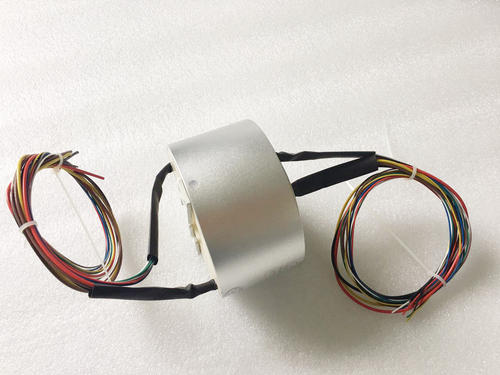

Slip Rings are an integral part of those machines that work based on rotation. These machines or systems have these high current Slip Rings at the center of their automation system. These current Slip Rings are particularly liable to transmit the current from a static part of the device to the rotating one and are used almost with every other machine that needs the power to operate and requires data connectivity to be channelized too. That is why; High Current Slip Rings have a significant overall impact on the consistency of equipment, the general performance, and the action. Not only does a high current slip modernize the utility of a system but it improves the mechanical performance of the machines. A high-current slip ring is the best alternative to the wires that are dangling from revolving joints. Slip Rings are more commonly referred to as rotary linkages, swivels, and commutates. These rings include brush blocks that are made available and commonly coordinated as a part of a brush and a ring. These days, almost every object that works on rotation has a slip ring in it. The market is full of numerous slip rings that can be used in the place of wires to make the process of producing and manufacturing items more streamlined and easier. Each of these slip rings serves a different purpose and has a different use. Read further to have a basic know-how about numerous different slip rings.

Types and Usage of Slip Rings

Slip Rings come in different sizes and serve different purposes in high-end electro-mechanical devices.

Wireless Slip Rings

- These Slip Rings don’t rely on procedures approved by the manufacturers. These are made using a resistance-based metal and carbon contact brush in Slip Rings.

- While acting as a substitute, the primary function of these slip rings is to transfer power without the usage of wires while making use of the electromagnetic field.

- Wireless slip rings are essentially made from making use of the coils that are present in the revolving receiver and are stationary.

- These Slip Rings are known as an addition to the conventional slip ring. The slip rings can be conserved easily and can withstand as much heat as possible.

Pancake Slip Rings

- Pancake Slip Rings are made in a way that electrodes are located on the flat disc. These rings are called concentric rings and are placed on the inside of a rotating shaft.

- The placement of these things possesses a slightly high burden and provides enhanced capacitance. Its gathers wear remains on the vertical axis proficiently.

- Occasionally, and according to the requirement, the pancake slip ring has a slightly condensed axial length which is suitable for numerous applications.

Mercury Wetted Slip Rings

- Mercury-wetted slip rings are distinct from others because of their ability to transmit the signals steadily without any forced resistance.

- These slip rings contain a pool of liquid metal that is confined to the links.

- While spinning inside the machine, the metallic liquid contained in the slip ring creates a link between both parts of the machine i.e. the stationary and the rotational part.

- While choosing by choosing a valuable metal contact, one must make a sensible decision, as most of the machines that require slip rings to operate either make pharmaceutical goods or food products.

Pneumatic Slip Ring

- Pneumatic slip rings are used not only to transport pneumatic pressure or the emptiness from the static part to the rotating part but it is also used to stabilize and separate the liquid connection when the machine is rotating at an axis of 360’.

- These Slip Rings are more commonly used in the making of industrial plants and commercial factories but are not limited to them as these rings are also beneficial when it comes to off-shore drilling and other geotechnical tools.

Fiber Optic Slip Rings

- These Slip Rings are also called Fiber Optic Rotatory Joints. These are extremely useful in passing the signals over the turning interfaces when there is a lot of information that should be transmitted.

- Primarily, these slip rings are useful in transmitting two-way and four-way fiber-optic connections. Due to this reason, they should be carefully made, because the diameter of fiber involved in the making of these slip rings is smaller. Moreover, single-mode fiber’s diameter is normally 9nm.

- Fiber Optic Slip Rings are designed with immense precision, and demand focus which makes the whole task quite challenging, as a single mistake could prove to be hurtful in the future.

USB Slip Rings

These slip rings are gaining popularity over time. These are purely used to acquire a USB signal from a static part of the slip ring to the moving part that is constantly rotating at the axis of 360’.

- On the other hand, a USB Slip Ring ensures that there isn’t any disposition in the whole work, It also focuses on the functionality of the slip ring and assures that the USB wires don’t become twisted within one another.

- These USB slip rings are typically utilized in King USB gadgets, gear of USB alongside different items.

Ethernet Slip Rings

- Ethernet slip rings are to the core electrical items and are manufactured with the sole purpose of transmitting the power from the stationary end to the rotary ends.

- The innovative design of these slip rings meets the requirements and standards of controlling crosstalk, reducing losses, and matching impedance.

There are numerous other slip rings in the market which I will discuss in the upcoming articles. Slip Rings are becoming the most crucial part of systems that run on automation and work on a rotatory basis. Along these lines, their presentation is straightforwardly identified with the consistency of the entire framework which runs easily during the entire activities. Grand Slip Rings is offering all of these slip rings at relatively low costs. Grand is always open to providing its customers with customized products as they have more than 200 plus molds to do so. Every one of their design is unique as compared to their competitors; even the budget is unique. They have innovative knowledge and experience in the field of making Slip Rings and offering products of international standards.

See What We Can Do