternating current (AC) flows through the stator windings, it generates a rotating magnetic field. This field passes through the air gap between the stator and the rotor, inducing a current in the rotor due to the relative motion between the rotor conductors and the magnetic field.

The induced current in the rotor bars generates its magnetic field, which interacts with the stator’s magnetic field. According to Lenz’s law, this interaction creates a mechanical torque on the rotor, causing it to turn. The rotor, thus induced to rotate, follows the rotating magnetic field of the stator but with a certain lag, known as slip. Slip is essential for torque generation and is a characteristic feature of an induction motor.

A standard SCIM consists of several key components:

- Stator: The stationary outer part of an induction motor, comprised of steel laminations to reduce hysteresis and eddy current losses. The stator carries windings connected in a specific fashion which, when energized with AC, produces a rotating magnetic field.

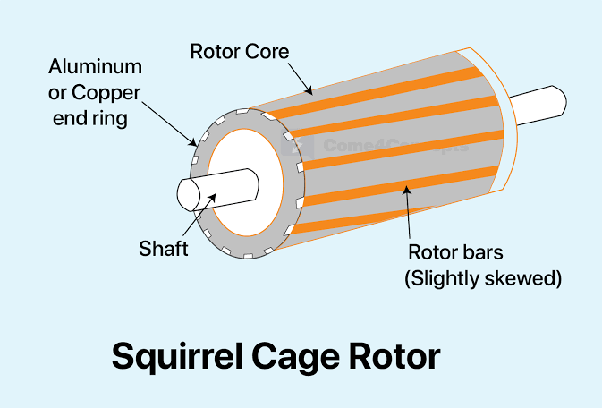

- Rotor (Squirrel Cage): The rotor, located within the stator, receives its name from its construction resembling a squirrel cage. It consists of aluminum or copper bars laid into slots and short-circuited at the end by rings, making a solid ‘cage’ construction. Because of this design, there is no need for brushes to deliver current, which aids in durability and reduces maintenance.

- Bearings: They support the rotor and allow it to rotate within the stator with minimal friction.

- End Rings and Shaft: Strength elements to ensure mechanical stability and to connect the load to the motor.

In comparison to other motors like slip ring or wound rotor machines, SCIMs offer simplified construction and operation. The squirrel cage rotor inherently has fewer parts that could wear out or fail, making it more reliable over time. Slip ring motors, on the other hand, have wound rotors with brushes and slip rings that conduct current, making them more complex and prone to wear but allowing for greater control over starting current and torque. Wound rotor motors also enjoy an edge in controllability, enabling larger motors to start heavy loads smoothly.

Despite the innovations in motor technology, the SCIM remains dominant in industries primarily because of its construction that favors simplicity, low maintenance, and robust, reliable operation. The contrast between SCIMs and other types affirms their suitability for a broad range of applications where durability and trouble-free continuous operation are paramount.

Working Principle of Squirrel Cage Induction Machines

A Squirrel Cage Induction Machine (SCIM) operates on one of the fundamental laws of electromagnetism, Faraday’s Law of electromagnetic induction. This law states that a change in magnetic flux through a closed loop of wire induces an electromotive force (EMF) in the wire. To understand how the SCIM harnesses this principle to generate torque, it is necessary to delve into the core workings of the motor.

Under normal operation, a SCIM is connected to an alternating current (AC) power source. The alternating voltage and current generate a rotating magnetic field in the stator, the stationary part of the motor. This is achieved by a specially designed winding on the stator known as the stator windings. The rotation of the magnetic field is synchronous with the frequency of the supply.

The rotating magnetic field of the stator cuts across the bars of the rotor, the moving part of the motor. According to Faraday’s Law, this change in magnetic flux induces an EMF in the rotor bars, known as rotor conductors. Because the rotor conductors are short-circuited by the end rings, the induced EMF triggers an electrical current to flow in the rotor conductors, creating an induced rotor current.

As per Lenz’s Law, this induced rotor current creates its magnetic field, which opposes the change that caused it, i.e., the stator’s rotating field. However, the interplay between the stator’s rotating magnetic field and the rotor current’s magnetic field results in the generation of a torque. This torque makes the rotor spin in the same direction as the stator’s magnetic field.

However, the rotor never reaches the actual speed of the rotating magnetic field (synchronous speed) and always lags a bit behind. This difference in speed, termed as ‘slip,’ is vital, for without it, relative motion between the stator field and rotor would cease, and so would the induction of EMF. It’s this intricate dance of magnetic fields and induced current that enables SCIMs to convert electrical power into mechanical power, essentially driving various applications across industries and households alike.

