Unravel the complex world of wind energy generation, focusing particularly on a vital component: wind generator slip rings. Explore their functionality, common concerns, the latest innovations, and critical advice to choose the right slip ring.

Introduction to Wind Generator Slip Rings

Wind energy stands as one of humanity’s cleanest and most abundant renewable energy sources. The harnessing of wind power to generate electricity does not produce greenhouse gas emissions, which makes it a critical component in the global efforts to combat climate change. With advancements in technology, wind turbines have become increasingly efficient, but their complexity has grown as well. Each turbine’s towering visage is the result of intricate engineering, designed to convert kinetic wind energy into electric power through a series of sophisticated mechanisms.

At the crux of a wind turbine’s ability to function optimally lies the slip ring—a seemingly modest but fundamentally crucial component. Slip rings facilitate the transfer of electrical currents, signals, and power from the static part of the turbine to its rotating blades and vice versa. This dynamic duo of stationary and rotational interfaces is the gateway for energy and data transmission that ensures the blades turn to capture wind efficiently, regardless of direction, and power generation remains constant.

The focus of this article is on these pivotal devices. Understanding wind generator slip rings, their operation, their challenges, and the technological advancements surrounding them is essential for the continued evolution and maintenance of wind power systems. This overview not only introduces the basics of how slip rings contribute to the incredible task of clean energy production but also sets the stage for a deeper exploration of their design nuances, longevity considerations, performance issues, and the criteria for selecting suitable slip ring systems. Our purpose is to demystify the technical complexities and shed light on the considerations essential to the integrity and functionality of wind generator slip rings—information that is vital for industry professionals, stakeholders, and the curious mind.

Understanding Wind Generator Slip Rings

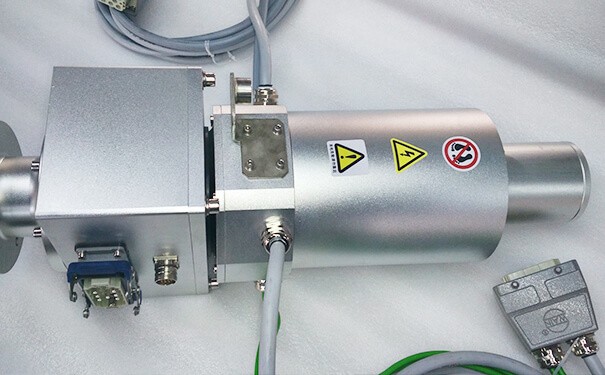

At their core, slip rings in a wind generator are electro-mechanical devices designed to transmit electricity, data, or signals from a stationary platform to a rotating component, and vice versa. They act as the link ensuring the continuous flow of data and power between these parts of the turbine, despite the perpetual motion. In essence, they serve as an electrical interconnection that can rotate indefinitely without tangling wires or hindering rotation, a challenging feat to accomplish with traditional wiring methods.

The contribution of slip rings to the efficiency and functionality of wind turbines is undeniable. They are the unsung heroes in the conversion of wind into electricity. Imagine wind turbines like giant fans catching the wind – it’s the movement of these turbine blades, facilitated by the ever-operating slip rings, that generates the electricity. However, wind direction is variable and for optimal power generation, the orientation of the blades (housed in the nacelle) needs changing. Slip rings come into play here. They empower the nacelle to rotate freely according to wind direction while maintaining continuous power and data flow. This ensures utmost adaptability and, in turn, maximized efficiency in power generation, independent of the wind’s whims.

At their most fundamental, wind generator slip rings are assemblies combining rotating, conductive rings and stationary, carbon-based brushes that glide over the rings. When the turbine blades spin, so do the conductive rings. Each brush maintains constant contact against its corresponding rotating ring, allowing for the transmission of electrical currents or signals. The simplicity of the design belies the nuances of operation it supports—providing a seamless transfer of electricity and data amidst high-speed rotations and variable environmental conditions.

Understanding the basic design, operation, and implications of the functionality of wind generator slip rings helps comprehend how they anchor the complex dance of wind power generation. Their unobstructed operation is essential to not only generating power efficiently but also the broader goal of expanding wind energy’s share in the overall energy mix.

Key Concerns and Considerations for Wind Generator Slip Rings

Wind energy, with its promise of clean, renewable power, hinges significantly on the reliability and performance of each turbine’s components, including the often-underappreciated slip rings. These components face the daunting task of delivering unparalleled durability and reliability, exceptional electrical performance, and convenient maintenance, all while accommodating the diverse needs of different turbine designs.