Therefore, the underlying principle of operation and the generation of torque in a SCIM can be attributed primarily to the rotating magnetic field, the phenomenon of electromagnetic induction, and the interaction between induced rotor currents and stator magnetic fields, governed by Faraday’s and Lenz’s laws.

Squirrel Cage Induction Machines: Design and Features

The design of the Squirrel Cage Induction Machine (SCIM) reflects simplicity while embodying a modern and efficient approach to converting electrical energy into mechanical energy. This simplicity is particularly embodied in the design of its rotor— the squirrel cage rotor.

The squirrel cage rotor gets its name from its unique structure, which resembles a hamster wheel or, historically, a squirrel cage. It consists of a cylindrical laminated core with parallel slots for carrying the rotor conductors, which are heavy copper or aluminum bars fitted into each slot. Each bar is short-circuited with adjacent ones at both ends by conducting rings. This creates a closed-loop path for current to flow whenever a voltage is induced by a varying magnetic field.

The most significant benefit of this design comes from its simplicity. There are no brushes, commutators, or slip rings for the rotor, meaning fewer parts to fail or maintain, making the machine highly robust and reliable. Additionally, as there are no electrical connections to the rotor, the machine can withstand harsh environments, ranging from high temperatures to dusty or volatile conditions. This ruggedness makes SCIMs one of the most durable types of electric motor available.

Moreover, the squirrel cage rotor has a high moment of inertia, implying resistance to changes in speed. This makes them highly advantageous in applications requiring stable operation and steady speed, even when load changes.

SCIMs are often preferred for various applications because of their robustness, simplicity, and low cost. Industrially, they are used in applications requiring variable loads and high inertia such as centrifugal pumps, compressors, conveyor belts, and crushing mills. At home, they power appliances like fans, blenders, washing machines, and refrigerators.

The design of a SCIM makes it highly versatile and capable of effectively operating under a wide range of conditions. The construction simplicity allows for easy maintenance and repair, while their operational ruggedness enables them to withstand demanding conditions. Consequently, their widespread use across diverse applications underlines why SCIMs continue to be one of the most popular motor types worldwide.

Squirrel Cage Induction Machines: Efficiency, Performance, and Control

Squirrel Cage Induction Machines (SCIMs) are integral in many industries due to their high efficiency, good performance, and ease of control.

SCIMs typically operate with efficiencies ranging from 75% to 95%, depending on their size and load. The efficiency of an SCIM is affected by various factors including the design of the machine, material properties, and operating conditions. Some losses are inevitable, such as hysteresis loss, eddy current loss, and resistive loss. These losses can be minimized by using high-quality materials and employing cutting-edge design techniques. The operational efficiency can be improved by ensuring that the machine operates close to its rated load.

The performance of a SCIM is determined by its torque-speed characteristic. SCIMs generally offer a near-constant speed under varying loads due to their inherent slip, allowing for stable and reliable operation. However, excessive load can cause the rotor to slow down and increase slip, thus reducing performance.

Speed and torque control in conventional SCIMs can be challenging due to their inherent characteristics. Traditionally, methods like changing the number of poles or supply voltage have been used for speed control. However, these methods offer limited flexibility and involve complex mechanical adjustments.

The advent of Variable Frequency Drives (VFDs) has revolutionized the control of SCIMs. A VFD controls the speed and torque of an SCIM by adjusting the frequency and voltage of the power supply to the motor. By varying the frequency of the supply, VFDs control the speed of the rotating magnetic field generated by the stator and hence the rotor speed, thus providing finer control over the motor’s speed and torque. This not only enhances the flexibility of operations but also improves the efficiency of the machine by allowing it to operate at optimal speed based on the load demand.

The relationship between technology advancements like VFDs and SCIMs demonstrates how electrical machines have continually evolved to offer better performance, control, and efficiency. Despite being a staple in electric motor technology for many years, innovative control mechanisms and materials continue to reposition SCIMs as a modern solution for a diverse range of applications.

Squirrel Cage Induction Machines: Applications

Squirrel Cage Induction Machines (SCIMs) enjoy a ubiquitous presence across various sectors due to their operational reliability, robust design, and high efficiency. They are the backbone of both industrial motor applications and numerous residential devices.

In the realm of household appliances, SCIMs are the hidden workhorses. Their reliability and low-maintenance design make them ideal for applications that demand consistent performance. From the cooling compressor of a refrigerator to the drum rotation in a washing machine, these appliances benefit from the robustness that SCIMs provide. In-ceiling fans and small air-movement devices, SCIMs afford a quiet and efficient operation, which is essential for a comfortable home environment.

In the industrial sector, SCIMs are harnessed for their strength in handling heavy-duty operations and their ease of use. They are a natural fit for conveyor belt systems, where a constant speed is essential for moving goods through production lines. Factories also utilize them in large fans and blowers where a steady airflow is critical for processes and ventilation.

Moreover, SCIMs drive pumps, which are fundamental in industries such as water treatment, oil and gas, and chemical manufacturing. Their simplicity provides reliability which is vital in these sectors where downtime can be costly. In processing plants, for instance, mixers and grinders make use of the high starting torque and effective speed control offered by SCIMs to process various materials.

Specific examples include:

- Centrifugal Pumps: SCIMs provide a constant speed ideal for these pumps, making them suitable for water supply systems, hot water circulation, and irrigation systems.

- HVAC Systems: The simplicity and the quiet operation of SCIMs suit the needs of heating, ventilation, and air conditioning systems in both residential and commercial buildings.

- Material Handling Equipment: In the automation industry, SCIMs are preferred for their ruggedness, critical to the long operational hours and consistent performance material handling demands.

- Electric Vehicles (EVs): While SCIMs are traditionally not the first choice for electric vehicles due to the requirement for variable speed, they are sometimes used in larger EVs, such as buses and trucks, because of their durability and ability to operate reliably under high-torque demands.

In emphasizing the application spectrum of SCIMs, it becomes clear why they are so widely adopted. Their strength lies in their simple yet effective design, which makes them suitable for a vast array of uses. From the most mundane household device to critical industrial machinery, SCIMs demonstrate unparalleled versatility, cementing their position as an indispensable element in the world of electric machines.

Squirrel Cage Induction Machines: Challenges and Solutions

While Squirrel Cage Induction Machines (SCIMs) boast many benefits, such as simplicity, robustness, and efficiency, they also come with their share of challenges. These involve several aspects, from operation to maintenance, but the technology has consistently risen to meet these challenges with comprehensive solutions and advancements.

One common challenge with SCIMs is heat generation. Due to losses in the rotor and stator windings, SCIMs tend to heat up during operation. If not properly managed, this can lead to thermal degradation of the insulation system and reduced motor life. Adequate cooling mechanisms, such as fan cooling or liquid cooling, are typically employed to manage this issue.

Another issue is the generation of noise and vibration. Although SCIMs are relatively quiet in operation, they do generate some noise and vibration due to the interaction of magnetic fields, cooling fan operation, electrical imbalances, and mechanical issues. These challenges can be mitigated by precision engineering during manufacturing and regular balancing and alignment during maintenance.

As for maintenance, even though SCIMs require less maintenance compared to other motor types, they still need regular checking. This includes inspection for mechanical issues, bearing lubrication, and verification of electrical connections. Regular temperature monitoring can be a good indication of a motor’s health as increased heat is often a precursor to failure.

Troubleshooting should be done carefully in the event of problems. Intelligent Motor Control Centers (MCCs) can help diagnose problems by monitoring parameters like current draw, voltage imbalance, and motor temperature. Following the manufacturer’s guidelines in bearing maintenance and alignment can also help in preventing and troubleshooting mechanical issues.

On the front of recent advancements, one of the most relevant improvements for SCIMs has been the integration with Variable Frequency Drives (VFDs), allowing for better control over the motor’s speed and torque and improved efficiency. Additionally, the advent of the Internet of Things (IoT) has revolutionized the maintenance and troubleshooting of SCIMs. Using sensors and connectivity, real-time monitoring and predictive maintenance are now a reality, helping to prevent unplanned shutdowns and increase motor longevity.

Another noteworthy advancement is the use of high-efficiency design standards set by organizations like the International Electrotechnical Commission (IEC). These standards like IE3 and IE4 encourage the development and use of high-efficiency motors which not only increase the performance but also minimize energy consumption.

While SCIMs do face some challenges, the continuous push for advancements and persistent innovation ensure that they remain up-to-date and ready to take on the ever-changing needs of modern applications. By addressing the challenges head-on, SCIMs continue to solidify their position as one of the most reliable, versatile, and efficient machines in the world of industry.

Squirrel Cage Induction Machines: Environmental Concerns and Energy Efficiency

Squirrel Cage Induction Machines (SCIMs), while playing a pivotal role in industrial and commercial applications, also bear significant energy consumption implications. As the quest for environmental sustainability becomes more pressing, the energy efficiency of SCIMs and their consequent environmental impact have come under scrutiny.