Durability and Reliability

In the ceaseless dance of wind turbine operation—marked by constant motion and subjected to variable, often harsh environmental conditions—the durability and reliability of slip rings cannot be overstated. The high stakes of their role are underscored by the detrimental impact environmental factors such as temperature fluctuations, humidity, and even salt-laden air in offshore installations, can have on slip ring longevity. To combat these challenges, material science and technology converge to enhance durability. Slip rings are fashioned from robust materials capable of withstanding environmental stressors, and cutting-edge coatings and treatments are applied to protect against corrosion and wear.

Electrical Performance

The core mission of a slip ring is to ensure efficient, uninterrupted power and data transmission—a task complicated by the need for maintaining consistent electrical contact in a rotating apparatus. The friction between brushes and rings, essential for transmission, naturally introduces challenges in maintaining a stable connection, potentially leading to power loss and signal interference. Advanced engineering solutions are employed to minimize these issues, ranging from optimizing the contact materials for better conductivity and wear resistance to employing sophisticated signal and power management techniques that mitigate loss and interference.

Maintenance and Serviceability

The operational life of wind turbines, often spanning decades, places a premium on the maintenance and serviceability of every component, including slip rings. Common maintenance needs, such as cleaning the contact surfaces and replacing worn parts, dictate a design that accommodates ease of access and repair. Design considerations, therefore, include modular assemblies that technicians can easily disassemble and reassemble, minimizing turbine downtime. Providing maintenance teams with tips and training for extending slip ring lifespan, such as regular inspections and adherence to cleaning schedules, ensures long-term reliability and performance.

Compatibility and Customization

Given the wide array of wind turbine models and the specific requirements of different installations, slip rings must offer a high degree of customization and compatibility. Adapting to various electrical and mechanical interfaces demands a modular design approach, allowing for specific configurations that meet individual turbine specifications and integration requirements. Beyond fits and specifications, compatibility extends to seamless integration with other systems within the turbine, including control and hydraulic units, ensuring coherent and efficient operation.

Addressing these key concerns and considerations with deliberate, informed strategies is essential for the successful integration of slip rings into wind turbines. Through a combination of advanced materials, engineering innovation, thoughtful design, and customization, slip rings can effectively meet the demanding requirements of wind energy generation, underscoring their pivotal role in harnessing wind power.

Innovations in Wind Generator Slip Rings

Advancements in technology and materials have never been more critical in the wind energy sector, particularly when it comes to components like slip rings that bridge the divide between rotating and stationary parts of the turbine. Innovations in slip ring technology are not only improving current designs but are also paving the way for future developments that could redefine their role in wind power generation.

Recent Technological Advancements and Materials

The drive for efficiency has led to significant improvements in slip ring design. Some of the most noteworthy advancements include the incorporation of novel materials with remarkable properties like high conductivity and reduced wear. Likewise, surface engineering techniques, such as diamond-like carbon coatings, have been developed to reduce friction and wear on the rings, thus enhancing their lifespan.

Furthermore, the miniaturization of electronic components has also been transformative, allowing slip rings to become more compact and lightweight without compromising their functionality. These high-density slip rings are engineered to handle more circuits in a smaller space, making them well-suited for the increasingly sophisticated wind turbines being produced today.

Wireless Data Transmission Technologies as an Emerging Trend

The growing need for reliable data transmission in wind turbines has also given rise to the adoption of wireless technologies. The use of inductive coupling, for example, is a wireless alternative to conventional slip rings, allowing for the transfer of power and data across a small air gap without any physical contact. This approach significantly reduces maintenance requirements and increases the longevity of the system since there are no wearing parts.

High-capacity wireless systems are not only reducing the complexity of turbine designs but are also facilitating the real-time monitoring of their performance and health. These systems are a leap toward the predictive maintenance model, a favorable trend in wind turbine operation that aims to preempt failures and minimize downtime.

Future Directions in Slip Ring Technology for Wind Generators

Looking to the future, slip ring technology for wind generators is poised for further innovation. One exciting avenue is the integration of smart technologies that include sensors directly within the slip ring assembly. These sensors would monitor the condition of the slip ring in real time, offering insights into wear rates and predicting potential failures before they occur.

Nanotechnology also holds promise for the development of new materials with superior electrical, mechanical, and self-healing properties. Researchers are experimenting with incorporating nanoparticles into slip ring contacts to improve performance and reduce maintenance.

Moreover, advancements in energy storage, in conjunction with slip ring technology, could lead to integrated systems that compensate for intermittent wind conditions, stabilizing the output and increasing the overall efficiency of the turbine.

As we look ahead, the synergy between material science, wireless technologies, and predictive analytics is set to catalyze the next wave of innovations in wind generator slip rings. This is crucial in meeting the escalating demands for reliable, high-performance components that can keep pace with the rapid evolution of wind turbines and the growing global appetite for renewable energy.