Energy Consumption and Environmental Impact

SCIMs are estimated to account for a significant portion of industrial electricity demand. This substantial energy use is not without its drawbacks, as it contributes to overall carbon emissions, especially in regions where electricity generation relies heavily on fossil fuels. Moreover, the heat generated by SCIMs, if not efficiently managed, can lead to increased energy use for cooling systems in applications, further exacerbating their environmental footprint.

The primary environmental concern revolves around the carbon footprint associated with the operation of SCIMs. As global awareness and regulations around greenhouse gas emissions tighten, the emphasis on improving the energy efficiency of SCIMs intensifies. Enhancing their efficiency not only contributes to combating climate change but also helps in reducing operational costs for businesses, thus providing both environmental and economic incentives.

Advances in Energy Efficiency

Recognizing these challenges, there have been significant advances aimed at increasing the energy efficiency of SCIMs and minimizing their environmental impact:

- High-Efficiency Motors: The development and adoption of high-efficiency SCIM designs have been a straightforward approach to reducing energy consumption. These motors incorporate improved materials, innovative designs, and precision manufacturing techniques to reduce electrical losses. By adhering to international efficiency standards such as IE3 and IE4 classifications, high-efficiency SCIMs are becoming more widespread.

- Integration with Variable Frequency Drives (VFDs): Pairing SCIMs with VFDs has been a game-changer in terms of energy efficiency. VFDs allow the motor speed to be precisely controlled according to the load requirement, significantly reducing energy consumption in variable-load applications. This is particularly relevant in industries where motor operation does not always need to be at full capacity.

- Advanced Cooling Technologies: Innovations in cooling methods for SCIMs, such as using liquid rather than traditional air cooling, have contributed to better overall efficiency. Better cooling directly impacts the electrical losses due to heat, thereby reducing the energy consumed for cooling purposes.

- Smart Monitoring Systems: The advent of smart sensors and Internet of Things (IoT) technology enables real-time monitoring and predictive maintenance. Such systems can identify inefficiencies in motor operation and predict failures before they happen, thus ensuring that SCIMs operate at peak efficiency and reducing unnecessary energy consumption due to malfunctioning equipment.

- Material Science Innovations: Advances in material science have led to the development of materials with better magnetic properties, reducing hysteresis and eddy current losses. New insulation materials have also contributed to minimizing thermal losses, further enhancing motor efficiency.

These advancements represent a multifaceted approach to addressing the environmental concerns associated with SCIMs. While the path to full sustainability is ongoing, the progress made in making SCIMs more energy-efficient illustrates the potential for industrial practices to evolve in harmony with ecological imperatives. As these technologies continue to develop and become more widespread, the environmental impact of SCIMs is expected to diminish, marking a significant step forward in the journey toward sustainable industrial operations.

Squirrel Cage Induction Machines: Future Prospects

Squirrel Cage Induction Machines (SCIMs), an integral part of modern industrial machinery, are on the cusp of significant transformations. Emerging trends and future developments promise to enhance their efficiency, versatility, and sustainability. Let’s delve into how these advancements could redefine the design and application of SCIMs.

Emerging Trends and Future Developments

The future of SCIMs is being shaped by a blend of technological innovation and a growing emphasis on energy efficiency and environmental sustainability. One key trend is the drive toward optimization through digitalization. The incorporation of smart sensors and Internet of Things (IoT) technology is not just about monitoring and maintenance; it’s paving the way for SCIMs to become more autonomous, and capable of adjusting operational parameters in real time for optimum efficiency.

Furthermore, there’s an ongoing shift towards using SCIMs in more varied and dynamic applications. Advances in control strategies, particularly with the integration of Variable Frequency Drives (VFDs), are expanding their usability beyond traditional constant-speed applications. This makes SCIMs more appealing for industries transitioning towards flexible manufacturing systems and automation.

Another exciting development is the exploration of SCIMs in renewable energy systems. As the world shifts towards greener energy sources, the role of efficient and reliable motors in applications such as wind turbines becomes increasingly critical. SCIMs, known for their ruggedness and low maintenance, are well-positioned to contribute to this sector.

Potential Impact of New Materials, Cooling Techniques, and Smart Technologies

New Materials: The advent of advanced magnetic materials with higher saturation magnetization and reduced hysteresis losses is a game-changer for SCIMs. These materials can significantly lower energy losses, making SCIMs even more energy-efficient. Moreover, the development of superior insulation materials can enhance thermal management, further improving efficiency and extending the lifespan of the motors.

Cooling Techniques: Traditional cooling methods are being reevaluated with a focus on enhancing efficiency and reducing environmental impact. Innovations such as liquid cooling systems are gaining traction. These systems can more effectively manage the heat generated by SCIMs, especially in high-power applications, leading to more compact designs and improved performance. Additionally, advancements in thermal interface materials and heat sink technologies are set to enhance cooling efficiency without significantly increasing the motor’s size or cost.

Smart Technologies: The integration of smart technologies is perhaps the most transformative trend. SCIMs equipped with sensors and connected to IoT platforms can offer unprecedented insight into operational parameters. This real-time data can be leveraged for predictive maintenance, reducing downtime and extending motor lifetime. Moreover, the ability to dynamically adjust operating conditions based on actual load requirements can optimize energy use, thereby lowering operational costs and reducing environmental impact.

The prospects for SCIMs point towards a new era where these motors are not only more efficient and powerful but also smarter and more adaptable to a wide range of applications. As industries continue to evolve towards more sustainable and efficient practices, innovations in SCIM technology are well-positioned to play a pivotal role. Through the synergy of advanced materials, innovative cooling solutions, and smart technologies, SCIMs are poised to meet the challenges of tomorrow, reinforcing their indispensable status in the modern industrial landscape.

Conclusion

Squirrel cage induction machines are indispensable and continue to evolve with technological advancements. Continuous research and innovation are set to keep SCIMs at the forefront of industrial progress.

FAQs about Squirrel Cage Induction Machines

Q: What makes a squirrel cage induction machine different from other motors?

A: Its simplicity, robustness, easy maintenance, and reliability set it apart, making it suitable for a wide range of applications without the need for complex control systems.

Q: How do I choose the right squirrel cage induction machine for my needs?

A: Consider the operational environment, power requirements, load characteristics, and desired speed control. Consulting with a specialist or manufacturer can help in selecting the optimal motor.

Q: Are squirrel cage induction machines energy-efficient?

A: While not as efficient as some modern motor designs, SCIMs offer considerable efficiency, and with the use of VFDs and other techniques, their energy consumption can be effectively managed.

Q: What makes a Squirrel Cage Induction Machine different from other types of electric motors?

A: SCIMs differ primarily in their rotor design, which consists of a cylindrical cage composed of conductive bars, short-circuited by end rings, resembling a squirrel cage. This design contributes to the simplicity, ruggedness, and reliability of SCIMs. Unlike other motors that might require external brushes for operation, SCIMs do not, minimizing maintenance requirements and enhancing durability.

Q: Why are SCIMs so popular in industrial applications?

A: SCIMs owe their popularity to several factors, including their simplicity of design, ease of maintenance, high efficiency, and robustness. They are capable of operating in harsh environments and under heavy loads, making them ideal for a wide range of industrial applications. Their efficiency and durability also mean reduced operational costs over time, an attractive trait for any industrial operation.

Q: Can the speed of a Squirrel Cage Induction Machine be controlled?

A: Yes, the speed of SCIMs can be controlled, but it requires external devices. Variable Frequency Drives (VFDs) are commonly used for this purpose. A VFD adjusts the motor’s electrical supply frequency, allowing precise control over the motor speed. This is particularly beneficial in applications requiring variable speed or soft starting capabilities.

Q: How do SCIMs handle heat generated during operation?

A: SCIMs are designed with various cooling methods to manage the heat they generate during operation. The most common method is fan cooling, where a fan attached to the motor shaft circulates air over the motor to dissipate heat. In more demanding applications, liquid cooling systems can be employed, providing more efficient cooling in compact spaces or in situations where heat generation is substantial.

Q: What are the maintenance requirements of a Squirrel Cage Induction Machine?

A: While SCIMs are known for their low maintenance requirements, regular checks are recommended to ensure optimal performance. These checks include monitoring bearings for lubrication and wear, ensuring cooling systems are working efficiently, and verifying that electrical connections are secure. Regular maintenance helps in identifying potential issues early, preventing unexpected downtimes.

Q: Are there any developments to make SCIMs more energy efficient?

A: Yes, there are ongoing developments aimed at improving the energy efficiency of SCIMs. These include the use of high-efficiency materials in the construction of the motor, advanced design techniques to reduce electrical losses, and the integration with smart technologies for more efficient control. Regulatory standards like the IE3 and IE4 classifications are also driving the adoption of more efficient motor designs.

Q: How do SCIMs contribute to energy conservation in industrial applications?

A: SCIMs contribute to energy conservation through their high efficiency and the ability to be controlled via VFDs for variable speed operations. By adjusting the motor speed to match the load requirements, significant energy savings can be achieved compared to running the motor at full speed regardless of the load. Additionally, the advancements in motor design and materials are continuously improving their efficiency, further aiding in energy conservation efforts.