Selecting the Right Wind Generator Slip Ring

The rapidly evolving landscape of wind energy generation demands high-quality, reliable components that can keep pace with technological advancements and the rigorous conditions of wind turbine operation. Slip rings, the critical link enabling the transmission of power and data between the turbine’s moving and stationary parts, require careful consideration during selection. Whether for new installations or upgrades, the selection process is pivotal to the operational efficiency and longevity of the turbines.

Criteria for Choosing Slip Rings

When selecting a slip ring for a wind turbine, several criteria stand at the forefront of decision-making. First and foremost, the electrical specifications of the slip ring must align with the turbine’s requirements, including voltage, current capacity, and signal types it needs to transmit. Equally important is the slip ring’s mechanical compatibility with the turbine, encompassing aspects such as size, mounting configuration, and rotational speed.

Durability is another critical factor, given the harsh conditions often faced by wind turbines. The selected slip ring must be robust enough to withstand environmental stressors such as extreme temperatures, moisture, and salinity, especially in offshore installations. Furthermore, the ease of maintenance and the ability to perform repairs or replacements in the field can significantly reduce downtime and operational costs.

Vetting Manufacturers: Quality Certifications, Reputation, and Support Services

Selecting the right slip ring extends beyond the product itself to evaluating the manufacturers. Manufacturers with established quality certifications (such as ISO standards) offer assurance that their products meet rigorous quality and reliability benchmarks. The reputation of the manufacturer in the industry gauged through reviews, case studies, and testimonials, can provide insights into their track record and expertise in producing slip rings suited for wind energy applications.

Support services are a crucial differentiator among manufacturers. Providers that offer comprehensive pre-sales consultation, custom engineering services, and prompt after-sales support ensure that the slip rings integrate seamlessly with the turbines and that any issues encountered during their lifecycle are promptly addressed.

The Importance of Warranties and Technical Support in the Selection Process

Warranties and technical support services are often indicative of the manufacturer’s confidence in their product and commitment to customer satisfaction. A warranty that covers a significant period and offers favorable terms can protect the investment and provide peace of mind. Technical support, particularly when available 24/7, ensures that expert assistance is at hand whenever needed, minimizing potential downtime.

Moreover, manufacturers that offer access to extensive documentation, training, and online resources empower turbine operators and maintenance teams with the knowledge to address issues and perform routine tasks efficiently.

In conclusion, selecting the right wind generator slip ring is a comprehensive process that extends beyond the technical specifications of the product. It demands a holistic evaluation that includes the durability of the slip ring, the reputation and certifications of the manufacturer, and the quality of support services provided. By meticulously considering these factors, wind energy operators can ensure that their turbines operate reliably and efficiently, harnessing the full potential of wind power.

Conclusion

To conclude, slip rings play a vital role in wind turbine functionality. With constant innovation required to match the evolving demands of wind energy generation, stakeholders in the sector must stay updated with the latest advancements to enhance wind power generation’s efficiency and reliability.

FAQs about Wind Generator Slip Rings

Q: Do slip rings significantly affect the overall efficiency of wind turbines?

A: Yes, slip rings play a crucial role in the efficiency of wind turbines. They ensure uninterrupted electrical connectivity between the stationary and rotating parts of the turbine, facilitating the transfer of power and data. Faulty or inefficient slip rings can lead to power losses and operational disruptions, affecting the overall efficiency.

Q: Are all slip rings the same, regardless of the turbine model?

A: No, slip rings are not one-size-fits-all components. They vary significantly in terms of electrical specifications, size, and design to match different turbine models and operational requirements. Choosing a slip ring that is specifically designed or adaptable to your turbine model is essential for optimal performance.

Q: Can wireless technologies completely replace traditional slip rings?

A: While wireless technologies for power and data transmission have seen significant advancements, they currently supplement rather than completely replace traditional slip rings in wind turbines. Wireless solutions offer benefits in terms of reduced maintenance, but traditional slip rings still provide more reliable power transmission for most large-scale turbine operations.

Q: How can I extend the lifespan of my wind generator’s slip rings?

A: Regular maintenance is key to extending the lifespan of slip rings. This includes periodic cleaning of contact surfaces, inspection for wear and tear, and timely replacement of worn parts. Employing environmental protective measures, such as corrosion-resistant coatings, can also safeguard against harsh conditions.

Q: What should I consider when upgrading slip rings in an existing wind turbine?

A: When upgrading, consider the current and future operational demands of the turbine. Evaluate the slip rings’ electrical and mechanical specifications to ensure they meet these requirements. Additionally, choose products from reputable manufacturers that offer solid warranties and technical support to secure your investment.

Q: How do I identify a reputable slip ring manufacturer?

A: Look for manufacturers with quality certifications (like ISO) and a solid track record in the wind energy sector. Recommendations from industry peers, case studies, and customer testimonials can provide insights into the manufacturer’s reputation. Additionally, assess the level of technical support and customization options they offer to meet specific turbine requirements.